Until recently, a chainsaw was used only for cutting logs crosswise. Craftsmen could use it to make boards, rectangular bars, and all kinds of wooden sculptures. This was not a good thing for the common people. It required experience, skill, and talent. Today, chainsaw manufacturers offer various attachments as a supplement, which have turned the tool into a universal device with which you can cut not only wood, but also other building materials, such as stone. In this article we will deal with one question - how to cut a log into boards using a regular chainsaw.

Option for cutting logs with a chainsaw

The advantage of a chainsaw as a tool for sawing logs

You can saw a log using a sawmill, gas or electric saw and additional accessories. When choosing one of these tools, you should consider the amount of work ahead. The cost of the cheapest stationary sawmill along with all components is 150 thousand rubles. A chainsaw is much cheaper. It is more convenient than an electric saw for the following reasons:

- Electricity is not required to operate the tool - this makes it possible to use a chainsaw on plots.

- It is more powerful compared to an electric saw.

- It starts smoothly and allows you to conveniently adjust the speed, which reduces the likelihood of a chain break.

- The inertial brake operates faster than that of an electric saw.

- Long working time without interruption – up to one hour.

- Can be used in conditions of high humidity.

Circular to help you!

One of the most commonly used tools used to solve this problem is a circular saw! You just need to know a few basic rules. First, it is necessary to ensure the longitudinal movement of the tree.

It is clear that it is almost impossible to do this on a regular horizontal table, because it will roll from place to place during sawing, which is very inconvenient and can lead to injury! Which is something we absolutely wouldn’t want.

But what should you do, you ask? There is one trick that is known to all professionals under the code name “fin”.

A fin is a device whose thickness corresponds to the width of the cut. But you need to install this thing in such a way that it is possible to correct and adjust its position. It is very important!

The log is cut into boards by two people, this happens using the following technology: first they saw it lengthwise, that is, the work is carried out according to the usual method. Then, when the fin is fully inserted, a spacer is inserted, which should slightly exceed the width of the cut. We install a handle clamp, which will perform two functions at once, one of which is holding, and the other will be needed in order to conveniently pull it.

File - the spacer at this moment will not allow the board to deviate anywhere, which is very convenient! Next you will need to act like this: the first worker will pull the object by the clamp, and the other will press it against the ruler, which is used in this case to determine the width of the board!

Thus, the work is in progress in the hands of the masters! Things are looking up! And the speed of action surprises them!

Types of working attachments

When sawing logs with a chainsaw, various attachments are used.

- Attachment for longitudinal sawing. It is used for sawing logs lengthwise, the process takes place in a horizontal position. After work, the master receives the same thickness of the product. The finished materials undergo a drying process, after which the boards are used in construction. In appearance, the device is a small frame; it is attached to the tire on each side.

- Drum debarker (debarker). With the help of such an attachment it is easy to dissolve the log; it works due to a V-belt drive. Attached to belts on both sides, special pulleys are used for this. The speed of rotation of the shaft depends on the size of the pulleys, so the performance of the attachment is easy to change. This technology forces the master to carefully monitor each stage of the process; some specialists use an assistant during this cutting. But this option requires increased security measures.

- Sawing with a lightweight nozzle. The method is not very productive, but is used quite often. The element is fastened on one side, but the workpieces are slightly uneven. Such materials are necessary for the construction of sheds or fences.

Features of cross cuts

Cross cutting is used only to create firewood or interior elements. The work is carried out according to several principles:

Before carrying out work, the log is placed in a horizontal position on supports. The height of its location should be 0.5 m. After this, it is necessary to completely clear the log from the bark. At the next stage, it is necessary to make marks on the entire log, located at an equal distance from each other. Then sawing can be done using the created marks.

Cross cutting does not require specialized tools.

Features of sawing using a homemade tool

You can easily saw a log into boards using a self-made tool. It's easy to make. To do this you need to do the following:

- As a support, you need to use a frame from a school desk or a pipe with a cross-section in the form of a square, its optimal size is 20x20, more is allowed.

- It is necessary to build two clamps, mount a cross member with two holes for coupling bolts at one end, and make a protrusion for the tire in the middle.

- To cut logs longitudinally into boards, you need to make a support frame; its width should be seven to eight centimeters less than the length.

- Then two parts ten centimeters long are welded to both sides, holes are made for the bolts, and a handle is attached in the middle for ease of operation.

- Then you need to insert the clamps into the grooves, install the tire, and secure everything carefully.

Working with a homemade tool is not difficult; for this you will need goats, they will serve as a support. In addition, you need to prepare a metal strip or board to use as a guide. A log is placed underneath and the required height for work is set.

