The importance of material quality

Not every wood is suitable for carving art. Since materials have different properties: moisture, strength, softness, flexibility, etc. Therefore, the choice of a specific option depends on:

- simplicity and speed of processing of workpieces;

- visual appeal of the product;

- the ability to make small and complex ornaments;

- durability of the product (figurines, furniture, etc.).

Which tree to choose with all the variety of species? The selection of a specific material is largely determined by the technique in which the master works.

So, for sculptural carvings, it is recommended to use durable wood species: oak, cedar, etc. And for relief or geometric carvings, it is recommended to use linden, birch and alder, which are soft and flexible.

When choosing a material you need to pay attention to:

- growth rings - their parallelism indicates that the tree has a rectilinear internal structure;

- wide layers of wood indicate looseness and fragility of the workpiece;

Single-growing trees are not suitable for work, since they are most susceptible to wind loads, as a result of which the fibers twist and have different densities. During the drying process, such wood cracks and warps greatly.

Particular attention is paid to the age of the tree. A young tree has a soft and loose structure, which is easily subject to mechanical stress. Old wood is susceptible to rotting and attacks by parasites. Mature (middle) aged wood is perfect for carving work. It varies for different breeds. For oak it is 80-150 years, for birch and ash - 60-70 years. Age is determined by the thickness of the trunk or the number of annual rings.

When choosing a workpiece, the moisture content of the wood is taken into account. Freshly sawn wood, which warps during the drying process, is not suitable for carving. Overdried wood absorbs atmospheric moisture, causing swelling and cracking. Under-drying or over-drying is very noticeable on dense and hard rocks, and to a lesser extent on soft ones.

Popular breeds

Hand carving can be carried out on blanks of various woods. However, there are several most popular breeds that are preferred. Among them:

- Linden. Workpieces made from this rock lend themselves well to processing with cutters and chisels. The wood itself has a fine-fiber structure, thanks to which craftsmen can create complex and delicate ornaments. The even white color of linden is another reason why carvers choose this particular species.

- Alder. What kind of wood is used for wood carving if the craftsman needs a unique shade of the species? First of all, of course, alder. Such wood changes color: initially the workpiece is white, but over time it acquires a reddish tint, and then light pink.

- Birch. It is easy to process, so it is often used for relief and geometric carvings. Due to their low strength, birch blanks are used in the manufacture of paintings, panels and other decorative items.

- Oak. What kind of wood is needed for carving if the master wants to make a figurine or decorative furniture? Oak will be the best choice. It is characterized by high strength, durability, and resistance to damage. That is why benches, chairs, kitchen utensils, etc. are made from oak.

What trees are suitable for carving, besides the species mentioned? First of all, it's maple. Its wood is similar in color to birch, but has an attractive texture and hardness. Maple is more difficult to process with cutters (small chisels, cerasics, cranberries, etc.), so large ornaments and relatively simple patterns are created on the blanks. Pine, cedar, yew and fir are also widely used in carving art. They need to be better prepared before work, since the rocks contain a lot of resins.

Related materials:

- DIY wood carving

- All about wood carving tools

- High-quality woodworking tools: choosing the right ones

Tools and accessories.

Wood is a material that can be easily processed, but still, in order to make figurines from wood, it is better to use special tools that will be easier to work with.

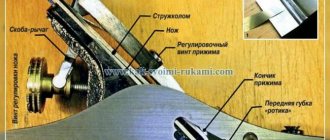

- Cutter. A knife with a shortened and beveled blade. It is the main tool, as it is used for processing both large and small parts, and for carving in hard-to-reach places.

- Knife-jamb. A knife that also has a short blade. It is used to create an ornament.

- Chisels. They are necessary to form recesses on the future product. In their shape they can be: flat, semicircular, curved.

- Chisels and rivets. They have a spear-shaped blade and are used to create small parts.

They are especially convenient for working in hard-to-reach places.

