Turning is considered an ancient Russian craft. In the old days, craftsmen turned unique products from scrap materials. In ancient times, turners enjoyed success.

They were highly valued and made various antiques. It was done by hand. The words: turner and turner originated in the old days, the old Russian dialect for working on wood, sharpening it.

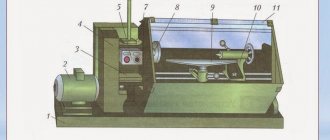

General design and purpose

Woodworking lathes have one functional purpose: processing workpieces. The output products take the form of a detail in the outline of the future furniture design, room interior, or decorative design.

The scale of production and processing of wood products depends on the equipment used. Manufacturers produce 3 types of machines:

- school;

- household;

- industrial installations.

The design of the devices is no different. They have different capabilities for processing parts. With high speed, accuracy, availability of devices, closers, sizes of installation fasteners. Their unit electrical power consumption differs.

Lathe with variator Jet JWL-1443

The next model is again produced by JET. Larger and more powerful, it represents a transitional option between home and industrial equipment.

JWL-1443 Specifications:

- workpiece diameter – 370 mm;

- length of the fastened part – 1100 mm;

- electric motor power – 750 W;

- dimensions – 1750×480×1165 mm;

- weight – 103 kg.

The design of the frame initially includes removable legs, which allows the machine to be used in both desktop and floor-standing versions. The main feature lies in the headstock. It is equipped with a ten-speed variator, allowing you to change speeds without stopping the spindle. The headstock is not permanently attached to the frame. It can be moved to any location to improve the convenience of operation. The headstock can also rotate 360 degrees around a vertical axis, which allows you to sharpen products not only above the bed, but also in almost any position. Thanks to this solution, JWL-1443 can be used for processing workpieces of increased diameter.

In comparison with previous models, only one drawback stands out - larger dimensions. The rating values of Jet JWL-1443 are higher than previous options, as are its technical characteristics.

Types of woodworking units

Lathes perform 5 tasks for processing a wooden workpiece:

- planing;

- milling;

- drilling;

- turning;

- grinding.

The ability to process a raw wooden piece in a plane and along a profile makes a product with a smooth surface. The resulting boards, panels, and bars are of good quality, ideal in shape and smooth in surface cleanliness. Thicknessing devices plane the workpiece to size and thickness.

Planing of a wooden part is done:

- planing;

- jointer.

Special profiled parts with processing of the front side of panels, frames along the contour, and decoration work can be performed by milling machines. They are 3 types:

- milling;

- copy-milling;

- four-sided.

Drilling holes and making recesses in a wooden part is performed by drilling and filler machines. They make a tongue and groove connection. Slotting machines are used to produce recesses in the form of nests in a product.

Drilling machines are available in 3 types:

- vertical;

- radial;

- drilling and filler.

Processing of workpieces by turning to obtain a cylindrical shape is performed by lathes. They are of 1 type. They have various modifications depending on the complexity of obtaining a finished part or workpiece.

Removing waves, irregularities, burrs, smoothing sharp edges, calibration. With their help, perfectly smooth surfaces are obtained.

Grinding units:

- drums;

- disk;

- combined.

Tabletop for home and household

Tabletop devices are also available with CNC. These machines are considered high precision machines. They are classified as a group of universal equipment. It performs a variety of wood processing operations.

Reference! The machine allows you to make small parts. Consumption of a small-sized machine is 500 W.

Manufacturers produce 3 types:

- turning milling machines, they make grooves in wooden parts;

- turning screws, make cuts in the form of large-sized threaded connections, various zigzags and shaped slots, as well as for the manufacture of conical products;

- with CNC, perform program control, make parts according to a given template.

Low-power home type. They are placed on workbenches and small tables. Frequent production of wooden parts is more profitable to do with a unit with a power of 0.8–1.2 kW; the selection indicator is the size of the wooden blank being produced.

On a home machine, the distance from the product to the bed is 250-405 mm. Center-to-center distance 330-1100 mm. Spindle speed 400-3500 rpm. Rapid rotation of the workpiece allows you to process the part more accurately and accurately.

Small-sized series are universal in operation of the device. They allow you to sharpen cylindrical and cone-shaped products.

Reference! The machines help make simple oval blanks, as well as apply cuts, notches with grooves and various tricks.

Small-sized devices are used at home. With their help, small, jewelry-precise parts are made. The weight of such machines is up to 10 kg.

There are 2 types of tabletop type lathe: devices that create a wooden part, a product with a zigzag appearance, or a carved-type design. This is done with a cutter.

Depending on the method of processing the product, devices are divided into: lathe and milling machine. They drill a through hole, make a recess, chamfer, trim the part; turning screw-cutting device and designs.

They are used for cutting threaded ornaments and turning blanks; universal machine, complex type of devices. Allows you to process workpieces of various shapes.