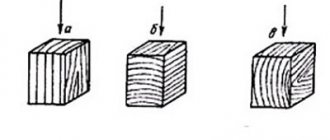

Types of log cutting

Before you start cutting the workpiece, you need to decide how to get a high-quality final product with the least amount of waste. The wood is uneven in quality; the lower part of the trunk produces the most valuable lumber. When sawing logs, you can obtain the following types of lumber:

- timber - lumber, more than 10 cm thick and wide. The most common type is four-edged timber, square in cross-section. Used as a building material and in furniture production;

- board - lumber, up to 10 cm thick and twice as wide as the thickness. Boards are obtained from logs or beams and are used in construction and in the furniture industry.

Having theoretical knowledge and practical skills, you can make boards and beams with your own hands.

The procedure for performing preparatory work

To cut a log lengthwise, you need to perform the following sequence of actions:

- Take two straight boards and attach one to the other at right angles. The result is a strong guide line.

- To support the manufactured ruler, you need to make stops from boards.

- Moving the trunks must be done using a tilter.

- The log should be placed on a comfortable base.

- You need to secure the frame to the chainsaw bar using nuts.

- The supports of the leading ruler must be attached to the ends of the log, checking the horizontal position with a level.

- Self-tapping screws must be used to secure all brackets and structural elements. Nails are not suitable for these purposes, since they are difficult to remove in the future without causing damage to the structural parts.

- The leading ruler needs to be attached to the supports using brackets and its height adjusted taking into account that the cut will not go along it, but approximately one centimeter higher.

- The log needs to be rotated and the second board secured so that it rests on the ground and supports the log.

Advantages of a homemade chainsaw sawmill

Although forest industry workers may be dismissive of the low-power “device,” it still has a number of advantages specifically for private use:

- Cheap . One of the decisive benefits. Industrial machines are designed for large volumes and continuous operation throughout the work shift. However, their cost, like other industrial equipment, is extremely high. These are aimed at large enterprises whose profits and production volumes allow them to recoup such costs. But in private farming there is no need for such volumes. Sawing logs is not performed constantly, but occasionally, and not for long. It is much more logical to assemble a homemade machine for dissolving trees. The cost of even the most expensive component - the chainsaw itself - rarely amounts to more than one hundred thousand rubles. The simplest and lowest-power domestic band sawmill costs one and a half times more. Foreign samples will cost several times more. The costs of metal parts and welding do not significantly affect the cost.

- Compactness . With rare exceptions, a homemade sawmill is a small unit. It can be transported without problems, and this gives an advantage: the dissolution of wood can be carried out on site, without transporting entire trunks to the location of the unit. True, if the logs lie far from the place where they are needed, then you will still have to transport the resulting boards, but this task is already simpler both during loading and in terms of transport requirements. When disassembled, the chainsaw sawmill takes up virtually no space.

- Simplicity of design . A DIY tool has a small number of parts and can be assembled by a person without special training other than welding skills. Accordingly, the only thing that can break in it is the chainsaw itself.

Procedure for performing basic work

- Now you need to start the chainsaw and make the first cut.

- Next, you need to free the log from the stops and boards and attach a guide ruler to the cut surface of the log in the direction of the next cut. The ruler is attached directly to the surface or to the ends of the log using supports. The second cut is made perpendicular to the first cut.

- The log needs to be turned and secured with a board against the ground.

- A ruler is not required to perform the following steps. One of the cut sides serves as a guide.

- It is necessary to adjust the thickness of the cut on the frame and saw off the log from the other side so that you get a beam with bark remaining on only one side.

- This beam must be turned over and secured so that the attachment point of the fixing board is as low as possible.

- Then you need to adjust the frame to the required thickness of the board and saw the timber into boards.

On a band sawmill - the fastest!

There are a huge number of techniques that can help you cut logs. To study them, I recommend reading my books on woodworking.

Now I’ll tell you the technique for doing it on a band sawmill. First you need to form a carriage.

To do this, you need to make cuts on two sides, or on four, but this is in special cases! The next stage is the creation of a map, which is needed so that the process of cutting the workpiece can be carefully prepared; it is at this stage that we indicate the dimensions of the board.

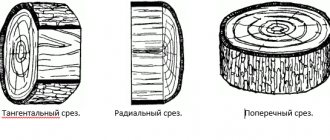

The determining parameter in this work is the direction of processing the log; it is especially important to pay attention to the movement of the edge that cuts the tree relative to the annual rings! It is by this criterion that various lumber with unique properties is formed. The aesthetic qualities and price of the board depend on the work performed at this stage.

There are several types of cuts that you need to know about: radial, cross, rustic and tangential.

Radial is the highest quality, because in the end you get an almost perfect board: uniform in color and texture! It does not deform under any conditions, it is clear that the price of such a product is quite high!

The tangential method is a little worse, because the boards are not so strong, but the pattern remains good, sometimes you get fancy patterns! Radical is also not bad, but it differs significantly from radial and tangential in the quality and beauty of the design! Rustic is the most unreliable, because boards of this type are heterogeneous and fragile.

It would be more expedient to talk about the simplest cutting method. It's called circular. They remove the first slab, then turn the log one hundred and eighty degrees, place it on the edge, then you have to turn it many, many times! And so you will definitely succeed!

