Given the choice, the vast majority of consumers will prefer to purchase furniture, interior doors and door frames, and window frames made of natural wood. They are beautiful, reliable, durable. However, you will have to pay a lot of money for them, and not everyone can afford such acquisitions and not always. But you can buy products made from cheap materials that have a finish - wood veneer. It covers the surface of furniture or structures in order to give them an aesthetic appearance. Externally, such products look like they are made of natural wood. Next - more about what veneer is and what types of this material are used in industry.

Definition

Veneer is thin layers (sheets) of wood, their thickness ranges from 0.01 to 1 cm. They are used to glue the surfaces of furniture, room doors, panels, etc. for decoration using special adhesives that meet environmental requirements. As a result of veneer cladding, structures made of chipboard, fiberboard and other materials look beautiful and elegant.

Currently, many varieties of veneer are produced. For this purpose, valuable wood is used. It looks beautiful and gives furniture or other items the appearance of being made from real wood. The color of the veneer can be different - creamy white, dark chocolate, reddish, golden, etc. The pattern completely conveys the pattern of natural wood, which no technical means can recreate.

The type of veneer depends on the type of wood from which it is made. And this can be almost any wood used in industry. But more often than others, the following breeds are used for this.

- Nut. This material is of high quality. Therefore, walnut veneer is used in the production of musical instruments (grand pianos), furniture, and interior doors. The beauty of such products brings a special charm to the interior. The color of furniture walnut veneer varies from light beige to brownish brown.

- Cherry. Cherry wood veneer has interesting orange-brick tones. They are used to decorate luxury, expensive furniture.

- Oak. This type of veneer has increased strength and is used for carpentry work. Products finished with it will last a long time without being damaged. Oak veneer is expensive, but its high quality justifies the cost. Colors and shades range from yellowish-beige to dark brown.

- Maple. There are many varieties of maple used in the industry, and all of them can be used to produce veneers in the light shades characteristic of maple wood.

- Karelian birch. This veneer has an unusual, pleasant pattern and a beautiful pearlescent sheen. Its beauty will not leave even the most picky consumer indifferent.

- Pine. Light veneer is made from it, sometimes with a pinkish tint. Furniture with such a coating looks interesting and aesthetically pleasing.

Other types of wood are also used for the production of veneer. Veneer is made from larch, almost equal in strength and other properties to oak. It is not afraid of moisture and is resistant to rotting. The unusual pattern of annual rings gives it a decorative appearance. Beech, alder, ash, elm, aspen, poplar, fruit trees, etc. are also used. Sliced veneer is made from them in accordance with the requirements of GOST 2977-82.

GOST 2977-82 Sliced veneer. Specifications

1 file 49.82 KB

Veneered doors: the best choice

"Warehouse Doors 169" offers customers interior doors made of natural veneer and products finished with fine-line veneer. Our specialists will advise you on any issues related to the purchase and installation of such doors, as well as:

- will help you choose the most suitable option;

- will tell you about the features of products with different top layers;

- will offer a choice of several doors finished with natural and engineered veneer at the best prices;

- will accept an order for measurements (the service is provided free of charge);

- will arrange the delivery and installation of veneered doors.

Types of veneer

Veneer is a general concept that includes several types of wood finishing material. In industry, different types of this sheet lumber are used, depending on the purpose of the items and the characteristics of the raw materials. For their manufacture, different types of wood are used, as well as various technologies. When finishing furniture, panels, stairs, special bent elements are formed. There are several veneer production technologies.

Sliced veneer

Sliced veneer, which has a certain thickness, is made from the wood of coniferous trees, beech, birch, hornbeam, etc. It is preferable to use wood species with core rays for this purpose. They have an original texture. Its features determine several types of finished material.

The first of them is radial veneer. The annual layers of a tree trunk appear on it as parallel longitudinal lines. The core rays are in the form of strips of unequal width. The second type of sliced veneer is semi-radial. The annual layers are visible over most of the leaf surface; the medullary rays look like stripes located obliquely or longitudinally. The third is tangential veneer. On it, the annual layers are located in the form of inclined cones or curved lines, like the medullary rays. And the fourth is end-tangential veneer. On its surface, the annual layers are visible as curved lines forming closed figures; the medullary rays form strokes or uneven lines.

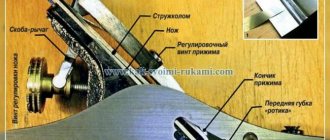

Sliced veneer is made by planing a piece of wood using a veneer planer. To increase plasticity, the wood is preheated to 30-60 °C. It also reduces the size and number of cracks.

Veneer obtained by planing is divided into 2 grades. The first grade includes products without flaws, or with minimal, barely noticeable cracks, stains, and scratches. The second grade allows the presence of such defects in small quantities, this is determined by the current standard. Certain roughness values are allowed for the surface. Products made from wood species such as ash, oak, larch, pine, and mahogany can have a roughness of 200 microns. Other rocks should have no more than 100 microns.

