Lumber: terms, definitions, classifications

Each type of wood has its own specific properties, and therefore it is customary to follow the generally accepted classification, regulated by existing standards, based on the shape and size of lumber, wood type and other defining indicators.

Classification according to external characteristics:

- Beams - rectangular lumber with a width and section thickness of more than 100 mm; Boards - lumber less than 10 cm thick and a width more than twice the thickness; Planks, planks, sleepers - a group of auxiliary materials of small size and rectangular cross-section; Slats - widely used in construction material, which is thin and narrow boards.

According to the surface treatment method, lumber can have wide surfaces (faces), narrow surfaces (edges), and end surfaces (ends). By type of wood sawing - radial (sawing from the core to the edges of the trunk), tangential (at a certain distance from the core), mixed lumber.

According to GOST, the moisture content of lumber is one of the most important qualities of wood, on the basis of which there is also a separate gradation. According to the degree of absolute humidity, wood is divided into the following types:

wet - humidity more than 100%; freshly cut - with a humidity of 50 ...

100%; air-dry - 15 ... 20%; room-dry - 8 ... 10%; absolutely dry - with a humidity of about 0%.

Common types of lumber and their uses

One of the lumber that is widely in demand today is four-, three- and two-edge timber. Widely used for the construction of supports and installation of rafters, in the construction of houses, for the construction of temporary buildings, subfloors.

When constructing rough structures and temporary fencing, unedged boards are no less popular. Edged boards are used everywhere in construction: making wooden windows and doors, laying wooden floors, erecting walls, stairs, and ceilings. For interior decoration, block houses and lining are in great demand.

The production of all these and other types of lumber is carried out in accordance with generally accepted standards (GOST) regulating the quality of lumber. GOST 2140-81 assumes a general gradation of 4 grades of lumber, based on product quality indicators:

- The first grade is lumber that has virtually no defects (lost knots, cracks, through growth, browning, mold, rottenness, etc.) The second grade allows for a small number of defects, and there should be no falling knots, deep cracks, damage, rottenness, foreign inclusions .For the third grade, many defects are allowed, but there are also certain ratios of the number of defects per unit of material. The fourth grade allows almost all defects, provided that the integrity of the material is maintained.

What is lumber? Types and purpose

Wood has long been known to mankind as one of the best building materials. Its characteristics allow it to be used in many areas of the national economy. This material is reliable, durable, and endowed with aesthetic qualities. Wood is also famous for its environmental friendliness. Therefore, the scope of its application is very wide. Various products are made from wood. What lumber is and what its purpose is should be considered in more detail. The variety of types of such products makes it possible to use them on a wide variety of objects.

general characteristics

Today there are a huge number of different types of lumber. They are obtained by cutting along the fibers. All lumber requires proper processing. GOST 8486-86 and 2695-83 are basic in the production of such products. However, this industry is regulated by many other standards. Their implementation is a necessary condition in the process of creating quality products.

Today, almost every branch of the national economy uses wood products for various purposes. This is due to the unique properties of this material. Synthetic products are not yet able to replace it. Therefore, the woodworking industry produces a variety of types of lumber.

Their properties and classification deserve detailed consideration.

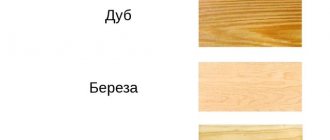

Softwood and hardwood lumber

All timber and types of lumber made from them are also classified into two large categories - coniferous and deciduous.

Coniferous lumber is made from tree species such as spruce, pine, cedar, fir, larch, and is distinguished by its particular breadth of application. The gradation of softwood lumber into grades is carried out in accordance with the following indicators:

Compliance of lumber with dimensions established by GOST.

The dimensions of softwood lumber are regulated by GOST 24454-80. According to this GOST, the dimensions of lumber, including the width and thickness of the ends, the width of the facets, are regulated by relevant standards or can be manufactured according to customer dimensions. Humidity - lumber can be produced raw (humidity more than 22%), dry (less than 22%) and wet antiseptic. Surface roughness (arithmetic mean of the maximum heights of irregularities) should not exceed 1250 microns for grades 0-3, 1600 microns for grade 4 (GOST 7016-82). Parallelism of faces and edges. Non-parallelism is allowed within the limits of deviations from the regulated dimensions of softwood lumber (GOST 24454). The presence of wood defects (knots, cracks, fungi, rot, etc.) is standardized by GOST 8486-86.

