A stationary circular saw is a machine that should be in the workshop of every craftsman who works with wood. With its help, you can quickly and effortlessly saw a board, cut a workpiece of the required size, or cut firewood.

A home craftsman simply must acquire such a machine. It is not necessary to buy it; a homemade circular saw is guaranteed to cope with the volume of work in a home workshop, and will cost a significantly less amount.

Circular saw device

Being a truly useful tool, the circular saw has a fairly simple design. Its main components:

- bed – frame on which the main units are mounted;

- tabletop with a slot for a disk;

- engine with rotation transmission system;

- cutting tool, disc with teeth.

Optionally, the device can be supplemented with a pusher, which ensures progressive movement of the workpiece towards the disk, and various lifting mechanisms that regulate the cutting depth.

The principle of operation of a circular saw (circular saw) is that the rotation of the electric motor shaft is transmitted to the cutting tool, a disk with sharply sharpened teeth. The center of the disk is located below the level of the tabletop, only a segment of it is removed from it. The workpiece is brought to the rotating disk, the teeth bite into the wood, creating an even cut.

Design of a homemade circular saw from an angle grinder

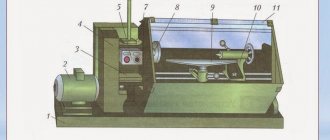

A homemade circular machine consists of the following elements:

- Bed. This element is a rectangular frame on which the main parts of the circular are attached. The frame is made of metal and has high strength. The parts of the circular machine are attached to the frame using bolts or by welding.

- Wood disc. He cuts lumber. This element is installed on the drive shaft. The diameter of the disc is 14-30 cm.

- Engine. It is used to transmit rotation to the sawing mechanisms of a circular saw. When creating a manual circular saw, it is recommended to use grinder motors with a power of at least 1600 W.

- Rotation transmission mechanism. It consists of 2 pulleys located on the motor and drive shaft. Pulleys allow you to adjust the speed of the saw, depending on the type of wood.

- Emphasis. It is designed for longitudinal sawing of workpieces and processing parts at an angle. The stop is attached to the working part of the machine.

A homemade circular saw has the following advantages:

- Low cost of the device in comparison with stationary models.

- Ease of manufacture.

- High disk rotation speed (9000 rpm), which increases the speed of sawing parts.

- The grinder can be dismantled and used for another purpose.

Homemade circular machines are most often used in repair and construction work. They can be used in the manufacture of furniture and other wood structures.

Making a table top for a circular saw

Assembling the table begins with making the tabletop. The plywood sheet is marked so that the two edges of the lid are the same size as the edges of the iron sheet. Plywood is cut out using a hacksaw or jigsaw.

The edge of the cut can be processed with a milling cutter, but this operation is not necessary. Since the main parameter in the frame is reliability, and not an attractive appearance. The tabletop is rubbed “roughly” with sandpaper.

At the bottom of the tabletop there is a slot for a circular circle. To do this, you first need to measure the dimensions of the sole of the unit. The easiest way to do this is to unscrew the disk from the device and simply circle the desired part of the saw. These measurements are required to determine the seat.

Using a hand cutter, the bars are selected to a depth of approximately 0.9−1.1 cm. If you do not have a cutter, then this work can be done using a chisel, but it will take much more time.

Then, when the seat is made, try the saw on and, if necessary, adjust the recess. Mark the slot locations for the circle and fixing the fasteners. If you need the circle to rise and fall, then you need to install a pendulum mechanism for the tabletop.

In this case, the slot must be made in the shape of a truncated pyramid. In this case, the hypothetical top of the pyramid will be directed downward. The frame itself for the lifting mechanism is best made from steel corners that are welded to each other.

Making a table frame

The markings for fixing the transverse and longitudinal slats, which serve as stiffening ribs, are best installed on the underside of the tabletop. The planks themselves are made from timber. You will need:

- Two transverse parts, length equal to the width of the table top minus 7-9 cm on each side.

- Two longitudinal ribs, the size equal to the length of the lid minus 7-9 cm on each side.

Then you need to make nests for the screws. The slats must be fixed on the lid so that the tabletop extends 7-9 cm beyond the edges of the frame. The fasteners must be as reliable and durable as possible.

The first fastener should be installed approximately 40-50 mm from the edge of the rail. The distance between the screws is approximately 23-25 cm. All parts must be drilled through. The self-tapping screw is attached to the side of the lid so that its head is completely recessed into the wood.

First, the transverse ribs are secured. To make the table top as strong as possible, the edges of the slats must first be coated with wood glue. The structure is fixed with clamps, and without removing them, screws are screwed in.

Allow the tabletop to dry completely. Afterwards, the longitudinal slats are installed in the same way. Then the parts of the frame are pulled together, installing two fasteners on each side. Now the clamps can be removed.

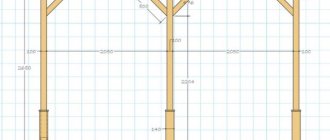

Attaching the legs (supports)

The table legs are made of timber. The height of the supports is selected individually. In practice, it is most convenient to work at the machine when the tabletop is located at hip level. Before fastening, each support must be planed so that the leg goes down to an angle from below. So, the area of the base of the support should be slightly larger, in contrast to the area of the top.