Peeled veneer

Peeling is a method of producing veneer by cutting a thin layer of wood from a wooden blank - block. It is installed on the peeling machine and rotates. From its surface, using a knife, the layer is removed in a spiral in the form of a tape. Peeled veneer is a material for the manufacture of plywood, cladding, panels, packaging, etc. It is often used to paste over wooden doors. Its main advantage is that the plates have a large area. This type of veneer is the thinnest: thickness ranges from 1 to 5 mm. Peeled veneer is the most budget-friendly type of such product. Inexpensive wood species are used for its production. This method of making veneer is the cheapest. Even when peeling more expensive wood - larch, cedar, oak, the cost of such veneer will be lower than planed or sawn veneer.

The appearance of peeled veneer is not particularly attractive, so it is not used for cladding furniture. If such a need arises, then various finishing methods are used: varnishing, hot printing, painting. An exception is veneer obtained by peeling wood with the presence of a defect - a random or tortuously uneven arrangement of fibers (kinkiness). This veneer looks impressive and beautiful.

Sawn veneer

The process of manufacturing sawn veneer, as the name implies, involves sawing boards using special equipment. Sawn veneer, or lamella, has a thickness of 0.2 to 1.2 cm. Such veneer is made from any wood, but more often raw materials from hardwood are used for this: ash, oak, beech. This material is the most expensive of all types of veneer. During its production, a large amount of waste remains, and it also requires a lot of labor.

Sawn veneer is most often used for finishing. But besides this, furniture, carpentry, panels, and floor coverings are made from it. It is used for finishing car interiors, as well as for the production of musical instruments, souvenirs: caskets, decorative boxes, etc. This type of veneer is suitable for products with curves and non-standard shapes. Such production from lamella is possible due to its elasticity. At the same time, the strength of the connection of wood fibers does not decrease. And the appearance of products made from lamellas is elegant and aesthetic. Virtually no additional finishing is required. All the beauty of the natural structure of wood is fully visible on such products. They look like they are made of natural wood.

Lamel has a number of advantages that make it popular; products made from it are in demand. In particular, we are talking about the following qualities:

- This material is environmentally friendly, and items made from it are safe for human health.

- The service life of such products is long; when used correctly, they are durable, not subject to deformation, do not crack or fade.

- Lamella coatings have high thermal insulation and sound insulation properties.

- Products made from sawn veneer are not afraid of temperature and humidity fluctuations and are resistant to mechanical stress.

- Such products look great and will decorate the interior of any room.

- The consumption of raw materials is low.

All these advantages are highly valued by consumers. As for the disadvantages, the main one is the high cost of the lamella.

Decor

Despite the fact that veneer itself is a material with a smooth structure, very often veneered kitchens are decorated with various decorative elements. For example, carved elements made of natural wood. They significantly increase the cost of your kitchen, but the appearance only benefits from it.

Curly veneer facades are expensive, but the appearance is stunning

Often, various ornaments are used as decoration for veneered kitchens: ethnic, floral, geometric motifs. We recommend choosing depending on the design style of your kitchen.

And sometimes the texture of the wood itself becomes a decoration

If you have a small kitchen, voluminous decorative elements may not be very appropriate: they will visually make the room even smaller. However, in this case, you can experiment with different textures. For example, a special primer helps to visually age the set - an excellent solution for classic kitchens or baroque-style rooms.

Aged veneer - another fashionable technique

As an option, try choosing a suitable shade and applying a patina. It makes even the simplest set look elegant and expensive.

With patina, veneer looks more noble

Production technology

The quality of veneer depends primarily on the material used for its manufacture. For this purpose, straight, slender tree trunks with few branches and twigs are used. However, wood processing technology is also of great importance. It is carried out according to approved instructions. The quality of the resulting products must comply with currently valid GOSTs.

Veneer production by one method or another - sawing, peeling, planing - is carried out at woodworking enterprises. First of all, heat treatment is carried out, which increases the elasticity of the wood. The log is then stripped of its bark. Before starting work on veneer production, specialists evaluate the material and determine the best processing method. To obtain veneer, specialized equipment is used. Many craftsmen make veneer with their own hands.

How to care

When it comes to maintenance, veneer is not too demanding, but it has its own characteristics. It is necessary to take into account that this is, first of all, natural wood, so an appropriate approach is needed.

To prevent the kitchen from losing its appearance, you need to take care of it

For daily care, a soft sponge or lint-free cloth will be enough. Wet them in water and then wipe the surface. After this, wipe dry with a soft towel. If there are stains or stains in the kitchen, you can use a soap solution or a special wood cleaner.

It’s not difficult to clean veneer if you don’t start cleaning

If you decide to use polish, you will need to degrease the surface first. To do this, you can use a weak solution of alcohol or, if desired, a regular window cleaner. Gently wipe the set, wipe it dry, and then apply polish and let it dry.

