If there is a need to manufacture a curved wooden element, then at first glance it may seem that it is easier to cut out the desired element in a curved form, but in this case, the fibers of the wood material will be cut, thus weakening the strength of the part, and as a result, the entire product . In addition, when sawing, a large waste of material is obtained, which cannot be said about the method when the wooden blank is simply bent.

Wood is cellulose fibers held together by a chemical called lignin. The flexibility of the tree depends on the arrangement of the fibers.

Only well-dried wood will be a reliable and durable source material for the production of various products. However, changing the shape of a dry wooden blank is a difficult process, because dry wood can break, which is very undesirable.

Having studied the technology of how to bend wood, as well as the basic physical properties of wood, which allow you to change its shape and subsequently preserve it, it is quite possible to start bending wood at home.

How to bend wood for furniture?

When making runners for a rocking chair, curved slats for the back of a chair, or a gunwale for a boat, you'll need curved wood pieces.

You can cut them from solid wood or bend a piece that has been steamed, laminated or slotted. Mastering these skills is another milestone towards mastering the art of carpentry. Below is the basics. Which wood is easier to bend and which is more difficult?

Some woods perform better than others due to their cellular structure and grain texture. The easiest woods to bend are those with long grain, such as white and red oak, ash and hickory. Elm, maple, walnut and cherry can be bent, but with great effort. You should avoid softwoods such as spruce and pine, as well as dense or oily tropical woods such as ironwood and African mahogany. Whatever type of wood you choose, make sure that the pieces are straight-grained and free of knots.

How long should wood be steamed before it becomes flexible enough to bend?

A rule of thumb is to steam for an hour for every inch (2.5 cm) of thickness of the workpiece. If the processing time is shorter, it will be difficult to bend the workpiece; if more, it will be difficult to work with wood.

What happens to wood during steam bending?

Wood fibers are held together by lignin, a glue-like substance that surrounds the cells. When wood is steamed at a temperature of 88-107°C, the lignin softens, allowing the fibers to stretch or contract as the workpiece is bent. When the wood cools, the lignin hardens again and the fibers are fixed in their new position.

Is it easier to bend freshly cut wood than dried wood?

Yes. Green wood is more flexible, and the fresher it is, the better. Air-dried wood is more difficult to bend, and kiln-dried wood is even more difficult.

Bending slats for the back of a rocking chair. Is it possible to build a small device for bending under steam?

Can. All you need is a steam source and a steam chamber. The simplest source of steam is an electric kettle; in second place is a wallpaper steaming machine. The simplest steam chamber is a box made of 19 mm thick plywood.

Here are some tips.

♦ Make the box as small as necessary because the steam must heat the entire chamber for maximum efficiency.

♦ Equip the chamber with dowels to create a shelf on which the wood will be accessible to steam from all sides.

♦ Build a simple device to supply steam from the source to the chamber. It can be made using PVC pipe and a few fittings.

♦ Do not make the box airtight. Drill several holes with a diameter of 6 mm to allow steam and condensation to escape and measure the temperature with a cook's thermometer.

♦ Tilt the drawer slightly to allow condensed moisture to drain away.

How do I make a mold to bend steam treated wood and how to use it?

Make a mold from several layers of 19mm plywood or bonded boards. Place beveled blocks under the bottom of the mold at both ends, on which the clamps of the clamps will rest securely.

Put on safety glasses and remove your workpiece from the steam chamber. Place it on the form and press one end with a clamp, placing a piece of wood under the clamp to evenly distribute the pressure across the width of the board. Press the other end of the workpiece in the same way. It is best to place the workpiece on the mold immediately after removing it from the steam chamber.

I'm making a set of curved back chairs for the dining room, but I'd rather glue together several thin slats rather than steam bend one thick piece. How thin should the backrest slats be and how should I prepare the wood for gluing?

Most types of wood become flexible at a thickness of 3 mm or less. First, select a board of such thickness that it is enough to make planks, taking into account the thickness of the cuts. It is better to take a board longer than you need, and after bending, cut the strips to the required length.

Cut one strip on a circular saw fitted with a smooth saw blade and set it aside. Smooth the edge of the board on the jointer, cut the next plank and repeat the process. By jointing the board before cutting the next piece, one side of each plank will be smooth, well suited for applying glue. Stack the planks in the same order in which they were cut.