It is best to secure the legs using steel corners. They need to be pressed a little so that the base of the machine is in the “spacer”. This gives the table additional stability. Bolts with washers are used as fasteners; they are secured with their heads facing outward. Otherwise, during work you can be injured by the protruding parts of the fasteners.

The whole structure will be more stable if additional supports are tightened with diagonal slats. They are attached in pairs on each side of the machine.

The surface of the lid is polished and varnished or a steel sheet is used for coating, which is attached to self-tapping screws. At the very end, the instrument is attached directly to the prepared place.

You can additionally make markings on the table top; it will help you cut the wood smoothly and correctly. The control panel of the circular saw is located on the outside of the machine. As a rule, it is mounted on one of the table legs. That's all, your DIY circular saw is ready.

Step-by-step instructions for making the machine

The technology we offer does not involve the use of complex woodworking machines and equipment; this makes the process much easier for beginners. Before starting, it is recommended to make a simple device in the form of a large wooden square. It is made from a 10×30 mm block and a 10×50 mm strip of plywood. It will greatly simplify the process of marking and checking the correct dimensions of individual machine parts.

The table is made from old laminated chipboard, but special moisture-resistant plywood for concrete work is excellent. If you have the opportunity, buy this material, you won’t regret it. It is better to choose foreign manufacturers, but it will cost more.

Step 1. Cut out the material for the tabletop.

Cutting the material for the tabletop

The specific dimensions do not matter much; proceed from the size of the shield and the free space in the workshop. You need to understand that workpieces are better held on a long table, which makes cutting long boards easier.

To ensure an even and perpendicular cut, use the prepared device, the rail should rest against the edge of the chipboard, and the saw should slide along a strip of plywood secured with a clamp.

Fixed rail

Sawing off chipboard

Our central part of the machine table is 36 cm wide, two side parts are 18 cm wide. Between them, wooden slats made of hardwood will be installed for attaching the cross-cut carriage. This carriage makes trimming and cutting parts much easier.

Measuring the distance for sawing chipboard

Sawing process

Three parts of the tabletop, between which there will be loose slats that move along with the carriage while cutting materials

Step 2. Place the saw on the center of the table and use an awl to trace the outline of the metal pad.

Marking

Step 3. Drill holes in the corners of the table; this can be done with an ordinary drill or on a drilling machine.

Drilling holes

Step 4: Using an electric jigsaw, carefully cut out the opening for the saw.

Cutting an opening for a saw with a jigsaw

Using this as a template, draw the liner and use a jigsaw to cut it out.

Liner markings

Cutting out the liner

There are options not to make an insert; in this case, the maximum cutting depth is reduced. Make a specific decision depending on the planned use of the saw, but practitioners always advise relying on maximum parameters. The fact is that no one can foresee the requirements for a machine in the long term.

Step 5. Attach the saw to the table. Adapt various available materials for this, select them according to length and thickness.

The saw needs to be secured

Photo of a saw on a tabletop

Important. Never screw screws into chipboard without first drilling a hole. The slab is not designed to withstand such loads and may crack.

Secure the saw to the back of the table.

The saw is secured with a block and a metal plate

Bottom view

Step 6: Reinstall the liner. It is made from durable material, preferably steel or aluminum, but plastic will also work. The liner must withstand strong shock loads that occur during sawing; chipboard cannot cope with such tasks.

Liner markings

Hardware used for fastening

The part is fixed to the saw blade, you need to prepare holes and use various hardware.

Fixed liner

Step 7. Make markings for the sides of the tabletop; they will be fixed using self-tapping screws. Attach all parts of the table to the cross rods with glue. On the front side, they are additionally screwed with self-tapping screws with countersunk heads; the holes for them must be countersunk.

Step 8: Check the movement of the wooden slats. If they jam in some places, then you need to find the cause and eliminate it. The slats should slide freely, but without wobbling.

Checking the travel of the racks

Practical advice. It is much easier to install metal profiles instead of slats. This requires less time, and the quality of the machine’s work increases significantly.

Example of a table for a circular saw, metal profiles installed

You can buy profiles at any hardware store; if possible, purchase aluminum elements. They have a low coefficient of friction, which is very important for the smooth movement of the cross-cut carriage.

Step 9. Attach chipboard or plastic boards to the bottom of the table; they prevent the slats from falling out.

Test the operation of the machine. Temporarily place it on a flat surface, plug it in and cut a few boards.

Switch for easy switching on of the saw

Immediately pay attention to uncharacteristic sounds and vibrations. It is necessary to find out the reason for their appearance and eliminate them immediately. At this stage of manufacturing a stationary circular saw, adjustments are much easier to make than on a fully assembled mechanism. Everything is normal - continue assembling the equipment.

Video - Simple sawing machine

Video - Circular saw table

Manufacturing of table side supports and sawing devices

Once you have corrected any problems found during testing, use your saw to make blanks for the sides of the table. The sizes are arbitrary, you can link them to your actual needs and the parameters of available materials.

