How to saw and work with a jigsaw?

Today, a jigsaw is one of the most popular and in-demand tools. Not a single carpentry, furniture or educational workshop can do without it; it is a reliable assistant in any household. The jigsaw received such recognition due, first of all, to its versatility. It can be used for a wide range of jobs: from cutting firewood for the barbecue to cutting out various ornaments and making musical instruments.

Along with the jigsaw, the old manual jigsaw has not been forgotten. Although this tool has a narrower range of uses, it still enjoys some popularity, especially in school workshops and those who enjoy sawing wood and plastic. A hand jigsaw is suitable for processing small workpieces that need to be given precise shapes.

Hacksaw - simplicity and safety

A hacksaw is a simple tool that is quite suitable for the job. And although the cutting speed is low and considerable physical effort is required, such a saw is the most acceptable option for home use.

It is not difficult to cut wood correctly with a hacksaw. The main condition for a high-quality cut of the material is to make the cut correctly. To simplify the task, you can use a regular flat block, which is used as a guide.

The question often arises of how to cut a board smoothly with a hacksaw at an angle. For this purpose, a special carpentry device is used - a miter box. Moreover, it will help not only to make a cut at the desired angle, but will also allow any beginner to cut the board smoothly.

You can also saw off the timber with a hacksaw. The only problem when working with such a workpiece is that you have to put in a lot of effort.

The last option is to use an angle grinder with a wheel with teeth installed for the work. But since the “grinder” is not intended for cutting wood, this method can only be used as a last resort: attempts to cut a board can result in serious consequences. It’s better to use a hacksaw - it’s labor-intensive, but safe.

The file must be placed close to the cutting line. The guide is compressed with the platform side. After this, they begin cutting.

The tool moves forward smoothly and the platform is carefully controlled. The platform and guide must move closer to each other so that nothing moves. The sawn-off part must be carefully held with a few centimeters remaining to the end. Then the part will not break off.

Preparing a manual jigsaw for work

Despite the apparent simplicity of the design of a hand jigsaw, modern tools have a number of features that should be paid attention to. First of all, we are talking about the material from which the jigsaw is made. We would advise avoiding instruments with a frame made of sheet metal. More relevant today are jigsaws made from tubular materials. This design provides better tension on the file, eliminating its skewing and swaying to the side when making figured and curved cuts. You should also pay attention to the quality of the nuts with which the blade is tensioned: the higher quality the steel and the wider the ears of the wing nuts, the more convenient it is to work.

Particular attention should be paid to the tension of the jigsaw blade. The saw should be positioned strictly vertically with the teeth down. When adjusting the blade, rest one end of the jigsaw against the edge of the table and tighten the wing nut until it stops. After this, the tubular structure of the jigsaw will straighten out a little, ensuring ideal saw tension.

Components of a jigsaw

The correct use of this tool also depends on the owner’s knowledge of the composition of the electric jigsaw. Since Bosch released its first copy of this multifunctional device into the world in 1944, its components have undergone many changes, but its basic design has remained unchanged. So, a jigsaw has the following components:

- gearbox (its body must be made exclusively of metal, since the rubber body calls into question the strength of the tool, as it impairs heat transfer);

- sole (the best option for the sole material is cast metal, because some jigsaws have a plastic plate, which does not have a good effect on the quality of work);

- motor housing (a jigsaw is considered good if this particular part is made of the highest quality, strongest material, because this is where the motor is located);

- lever.

We advise you to study - Blue color in the bedroom interior - breathtaking shades

Some tips for working with a hand jigsaw

- Saw blade. The choice of cutting tool depends on the material and nature of the work. If you are going to use a jigsaw to make large curved and straight cuts, then a saw with large teeth is better. When cutting out precise patterns with small diameters with a jigsaw, we recommend using blades with a large number of small teeth.

- Organization of the workplace. Decide how you will work: standing or sitting. Organize your workplace in such a way that all the necessary tools and devices are “at hand”, but do not interfere with the sawing process, take care of good lighting of the work area;

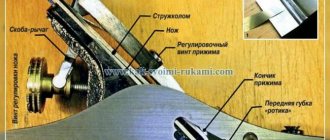

- Secure the part. The productivity and accuracy of working with a manual jigsaw largely depends on how the part is secured. When carrying out any types of sawing, it is necessary to secure the workpiece in a vice so that it does not move. For these purposes, it is best to use a dovetail table machine. You can make the device yourself or buy it in a store.