How to make and use a mold for gluing thin planks?

First, cut a template from plywood or MDF to the shape of the bottom of the desired curve (actually slightly smaller to compensate for the elastic deformation of the planks). To bend wider planks, you will need to glue two or three layers of material together.

Using a feather drill, drill holes a couple of inches from the edge to give the clamps something to grab onto. Press the mold onto a sheet of plywood.

Cut several curved clamping blocks to distribute the pressure of the clamps evenly along the outside of the curved strips. Apply glue to the planks, stack them and press one end to the form with a clamp. Continue adding clamps and blocks, pressing the planks into the mold. Tap the edges of the slats occasionally to ensure they are flush. Leave the clamps overnight, then remove them.

Why does wood become more plastic under different influences?

It's no secret that wood is an elastic, tough, compression-resistant material. This is due to the presence in wood of a natural polymer - lignin (similar to glue), which gives the wood strength and permanent shape. Lignin binds cellulose fibers together. Lignin is located in the cell walls and intercellular space of wood.

In different wood species, lignin content varies from 20 to 40 percent.

Under the influence of temperature, water, chemicals, “natural glue” softens. And after giving the wooden workpiece the required shape, the lignin cools and returns the wood to its former elasticity and strength, without changing the shape that the master gave it.

Optimal wood temperature for bending

In order for lignin to reach the desired state and the wood to become more plastic, it is necessary to heat lumber from solid wood to 95-105 degrees Celsius. The wood must be completely heated to the required temperature, not just the surface layer.

Based on this, it follows that the thicker the part, the longer it needs to be heated. Parts of any type of wood of the same size heat up at the same time.

Please note that the workpiece should not be overheated. Because “natural glue”, once it hardens, will become brittle and ruin your product

Important! fresh wood (natural moisture) bends better than dry wood

Processing methods for bending wood

Boiling wood in water

The method of boiling wood in water is suitable if you need to process part of the workpiece (shooting bows, etc.). In other cases, boiling is rarely used, since the wooden element is moistened excessively and unevenly. Cells and fibers of wood that are oversaturated with water can tear when bent. At best, lint will form. It takes a long time to dry and stabilize the shape.

Steaming wood

In order to steam wood, you need to make a cylindrical box from polymer or metal pipes. Homemade rectangular wooden boxes are also used. In order to heat wood with steam, various steam sources are used, in the form of teapots and other devices. The required temperature should be in the range of 95-105 degrees Celsius plus a slight pressure (this will be provided by the box). With the help of steam, the wood is heated much more evenly than by cooking. Moreover, the moisture content of the wood remains optimal at the output.

Wood bending technologies

Nature does not like straight lines and it takes a lot of time and effort to make wooden products straight. However, bending wood is also a rather labor-intensive process. Bent wood elements are often used in Scandinavian furniture in the form of beautiful, light and durable products with unity of structure and form. In this article we will look at several ways to bend wood: simple power bending, bending using cuts, steam bending and layer bending.

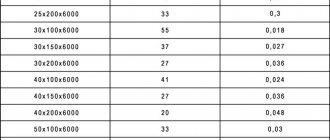

Simple power flexion

This is the simplest method and involves bending wood by hand and attaching it to a mold to secure the bend. The thinner the wood, the easier it is to bend. It follows from this that the greater the bend, the thinner the wood should be. Veneer can take on almost any bend, while an oak blank 2 cm thick is almost impossible to bend. It should also be taken into account that different types of wood have different degrees of flexibility. So the ratio of the thickness of the workpiece and the minimum bending radius for some species will be: beech - 1/2.5; oak – 1/4; birch – 1/5.7; alder – 1/8; spruce – 1/10; pine – 1/11. That is, with a beech blank thickness of 10 mm, the minimum bending radius will be 25 mm.

As a rule, the workpiece is fixed with glue, since the use of nails or screws in bending areas can lead to the formation of cracks and breaks. There is an unspoken rule - what can be fixed by hand can also be fixed with glue. When gluing, to reduce gaps, you need to move from the center to the edges, or from one edge to the other.