Step 1. Prepare blanks for the sidewalls.

Practical advice. To speed up the trimming process, attach a temporary device to the saw - attach a small piece of flat board under the square to the rail with self-tapping screws.

After trimming the workpieces, the temporary device is removed and the machine returns to its previous state.

Step 2. Place the table on permanent legs, drill holes and countersink them for countersunk screw heads.

Step 3. Attach boards of the appropriate length to the bottom of the sides. They strengthen the structure and increase the support area. This increases the stability of the structure, which is very important for a compass machine.

Interesting fact. Have you ever wondered why all the old machines have a heavy cast frame? In those days, the domestic industry could not produce precise parts for high-speed mechanisms, because of this, beats inevitably appeared during their operation. The heavy bed dampened vibrations and improved the quality of processing. This is to point out how important the quality of all circular elements is.

Step 4. Test the structure again, this time applying maximum loads.

Device for feeding sawn materials

Side support of the table

Video - Homemade stop for a circular saw

Making the carriage

Carriage diagram

It is made from a chipboard shelf 16 mm thick.

Step 1. Drill holes for the runners along the edges and countersink them. The distance between fasteners is approximately 10 cm.

Step 2. Screw the base of the carriage to the wooden slats installed on the tabletop. Check its progress; if there are problems, the sliding wooden surfaces can be smeared with soap or paraffin. Large jams will have to be sanded with fine sandpaper. Work very carefully, check the progress, do not remove excess material.

Step 3. Screw the two backs, constantly measure the corners, they should all be straight.

Step 4: Cut the hole for the saw. This is done in several stages.

- Place the carriage in the grooves, lift it up, the plane should not touch the saw teeth.

- Turn on the saw and slowly lower the carriage. The hole is sawed until the carriage is lowered to a horizontal position.

- Carefully make a hole along the entire length of the carriage.

- Check the angle, achieve the correct position. If everything is normal, then you need to additionally secure the carriage backs.

Step 5. Install a stop parallel to the saw and make sure it works.

Carriage for table circular saw

Front view. For ease of movement, the carriage is equipped with a handle

The stationary circular saw is ready for use; you can make various wood products with your own hands. This is a very exciting and rewarding process.

How to saw a board evenly lengthwise and crosswise

Video - Carriage for circular saw

A stationary circular saw greatly increases productivity and improves safety. Every novice craftsman should have such a machine; it can be made using a minimal set of tools. We talked about only one option for making a saw, but there are many other equally interesting solutions. How to make different types of tables for a circular saw can be read on the pages of our website.

Main parameters - calculation of power, speed, gear

The characteristics of the circular saw, the engine and the maximum thickness of lumber that can be cut are interconnected. The maximum speed for which it is designed is indicated on the purchased circular disk. The number of revolutions transmitted by the engine to the shaft should be less. The engine power affects the maximum permissible saw tooth diameter. The diameter must be at least three times the thickness of the material, otherwise sawing will be difficult. It is believed that to cut materials 100 mm thick, you need a motor of at least 1 kW of power.

The transmission is made only by a V-belt - if foreign objects get under the saw, the material jams, the belt slips on the pulleys. Injuries in such cases are practically eliminated

It is important to choose the right gear ratio

We take into account two indicators: engine speed and the maximum permissible speed of the circular saw. We calculate the required pulley diameters

A pulley with a large diameter is installed on the engine, and a smaller one on the circular shaft to increase the number of revolutions.

How to choose a saw

Of course, when you have work experience and you do not want to invest large amounts of money in the purchase, you can make such a machine yourself. When purchasing a saw for it, take into account:

- Buy a device with protection that must cover the disk not only in peace, but also during operation.

- Select the weight and dimensions of the device taking into account your own goals. It will be more difficult to interact with volumetric ones; you will get tired after half an hour of activity.

- Consider the convenience of the saw so that you can work comfortably with it.

- Consider the diameter of the disk (no more than the 0.2 m mark). Examine the dimensions of the cut - when cutting volumetric parts, you need to select a larger size.

- Make sure the rotary block and bed are of good quality.

Regardless of whether you decide to buy a factory version or create a saw yourself, it should be easy to work with and the result should be of high quality.

Setting up band saw equipment

For the first time, the launch is performed without guides. At this stage, the smooth start-up and clean operation of the engine are checked, and then a test cut is carried out using a blade, but with minimal loads. To work with increased loads, a block with guide belts is used. This design consists of two halves, which are installed along the line of the cutting blade.

Previously, craftsmen made not only machines, but also cutting blades with their own hands. It is difficult to independently close the belt unit into a ring and requires at least some initial experience in assembling the machine. Sharpening using a template is also carried out manually. You can do all this yourself, saving your money, but the modern market is simply filled with all sorts of devices and parts that improve the quality of material processing or make the equipment multifunctional. The main thing in this matter is to remember about safety precautions, because production models or homemade ones pose a great danger to human health.

Assembly order

A homemade circular saw can be easily assembled with your own hands if you have an unnecessary grinder in your home workshop.