Hardwood lumber, made from trees of almost any deciduous species, is distinguished by its special density, beautiful wood texture and durability. They are widely used for cladding ceilings, partitions, walls, as well as for the manufacture of various architectural details.

According to GOST, hardwood lumber is differentiated into 3 grades (GOST 2695-83). The list of quality indicators for hardwood lumber, according to which the division into grades is made, includes the presence of the following defects: fused, falling out, rotten knots, cracks, browning, sprouts, wane, warping and some other defects.

Wood, as a material, has been used in the construction industry for quite a long time, and it is the most popular material both now and many thousands of years ago. This popularity of the material depends on the characteristics of the wood and its advantages. Despite the fact that modern technologies offer customers on the website https://domdosok.ru all kinds of materials, wood is still among the leaders in popularity.

Lumber sizes

All lumber is produced according to the required dimensions. The main standard sizes are as follows.

| Type of lumber | Dimensions | ||

| One side, mm | Second side, mm | Length, m | |

| timber | 50 – 250 | 130 – 250 | From 1.00 to 6.50 |

| Edged board | 16 – 75 | 64 – 275 (with gradations of 25 cm) | |

| Bar | For 2 sides for: · coniferous species – from 16 to 75 · hardwood – from 19 to 100 | ||

Standard lumber sizes

Side Measurement

Note: As a rule, the most popular lumber is 6 m long. It is also worth noting that in some cases orders are made to individual sizes (made to order).

Benefits of wood

Wood is the most popular building material and this is explained by the fact that it is quite affordable. However, this is not the only thing that makes it popular and frequently used.

- Environmental friendliness, Strength, Reliability, Durability, Aesthetics.

And this is not the whole list of why such material as wood is used in our time.

Lumber classes

There are a lot of options for lumber, but if we consider the main ones, these are:

Each type of lumber is used both in construction and other industries.

If we consider timber and boards, then this material is used mainly in the construction of houses or other structures. The material is quite versatile and everyone can find it used in the household. As for sleepers, the main use is in the construction of iron joints.

Also, wood can be edged or unedged. The first type is used, as a rule, in those buildings where there is no need for an aesthetic appearance; as for the second option, its scope is unlimited.

The first three grades are used in construction.

Without being a professional, it is difficult to accurately determine the differences between lumber, for example, between 2nd and 1st grades, or 2nd and 3rd.

Grade 1 is considered the standard of quality. Such lumber is used for the most critical structural elements, for example, for the manufacture of frames, in the construction of load-bearing structures, interior, exterior or finishing work.

Grade 2 is used for less demanding tasks, such as flooring or wall cladding. For external work, for example, in the form of boards for formwork, second-grade wood is also most often used.

Grade 3 is suitable for elements that do not experience severe loads - various cladding or flooring.

Grade 4 is used as an element of various blanks that have a minor purpose. It is used for the production of packaging, containers and other small items useful in the household. Also, fourth grade wood can be used as firewood or raw material for pulp and paper production.

* Wood defects that are used to determine grade are described in GOST 2140-88 “Visible wood defects”.

FORMING AN ORDER - what type of lumber do you receive?

Unfortunately, not all hardware stores accurately determine the grade of lumber and sell the material at a price corresponding to its grade.

Thus, an uninformed buyer may be sold the 2nd grade instead of the 1st at a price corresponding to the latter. The seller may indicate that he has 1-2 grades or 1-3. Or, without the buyer’s knowledge, mix different types of material – boards, beams or timber – in one order. It can be quite difficult to notice a substitution right away, because... lumber is usually delivered in a bundle. You will have to wait until it is unloaded and laid out individually.

Some companies do not indicate the grade of their material at all. In this case, in principle, you should not expect price to match quality.

Characteristics of tree species

There are lumber from coniferous and deciduous trees, where the former are used for the construction of load-bearing structures in the form of a frame. Hardwood is typically used as a siding material due to its appearance and level of durability.

Pine is considered the most common type of wood.

It has good density, has relative flexibility and elasticity. This type of material is easy to process, so it is often used both for the construction of durable and reliable structures and for interior decoration. Very often, pine is used as a floorboard.

Spruce. According to its characteristics, this type of wood is somewhat stronger and more durable than pine, and its cost is somewhat cheaper. This type of material is quite flexible and elastic, easy to process, but has the disadvantage that it absorbs moisture.

Fir.