Bending using cuts

This method of bending wood is the least durable because the wood is sawed through almost the entire thickness and very little strength remains in it. Therefore, this method of bending wood is used only where there is no heavy load, for example rounded corners, etc.

The main material for the manufacture of bent-sawn parts is plywood. To achieve the best results, cuts are best made on a circular saw using a limit stop. The cuts should be made across the grain at a distance of about 5-10 mm. from each other. The depth of the cut should be about 1/5 of the thickness of the workpiece.

To fix the bend, you can use glue or wood filler. By gluing and fixing two curved slats with the cuts inward, it is possible to create interesting elements in some designs, although with limited strength.

Steam box heating

Steam box

First you need to prepare the steam box. It can be made by yourself. Its main task is to hold the tree that needs to be bent. There should be a hole in it to allow the steam pressure to escape. Otherwise it will explode.

The steam outlet should be located in the bottom of the box. In addition, the box should have a removable lid through which you can pull out the bent wood after it has acquired the desired shape. To hold the bent wood piece in the desired shape, clamps should be used. You can make them yourself from wood or buy them at a specialty store.

You should make round scraps of wood - several pieces. Off-center holes are drilled in them. After this, you need to push the bolts through them, and then drill another hole through the sides to push them in tightly. Such simple crafts can become excellent clips.

Now it’s time to steam the wood; to do this, you should take care of the heat source and close the wood piece in the steam box. For every 2.5 cm of thickness of the workpiece, the product needs to be steamed for about an hour. After time has passed, the tree must be removed from the box and given the required shape. The process must be completed very quickly. The workpiece bends neatly and softly.

Shaping

Some types of wood bend more easily than others due to different elasticity. Different methods require different amounts of force to be applied.

Once the desired result is achieved, the bent tree must be fixed in this position. You can secure the tree while shaping it. This makes it easier to control the process.

How to bend wood

If there is a need to manufacture a curved wooden element, then at first glance it may seem that it is easier to cut out the necessary element in a curved form, but under such conditions the fibers of the wood material will be cut, weakening the strength of the part, and as a result, the entire products. In addition, when sawing, there is a huge waste of material, which cannot be said about the method, while the wooden blank is simply bent.

Wood is cellulose fibers held together by a chemical called lignin. The flexibility of the tree depends on the placement of the fibers.

Only well-dried wood will be a reliable and durable source material for the production of various products. But changing the shape of a dry wooden blank is a difficult process, since dry wood can break, which is very undesirable.

Having studied the technology of how to bend wood, and the fundamental physical properties of wood, which allow you to change its shape and then preserve it, you can fully engage in bending wood at home.

Why bend wood?

Wood bending is one of the oldest methods, used since ancient times to make canoes, bows, sleighs, barrels and so on. How to make bent wood parts?

At a time when wood was mainly used for the construction of mobile structures such as wheels for carts and carriages, bending the material was a defining process.

We can say that bending wood is a very simple process, provided you have the necessary knowledge and skills

Wooden products such as wooden toys, spoons, picture frames, etc. can also be made using various wood bending techniques.

The bending of wood can be different, depending on what purpose is being pursued - whether the shape of a boat, an arch, a barrel is needed...

Some features of working with wood

Bending of wood is accompanied by its deformation, compression of the inner layers and stretching of the outer layers. It is not uncommon for tensile forces to cause the outer fibers to break. This can be prevented by preliminary hydrothermal treatment.

So, it is possible to bend blanks of timber made from solid and laminated wood. In addition, planed and peeled veneer is used for bending. The most plastic are hardwoods. These include beech, ash, birch, hornbeam, maple, oak, poplar, linden and alder. It is best to make bent glued blanks from birch veneer. It must be emphasized that in the total volume of bent-glued blanks, birch veneer occupies approximately 60%.

When steaming the workpiece, the compressive property increases significantly, namely by a third, while the tensile property increases by only a couple of percent. This means that one should not think a priori about whether it is possible to bend a tree thicker than 2 cm.

The process of steaming and bending wood

The chamber profile is often made of wood or PVC pipes. The workpiece must be completely in the chamber so that steam can saturate its entire length. The steam chamber must be sufficiently sealed and the steam outlet hole must be positioned in such a way that moist air washes the workpiece from all sides.