To complete the assembly of the device, you need to prepare the following materials and tools:

- Bulgarian;

- aluminum corner;

- nuts;

- metal rod or pipe;

- metal sheet;

- sliding stop (needs to be assembled);

- axial handle (needs to be made).

First of all, a stop with the necessary holes is constructed. It is constructed using short parts of a metal angle. The corner trims will be located on both sides of the toothed disk.

For them, it is necessary to make recesses on the sides with a depth of 0.2 to 0.5 cm. To ensure that the lower edges of the corners do not come into contact with the element being cut, they should be smoothed.

The parts are secured at the back and front with transverse ligaments using nuts and bolts.

Video:

https://youtube.com/watch?v=K2u3zO1l9EY

The assembly diagram of the stop is not complicated. A metal clamp is placed on the body, the tie of which is made from the bottom of the device.

Then a hole is prepared through which the product is secured with a clamp for rear fastening, which secures the stop for subsequent sliding.

In the gearbox of the device, holes with threads are drilled into which small parts will be attached.

At the beginning of work, the gearbox is disassembled to determine a suitable place where the recesses will be made.

Recesses are required for subsequent fastening of the axial handle. If you use the handle located on the side of an ordinary angle grinder, then making a hole will be quite difficult.

If the handle is made in the form of a horn, then its far end should be flattened and recesses made for the axle. A forward-facing part is inserted into the recesses located in the gearbox. The edges of the part are pressed.

Using washers under the front part of the stop, the gap parameters are equalized along the entire length of the circular saw.

If you use a 0.6 cm rod, you will need thin washers. A thread is applied to the back of the rod.

The part is then placed into the recess on the handle. The device is now ready for use.

When operating a circular saw, you must follow safety rules, especially you should not drink alcoholic beverages, as their consumption leads to impaired coordination.

Required tools and materials

To correctly and reliably connect parts and create a rigid structure capable of withstanding heavy loads, you will need:

- tools:

- grinder with cutting wheels;

- welding machine;

- hammer;

- drill with a set of drills;

- marking tool - tape measure, meter, square, scriber, core;

- consumables – electrodes, metal brushes;

- clamps, vices

- materials:

- metal corners or profile pipe;

- metal sheet for the work plate;

- bolts, washers, nuts, studs;

- metal strip;

- hardwood boards;

Technology for assembling a stationary installation of a circular saw

To create such a tool, it is recommended to carry out work in the following sequence:

- creation of a working sketch, general and detailed drawings;

- marking the main elements;

- cutting blanks;

- assembly of the machine frame;

- marking and cutting out slots and holes in the work plate;

- installation of the engine, shaft, lifting mechanism;

- installation of electrical wiring;

- production of additional equipment.

Desktop device

A table for a hand-held cutting circular saw should be a comfortable, reliable and safe workplace. To do this, he must meet the following requirements:

- Stable and rigid design;

- flat and smooth surface;

- fixing the legs in the ground;

- have a place for wood waste;

- be equipped with protective shields.

If the cutting table for a circular saw meets these simple five requirements, then the design will truly perform all its functions.

The machine must also meet certain requirements (after installing the saw on the table):

- High-quality fastening of the saw blade;

- the presence of protective walls that cover the cutting part;

- convenient location of the on/off button.

The more carpentry experience, the better the structure can be built. By choosing the right table dimensions, you will be able to better perform tasks on it in the future. Whether it will be possible to cut long boards and process workpieces depends only on the drawings and the execution of the work.

Stationary machine with your own hands

To perform everyday or one-time tasks, a hand-made circular saw is quite suitable. Small-volume sawing work does not imply heavy loads on the disk drive. The compact tool has small dimensions, which makes it possible to put it away after finishing work in a certain place. An experienced carpenter will need to make a large stationary type circular saw.

Circulation table

The main condition for making a table is the selected material. It is recommended to use a solid steel sheet, duralumin or silumin alloy. Materials such as moisture-resistant plywood, plexiglass and textolite require processing and installation on top of a galvanized sheet. The use of any material in manufacturing must meet the main conditions:

- increased vibration resistance;

- sagging with a load exceeding 50-60 kg is unacceptable;

- the presence of a perfectly flat surface.

In cases where the conditions are not met, a DIY circular saw may stop due to a jammed disk or a broken drive. The consequences can be different, from a damaged part to injury to a person.

There are several options for making a circular table. Stationary tables can be sawed or made from two parts. The circular saw blade should protrude no more than a third of its diameter.

Saw blade

Saw blade

The design of a DIY circular saw must contain a saw blade. The working surface of the disk is set to one third of the total diameter. For example, with a diameter of 210 mm, the disk should protrude 70 mm from the table. Parts with greater thickness will require a powerful motor, from 1 kW. A miniature circular saw will not cope with such tasks.

The splitting knife installed on some models serves to prevent short circuits and jamming during operation. It is located at the back a few millimeters from the teeth of the saw blade. The device may also be needed when making a circular saw with your own hands.

