It is very difficult to manage on a private plot or cottage without a hand hacksaw for wood. This tool is also called a hacksaw. With such a simple device you can cut down trees or branches in the garden, shorten fences and perform many other types of work where you need to change the length of some wooden product: boards, laminate, and so on.

It’s unlikely that anyone has seriously thought about this, but if you make the right choice of saw, its service life, as well as ease of use and cut quality will depend on this. That is why it is necessary to know all the basic parameters for the correct selection of such carpentry tools.

Choosing a saw

There is a wide variety of wood saws available in markets and stores. They all differ in several parameters:

- shape and size of teeth;

- canvas size;

- grade of steel from which the blade is made;

- shape of the handle.

If one of the specified parameters changes, then the hacksaw will radically change its original characteristics. All these factors must be taken into account when purchasing tools for different tasks. You should also always make sure that the saw fits very well in the hand of the master , because this will make the work much easier. A person who has large hands should not buy a tool with a small handle. Such a hacksaw will be very inconvenient to use, and therefore the quality of the cut will suffer.

Teeth size

This parameter will greatly affect the speed of work, as well as quality. To make it convenient to determine the size and number of teeth, the designation TPI was specially introduced, which should indicate the number of teeth in one inch. This parameter can always be found in the tool description, and this value is often drawn directly on the canvas.

- A wood saw with a large tooth will provide a rough cut, as well as high speed. This parameter will be needed for sawing large boards, firewood and branches. The TPI of such a tool is 3...6.

- If there is a need to make a neat and even cut , then you need to buy a saw with fine teeth - T PI 7...9. This hacksaw is ideal for cutting chipboard, fiberboard, and laminate. But it is worth noting that the productivity will be much less than that of a coarse-toothed hacksaw.

The carpenter's saw is selected according to the size of the teeth. To process ordinary wood, you can buy a large or small saw, but for delicate materials such as fiberboard, it is better to purchase a fine-toothed saw. There are several designations in stores: for drywall, for wood, and so on. The difference lies in the same size of teeth. The optimal size will be selected for each material.

The teeth can also vary in shape, and this will affect the purpose of the tool:

- For longitudinal sawing, the teeth are made of a triangular shape with oblique angles. Their appearance will resemble hooks that are sharpened on both sides. A saw like this will slide along the grain of the wood and make the cut very smoothly, without leaving any nicks.

- For cross cutting, teeth are made in the shape of an isosceles triangle. This type of hacksaw cuts when going back and forth, but it is advisable to use it only on dry wood.

- Sometimes it is necessary to use a mixed type of sawing , and for this option two types of teeth, which are alternately located one after another, are ideal. Long curved ones will cut materials in the forward direction, and triangles, when moving in the opposite direction, will expand the channel and catch sawdust and shavings behind them.

Steel

No one wants the saw to fail after just a few uses, so it is advisable to choose the highest grades of steel. The teeth can be regular or hardened. Ordinary ones are sharpened at home.

Saws with hardened teeth are disposable, because once they wear out, you can’t do anything with them yourself. This species is very easy to spot due to its dark color. It is advisable to choose a saw that is made of stainless steel, since garages can often be very damp, and therefore the saw will become covered with unnecessary corrosion. And there are often situations when work is carried out on the street, but after use the saw is forgotten on the site, then it rains, after which the tool also becomes covered with rust.

Blade length

This parameter will be determined by the pitch of the teeth and the size of the saw.

- Small hacksaws are equipped with small and frequent teeth; the length of the blade will not exceed 350 mm.

- Universal hacksaws are available with a medium tooth size, and the length of the entire tool is no more than 550 mm.

- A wide hacksaw has large teeth and an increased pitch; the blade length is usually no more than 600 mm.

The canvas can vary not only in length, but also in shape. A traditional saw is usually tapered on one side of the rectangle. This means that you have purchased a universal tool that can be used to saw various objects. The rounded blade is usually used for cutting branches or other objects at a distance. This hacksaw is very light and glides efficiently through wood without causing much trouble to the owner.

Lever

Thanks to the handle, it is convenient to carry out any work. The tool should fit perfectly in your hand and also be very comfortable. To make a handle, different plastics are used that will be pleasant to the touch. When choosing, you need to make sure that the material will not slip if your hand gets sweaty while working.

It is for this purpose that special grooves and recesses are made in the handle, as well as rubberized linings. It is these parameters that all manufacturers take into account, and therefore produce products that differ in a wide variety of handles.