The dimensions of the hole for the steam outlet are selected so that the saturated air comes out under pressure as in the video above. The fact is that if the steam concentration is insufficient, the workpiece will not be steamed; if the pressure is too high, the steam chamber may even rupture or the hoses may break. Sometimes, to create the required amount of steam, a light cap is placed on the outlet, which opens when the pressure increases and closes when the pressure is low.

As a steam boiler at home, you can use a regular kettle or a pan of water on the stove. For a more frequent bending process, you can buy a special generator.

The wood bending process must be started only after there is sufficient water in the generator, since interruption of the saturation process negatively affects the quality and time of the entire wood bending process.

Using chemical impregnation

In order to destroy the lignin bonds between fibers, it is possible to influence the wood with chemicals, and this can be done to the fullest extent at home. Ammonia is ideal for this. The workpiece is soaked in a 25% aqueous ammonia solution. At the end of which it becomes very obedient and elastic, which allows you to bend, twist it and squeeze out relief shapes in it under pressure.

Ammonia is scary! Based on this, when working with it, you should follow all safety regulations. Soaking of the workpiece should be carried out in a tightly closed container located in a well-ventilated room.

The longer the wood is in the ammonia solution, the more plastic it becomes. After soaking the workpiece and giving it a shape, it is necessary to leave it in this curved form. This is necessary to fix the shape, and so that the ammonia evaporates. Again, bent wood should be left in a ventilated area. It is noteworthy that after the ammonia has evaporated, the wood fibers will regain their former strength, and this will allow the workpiece to retain its shape!

Steaming and bending video

We present to your attention a video about the technological process of bending wood:

Good luck and success! Until we meet again, Andrey Noak was with you!

Natural materials, in particular wood, have always been popular. But now designers are increasingly suggesting the use of affordable and cheap plywood. You can make wonderful bent furniture from it with your own hands.

Plywood boards have the ability to easily deform and take on the desired shape.

First, the workpiece is cut out, then soaked in boiling water for some time. The material becomes plastic and you can bend it however you like.

Often plywood is combined with other materials - plastic, metal, wicker, wood, glass.

Depending on the treatment, such things can be used both indoors and outdoors.

Bent headsets come in the most unusual original shapes. It all depends on the imagination of the master.

It is believed that plywood is a fragile material. But that's not true. You just need to choose sheets of sufficient thickness, then the furniture will be reliable. In addition, it almost does not deform when temperature and humidity changes.

Any person with at least minimal skills in working with carpentry tools can make such unusual furniture on their own.

Creating such interesting bent products is a fascinating process. And most importantly, you certainly won’t find a similar thing in any other home.

Layering method

First you need to make a piece of wood that will be bent. The boards should be slightly longer than the length of the finished part. This is explained by the fact that bending will shorten the lamellas. Before you start cutting, draw a diagonal line with a pencil. This must be done across the underside of the board. This will allow the lamella sequence to be maintained after they have been moved.

The boards are cut with a straight edge, never with the right side. So, it will be possible to put them together with the slightest transformation. A layer of cork is applied to the mold. This will help avoid unevenness in the shape of the saw, which will allow you to make a clearer bend. In addition, the cork will keep the delamination in shape. Now glue is applied to the top side of one of the wooden slats.

The glue is applied to the lamellas with a roller. It is best to use urea-formaldehyde glue, which consists of 2 parts. It has a high level of adhesion, but takes a long time to dry. It is also possible to use epoxy resin, but such a composition costs a lot, and not everyone can afford it. Regular wood glue cannot be used in this case. It dries quickly, but is very soft, which is not welcome in this environment.

Place the bent wood blank into the mold as quickly as possible. So, another lamella is placed on top of the lamella coated with glue. The process is repeated until the bent piece reaches the desired thickness. The boards are fastened together. Once the glue has completely dried, proceed to shorten it to the desired length.

BONDING WITH SIMULTANEOUS BENDING

When bending wood

the fibers on the inner side are compressed, and on the outer side they are stretched. Wood “tolerates” fiber compression relatively easily, especially if it is pre-steamed. It is almost impossible to stretch it.