- Don't try too hard. When cutting plastic, wood or plywood, try to cut the material in small layers. If you put excessive pressure on the blade, it may burst; if you apply insufficient force to the jigsaw, the quality of the cut will be very poor. Do not apply lateral pressure to the canvas.

- Watch the tension of the file. While working, check the tension of the saw blade from time to time - it may weaken. Do not overtighten the file - it may burst.

- Use sketches and stencils. When cutting out complex ornaments and patterns, we recommend that you first apply all the lines to the workpiece. This way you will do the job with maximum precision and not spoil the material.

Safety precautions

A jigsaw is one of the tools that is fairly easy to use. But still, the presence of a sufficiently sharp cutting element requires compliance with certain safety rules:

- Cutting any materials should be done on a flat, stable surface with the blade first secured. In this case, cutting parts in midair is completely eliminated.

- The workpieces should be cut at a distance of at least 40 centimeters from the eyes. For protection, it is recommended to use special glasses.

- Before work, you should make sure that the file and other parts adjacent to it are firmly fixed.

- Before connecting the jigsaw to the network, you must check the integrity of the electrical cable.

- The handle of the cutting device must be securely fastened. Otherwise, the tool may slip and cause injury.

When cutting workpieces from various materials, you should always take into account the technical capabilities of the tool. Proper use of a jigsaw and compliance with all safety rules during its operation will allow you to cut any part according to the intended sketch without any problems.

Jigsaw: preparing the tool for work

The next section of our review is devoted to processing various materials using a jigsaw. This tool is more common than a hand jigsaw, it is more productive and has a wider range of applications.

First of all, make sure you have a comfortable and safe workplace. Remove unnecessary debris, prepare a clamp or vice with which you will secure the workpiece. You should also make sure that the electrical outlet, power cord and extension cord (if used) are in good working order. Inspect the body of the jigsaw, make sure there are no visible damage or faults in the insulation of the electric motor.

The selection of saw blade is important. There are a huge number of different types of jigsaw files available for sale, the choice of which is made depending on the material of the workpiece and the type of work performed. It should also be taken into account that the cutting performance and serviceability of a jigsaw largely depend on the serviceability and sharpness of the saw. Change blades in a timely manner, do not allow them to become excessively dull.

Before you begin, consider choosing the correct speed setting. Most jigsaws have a saw blade speed control. Choose a mode that will ensure not only high speed and accuracy of part processing, but also operator safety.

Bosch PST 900 PEL jigsaw in use

Sawing technology

Preparation

When we cut out plywood with a jigsaw, the quality of the finished product largely depends on how responsibly we approached the preparation process.

To avoid incidents during work, you need to spend just a few minutes:

- We inspect the plywood intended for work for damage and peeling of the veneer.

- We check the quality of drying by making a test cut.

- We attach the template printed on the printer to the plywood and secure it with tape or push pins.

- Simple shapes can be transferred to plywood by piercing, leaving awl marks on the material.

Advice! It is more convenient to saw plywood across the grain, so you need to place the pattern on the workpiece in such a way that the maximum number of cuts has to be made in this position.

- We transfer more complex ornaments through carbon paper, tracing the contours of the printed template with a medium-hard pencil.

Copying the drawing

- For clarity, we paint over with a pencil those places on the workpiece that must be removed after cutting. It is better to do this immediately after translating the template, since it will be more difficult to understand the interweaving of lines later.

Basic Operations

So, the preparation is complete, and you can begin your first attempts to cut something out of plywood with your own hands. Of course, if you have never picked up a jigsaw before, then it is worth practicing on simple products before starting a large-scale project.

Furniture work using a jigsaw

The work begins with cutting out the outline of the workpiece, after which internal cuts are made. To make a through hole, first drill the plywood with a drill, and only then insert the jigsaw blade.

Advice! If you need to make several through closed cuts, then the holes for them need to be drilled at once. This is due to the fact that after cutting out part of the material, the workpiece loses strength and may crack during drilling.

Below we will describe the sequence of performing basic operations using a hand jigsaw. Using an electric or band saw has its own nuances, but once you master the basics, you will not have any difficulties when working with more advanced equipment.

Straight cut

The simplest operation is cutting in a straight line.

The instructions for this operation are as follows:

- We insert the jigsaw file into the drilled hole so that the teeth are directed towards the handle.

- We stretch the canvas so that it does not vibrate during operation, and fix it with a screw.

- We place the workpiece on the workbench, press it with our left hand to the sawing table and gradually begin to saw through.

- When cutting a straight line, move the jigsaw up and down, gradually feeding the workpiece under the saw.

- Control of the straightness of the cut can be ensured by placing a guide bar on the workbench.