Safety rules when performing work

- The circular saw should not be used without a protective guard.

- It is necessary to wear headphones, gloves, glasses, thick clothing and a respirator.

- You should not pour fuel into a hot tool tank; you need to wait until it cools down.

- Children should not be allowed to be present at the work site.

- It is necessary to start the tool on the ground with the chain brake engaged, which must be released only before starting to cut.

- You should always have a first aid kit on hand.

- When working, you need to hold the chainsaw by the arc handle, moving it forward along the guide. You should not put too much pressure on the chainsaw - it should move freely.

- Right-handed people should place the log on their right side, left-handed people should place it on their left.

Safety precautions

When working with a chainsaw, you must follow safety rules; they will help you avoid injuries and unpleasant situations:

- People, especially children, should not be allowed onto the work site.

- When working with a circular saw, be sure to wear a special protective cover on it.

- During the process of sawing logs, you should use protective equipment against sawdust and noise.

- It is necessary to have a first aid kit with medications to treat the wound during cuts.

- Do not pour gasoline into a heated tank of a chainsaw.

- The chainsaw must be used only for its intended purpose; it is prohibited to turn it on at full power if it is not in use.

- Installation of logs is carried out only on the right side.

- When working with equipment, it is strictly forbidden to press it with force.

If you follow safety precautions, the work will not be difficult, and the result will be high-quality material without harm to health.

A chainsaw is a versatile piece of equipment that is easy to use. Craftsmen can use it on a personal plot, in a private house. In addition to producing boards, it is used for repair work on outbuildings and wooden decorative elements. You don’t need a large number of boards; just take a couple of logs.

Design features of a chainsaw sawmill

Portable homemade sawmill based on a chainsaw

If factory-assembled machines are mainly stationary options, then homemade ones are more profitable and easier to make portable. This determines the design features. If in a factory unit the cutting part is mounted on a frame, then in a homemade saw blade it is installed in a special frame welded from a metal profile. It acts as a stroke limiter and also determines the evenness of the cut.

True, sometimes you can find a stationary model on the farm, which enterprising owners assemble in a specially designated place on the site. Here, more massive rolled metal is already used - a channel, and a corner from which the bed for the tree trunk is made. A massive carriage with a chainsaw mounted on it moves along the log along rail guides using rollers. Although such products provide a more accurate cut, they are much more complex and expensive to produce, so they are justified only where you need to work with a large volume or for a long time.

Requirements for a chainsaw

No matter what drawings the sawmill is assembled according to, it will not provide the performance required of it if the main element - the chainsaw itself - is chosen incorrectly.

It is worth noting right away that longitudinal sawing of wood puts a long and heavy load on the engine, transmission and saw set. Therefore, the higher quality and expensive the chainsaw works in conjunction with the frame, the faster, better and safer the work will be. Therefore, for work it is better to use products of the semi-professional and professional segment of such brands as Stihl, Husqvarna, Echo, Makita, Oleo-Mac, Komatsu. Firstly, in the range of these companies you can find tools for professional use. And secondly, the high quality and reliability of components and components will allow you to cope with the task assigned to the saw without breakdowns or interruptions in work.

Actually, no one forbids using an inexpensive Chinese chainsaw for a sawmill, like the same Caliber or Hooter. However, when taking this step, the owner must be aware that for the tool, the work of cutting a couple of trunks into planks in a day may be the last. Even with successful work in collecting firewood and even felling trees, there is no guarantee that when making a longitudinal cut the engine will not overheat and jam. When unraveling the log, the length of the workpiece is passed at one time. After such a load, when using the household option, you will need to wait 10 - 15 minutes to allow the engine to cool.

Regardless of the manufacturer, the following parameters should be taken into account:

- Sufficient power , not less than 3.5 liters. With. this will allow the motor not to choke when the saw blade gets stuck in the wood. It’s even better when this figure is 4 - 4.5 hp. Well, the happy owners of professional shaft chainsaws of 5 - 6 kW will generally be able to easily operate the assembled machine.

- Tire length is at least 45 cm . The smaller reach of the saw set is clearly insufficient for longitudinal sawing work. Considering that it is impossible to finish the cut, as with cross cutting, the length of the tire limits the maximum possible diameter of the log or timber.

- The chain must be strong and of high quality so as not to stretch after one or two passes. Since to replace the chain you will have to remove the chainsaw from its mounts, it’s better not to deal with cheap options without a name, which are riveted from a nameless bay right before your eyes. Shtil, Oregon, Husqvarna, and, in extreme cases, Champion - this is a range of products that can be used for a relatively long time without replacement.

Separately, it is worth noting such blade parameters as the chisel shape of the teeth, which increases the cutting speed, as well as the sharpening angle. For longitudinal spreading, the cutting edge must be adjusted to 10 degrees. These chains are sold separately, but you can resharpen an old chain, especially if you have a sharpening machine.