Flexibility also depends on the type of wood and the thickness of the workpieces. For example, hard wood from temperate climate zones - beech, oak, ash, elm - is easier to bend than tropical wood species (mahogany, teak, sipo, etc.). Conifers are too tough for this.

The resistance value of bent wood until it breaks is determined by the ratio 1:50, i.e. The bending radius must be at least 50 times the thickness of the workpiece. For example, a workpiece with a thickness of 25 mm requires a radius of at least 1250 mm. The thinner the wood, the easier it bends. Therefore, where possible, it is advisable to make a part of the appropriate shape by bending (Fig. 1).

In this method, individual strips of wood of the same thickness and width are glued, laid in several layers so that their grains are parallel, and placed in a mold made of hardwood. The matrix and the mold punch are compressed with clamps and the bag is left in this position until the glue dries.

The thickness of the strips glued to each other can vary between 1-6 mm, again depending on the required bending radius. Cold-curing glue is suitable for gluing layers. If bent-glued blanks are intended for use in external structures, it is best to use waterproof glue.

I drank it as a way

The prepared piece of wood must be sawn through. The cuts are made 2/3 of the thickness of the workpiece. They should be on the inside of the bend. Be extremely careful, as rough cuts can break the tree.

The key to success when cutting cuts is to keep the distance between cuts as even as possible. Perfectly 1.25 cm.

The cuts are made across the grain of the wood. Then try to squeeze the edges of the workpiece so as to connect the gaps together. This is the shape the bend will take upon completion of the work. After this, the bend is corrected. Much more often, the outer side is treated with veneer, or in some cases with laminate. This effect allows you to correct the bend and hide any flaws made during production. The gaps between the bent wood are easily hidden - for this, glue and sawdust are mixed, and when finished, the gaps are filled with this mixture.

Regardless of the bending method, once the wood is removed from the mold, the bend will easily relax. In view of this, it needs to be made a little more in order to compensate for this effect later. The sawing method can be used when bending part of a box or an iron corner.

So, using these simple tips, you can bend a tree with your own hands without much effort.

Sawing a curved piece of wood

- A wooden curved piece can be made either by sawing out the shape or by bending it. When cutting a wooden part, there is no need to use additional types of processing, special devices and knowledge, as is the case with bending.

- In addition, cutting out a curved part saves time; cutting out a spatial shape is faster. But this is where the positive aspects of sawing, in comparison with bending, end.

- If you cut out a curved product, a mass of irretrievably lost material is formed, which becomes waste. In addition, cross sections of conventional edged lumber fall within the radius zone of the cut part. This significantly worsens the appearance and complicates sanding and other finishing of the wood.

- The manufactured part may break at the rounded sections of the fiber that run across the section.

BENDING USING CLAMPING DEVICES AND PRESS FORMS

To determine the permissible thickness of the veneer strips or planks to be bent (with a larger thickness, the wood may break), you need to know the smallest bending radius. The wood is most deformed on the inside of the bend. Therefore, it is always necessary to measure here.

As an auxiliary device, it is advisable to use a template that you can make yourself. To determine the bending radius, we take an ordinary school compass and draw several circles on tracing paper (with a slight increase in their radius) that have a common center. As a result, we get a template. We apply it to the surface of the bend, for example, a mold, and move it until we find a suitable circle of the largest diameter. We measure its radius on a template. We divide the resulting value by 50. The quotient of the division will be the maximum allowable thickness of the strip of plank or veneer.

When working with molds, the bend on the outside of the workpiece should be smoother than on the inside. In this case, we draw two circles from one center, the radii of which differ by the total thickness of the strip material.

The most difficult situation is when it is necessary to bend a part of a complex configuration with different bending radii. Here, curves for the inside or outside of the workpiece can be constructed freely if its shape is not tied to the contours of any piece of furniture.

In this case, the line for the second cut (the first one is at the beginning of the bend) can be constructed like this. Using a compass, measure the total thickness of the layers to be glued, draw a circle with it on hard cardboard, cut out a circle and apply it in several places to the line of the first cut. At the same time, we apply the circle so that it is in contact with the first line, and draw its outline on the opposite side, respectively. The second cut line will be the end-to-end connection between these auxiliary lines.