This type of wood is distinguished by its evenness. The material obtained from fir wood has virtually no knots and tolerates moisture well without rotting. In addition, the length of the finished product can be quite impressive.

Larch. This type of wood is considered the most durable of all conifers, due to the fact that the material is hard, it is poorly processed, but its reliability is at a high level.

As for deciduous wood, their hardness is even higher than that of coniferous fauna. Deciduous trees are used not only in construction, but also in the production of furniture products. The most popular materials of deciduous trees are: oaks, ash, birch, linden and maple.

The woodworking industry is constantly busy with work, since, despite the simplicity of the material, it is in great demand, and therefore there is a need for it. Currently, the lumber market is overflowing with a range of products, while everyone can choose for themselves exactly what interests them. Wood has always been valued for its characteristics, which are suitable for both the construction, furniture and agricultural industries.

Design of engineering systems: features and stages of work

Correct design of engineering systems is the key to successful construction of a facility.

The comfort of the future room directly depends on how correctly the calculations are made. Every year, the requirements for engineering systems increase, modern technologies are being introduced, so drawing up a project takes a lot of time and effort. The price depends on the area of the object and its features, the amount can reach about forty percent of the total cost of the house project.

Lumber is a material obtained by longitudinal sawing of logs, followed by longitudinal and transverse (if necessary) division of the resulting parts. The end result is a product of a certain shape and size, with at least two (front and back) parallel sides. This type of material is produced at special enterprises equipped with band saws, circular saws and other equipment.

Types of materials used

Lumber for flooring is selected based on the combination of the following indicators:

- Strength (depends on density). Strength can be used to judge how well the wood retains its original characteristics, does not warp, or dry out during use.

- Wear resistance (or hardness). The ability of wood to resist abrasion (in fact, resistance to mechanical stress).

Source boss-floors.ru

Pine and spruce are the main species for the production of flooring boards in the house. They have all the necessary advantages: a suitable combination of density and hardness, widespread availability (which has a positive effect on cost). The density of coniferous species is quite low, so they are not used for making parquet boards, preferring oak and beech wood.

A good-quality wooden floor is made from oak; ash can serve as an alternative. Beech as a floor covering is suitable only for dry regions: it actively absorbs moisture, which is why it is deformed and affected by fungus. Other popular breeds should also be chosen carefully, taking into account their characteristics:

- Maple. Slightly less dense than oak, comparable in hardness to ash. The wood is considered to be of high quality, but it still does not like excessive moisture. If you are leaning towards maple lumber, be aware that over time the finish will take on a yellowish (or pinkish) tint (which may be important for the interior).

Source parkett-shop.ru

- Birch. The Birch family consists of species that differ in appearance and wood properties. Karelian birch is often used to make flooring, as it is the hardest and hardest.

- Larch. Its high resistance to moisture and high density are known, but few people know that the hardness of the wood is low. Hence the low wear resistance of larch and the possibility of laying the floor only in rooms with low traffic.

The choice of the type of wooden boards depends not only on personal preferences, but also on the construction budget. But no matter what option you choose, you will have to decide on the type of lumber. Grades are established by GOST and describe the external features of the board, for example, the presence and quality of knots, cracks (quantity per unit area), uniformity of texture. The classification can have different types, for example: Extra, A, B, C, or: Elite, Prima, AB, BC, C.

Source stroy-podskazka.ru

Raw materials for production

The primary raw material for the production of lumber is the trunks of almost any tree, previously cleared of branches and bark.

Coniferous wood is usually used for the construction of load-bearing structures. Hardwood is most often used for all kinds of finishing work. It is worth noting that the waste obtained during the production of lumber is used both in industry and in everyday life.

The most affordable wood for lumber production is poplar and birch. Quite often, pine, spruce, linden, larch, ash and maple wood is used for these purposes. Hornbeam, oak, and cedar wood are important for industry.

The lightness of birch does not make the wood less durable, but its beautiful structure and affordable price have made it even more popular. Larch is considered very moisture resistant, resistant to fungus and mold. Ash wood boasts good elasticity and impact resistance.

Beech is indispensable for making floors, stairs and furniture.

Incredibly durable and incredibly beautiful oak wood, despite its fairly high price, is very much in demand. Pine contains a large amount of resin, so it is most prone to rapid combustion. Although spruce wood is less durable, it is quite flexible and soft, so it can be easily processed.