Position of the tool when cutting

Figure cutting is more complex, and you should start it only when you have fully mastered the straight cut:

- We fix the jigsaw file in the same way as in the previous case.

- We lay the workpiece with a clearly drawn line on the workbench.

- We saw from top to bottom, feeding the plywood with our left hand so that the blade does not go beyond the line.

- When the file moves in relation to the template line, we stop moving with our left hand until the file begins to move freely. After this, we adjust the position of the plywood and continue working.

All elements are cut out using this principle, including obtuse corners. But you shouldn’t cut out an acute angle by turning the workpiece, since there is a high risk of the final fragment breaking off. In this case, two slits should be made, connecting them at the top of the corner.

We process the edge of the workpiece with a file

After cutting out all the elements, the workpiece must be processed with a file, since even the most careful work does not allow making a product with perfectly smooth edges. Using wood files, we carefully polish the outer and inner cutting lines, after which we process the entire workpiece with sandpaper and sandpaper.

The final stage is finishing the product. Plywood can be stained, painted or varnished.

Safety precautions

Sawing from plywood is not a hazardous activity, but safety rules must still be followed:

- Only proper tools should be used for the job.

- It is prohibited to cut using blade fragments or band saw fragments.

- When working with power tools, you should check the quality of the insulation to avoid electric shock.

Eyes and hands must be protected

- Sawing with a jigsaw or band saw is carried out only on a special workbench, and the cutting part of the tool must be limited by special devices (frames, shields, etc.).

- When performing work, you must use personal protective equipment: goggles, gloves, dust mask or respirator.

Features of working with a jigsaw when sawing wood

Recommended blades for wood processing have medium-sized teeth pointing upward. The length of the file depends on the thickness, the workpiece and the capabilities of your jigsaw. The speed should be set to maximum or a value close to maximum. However, if the blade overheats, then it is better to reduce the frequency of saw strokes.

Before starting to work with a jigsaw, we recommend marking the workpiece for performing a particular type of cut. To achieve a clean surface, we recommend placing the part face down - working on the back side. The jigsaw should be held level without exerting lateral forces. Also, you should not push the jigsaw forward too much: as you cut, it will move forward under a slight hand force.

Many manufacturers equip their jigsaws with a pendulum mechanism. However, it should be understood that using this function increases speed, but significantly reduces the accuracy and cleanliness of the cut.

Rules for straight cutting

Thus, in order to make a cut correctly and evenly, you must adhere to the following rules:

- Carefully select a file that is suitable for your source material.

- Prepare all necessary auxiliary items.

- Carefully secure the workpiece.

- Take into account the correct positioning of the workpiece so that you do not have to correct flaws - in some cases the canvas is positioned face down.

- Practice the technique of operating the device with the help of professionals or through a training video.

- Follow safety precautions carefully.

In fact, processing products with a jigsaw is not such a difficult task that any novice carpenter can do. Even if an even and neat cut does not work out right away, you should not despair: you need to soberly assess what nuances you may not have paid attention to. And you shouldn’t ignore the advice of professionals who can speed up the process of mastering the art of sawing with a jigsaw and reveal some secrets. Try and improve!

In most cases, the process of straight and figured cutting of materials requires extreme precision of the tool. This statement is most true for an electric jigsaw. The thin saw blades used in this device can easily change the cutting angle, which can negatively affect the accuracy of the line. The clarity of the edges of the product and the evenness of the cutting line depend on the skills of the operator, the serviceability of the device and the saw. Next, we will tell you how to get the planned contour with perfectly clear edges and what to do if the jigsaw moves to the side.

Cutting laminate and chipboard with a jigsaw

To cut these materials, you should choose a reverse cut saw. True, this increases vibration, but the quality of material processing does not suffer in any way. Some craftsmen use standard wood blades, but in this case they should work on the back side of the workpiece.

Just like when processing wood, when sawing laminate and chipboard, you should set the maximum speed of the saw. But the pendulum function should be turned off, otherwise the file will “tear” the edges of the part. When working, we recommend that you press the sole of the jigsaw firmly against the surface being processed, avoiding lateral forces.

In their reviews, many craftsmen recommend using an anti-splinter liner when cutting laminate and chipboard. This is a specific device that is inserted into the grooves on the sole of the jigsaw. It is designed in such a way as to prevent chipping. In each specific case, it is necessary to make a test cut and select an anti-splinter liner with the necessary parameters. The ideal insert is one in which the cut exactly matches the thickness of the saw blade mounted on the jigsaw.