Adjustable side support

Any type of work will require a stop. The side support is made of a block of dense wood. In other cases, it is possible to make it from a metal corner. The arrangement should be slightly longer than the table structure. The stop is installed using bolts. The template is installed between the table and the cutter for precise installation and better settings.

Shaft

Homemade shaft

The most important part of the design is the shaft mounted on the circular saw. A self-made shaft for a circular saw can damage the structure and cause injury. The reason for this is runout, which cannot be avoided when making a shaft using artisanal methods. The manufacture of the shaft should be entrusted to a specialist with good turning equipment. You should remember that there is a cutter that needs a seat. The holes must be symmetrically machined and machined.

Finished shafts are sold in specialized markets. Preference should be given to parts with a self-aligning bearing. Otherwise, the conventional mechanism may soon render the circular machine unusable.

Broadcast

There are several types of gears that can be used in the design of a DIY circular saw:

- V-belt transmission;

- mechanism consisting of gears.

The preferred option is to use a belt drive. Using a mechanism with gears can lead to jamming if a foreign body enters and injury to the worker. When choosing the pulley diameter, the maximum number of revolutions of the saw blade is taken into account.

Motor

Electric motor for circular saw

In most cases, homemade machines are equipped with an engine from an old washing machine. The main features are increased service life and efficiency. The speed of such engines is not high, which makes working on a circular saw assembled with your own hands safer, longer, and has a positive effect on the result. The use of a special three-phase motor implies the presence of a 380 Volt network. If one is not available, you will have to use a starting and running capacitor, which leads to additional costs.

Miniature machine made from a washing machine engine

The circular is distinguished by its extreme simplicity and availability of materials for its manufacture. Perhaps its only expensive part is the electric motor. Stationary machines are equipped with a powerful asynchronous motor, which ensures cutting of thick wood of any species, but in a home workshop you can limit yourself to less power.

Note! To cut boards of medium thickness, it is enough to make your own circular table driven by a washing machine motor.

This design has a number of advantages. An engine from an old washing machine is inexpensive; moreover, a similar unit can probably be found in a home craftsman’s household. Connecting this motor is not particularly difficult; there is no need to look for circuit diagrams or do soldering. With all this, the power of such a unit is quite sufficient for most types of work.

The machine diagram can be simplified as much as possible by eliminating the belt drive. In this embodiment, the cutting tool will be mounted directly on the motor shaft. The base of the desktop mini-machine will be a frame assembled from a block with a cross-section of 40 x 40 mm. If desired, it can be welded from a corner or profile pipe.

Part of the body of an old TV, coated chipboard, is ideal as a stand (tabletop) for a circular table. As practice shows, this part is quite durable, and thanks to the varnish coating, it does not prevent the workpiece from sliding.

Using a jigsaw, two parallel cuts are made in the tabletop perpendicular to the cutout for the disk. A movable square will slide along them, playing the role of a side stop. It will help you make an even cut, if necessary, at a given angle.

Main components, materials, tools

The algorithm for creating a circular saw with your own hands is quite simple. First you need to determine for what purposes the circular will be used. If this is a small portable machine for working with laminate and plywood, then it is worth considering a device made from a hand-held circular saw, and if there are more ambitious tasks, then it is better to think about a more reliable engine and the impressive size of the machine.

In any case, you will have to make drawings of the device in order to calculate how and where the equipment will be installed, how the main parts will be attached, and at the same time think about what tools will be needed for the work.

For a small portable circular saw made from a handsaw, you can use the popular design of assembling a body from multi-layer plywood or pieces of chipboard. Well, if you plan to use a belt drive and a motor from a washing machine, then you will need a tool for working with metal. You can't do without welding work here.

Model overview

Today there are many popular and productive models of small circular saws. They are very popular due to their functionality and small size. It is worth considering a small rating of the most popular models.

The Skil brand produces good budget-class instruments. They are distinguished by a 10 mm seat and a large diameter saw blade (89 mm). This popular tool can easily withstand impressive loads, as it is distinguished by the highest quality workmanship.

Skil products can be easily compared with expensive items from more well-known and larger brands. They are aimed not only at household use, but also at more serious applications.

Many furniture makers turn to such tools because they provide the highest performance and do not require constant repairs.

One of the most popular models of the Skil brand is the one marked 5330. This tool is ideal as a professional one.

However, it also has such disadvantages as:

- impressive weight;

- not the best ergonomics;

- high cost for certain ones - even for the simplest saw you will have to pay at least 2 thousand rubles.

Manual

This instrument has a rather complex design and structure. As a rule, these types of tools are designed to work with fairly thin and pliable materials.

Using them, it is permissible to perform the following tasks:

- saw wood moving along the grain;

- sawing wood across the grain;

- cut various subtypes of wood (these include materials such as MDF, laminate and chipboard);

- cut metal with a thin and soft structure.

Such instruments have the following characteristic features:

POWERFUL 250 Watt DIY mini table circular circular

- they have very modest sizes, making them easy to use and move from place to place;

- are distinguished by their low weight (this figure rarely exceeds 2 cm);

- as a rule, these models have low power;

- The saw blade size in hand saws is small;

- The cutting depth of this tool is also not very deep.