Types of lumber

The characteristics of finished lumber depend on the type of wood, the equipment used, adherence to production and drying technology, as well as the cutting method. It is the last factor that affects the texture of the board.

Wood sawing is carried out in several ways, differing in the direction of sawing:

- transverse (across the grain); rustic (at an acute angle to the grain); radial (along the radius to the center of the log); tangential (tangent).

Cross-cutting is used to produce artistic parquet, while the rustic method is used to produce flooring. Lumber obtained by radial sawing has a very attractive appearance, is durable, resistant to deformation and external influences. Tangential cutting creates a beautiful pattern on the surface of the board in the form of interesting arches and rings.

However, some boards may develop flaking on the surface over time. The most popular and expensive are radial lumber, since their surface has a uniform texture, constant dimensions, good mechanical characteristics, and a degree of shrinkage.

Drying of lumber is carried out both in the open air and using special chambers, which are tightly closed rooms. The first type of product contains up to 20% moisture, the second can be additionally treated with protective agents, and the moisture content is up to 14%. Lumber cuts can be trimmed (cut along the entire length) or uncut.

Depending on the degree of processing, lumber is:

- unedged (although there are no knots, there are untreated sections of logs); edged (the profile of the materials has a rectangular shape due to sawing off the defective side parts of the log); planed (there is no roughness on one or more edges).

What are lumber

Lumber is produced by cutting logs longitudinally into long components that have at least one flat side (face). Most lumber has two flat edges parallel to each other.

Two methods of sawing logs are used - radial and tangential. With a radial approach, the cutting directions are oriented towards the center of the growth rings. The resulting boards or beams have different sizes, and their width is limited by the diameter of the tree being opened.

Tangential sawing is designed to produce long boards and is directed tangentially to the growth rings. In this way, a large number of fragments are obtained that have the same dimensions and cross-sectional shape.

Further processing and appearance depend on the planned use of the lumber. The more work is carried out to refine the surface and protect it from external influences, the higher the cost of the final product will be.

It is very important to choose high-quality lumber; which ones you should not buy can be seen in the video:

Classification

The shape, size and mechanical characteristics determine the division of lumber into several types.

A timber is a log, hewn on all sides, used in the construction of houses, as well as for the manufacture of individual large elements of windows, stairs and others. The thickness of the timber is 100 mm.

Bars are “timber in miniature”, less than 100 mm thick, and can be untreated, planed (at least one side is processed) and calibrated (adjusted to a certain size). Scope of application: furniture production, lathing, flooring, frames, gazebos and other objects.

Boards are made from logs or beams. They come in unedged, edged (having a smooth edge) and edged only on one side. In addition, the boards can be calibrated, that is, they have specified dimensions.

Sleepers are a material with increased strength and minimal sensitivity to temperature fluctuations.

Slabs are boards obtained by sawing logs, having a smooth and semicircular surface.

Obapol is lumber produced from the side of a log, having only one flat side.

Sawing tools

For sawing, tools and equipment with various technical capabilities are used.

When carrying out current household work, ordinary hacksaws are used, as well as mechanized units powered by fuel or electricity.

For amateur work, craftsmen often buy cheap, not the most expensive raw materials, so it makes no sense to spend money on special equipment.

The type of boards obtained after sawing logs with a chainsaw is quite acceptable for the construction of fences, sheds, utility rooms on a country plot, as well as some production tasks.

The production of parquet and high-quality lumber for construction purposes is based on the use of woodworking machines, which make it possible to produce both edged and unedged products, and to carry out sawing along the main and angular axes.

Special equipment ensures the production of a minimum amount of waste and delivers a defect-free product. Hand tools and any sawmills produce, in parallel with the required lumber, a large amount of sawdust, which significantly reduces the profitability of the process.

Advantages and disadvantages

Man has always been surrounded by objects and wood products. This material was used for the construction of houses and churches, baths and all kinds of outbuildings.

The man was surrounded by wooden windows, doors, tables, chairs and other furniture. Wood has not lost its popularity even today. On the contrary, thanks to the positive qualities of wood, construction and finishing materials made from wood are becoming even more in demand.

Advantages of lumber:

- have a high load-bearing capacity with a relatively low weight; despite sufficient strength, the material is characterized by simplicity and ease of processing (it is flexible to drilling, easy to saw, allows you to produce figures of various shapes and complexity); ease and speed of installation; due to its natural origin and environmental friendliness, the material is considered completely safe for human health and the environment, does not cause allergies; processing does not require expensive and time-consuming work; visual appeal; the pleasant smell of wood creates a favorable microclimate in the room; variety of shapes and sizes of products; affordable price.