It is easy to select the minimum size turning device. They are characterized by low power and compact size. Their power of 0.15-1.8 kW is enough to produce any type and shape of product. The rotation speed and operating time are sufficient for such a device.

Home-type devices do not require high power. Not economical. There are no large or lengthy jobs. The width of the workpiece is 25-175 cm. Determined by the permissible overall length of the workpiece. The cross section of the wooden part is 10-38 cm, which makes it easy to process it.

The size of the part is determined by the overall dimensions of the installation. The device has a large number of speeds, 10 switchings. This is a good indicator. Speeds make it possible to select the desired rotation of the part for processing and grinding. Carefully make cuts that are accurate in size and zigzag.

There are many modifications of wood processing machines on sale. The home workshop can be replenished with models of small-sized devices. Their purpose is to process wooden products in small spaces.

School

The STD-120M model is used in school labor training classes. They are compact, have an optimal number of operations depending on operating conditions and workpiece sizes. They combine technical capabilities and price.

Difference: spindle rotation speed. The installation operates at spindle speeds: 1100 and 2150 rpm; presence of a push-button start and stop unit; complete with spare and replacement spindles.

Industrial

The turning and copying machine is common in the industrial production of furniture and household products. They are used to make figured racks and structures for decorative flights of stairs. The installation is distinguished by reliability, power, productivity, and production of parts according to the pattern.

They read the exact configuration of the templates and make a copy of them with exact dimensions. What is important for the production of high quality furniture. Products are made serially and in large quantities.

Record Power DML 250 is a small device designed for highly professional professionals. The device allows you to make any product configuration. Blanks fit dimensions 45.7 cm, F up to 25.4 cm.

The bed is extended to 57 cm. Wooden blanks up to 100 cm are processed on the machine. The machine drive allows you to change speeds from 1 to 5. 390W motor for a lathe of this size. The engine is equipped with aluminum cooling fins.

Minimum machine sizes:

- Record Power DML250.

- JML-1014i 40,722.

- Record Power DML 305 61 050.

- JET JWL-1015.

The JET series is more compact. They are in high demand among professionals and amateurs. An increase in the machining part up to 90 cm is achieved by lengthening the bed.

Features of JET JWL-1015:

- made on a cast iron frame;

- 5-6 belt drive speeds;

- The drive belt is quickly tensioned and slackened;

- dividing mechanism;

- Tailstock eccentric lock.

Review of mini-lathe models

If you are faced with the task of purchasing a wood lathe for domestic use, then when searching for equipment, the choice should be made in favor of imported models.

And the point here is not only that the machines of domestic companies are of lower quality in comparison with foreign analogues. Imported models of wood lathes have a higher power class. They can be used for industrial purposes. The choice of such equipment is quite large. Regardless of the country of origin, most models are assembled in China. Therefore, when choosing such equipment for your workshop, you need to pay attention to parameters such as price, quality and functionality. The best choice would be a machine that has the optimal ratio of these parameters.

Proma DSO-1000

If we talk about the most affordable model of an imported wood lathe, then this is the Czech unit Proma DSO-1000. Its minimum cost is 6,500 rubles. It has a power of 400 W. It has the ability to adjust the spindle speed in the range from 850 to 2500 rpm. The weight of this machine is 35 kg. It has fairly compact dimensions: 1450x250x370 mm.

HolzStar DB450

If you are looking for a machine with an optimal price-quality ratio, then you should pay attention to the HolzStar DB450 model. This Chinese-made machine has a minimum price tag of 12,000 rubles. This mini-lathe is equipped with a frame made of cast iron, due to which vibration is minimal when using it. This means that when performing operations, small parts will be processed with high precision.

However, the main advantage of this equipment over its competitors is the high spindle speed. This parameter can be changed in the range from 500 to 3150 rpm. As for the power of the equipment, this machine has this parameter of 370 W. The weight of the machine is 38 kg, and its dimensions are small - 820x300x430 mm .

JET JWL-1220

Another model worth mentioning is the Chinese JET JWL-1220 lathe.

It differs from the models presented above in its high price. The minimum cost of this equipment is 18,500 rubles. However, by paying that kind of money, you get equipment with a large power of 750 W. The main element of this equipment (bed) is made of gray cast iron. A number of important elements of this machine are made from it. Thanks to the choice of such material, vibrations are eliminated when performing operations on this equipment. The engine with which this machine is equipped has 6 speeds and two modes .

When using the first mode, the rotation speed varies from 400 to 3300 rpm. The second has smooth adjustment from 500 to 3900 rpm. This lathe can be easily locked using the quick release lever. The machine is equipped with rubber feet, thanks to which it cannot move during operations. Additionally, with the equipment set, the manufacturer offers a bed extension 710 mm long. As for the weight of this equipment, it is 45 kg.