Other process features

We continue the conversation about how to cut plywood using an electric jigsaw. If you plan to cut a round hole in the material, first make a small hole and place a hacksaw blade into it. You can also use plunge sawing if the previous method does not work.

When using an electric jigsaw to cut plywood, you will not need to use any additional equipment. However, they - devices - can still be used to make work easier and more comfortable.

If you are working with plywood of considerable thickness, then use a special sawing table (this way you can work more accurately). Finally, if you are working with material of different thicknesses, then use replaceable inserts that are attached to the tool.

As a result, we note that a jigsaw can be either with a pendulum stroke or a regular one. If the material is thick, the stroke should be normal. In this case, the plywood itself must move vertically and be cut as it moves.

Features of cutting out curved and shaped elements with a jigsaw

According to many jigsaw owners, this is the most difficult type of work. First you need to make markings on the surface of the part. Next, we select the point from which we will begin sawing and drill a hole here sufficient for the free movement of the saw blade. It should be remembered that when cutting out figured elements it is necessary to use a narrow saw, and the diameter of the drill with which we drill the starting hole is only slightly greater than the width of the blade.

Sawing curved surfaces is done by slowly moving the jigsaw (not only the saw blade, but also the tool itself). During the sawing process, we recommend following the markings and the position of the blade. In this case, it is better to turn off the laser - it only interferes with the work and confuses the direction.

When cutting out particularly complex patterns or shapes, we recommend using a jigsaw. In this case, the jigsaw is secured with the file upward using special fasteners. Note that when using a jigsaw, you will have to cut by moving not the jigsaw, but the workpiece. This cutting method ensures maximum cleanliness, precision and operator comfort.

The saw blade and jigsaw settings, when cutting out figured patterns, are set according to the material being processed.

Tool Details

A jigsaw is a tool that is designed for shaped (curvilinear) cutting of wooden blanks. A manual jigsaw is used to cut out various decorative elements, since it is very difficult for an electric one to do delicate work. The hand tool has a steel frame in the shape of the letter “U”, the ends of which have clamps, and at one end there is a handle. Clamps are used to secure the saw blade and allow you to adjust the tension of the blade.

Hand jigsaw and additional tools for working with it.

The clamps for fixing the blade can rotate, which allows you to change the direction of the cut. This is what allows you to cut out almost any complex pattern along complex trajectories. However, it is worth remembering that the canvas is very thin and can tear, so it is always necessary to have several dozen canvases in stock. It is worth remembering that the blades may differ in the size of the teeth, sharpening of the teeth, etc. At the moment, there are 2 main types of canvas:

- Straight. It is a smaller copy of a saw. It is used for making straight cuts and often for rough processing.

- Spiral fabric. It is used for finer processing, surface grinding, etc. This fabric is ideal for making circles and ovals.

Now that you have an idea about the jigsaw, you should start purchasing all the necessary materials and tools.

Straight cutting of various materials

Most often, a jigsaw is used for straight cutting of various materials. However, even in this case, many novice users may experience certain difficulties during operation. First of all, it is necessary to securely fasten the part and make markings. For straight cuts, we recommend using wide blades; they hold the marking line better and are less prone to moving to the side. Higher processing quality is achieved using the “Soft Start” function. In this case, the saw begins to smoothly pick up speed, which prevents chipping and inaccuracy at the initial stage of cutting.

During the sawing process, do not apply excessive pressure to the body of the jigsaw and completely avoid lateral pressure. The sole of the tool is pressed tightly against the part, the jigsaw should be moved without jerking or stopping. Since straight sawing involves a large amount of work, we strongly recommend that you monitor the serviceability of the saw blades and promptly replace them if they are not working properly.

The operator's work when performing straight cuts is greatly facilitated by the use of a guide bar or rip fence. These devices are sometimes included in the basic package of some jigsaws; more often they must be purchased separately.

Accuracy problems

Let's look at how to cut smoothly with a jigsaw:

- The object to be processed must be securely fastened. Moreover, in such a way that it would be convenient to make the cut.

- In cases of particular uncertainty or for greater guarantee of accuracy, it makes sense to use guides. When making a straight cut, you can use a wooden block fixed along the marking as a guide. If the cut shape is complex, then the situation becomes more complicated. In this case, you can use patterns, if any, or you will have to reduce the speed of work by more carefully guiding the jigsaw.

- One of the options why a jigsaw cuts crookedly is problems with the saw. It may be dull or have chipped teeth. If you notice that the jigsaw literally turns itself wherever it likes, inspect the saw.