Minuses:

- ability to quickly ignite, maintain combustion; are destroyed under the influence of fungus, mold, various insects; prolonged exposure to water and a humid environment often causes the process of wood rotting.

To protect lumber, make it more wear-resistant and durable, they are treated with special protective substances that can significantly reduce the above-mentioned disadvantages.

Types of lumber

Division into grades is carried out by assessing the condition of the worst side of the face, edge, and section.

Selected lumber should not have rot, mold, cancerous and fungal stains, growths and other foreign inclusions on the surface, as well as cracks from shrinkage. The permissibility of fused healthy knots is two per one meter in length, shallow edge and face cracks are 16%, deep ones are no more than 10%. The scope of application of the products is mainly shipbuilding and automotive construction.

The area of application of first grade lumber is the wood manufacturing industry. This type of material should not have dry wobbly knots, healthy knots larger than 1 cm, through and cracks larger than 1 cm, wounds on the wood overgrown with bark, young active layers of wood, mold, mechanical damage, various foreign inclusions, and rottenness.

Second-grade products are most often used in the manufacture of furniture. Such lumber is characterized by the absence of through and cracks, the total length of which is more than a third of the length of the product, three wormholes per meter of material length, rottenness, traces with parasites, mechanical damage and various inclusions. Third-grade lumber may have certain defects; they are used in the production of containers .

The scope of application of materials of the fourth grade is the construction of cabins, utility buildings, gazebos, the production of boxes, loess, pallets and construction formwork.

Board

Types of cutting lumber allow you to create many shapes of products. A very popular variety is the board. The range of its application is wide.

Depending on the type of wood and the precision of its processing, these products are used both for rough work and for finishing premises. Boards are in demand in the manufacture of furniture, partitions, small buildings in the country, etc. They are divided into 5 grades:

- Selected - used in luxury interiors, as well as in shipbuilding.

- The first and second grades are suitable for creating furniture facades.

- The third class is applicable in construction.

- The fourth grade is suitable for creating packaging and boxes.

Dimensions, level of processing, material characteristics must be taken into account in the selection process.

Wood derivatives

A wonderful material for building a house is rounded logs. Thanks to a well-thought-out system of locks and a completely even, rounded shape of the material, fairly strong and reliable structures are obtained. This material is considered the most expensive today, and buildings made of rounded logs do not require additional finishing.

An equally popular material is profiled timber. There are two ways to produce it: milling and planing.

During the construction of houses, the elements are connected very firmly, ensuring a high degree of reliability of the building. In addition, such buildings do not require powerful foundations. Structures made from this lumber do not require additional finishing work.

Glued laminated timber is made from whole boards or individual pieces. The material consists of lamellas firmly fastened together. It is distinguished by strength, durability and resistance to external influences.

Plywood is a material consisting of several thin layers of wood tightly glued together. Due to its strength and good flexibility, this material is in demand in the production of furniture, decorative elements and many other products.

Fibreboard is produced by pressing waste wood at very high temperatures with the addition of a special binder. Fairly hard wood fiber boards are called hardboard. The sides of such sheets can be either smooth, or one of them is corrugated, the other smooth.

Chipboard is a combination of small wood particles and synthetic resins. MDF is produced from waste from the woodworking industry, free of all impurities.

In the manufacture of this type of slabs, no adhesives are used. In this case, the binding element is lignin, which is released from wood under the influence of high temperatures. The area of application of such lumber is construction and furniture industry.

Block house is a material obtained from rounded logs by sawing according to the “square in a circle” principle. Thanks to good noise and heat insulation, strength and attractiveness, this lumber is highly valued in the exterior decoration of houses.

Lining is lumber used for all kinds of finishing work. Although the material is small in thickness, it is very durable, resistant to deformation, cracks and crevices. The external attractiveness of the lining, simplicity and ease of installation made it even more popular.

Lumber is a unique wood processing product that is indispensable in construction, furniture and other types of industry.

Lumber is produced by sawing wood into individual parts - plates, quarters, beams and beams, boards, slabs. There is a wide variety of types of lumber.

Classification of lumber by appearance and processing method.

The thickness of boards made in production conditions can be no more than 100 mm; the width has a value greater than the thickness value multiplied by two. The beams have a thickness of no more than 100 mm; the width should be less than twice the thickness.