These are the basic tools that are needed at the initial stage. But besides this, some other devices will be needed:

- drill (if necessary, to create through holes),

- Sander,

- saw (for creating blanks),

- sandpaper and rasps (for processing the product at the final stage).

In order for the final result to be as high quality as possible and look presentable, it is necessary to choose the right material for the job.

First you need to decide what size the future wooden figurines will be. If you plan to make a small figurine, then knots and medium-sized logs will do. But if your plans include a larger-scale sculpture, then it is better to opt for large massive logs. It is worth paying attention to ensure that the workpieces are not damaged or chipped.

Experienced craftsmen advise beginners to use rectangular bars, since they are the easiest to transfer images to.

Regarding the choice of the tree itself, the most commonly used are the following:

- Linden. It is easy to cut, and its structure does not have a pronounced pattern. Therefore, it will be easier to transfer the future image onto it. This material rarely cracks.

- Alder. Has the same positive characteristics. Working with such material is not particularly difficult.

- Aspen. Well suited for large sculptures as it is susceptible to chipping. Over time, unvarnished aspen will acquire a silvery tint. It also does not cause any difficulties in work, having a soft structure.

- Birch. The material is harder and more difficult to cut. Most often used to create small parts. It has an unusual relief.

- Nut. Great for applications where fine carving is involved. It is easy to process and is not susceptible to chipping. Often used to create decorative elements.

- Oak. More often used for large-sized sculptures, since the material is prone to chipping and is much more difficult to cut.

Before use, any selected wood must be thoroughly dried. So that, in the future, on the finished product, it does not crack. They usually dry in a warm place, wrapping the workpiece in polyethylene.

Quality criteria

How to choose wood for carving, given that the materials differ in properties? When preparing, it is important to consider:

- Humidity. This indicator directly affects the durability of the finished product. Excessive moisture in wood can lead to deformation, cracking, and loss of attractive appearance. Therefore, freshly cut material is not suitable for processing. If there is a need to create relief and ornament, craftsmen choose dry blanks with a humidity of about 8%.

- State. What wood is absolutely not recommended to use? One that has knots, growths and other defects. This material is difficult to process due to twisted fibers. They prevent the master from moving the tool in the desired direction. In addition, chips and cracks form faster at the site of knots, which leads to product breakage.

- Weight. The heavier the material, the higher its strength. Therefore, craftsmen try not to use heavy wood when making panels, paintings and other products that require delicate processing. Heaviness can also indicate high humidity.

This is basic information about which wood is best to choose for further carving. When selecting a specific workpiece, craftsmen are also recommended to always take into account the technique in which they are going to work.

Interior design and architecture

Since ancient times, man has used wood in various areas of his life. It was used to make dishes, furniture, household items and works of art. Ships were built from wood, houses and outbuildings were constructed. And today wood is widely used in construction and interior decoration.

The highest quality and most expensive furniture is made from noble, truly precious wood. For many buyers, it is simply inaccessible, and therefore, to reduce the cost of producing furniture, chipboards (chipboards) are widely used, which are covered with a thin layer of beautiful finishing wood - veneer.

Chipboard - wood chipboards

In turn, veneer is obtained from easily processed tree species, which have a special decorative texture and pronounced patterns on the wood section. Typically, such trees grow in the hot climates of most tropical countries.

The production of facing sheets occurs as follows: the tree trunk is sawn into equal parts two meters long. After this, each part is given the correct cylindrical shape.

Next, a thin outer layer is cut off from such a cylinder with a sharp blade. The resulting veneer is glued to particle boards and then pressed under slight pressure. Such facing slabs are an excellent finishing material, but to create a truly luxurious room design, it is still better to use natural wood.

Let's look at finishing wood species that have high quality indicators and a pronounced texture pattern. These wood species have long established themselves as an excellent material for interior decoration.

Wood species for interior decoration

Abacha is a soft but durable wood with a creamy white or yellowish tint. Used in finishing and carpentry work, as well as in the manufacture of decorative veneer.

Azobe is characterized by very dense, hard and heavy wood, resistant to damage and rot. It is used for flooring and finishing work.