Two-handed cross saw - a harsh tool

The crosscut saw is the largest of the hand saws, its length can reach almost two meters! There are four standard sizes in total, starting with 1 meter and ending with a canvas of 1750 mm, that is, each size is increased by 250 mm. The characteristic shape of the blades is rounded, and the tooth height usually does not exceed 20 mm. Even the smallest size of such a saw is a rather heavy tool that you cannot use alone for a long time...

The first two sizes were once produced for the needs of the population - their tooth shape is classic, triangular, with a sharpening angle of about 70°. However, everyone adapts the sharpening angle for themselves, because for soft wood in the summer it is better to reduce it to 35°, but for sawing in winter or for dry wood it is better to stick to 50° when sharpening. The longest saws (1500 mm and 1750 mm) were produced for sawing lumber. The teeth in such tools have a complex shape - between two M-shaped (Kremlin) cleaning teeth there are several simple ones, characteristic of cross-cut saws. They are sharpened and bred accordingly. Such teeth cut the fibers in the cut, and M-shaped cleaning teeth remove pieces of wood from the cut.

Varieties

In modern stores and markets there is a huge variety of saws for any purpose. Therefore, in order to understand which tool is useful for you, you first need to familiarize yourself with all their types.

- Classic . This is the main type of hacksaw that almost every man has in his garage. Even those who have the most distant connection with construction still acquire such a device. This type of saw can have any length, as well as a different number of teeth. The tool is often equipped with a replaceable blade, which is included in the kit.

- Narrow . This type of hacksaw is also called a circular saw. The name appeared because of its use - with a saw you can create lines of various shapes, and everything is done very clearly and accurately. This device can also be used for cutting out various holes. The blade is very narrow, and the teeth are frequent; they are located both on one working plane and on both. It is necessary to remember that when working you need to act very carefully, because if uncertain movements are made, the blade can easily turn in the other direction. That is why it is advisable to buy a blade made of high-quality and good steel that will not bend during operation.

- With a butt . This type of wood hacksaw is equipped with a stiffening rib, which will prevent the blade from bending while cutting the material. This is why the tool cannot make a low cut, since the backing will interfere with this process. It is worth noting that this type of saw has a very comfortable handle at an angle of 45 degrees. That is why the canvas is very easy to work with.

- Luchkovaya . This type of saw is very often used in plumbing work. Using a hacksaw, you can cut down rough parts of a trunk, cut out various shapes from plywood, and also remove knots from a tree. Wood cutting can be done both crosswise and lengthwise. The use of a bow saw is very wide, and therefore it can often replace a small woodworking machine. But such a tool has its drawbacks. The saw is quite bulky. It has a complex design, and all the load-bearing parts are made in the form of a curved arc, to which a very narrow canvas will be attached. You also need to work with the tool very carefully, since the blade is fragile and can very easily break during operation.

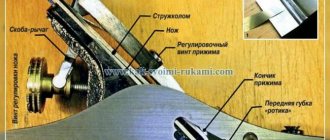

- Award . It takes a lot of effort to get comfortable with this type of device. This tool resembles a plane. There are several handles. With the help of such a saw, you can cut grooves and tenons, make recesses of different sizes, and on any type of wood.

- Folding saw . This type of tool is very convenient because you can take it with you on vacation or on a hike. It is very light, compact and when folded will not harm a person. It is worth noting the very small teeth, which are well sharpened.

Tips to make your saw obedient

The saw must be moved in the cut along the entire length of its blade, which guarantees effective removal of the resulting sawdust.

The cause of the saw getting stuck in the cut may be insufficient tooth set or structural features of the material being processed. In the latter case, the hacksaw blade can be lubricated with soap or wax, and a wedge can be inserted into the cut.

When sawing layered materials or wood with a coarse-tooth blade, the saw should be slightly tilted towards the surface (15÷25 degrees). In this case, the material will be in contact with only three to five teeth, and this will eliminate the likelihood of individual fragments breaking off.

To avoid splitting when finishing the cut, place a block of wood directly under it.

So, we have introduced you to some important points that will allow you to choose the right type of hand saw, properly prepare it for work and work with it so that the work you do is enjoyable.

Selection by purpose

As we have already found out, there is a wide variety of saws, but the choice of a hacksaw should also be carried out in accordance with certain types of work:

- For rip cutting you must use a swing saw.

- The transverse one will cope well with wood where there is a transverse arrangement of fibers.

- The tenon tool can be used to cut various grooves and tenons, as well as technological recesses in the wood.

- The round cutter cuts out holes of various shapes.