Processing quality and profile

The floorboard manufacturing technology includes drying and surface treatment. Based on drying, the following types of lumber are distinguished:

- Natural humidity. Suitable for making subfloors or for flooring, for example, in a country house (in an unheated house).

- Dry. The finishing coating does not require additional processing after installation and does not deform over time; used in heated housing.

- After processing, lumber suitable for laying floors is divided according to two principles:

- Unplaned and planed. The latter, as an economical option, is suitable for interior decoration.

- Unsanded and sanded. Sanded boards on the floor of a house (more often called solid boards) can be laid without additional finishing.

If a board made of solid wood is equipped with a protrusion (tenon) and groove on the side surfaces, then it is called tongue-and-groove. In this case, the profile is what we see if we look at the lumber from the end. It’s good if the profile, in addition to the tongue-and-groove system, has a cut for air ventilation (there can be two cuts).

Source elitwood74.ru

About the intricacies of choosing a floorboard in the following video:

How lumber is divided depending on processing

According to the method chosen for processing raw materials, lumber is divided into unedged and edged.

The latter are characterized by processing on four sides; on the faces and edges, wane values should only be allowed as determined in accordance with the type of product. Wane is the part of the log surface that remains on the part after mechanical trimming. The result is a piece of board, untreated at the edges, which can be used in architectural structures or for carpentry finishing of buildings.

Uncut lumber has edges that are partially sawn or not sawn at all.

Single-sided products have one edge and sawn edges, while the sawn lump is not allowed to have wane that is larger than the parameters allowed for a particular product. This type is used somewhat less frequently in construction. It can be used for cladding various parts of the structure, making flooring, and other options are possible.

Types of lumber and cutting logs.

Depending on the processing method, materials can be called unmilled or milled, that is, planed. The latter are a material in which at least one of the cavities is planed.

In order to produce planed timber, timber is taken only with a certain diameter so that the blanks for the timber are formed to the required size. The workpieces must be dried - this is done using steam chambers or under natural conditions. Products are obtained by processing raw materials on machines.

Classification of lumber by size, shape

When processing wood using modern technologies, different types of products are made.

The assortment includes bars and sleepers, boards and slats, quarters, slabs, plates and other products. Types of lumber may vary depending on the methods of working with raw materials. You can familiarize yourself with them in more detail.

Depending on the number of sides processed, the beam will be called two-edged, three-edged, or four-edged. The thickness and width of products is, as a rule, more than 100 mm. The main area of their use is the construction of load-bearing structures, cottages or summer houses, since these products can easily withstand significant loads.

The bar is similar to the timber, but has different dimensions. It is made with a thickness of up to 100 mm, the width is less than double the thickness. It is used in the furniture and carpentry industry, for finishing buildings, for example, door frames and crossbars are made from them.

Table of shrinkage coefficients and mechanical strength of lumber.

The boards are made from logs or beams of sufficient thickness.

Boards can be uncut or trimmed. The thickness can be no more than 100 mm, the width more than double the thickness. Application: wall decoration, flooring, furniture production.

The sleeper is a product with a short length, but wide and thick. This is in some way a type of timber, the cross-sectional size of which differs in size. The most common application is for making railway tracks.

A croaker is a piece of log, a side cut. In the process of sawing logs into various boards, waste is produced, which is called slab. It is convenient to make temporary buildings like sheds from it; they are also suitable for constructing roof sheathing.

Quarters (obapol) are also obtained from the side parts of logs. One of the surfaces of the product is propylene, the other is not. Convenient to use for making small carpentry products.

The plate is half of a log, which is obtained by cutting it down the center.

The plates have only one straight side. The length depends on the log used as raw material. They are used mainly for the production of the above products - sleepers, beams, and sometimes for the production of solid boards.

Lumber used for construction

Lumber used for construction

Today, different building materials are used in construction, but wood is still among the leaders. It is used in different forms - as logs, as plywood, and as chipboard; even concrete blocks in many cases are produced with the addition of sawdust (arbolite, or wood concrete). But most often wood is used as lumber. Lumber is timber in the form of a log, which is sawn into boards, beams, beams, obapol, lining and slabs.

Any lumber is a lightweight, environmentally friendly, heat-insulating material. It is easy to work with, and if it is impregnated with a special composition, it will serve for a long time and is not afraid of fire. In addition, building a house or any other structure made of wood will cost several times less.