- Jigsaw failure. For example, if the motor runs jerkily, the likelihood of a crooked cut increases sharply. Likewise, other mechanism failures can lead to a decrease in accuracy. Such problems are difficult to eliminate on site, as they require diagnostics and, possibly, repairs.

- Finally, the accuracy of the work is greatly influenced by the skill of the performer. If you are a novice carpenter, do not be discouraged by periodic failures: accuracy comes with experience.

A few tips for proper use of a jigsaw

- Before sawing hardwood or metal, lubricate the intended cut with machine oil (on metal surfaces) or water. This will protect the file from overheating and make sawing the workpiece easier;

- When sawing a part, apply even force to the jigsaw: without jerking or slowing down. This will help make the cut with maximum accuracy and cleanliness;

- Mark the intended cut line with a pencil. When making a cut, try to ensure that the file does not go along the line, but to the side of it, at a distance equal to the width of the file - this will increase the accuracy of the work.

How to cut chipboard evenly with a grinder?

In order to make a stop pad for a jigsaw, it is enough to cut out a rectangle from any dense material (for example, laminate) with dimensions identical to the dimensions of the sole of the power tool.

Then, along the larger center line, you should make a notch and secure the resulting equipment to the sole of the jigsaw using insulating tape or double-sided tape. All modifications are ready and finishing work can be carried out in compliance with certain recommendations.

Firstly, as mentioned above, you should use a jigsaw file with a straight cut.

Secondly, in order to better control the cutting process, it is justified to apply a marking line on both sides of the chipboard and check the accuracy of the processing from above and below.

And thirdly, take constant breaks from work to cool the cutting equipment.

Sometimes the solution to this issue can be simply cutting through the laminated layer of material using a mounting knife, and subsequent work with a jigsaw will no longer cause large defects in the form of chips. However, this work requires the performer to have some experience and accuracy.

How to deal with chips

The frequency of occurrence and size of chips are determined by:

- quality of material;

- saw quality;

- correspondence of blade parameters to the material and type of cut;

- individual sawing technique.

There are several techniques to reduce the number and size of chips:

- If the plywood is of poor quality, you should take a saw with smaller teeth and cut faster.

- Use a file with a reverse or reverse arrangement of teeth.

- Cover the cutting line with masking tape or tape.

- Wet the back side of the plywood.

Metal cutting

Not every file can cope with the strong structure of metals such as steel and even aluminum. To make your work with this material most effective, just follow simple rules.

- Set the minimum frequency of saw strokes. Unlike wood, where working at maximum speed is permissible, the dense structure of the metal will simply dull saws even with the strongest teeth. In this case, the presence of a regulator will be very useful, which will eliminate the need to buy a special electric jigsaw for metal.

- Use saw blades marked HSS (High Speed Steel). There are many types of canvases, and before purchasing, you should have a clear understanding of the thickness and density of the material you will be working with. For soft, sheet aluminum, the usual T118A is suitable, and for cutting steel, 3-6 cm thick, a T118B metal jigsaw file is suitable. Where is the first letter “T”, the name of the shank, which may not fit your instrument (more details about fasteners are written above).

How to choose?

In order to choose the right manual jigsaw, you need to study several circumstances that are of fundamental importance for the operating characteristics of the tool.

- Shape. You will like it rectangular and pointed - no matter which one is used for certain types of sawing.

- Weight of tools. Working with hand tools is usually quite painstaking and long, so the hand gets tired in a short time. That is why you should give preference to light-weight models with ergonomic handles. It is normal if the shape of the handle is anatomical - in other words, corresponding to the curves of the human palm (they are much more convenient to use).

- Jigsaw frames are made of aluminum, iron, titanium or steel. If you want a long-lasting and strong tool, then it is not advisable to choose jigsaws with an aluminum frame, because the strength of this metal is low. It is better to trust titanium or steel options. They are significantly more expensive, but they are able to cope with heavy loads, last a long time, and in addition, the work process itself is even more comfortable.

- Tool clamps can be represented by nuts or drums. The second option is considered more desirable, since it makes working with such a jigsaw very comfortable - in this case, no disks or cassettes are required, additional devices, for example, wrenches for replacing the blade. What remains for our client to do, what will be required of you, is to simply unscrew the drum and later change the blade manually.

- Manufacturer. Chinese tools are cheap, but you should not buy them because their service life is usually very short. Masters recommend working with products from global brands Stanley and Intertool, Mastertool, and Topex. These companies have long and firmly established themselves in the current sector of the market as the Russian automotive industry for the highest quality, reliable sets of locksmith tools.

READ Disassembly Stihl MS 180