It is recommended to buy a tool with similar listed properties and features to cut thin wood, as well as soft metal profiles. For these materials, such a device is ideal. As for denser raw materials, a small hand-held circular saw is unlikely to cope with them and can cause serious damage.

Tabletop

Otherwise, such a circular saw is called stationary. It is multifunctional and very convenient to use. Moreover, such a machine can be made with your own hands, which is what many home craftsmen do. Of course, this unit will take up more free space, but it will also be more productive in its functions.

It is more convenient to work with these devices because your hands do not get tired. The master can cut the parts he needs for a long time without looking for support.

Making legs

When making a table for a hand-held circular saw, at the next stage you can start making the legs; for this, boards with dimensions equal to 50 x 100 mm are used. The legs need to be made taking into account that it is convenient to work. On average, this parameter reaches 110 cm. The board must be cut along the longitudinal axis, ensuring a small angle on one side.

The workpiece is tried on the work surface so that during installation it stands slightly apart. The legs are fixed on the outside of the elements to provide rigidity; bolts should be used for this. In order to achieve stability, you can use ties; they are made from square timber with a side of 50 mm.

Making a workbench

The working table of a circular saw made from a grinder is a workbench. It performs the following functions:

- Fixation of wooden products for their further processing.

- Storage of necessary tools.

- Assembly of wood structures at any stage of work.

The workbench must meet the following requirements:

- Its height should be no more than 95 cm.

- The working surface has the shape of a rectangle. Its length should be no more than 180 cm, width - 92 cm.

- The support legs are manufactured according to individual parameters and can have different sizes.

To make a layout for a circular table, 4x8 cm boards or 5x10 cm timber are used. The main material of the tabletop is hardwood. The boards are covered with plywood sheets on top. When constructing the workbench cover, metal materials are used.

The workbench is made in several stages:

- Creating a drawing indicating the dimensions of the workbench parts.

- Making a supporting frame by cutting timber. It is necessary to make 4 support legs, 4 spacers and 4 horizontal beams. All elements are fastened using self-tapping screws and a screwdriver.

- Design of the cover layout. The boards are treated with glue and attached to each other.

- Sanding the table top. To fix it, it is recommended to use a frame made of boards connected with staples.

- Installation of tabletops and cabinets using self-tapping screws.

To expand the functionality of the workbench, it is recommended to equip it with a vice that allows you to work with workpieces of various shapes.

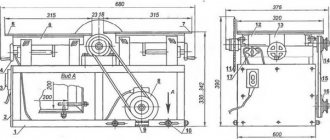

Design of a stationary circular saw

A stationary circular saw is designed to perform fairly large volumes of work. The design of the implemented option in two forms is presented in the diagram below. It also shows the main dimensions of the installation, which are recommended to be used as a starting point for self-assembly.

In the drawing, the numbers correspond to the following structural elements of homemade equipment:

- 1 – frame (bed);

- 2 – side panel;

- 3 – starting device;

- 4 – mechanism for adjusting the height of the table, 13 – its stops;

- 5, 6 and 7 – two halves of the sawing table with a base;

- 8 – electric motor;

- 9 – platform for installing the motor;

- 10 – studs (M10);

- 11 – saw;

- 12 – shaft;

- 14 and 16 – driven and driven pulleys, respectively;

- 15 – belt;

- 17 – switch.

Advice! To improve personal safety when operating a homemade mechanism, its rotating parts located under the table should be covered with lids. A protective cover must be installed over the disk during equipment downtime.

It is better to place the starting device in a visible place on the panel (made of dielectric material) so that access to it is free. It is also recommended to equip the machine with an emergency switch. It is convenient when it is large in size.

Focusing on your own needs, you can improve the unit by making it with a jointer or planer. To do this, it is enough to secure a drum with knives on the existing shaft, and make a slot of the appropriate size in the table for it. This will allow you to expand the functionality of the created installation: plan lumber on it, chamfer and select a quarter from wooden blanks.

If you plan to regularly perform carpentry operations using homemade equipment, it is recommended to equip it with a coordinate table with several guides. They need to be fixed at different angles. To organize productive work, it should also be possible to regulate the speed of the electric motor and quickly replace disks if necessary.

Disk selection criteria

The disk for the mini-circular machine must be chosen correctly, and several criteria are important.

- Number of cloves. Keep track of the number of disc teeth. Their number will affect the quality of the cut parts and the cutting speed. The fewer teeth, the longer this or that work will take. It should be taken into account that the optimal diameter is 20 mm (models up to 85 mm are available for sale).

- Parameters of the material that will be cut. If you plan to separate dense raw materials, it is recommended to use plates supplemented with carbide solders. Such devices are more expensive, but can be used longer and with higher productivity.

- Disc type based on engine power. The power level of the engine influences the choice of a suitable saw blade. For example, for equipment that is planned to be operated in “peak” order, it is recommended to purchase negative angle disks with a large number of teeth.

- External disk size. Be sure to keep an eye on this parameter of the saw blade you choose. This indicator should not exceed the casing indicators. If this rule is violated, then the small tool will turn out to be less convenient and, if necessary, it will be very difficult to fix it on a special plate.