All lumber is classified according to strictly defined types of products. The most common are boards, but timber and veneer are gaining popularity very quickly. Let's look at the main types of lumber in more detail.

Boards

Boards are lumber, width from 70 to 200 mm and thickness from 15 to 100 mm. The length of the boards can be very different, but no more than 6 meters. Boards can be divided into subtypes: flooring, planed, oak, edged, beech, lining.

Planed boards are used in the production of window frames and furniture (the surface is smooth on both sides).

Floor boards are made with grooves so that they fit better together. For this purpose, more wear-resistant wood species are selected.

Lining - similar to floor boards, has grooves along the entire length for better connection, used for external cladding of facades.

Edged boards are made from coniferous trees, mainly pine and spruce, but larch is often used for their production. Edged boards are mainly used for interior decoration; cabinet furniture is also made from it.

Beech board is made from beech and is used to make tables and chairs. Beech has a fine texture and furniture makers use the wood of this tree to make a variety of shaped designs and artistic finishing elements.

Oak boards are perhaps the most durable and visually more attractive. Builders use oak boards to cover roofs, and furniture makers use them to make furniture.

Edged and unedged boards.

Edged boards are used in the manufacture of formwork for the foundation, installation of rough and finished floors, installation of walls and partitions in the house, and so on. Edged boards differ according to different criteria. The cut is one of the first criteria. There are several cuts: radial, semi-radial and tangential. According to the method of application, edged boards can be planed or floored.

An unedged board is a board with not completely sawn edges. A single-sided board has one edge. Unedged boards are used for sheathing structures in the manufacture of flooring.

Their grade depends on what type of wood the lumber is made of (coniferous or deciduous). Coniferous lumber is used everywhere in construction, since coniferous wood almost does not absorb moisture and such materials are quite easy to process. Load-bearing structures are often made from softwood lumber. But conifers have one drawback - they burn faster due to the resin with which the wood is impregnated.

Boards for furniture

Garden furniture is made from pine, spruce boards and timber. If they are impregnated with a special composition, then such furniture will last quite a long time. In addition, coniferous furniture is usually light in color and not heavy. The same applies to log houses for houses made from this wood.

If you decide to make furniture from oak, you will have to try hard. Oak is difficult to process. But a cabinet or table made from it is forever. If you cut down an oak tree, you should know that it has a fairly high humidity, but after a year or more, its humidity drops and is no more than 30% - this is a normal percentage for wood. Therefore, you need to dry oak lumber for furniture thoroughly (natural drying lasts about two years).

Boards for cladding house facades

Hardwood tolerates weather changes and temperature changes well. They are not affected by sunlight. If wood is impregnated with special compounds, it practically does not burn. Facade boards are most often made from a species such as larch.

The facade board is made so that it has an edge on one side and a groove on the other. There is a facade board that has beveled edges and is upholstered using the “rustic” method.

Terrace boards are also made from larch. Such boards are used quite often in the construction of houses. It is used to line the floors in swimming pools, on the veranda and in the gazebo. The decking board has excellent performance properties, is easy to maintain and looks excellent in appearance.

Since floors made from decking boards will be subject to loads, larch is considered the most optimal option.

This type of wood has excellent technical characteristics, and if it is impregnated with special compounds, it can be used for a long time. Larch will not lose its natural pattern and practically does not react to sunlight. Today, decking boards are manufactured according to standards that differ little from European ones.

timber

If we talk about timber, these are logs sawn from different sides and used in the construction of buildings - walls, load-bearing structures, and rafter structures are made from timber. Also, boards are later made from timber. According to technology, timber can be profiled or glued. Profiled beams are used to fasten the beams together in a tongue-and-groove manner. Glued laminated timber is glued boards in which the fibers are located in the opposite direction to each other.

Gorbyl

When sawing into different types of boards, pieces with uncut edges remain, which make no sense to process. This is a croaker (business and wood). Wood pieces are used as fuel and for making wood chips. But business slab is used in the manufacture of subfloors, but most often it is used to assemble formwork and fastening elements of scaffolding.

Obapol is the side parts of logs. It is used in the manufacture of formwork for foundations. When you need to quickly make scaffolding, tighten the roof, or make fastenings for relatively massive elements, you will also need a double floor.

Bar

To produce bars, boards undergo special processing. There are two types of lumber: calibrated and planed. During construction and finishing, calibrated timber is used, and furniture is made using planed lumber. A wide variety of containers are also made from the block.