Amboyna is a red-brown wood with a distinct pattern obtained from growths on a tree trunk. Amboyna solid wood is used in the production of high-quality veneer, which is used to decorate the interiors of yachts and expensive cars. Amboyna is also suitable for decorating a home library or office.

Amazaku - This breed has beautiful chocolate-colored wood with black stripes. It is used in furniture production, carpentry, and in the design of luxury interiors.

Amaranth is the kernel of a tree of bright red-violet or deep lilac color. Over time, the purple tint disappears, and the wood acquires a noble dark brown color. The texture of amaranth is extremely resistant, making it difficult to process. Most often, amaranth is used for luxury interior decoration, as well as for cladding the walls of a home library or study.

Anegri is a solid wood with a light gray to brown color, sometimes with a pink tint. Used for the production of plywood and veneer, as well as in carpentry. Suitable for finishing wooden interiors in the Russian style.

Afromosia is a very durable species, close in quality to beech wood. It is used for the production of veneer, expensive carpentry and furniture production.

Balsa - the wood of this species is the lightest and softest, easy to process. Used in the manufacture of fishing floats, life jackets, and toys. Wood has excellent heat and sound insulation properties, so its use is justified in decorating a children's room or bedroom.

Birch - the wood is easy to process, but sometimes hairiness can form. It is used in the production of wood panels and plywood, as well as for the manufacture of stairs and finishing work.

Karelian birch is characterized by durable and hard wood. which, however, is not very durable during operation. Thanks to its amazing texture, Karelian birch is used in the decorative finishing of expensive furniture, in the manufacture of highly artistic products and in the design of luxury interiors.

Flamed birch - its wood is easily processed with any kind of tools, easily painted and polished. Most often used for wood finishing and in the manufacture of decorative veneer.

Berlinia - characterized by moderate density and hardness of wood. It is used for the manufacture of vehicle bodies, as well as in carpentry, turning and cabinetry.

Bibolo - wood is perfectly processed manually and on machines. Used in cabinetry and furniture production, for the manufacture of high-quality billiard tables. Suitable for panel finishing of interiors.

Bosse - this species is characterized by pinkish-brown wood with straight grains. It is used in the construction of small boats, in the production of furniture, as well as in the decoration of premises. Best suited for finishing a home office or staircase.

Bubinga has a very hard and heavy wood with a fine texture. Solid wood and bubingo veneer are used in finishing work and for the manufacture of expensive furniture.

Beech is a fairly dense and hard wood, but it is easy to process and is suitable for making bent products. In finishing works it is used to cover walls and ceilings. Beech is used in the production of veneer, plywood and modified wood.

Vavona is the trade name for wood of a bright red-brown hue with a pronounced pattern, which is obtained from growths on a tree trunk. Vavona is used for the production of decorative veneer and in the production of luxury furniture.

Wenge is a hard and heavy wood, easy to work with but difficult to polish. Due to its high decorative value, wenge wood is used in the production of veneer, which is used for the manufacture of luxury furniture, interior decoration and inlays.

Cherry is characterized by fairly hard and dense wood of a beautiful red-brown hue. Cherry wood is highly valued in cabinetry and furniture production. It is used in the manufacture of musical instruments (mainly grand pianos and grand pianos), as well as exclusive carpentry.

Gabon - its wood is considered one of the most valuable hardwoods. Used for the production of wood panels, plywood and veneer. The color of the wood has a stable pink-brown tint that does not change over time. Gabon is used in interior finishing work as a cheaper substitute for mahogany.

Goiabao is characterized by a wide range of wood colors from light beige to golden brown. The species is used as structural lumber, used for the production of veneer and for the manufacture of handles for various tools.

Hornbeam is a strong and durable wood species, which, however, is not particularly durable and deteriorates quickly. Hornbeam is used to make piano percussion mechanisms, turning products, and produce veneer and lumber.

Pear is a dense and hard wood that is easy to process and polish. It is used for the production of decorative veneer, musical instruments, furniture and art products.