Mini circular.

Additional Important Information

Carpentry work requires special attention. If you want to make a high-quality and highly reliable table for a circular saw with your own hands, then be well prepared for the work.

Do the following:

Purchase all the necessary materials and equipment without exception. After installing the frame, be sure to install it on a flat plane and check that the cover of the structure does not overhang in any direction. It is better to install the table for the circular saw in the area where it will be located in the future in order to eliminate possible problems associated with uneven floors. If, due to the rough floor, the table vibrates during operation, then it is necessary to adjust the length of the legs using compacted material or rubber. The product tabletop can be either single or folding

In order to form a folding table for a saw, it will be necessary to spend a little more time and the material itself and pay attention to increasing the strength of the frame, which is in a disassembled state. The dimensions of the material used to create the table are determined experimentally. Ideally, the level of the design should correspond to the height of the master. The hole that will be made in the tabletop must correspond to the dimensions of the specific saw available. To extend the service life of all materials used, assembled into a common structure, it is necessary to subject them to treatment with special chemicals that can increase the working properties of wood or metal (for example, protect their surface from rust, rotting, mold, etc.

). It is better to process wood or iron outdoors, rather than indoors, to avoid poisoning from intense fumes.

d.). It is better to process wood or iron outdoors, rather than indoors, to avoid poisoning from intense fumes.

Using this article as inspiration, you can make a durable table saw stand for your circular saw.

Homemade devices

Making a circular saw is not that difficult; problems may arise when fitting the components. Choosing all the elements correctly so that they work flawlessly is an important task. The shaft must have self-adjusting bearings if the unit is used daily. It is best to select the bearings themselves with two rows of balls, which will be adjusted using a clamping nut.

The working surface must have a “grid” marking. Without this coordinate system, accurate woodworking is quite difficult. The protective casing must not be neglected - during operation it reliably protects the device from mechanical damage. A circular saw operates in different modes when working with different materials, so it is advisable to have a device that controls such a process. Several grooves should be made on the shaft so that it is possible to rearrange the pulleys, thus changing the speed.

When you have to saw bars or make several cuts from different directions, you need a stop that has a “P” configuration. At its base lies a board 30 mm thick. Sidewalls 12 mm thick are screwed to the base. Thus, the emphasis is installed on a beam, the size of which from the cutting point corresponds to the size of the cutting disc. On both sides it is pressed against the beam with clamps. If the beam is too massive, then it is rearranged and another cut is made.

There is also an edge stop that is in demand. To make it requires a lot of time and good qualifications of the craftsman. Be sure to make a diagram before starting work. This stop is made from plywood (20 mm), and the stop strip is also made from this material. Manufacturing phases:

- longitudinal grooves for keys are cut;

- the keys are mounted on a thrust strip;

- Another groove is cut between the grooves made to secure the thrust strip;

- another hole is made in the base, its size corresponds to the saw blade of a circular saw;

Sidewalls-limiters are mounted, and there must be clamps in order to securely fasten them. To place the emphasis on the workpiece, the bar moves in the grooves and is fixed through the slot with clamps. It is best to immediately attach a ruler or tape measure to the frame - this makes the work much easier. The pusher is convenient for working with small workpieces - it allows you to fasten the part on both sides, which ensures precision in work

It is also important to do:

- elevator;

- riving knife;

- lifting mechanism.

Capacitors are calculated according to the following scheme: per 1000 watts there are 100 uF for a working type capacitor. The capacity of the starting capacitor must be ordered twice as large. It should be remembered that the SB starting block is a device that automatically returns to its original position. This is very convenient, since literally a few seconds after the start you can begin the workflow.

Making the stop and preparing the necessary holes

For a stationary saw intended for longer operating hours, the presence of a reliable stop for fixing the thickness of standard opening boards is an important and necessary condition.

The emphasis itself is made of metal or using a metal base and individual wooden parts.

The most acceptable option is to create a stop from a 100x100 mm corner, with metal plates of at least 5 mm thick welded to it with slots along the length. The length of the stop must be no less than the length of the working plate of the circular saw. The length of the plates must correspond to the width of the working surface of the stove.

Holes are drilled in the body through the work plate:

- on the edge through the machine frame; in the middle of the work plate.

The holes should form a regular rectangle with the vertices in the center of the holes.

The holes are necessary so that on the inside of the machine in these places, on strips reinforced with a strip of metal 5-6 mm thick, nuts are welded to fix the clamping bolts of the stop.

When making a stop and drilling holes, you need to take into account that the stop must be parallel to the plane of the saw.

Do-it-yourself circular: safety of use

If you take into account how much a circular saw costs (from 16,000 rubles - the most modest model), and compare the price with the costs of making it yourself (this is 60-90% less), then the difference is significant. But no savings will be justified if work safety is not ensured

Before you start using the circular saw, be sure to wear goggles and gloves.