- A folding hacksaw is used on trees.

The choice should always be made according to the main purpose for which a certain tool is purchased. A saw with replaceable blades is suitable for household use, and it is also advisable to have several types of cutting tools at home.

Hand saws - the main types and how to saw with them correctly | With your own hands

Although power saws now predominate in the vast majority of carpentry shops, sooner or later you will inevitably encounter situations where you can make cuts easier or more efficiently by hand. Here's how to get the most out of hand saws in critical situations.

When is a hand saw needed?

Some operations, such as trimming protruding dowels and plugs flush with the surface, forming oblique tenons or sawing off short finishing profiles, are best done manually. It is often faster and safer to do cross cutting into workpieces with a regular hacksaw than trying to balance a long board at a saw. And many woodworkers simply enjoy cutting tenons and other joints by hand.

While a hacksaw is often the best tool, the cuts usually don't come out as clean as a miter saw or circular saw with a high-quality blade. Therefore, when the quality of the cut is important, you need to saw by hand slightly to the side of the intended line, and then remove the allowance by planing or grinding, or saw to the final size on a machine with a saw blade.

The difference between the European and Japanese hacksaw is in the direction. In Japanese saws, the tips of the teeth are inclined towards the handle, so the working stroke is carried out when you pull the saw towards you, rather than pushing it away from you.

Tips for choosing

It is very difficult to master all the information and choose exactly the saw that is suitable for a particular situation. That is why it is advisable to learn a few more tips that will help you choose the right hacksaw.

- First, we decide on the material that will need to be cut. Carpenters who work on small projects usually choose a small saw with a short blade. Carpenters usually use large teeth and blades because high precision work is not required, but speed is important. A folding hacksaw is ideal for summer residents who will process shrubs and trees.

- Frequency of application . You need to decide how often the tool will be used. If it is rare, then it is better to purchase a saw with hardened teeth, and if the work will be done very often, a saw made of ordinary steel is ideal.

- , the quality of the steel should be the best. The higher the class of metal, the better the quality of the product. Before purchasing, you need to take the tool in your hands and carefully bend it. A good metal will be elastic and will regain its shape when released. If you notice any deviation in shape, then you should not buy such a tool. If the seller does not allow you to bend metal, then do not buy a saw from this store. Most likely, the seller knows that the material is not of the best quality, and therefore will not allow the buyer to verify this.

- When buying a saw you need to look at the price . Not all instruments have a price that matches their quality, because very often the price increases due to the well-known name of the manufacturer. But here the situation is different - the higher the price, the better the drink. Of course, this is if the owner is honest and does not offer a fake. A good product will not be cheap. It is best to choose the middle range. And if finances allow, then buy an expensive saw. It is also advisable to select a saw based on product ratings and give preference to those options that people recommend on the Internet.

- Always take a hacksaw in your hand before purchasing. It should be very comfortable for you.

Which hacksaw is better for wood? You shouldn’t ask such a question, because each tool is useful for a specific situation. Therefore, you need to know how to choose a hacksaw for wood depending on the purpose. By following these simple rules, you can easily choose the right tool that suits you.

“Friendship-2” – where does the name come from?

“Friendship” - under this name in the USSR both processed cheese and chainsaws were produced. But it suits a two-handed cross saw perfectly! Why "Friendship-2"? Yes, because it takes two to cut, and their actions must be well coordinated, in a word, like friends. So the people who gave such an unofficial name to the instrument hit, as they say, not in the eyebrow, but in the eye.

If you inherited such a tool and are collecting dust in your workshop or garage, don’t even think about parting with it! Think for yourself - the saw is hand-held, which means it does not need electricity or other fuel. Without gasoline, a chainsaw is just a pile of metal, but Druzhba-2 will always help you out. So wipe the canvas with machine oil and place it in the far corner, fortunately, it does not take up much space.

Wood saw and miter box combination

Every carpenter knows how important it is to properly secure the work base during the cutting process. In the case of hand tools, the importance of fastening becomes decisive, regardless of the characteristics and type of hacksaw. For cushioned models, a miter box device is optimally suited. This is an auxiliary device designed to create precise cuts, including corner cuts. The design of the device resembles a box with slots and a ditch. During the work process, the canvas will pass through the oblong holes, and the central part will serve to place the workpiece. You should select a backing saw for a miter box according to its cutting capabilities at different angles - 45, 60 and 90 degrees. But this value is not important, since most structures have a universal purpose. The material of manufacture and the parameters of the miter box are more significant in terms of compatibility with the material being processed.