Danielle - the wood is easy to process and sand. When polished it gives a strong shine. However, this breed cannot be classified as durable. Daniella wood is used for the production of decorative veneers, wooden containers and lightweight joinery.

Oak - wood is characterized by strength and durability, but requires long-term drying to avoid the appearance of cracks on the surface of the products. Oak furniture can last for centuries. At the same time, the beautiful natural texture of the wood does not require painting at all. Bog oak, which has lain in water for a long time and has acquired a dark shade of wood, is considered especially valuable. Oak is an excellent construction and finishing material, but it is also expensive. It is used for the manufacture of luxury furniture, cooperage and finishing work.

Luxurious oak furniture in the interior

Sitka spruce is a creamy white wood with a pinkish tint. The tree is devoid of resin and characteristic pine smell. It is easy to process, polishes well and gives an excellent clean surface. Sitka spruce wood is used to make carpentry, parts of musical instruments, as well as boats, oars and gliders.

Emien - characterized by a white and pure color of wood, which darkens slightly over time. Emien wood is soft and light, so it can be easily processed both manually and on machines. The species is used for interior finishing work, as well as for the production of decorative veneer.

Zebrawood is a wood of a very beautiful light golden hue with pronounced narrow black and brown strokes. The texture of the wood is coarse and somewhat porous, so the pores must be filled with a filler before polishing. Zebrawood is used as a raw material for the production of decorative spurs, parquet flooring, and also for the manufacture of inlays.

Zirikot is a resistant and durable rock that is easy to process and polish. The color of the wood is interesting, red-brown with spectacular dark veins. The structure of the tree is dense and heavy. Zirikot is used in finishing and cabinetry. Zirikot wood looks beautiful in the interior design of a home library or office.

Imbaya is a moderately hard and dense species, with wood color ranging from yellowish olive to chocolate with a variegated pattern. Imbaya is easy to process, but during the planing process it is possible to raise the fibers. The wood is valuable and is used for making furniture, interior decoration and high-level carpentry. Imbaya is used for the production of decorative veneer.

Iroko is a wood with a pleasant golden hue. In the structure of the tree there are deposits of calcium carbonate (so-called “stones”). The breed is resistant, dense, but at the same time perfectly processed. Used for the production of plywood and decorative veneer, as well as for the production of solid panels for wall decoration.

Ipe is characterized by bright wood that darkens over time. The breed is strong, heavy, with a high content of oily substances. The wood is difficult to process, but is easily polished. Ipe wood is used in the production of planed decorative veneer, in turning and cabinetry, and in interior decoration.

Camphor root - this mass is obtained from growths on a tree trunk. This is a fairly rare material that serves as the raw material for the production of valuable decorative veneer, which is used in the finishing of luxury interiors and to create floor coverings.

Kingwood - dense and heavy wood has a white or light yellow color with beautiful black or violet-brown stripes. Despite its hardness, the rock can be easily processed with sharp tools. Kingwood is used in finishing expensive interiors (for example, a high-status executive office or an elite home library).

Cocobolo - wood is characterized by a fine, uniform texture of varied structure. Hard, very dense and heavy cocobolo wood is easy to work with sharp tools, polishes well, but is difficult to glue. Most often, the breed is used for making knife handles, parts of musical instruments, as well as for making inlays and artistic and decorative items. Cocobolo wood allows you to obtain high-quality, very beautiful veneer.

Maple root is a trade name for hardwood obtained from maple root cuttings. The resulting material is distinguished by its strength and durability. Most often, maple root is used in the production of veneer.

Koto - the wood texture is moderately coarse and is similar in strength to ash, that is, it is not particularly durable. The species is used as a raw material for the production of peeled veneer, which is used in interior cladding work. It is rarely used for making furniture, as koto wood is susceptible to cracking.

Maple - characterized by white or creamy yellow wood with a pink tint. The rock is very dense and hard, and during the polishing process it gives a wear-resistant shiny surface. Maple is used for making musical instruments and furniture, as well as in the production of peeled and sliced veneer.