Review of modern manufacturers

official dealer in the Russian Federation of companies producing wood lathes. The central representative office is located in Moscow.

The Swedish company Logosol has been a global manufacturer and supplier of woodworking equipment around the world for more than half a century.

The products of this brand are rightfully appreciated by representatives of small and medium-sized businesses for their excellent quality combined with an affordable price. They produce high-precision industrial machines:

- turning;

- turning and milling;

- CNC turning;

- turning and copying.

The Chinese company WoodTec exports equipment to the foreign market. Since 2003, the machines have been used at factories in the Russian Federation. It specializes in complex and expensive equipment. It supplies them to large enterprises and entrepreneurs working in the production of furniture and decorative wood products. Machines of 3 types:

- CNC milling and engraving;

- CNC turning and milling;

- turning and milling with CNC.

The company is based on the Belarusian Machine-Building Plant , a young holding. Develops, produces, and sells high-quality multifunctional machines. Of these, more than 10 modifications of desktop and household lathes for the home workshop.

The manufacturer supplies products at reasonable prices. Now the company operates as a distributed holding throughout the Russian Federation, with production in the Republic of Belarus, the city of Mogilev.

What cheap used machines can you find?

BELMASH WL-300/450. Made for mechanical processing of wood. Cast iron bed. Smooth rotation allows for high-quality grinding of parts. The small diameter of the workpiece is 30.5 cm, the clearance between centers is 45.5 cm, which provides a good opportunity to work productively on the machine without fatigue or fatigue.

The machine has 5 speeds. Changing the speed is done by shifting the drive belt to another pulley stage. A convenient arrangement of machine tools is created by the console. Rotation speed can be easily changed.

Safety precautions

After setting up the machine, it is worth studying the operating instructions regarding following safety rules.

Before work, inspect the equipment for obvious defects, and if found, correct them.- There should be no foreign objects or interfering workpieces in the workplace. It should be provided with good lighting.

- The unit must stand stably on a level and solid base.

- The machine is installed in such a way that there is enough space for its maintenance and material placement.

- Do not use the equipment near flammable gases or liquids.

- Do not use the device in areas with high humidity or exposure to rain.

- It is worth using an exhaust system; wood dust is explosive and can cause harm to health.

- When working, clothing should fit tightly, a hat, glasses and dust protection should be worn.

- It is forbidden to leave the machine running and allow strangers to access it.

- Before work, all foreign objects are removed from the workpiece, and the tool is well sharpened.

- The workpiece is securely fixed.

Compliance with the rules will ensure safe operation of the machine and extend the life of the equipment. It is best to entrust all electrical and service work to a qualified specialist.

Originally posted 2018-04-06 09:34:22.

What factors influence the cost and main selection criteria?

The cost is influenced by the factors of using machines for their intended purpose, dimensions, the presence of software devices, the number of rotational speeds of the engine and drive system. The brand of a turning machine increases its cost by 1.3-1.6 times. Important, equipment.

The device, just like a machine, is equipped with a variety of devices for comfort and good control. You need to choose wisely for complete sets at an affordable price. An equipped machine may not produce what you want for work:

- It is better to have a collapsible bed, up to 5-6 mm thick. No longer required. - the basis of a milling machine.

- The engine, economical and not expensive, also helps process wood workpieces well.

- Drivers are selected for the engine and are supplied with it.

Installation options

The longest distance between centers is one of the main dimensions of the equipment. It allows you not only to determine the most likely length of the product for processing, but also provides information about the dimensions of the machine itself. In some devices, these values are indicated in the labeling.

For the workpiece being processed, the maximum diameter is determined by the height of the centers above the support and the maximum interval of the tool rest from the axis of rotation. When using a support or copier, this indicator does not have such a meaning.

If we compare a wood lathe with other electric tools, the power consumption of the machine is sufficient to perform the functions assigned to it.

On all current installations, the rotation speed is modified. There are two ways to configure:

- By rearranging the drive belt on the gearbox to a driven pulley or drive pulley of the required diameters. This is done manually or using a lever located on the front panel.

- Electronic adjustment combined with belt movement. This method provides more precise tuning.

This parameter allows you to adapt the installation to work with a product of a certain diameter and a given cleanliness. Typically the rotation speed ranges from 500 rpm to 5000 rpm.

Tips and tricks for choosing

Online stores allow you to purchase a profitable, convenient lathe. Machines in the catalog of the online salon with a wide level of functionality. They differ in power. Cooperation with store specialists will save money when purchasing goods at a low price.

The same characteristics of equipment in other retail chains will be 1.3-2 times more expensive. Here you can profitably receive your order in the shortest possible time. Buying a tabletop lathe is very simple when you enter the website of the company that sells this equipment. Information center specialists will help you choose the appropriate model.