In order to avoid traumatic situations, you should adhere to the following recommendations:

- do not use wood with metal inclusions (nails, angles, bolts, etc.) as raw materials;

- cutting boards larger than 200 cm must be done by two people;

- When using a circular saw, you should not make sudden movements;

- Before starting work, be sure to wear goggles and gloves;

- Wood waste should be removed from the surface of the circular saw, as it can cause a short circuit.

It is strictly forbidden to work on a homemade circular saw:

- if the guiding device is not made;

- no casing;

- there are no finger guards;

- the riving knife is higher than the saw blade.

To avoid hazardous situations when working with a circular saw, you should adhere to safety precautions

A good tool allows you to enjoy your work. And the result pleases with a high level of quality. Making a tool with your own hands will allow you to obtain the desired parameters and necessary performance characteristics. You cannot limit yourself to superficial knowledge in any type of activity, especially in a technical area. You should take on the task of assembling a circular saw yourself only after thorough theoretical preparation and a full understanding of the practical part of the process.

Trimming from various scrap metals

This is a fairly heavy crosscut on a stationary metal table. It will take some effort to control it. But in the end, the saw mechanism moves smoothly, without jerking, and trimming with your own hands is easy.

- electric motor power - 2.2 kW;

- disk revolutions - 2800;

- cutting depth 80 mm.

Materials and tools required for assembly:

- 900 W electric motor;

- a metal sheet;

- metal corner;

- channel;

- hinge group;

- powerful spring;

- Bulgarian;

- welding machine;

- file.

The bed is made from adjustable supports, a metal corner and posts from an old bed. The working surface is a metal sheet like a table surface, in which we cut a hole, and process the edges with our own hands using a file.

- The pendulum stand for the saw is welded from a channel mounted on a sheet of metal; its height is about 80 cm.

- The stand for the electric motor is made in the form of a movable metal plate mounted on hinges. When installing an electric motor, a spring is used as a stabilizer. Then you can do without a pendulum and belts.

- The tension belts are adjusted with a conventional hinged bolt, and the pendulum for the mechanism is also made of metal.

- As an operating tool, a disk with a diameter of 420 mm is installed on the trimmer.

A miter saw is quite dangerous equipment; when assembling it with your own hands, you need to take care of protective boxes and covers. After all, the errors in the operation of homemade equipment are much greater than those of factory equipment.

Bed for home circular saw

Such a bed can be made at home. There are two drive options with a power not exceeding 1.2 kW. This is done in order to eliminate increased energy consumption. The design of the first drive may include an electric drill of the specified power. This design is ideal for home use, but for professional work its use would be inappropriate.

The bed consists of a work table and a base. To simplify the mechanism, you need to achieve this as much as possible in fastening the disk. There are three main options: a hand-held circular saw on a tabletop, a connection between the disk and the chuck of an electric saw, and shafts driven by a motor.

The table must have a strong and rigid base to ensure safe operation. In everyday life there can be many options, it all depends on the author’s imagination. An important design parameter will be the cutting thickness of the workpieces.

Important! At home and for everyday needs, the capabilities of a circular saw made from a hand tool will be quite sufficient. In this case, you can make a speed controller, which will allow you to work with even greater productivity.

Circular saw from a grinder or circular saw

When working with small workpieces, it is enough to get by with a small circular saw. A circular saw is made with your own hands from available power tools; you will need a grinder or a circular saw.

There are many options for stationary use of improvised tools. It is enough to secure the device from the bottom of the table to access the material to the disk. The height is adjustable depending on the workpiece, but for safety reasons should not exceed one third of the size of the saw blade. This installation option is not available for the switch; it is necessary to modify the device for convenient operation.

A fairly common option is to use a frame on guides. The simple design allows you to use the tool to work at any angle. It consists of two parallel metal pipes or angles on which the saw is mounted.

A hand-made circular saw makes the work you do faster and more economical. Such a device will be needed during major repairs and other actions related to cutting wood. The simplicity of the design, the possibility of using scrap materials, makes the cost almost zero, and making it yourself allows you to add the necessary functionality for the job.

Now the guides

There is no point in specifically describing the limit bar. The design is clear from the photographs. To prevent the bar from moving after adjustment, two side screws are used. The front guide (slider) has a rather complex design. This is due to the fact that it has been redone and refined many times. If I did it again, I would do it differently. In addition to the usual requirements - rotation at an arbitrary angle with position fixation, easy movement, there were also special requirements. I wanted it to be non-removable, and at the same time not to interfere when there is no need for it. As a result, it is made reclining. The slider itself moves along a guide and with the help of a bearing along the surface of the table. The bearing was not chosen immediately. From the beginning there were experiments with plates from wood to fluoroplastic. But all this created scratches on the aluminum table. If you make a table out of steel, then there will be no such problem. Thus, the slider moves along the guide. It can be folded back by rotating around this guide. To do this, pull the spring-loaded handle. She pulls back the plastic cracker preventing the slider from reclining spontaneously. Clamps were made as additional bells and whistles. They will, of course, not be secured with clamps. But, so far, we haven’t gotten around to fastening it. So that the circular saw could be stored in a closet without any damage to it, a plywood casing was made. In this case, it can be safely removed.