Important! Never use abrasive detergents or hard sponges. They will scratch the surface and you will need to spend effort and money on restoring the headset.

How to choose furniture veneer

Furniture made from natural wood is available to a limited number of consumers due to its high cost. But there is a wonderful alternative: furniture veneer - a material that is used for decoration. They not only cover the surface of products, but also inlay them. The appearance of such pieces of furniture is not inferior to expensive, exclusive models made from valuable wood. With the help of designer veneer you can create a magnificent composition that will decorate any interior. The different colors and textures of this natural wood material, harmoniously selected and combined with each other, will add charm and comfort to the room.

When choosing veneer for making custom-made furniture, the consumer is guided by his own taste, as well as the purpose of the room for which the furniture is required.

Peculiarities

- Exclusive inlays. There is a veneer finishing method that turns furniture into an unusual art object. Only real professionals can do this. But the cost of such piece ones will be an order of magnitude higher. Craftsmen use rare types of wood for these purposes and create magnificent patterns on facades and countertops.

- Variety of textures. In nature, there are no two identical trees and the pattern of one piece of furniture will always be different from another. This is especially noticeable on small furniture forms. This point should be taken into account when ordering paired items, for example, bedside tables or identical coffee tables.

- Repair. Although the damage is annoying, it can be easily repaired. But one thing needs to be taken into account. Modern veneer furniture differs from those products produced back in Soviet times and is not subject to delamination or swelling. Over the past few decades, construction technologies and materials have significantly improved the performance properties of furniture products.

- Coffee table Ashley Stownbranner T640-1

RUR 41,691

Look in the "Designer tables" section

Caring for veneered products

Veneered products with proper care will have an attractive appearance. To do this you need to follow simple rules:

- Keep them away from hot and cold objects to avoid stains.

- Avoid spilling water on the veneer surface, otherwise the coating may peel off.

- Wipe off dust with a soft cloth to avoid leaving scratches on the surface.

- To clean dirt, use non-aggressive chemicals that will not damage the coating.

- To protect against dust, use products with an antistatic effect.

- Protect the surface from rough mechanical damage and direct sunlight.

With proper use, veneered furniture will last a long period and will delight the owner with its beauty and reliability.

Advantages and disadvantages

Like any other facades, veneered ones have both advantages and disadvantages. We suggest you study this aspect in detail so that you know what problems you are likely to encounter.

Veneered kitchens look stylish and have a lot of advantages

- No matter how high-quality plastic or PVC film is, they can only imitate wood . This means that upon closer inspection the fake will be noticeable. Veneer is completely natural wood, albeit very thin. Even with meticulous study, high-quality veneer facades are indistinguishable from kitchens made of solid wood.

- If the veneer is treated with varnish or a special paint coating, it will be resistant to any of the most unpleasant influences that occur in the kitchen - high temperatures, mechanical damage, moisture and steam, drops of fat and various acids.

- Like any wood, veneer can be restored. Of course, we are not talking about serious damage - in this case you will need to install a patch. However, small scratches and abrasions can be easily hidden and the kitchen restored to its original appearance.

- It cannot be denied that veneer facades look truly luxurious. A set made of solid wood looks exactly the same, but costs several times more.

- The material is environmentally friendly, does not contain harmful impurities and is non-toxic to humans even when heated. This means that veneered facades can be installed even in close proximity to the stove - there will be no toxic fumes that often occur with plastic or PVC film.

- Caring for veneer kitchens is very simple : just wipe them regularly with a damp sponge and then wipe dry. Some people use special polishes that add shine to surfaces. However, in the kitchen we recommend avoiding such products: they attract dust and other debris, which means maintenance becomes more difficult.

However, if you thought that a veneered kitchen was the ideal solution, we will disappoint you.

- It is almost impossible to visually determine the quality of veneered furniture . This means that if you were sold a not very high-quality headset, you will most likely find out about it already in the process of using it. You can avoid the problem if you contact only trusted furniture stores and craftsmen who value their reputation.

- The problem stemming from the previous drawback is the low quality of some veneered kitchens. Veneer can become deformed, peel off... This happens due to the influence of moisture, fat, steam and constant temperature changes. Therefore, we emphasize once again that you should not save on buying a kitchen set.

- In any case, its cost will be higher than that of film or plastic facades. However, you pay for a spectacular appearance, quality and environmental friendliness.

- Like any wood, veneer does not tolerate direct sunlight very well. Under their influence, wood can darken and change shade. This can be avoided by varnishing the veneer. We strongly do not recommend leaving it without a protective coating.

As you can see, most of the disadvantages of veneered kitchens can be avoided if you purchase high-quality sets from trusted places. As for expenses, if you have a good kitchen, they will pay off very quickly.

In general, we strongly recommend veneered kitchens: they are worth it!