Lacewood - fresh wood has a reddish-pink or soft brown color, which darkens over time to a rich brown. The density and strength of the wood is average. The breed is most often used for the production of veneer and cladding panels. Lacewood wood is also used in furniture and cabinetmaking.

Linden is a soft wood with straight grain and a fine, uniform texture. The breed is not strong and durable, as it quickly deteriorates, so it is not used in furniture production and finishing work. Linden wood is used to make carved decorative items and small household items. The breed is also suitable for veneer production.

Larch is characterized by very strong and hard wood, superior even to pine. The rock is used in the construction of underwater structures and shipbuilding. Larch is used to make high-quality and durable window and door structures.

Makassar is a gray-brown wood with black stripes or expressive dark strokes. The breed is very resistant and durable, so it is difficult to process. Makassar is used in finishing work, for the manufacture of artistic products and inlays.

Makore - has some similarities with mahogany wood, but is characterized by a finer grain texture with an original variegated pattern. Makore wood is strong, dense and heavy, yet hard-wearing and durable. It is used in the production of high-quality decorative veneer, as well as in the manufacture of furniture and joinery.

African mahogany - its wood of a beautiful pale red or rich pink color has all the properties of mahogany. African mahogany is widely used in the production of furniture and decorative veneer, for the manufacture of expensive joinery and finishing panels. The veneer pattern can be different, but the most valuable is the branching “pyramid”, which gives the products a unique beauty.

Central American Mahogany is a true red mahogany tree. Fresh wood is characterized by a light yellow color, but over time it acquires a noble red-brown tint. The rock is easy to work with, but is difficult to grind. Central American mahogany is used for the manufacture of expensive furniture, parts of various musical instruments, as well as in the decoration of luxury interiors.

Meranti is a porous wood, light pink in color. After filling the pores and carefully polishing, meranti products are characterized by a long service life. The breed is used to make furniture, stairs, window and door structures.

Merbau is a hard and heavy wood, characterized by a coarse, uniform texture. It is used in construction work, for the manufacture of furniture, equipment and turning products. Sometimes decorative panels are made from merbau wood for interior decoration.

Myrtle root is a trade name for high-quality veneer that is produced from growths (burls) on a tree trunk. Such growths rarely occur, so the material is considered especially valuable. Natural burl myrtle veneer is used in cabinetry, furniture production, and is also suitable for the manufacture of expensive veneer. Myrtle root is easy to process and polish.

Movingu - this species has moderately hard and heavy wood, which is easily processed by hand and on machines. Used for interior carpentry, for the manufacture of flooring, in furniture and cabinetry production.

Olive is a light yellow-brown wood with characteristic brown marble stains and is highly decorative. Difficulties in processing arise due to frequent changes in the direction of fibers in the structure of the wood. After polishing, the olive board gives a wonderful smooth surface. It is used in the production of veneer, for making furniture and in finishing work.

Alder is a light and soft wood, easily processed (except for drilling) and painted, taking on the appearance of more valuable wood species. Thanks to this property, craftsmen willingly use alder to make furniture facades, doorways, portals and arches.

American walnut (black walnut) grows almost everywhere. The wood is brightly colored in rich shades from chocolate to black. The moderately hard and durable rock is ideal for making furniture and for interior finishing work. Used in the production of decorative veneer.

Far Eastern walnut is a fairly hard species, resistant to deformation and cracking during the drying process, but easy to process and polish. Widely used for finishing work and the production of furniture sets.

European walnut is a hard wood that is resistant to deformation and cracking during the drying process. Easily processed by various types of tools. European walnut wood can have several color options, from gray-straw to smoky-brown. Widely used in finishing works.

Walnut - root - wood obtained from sections of the root part of the European walnut. This material is dense and durable, characterized by high decorative properties. Widely used in finishing works and for the production of veneer.

Ofram - the wood of this species looks very impressive, and therefore is often used in the production of decorative veneer and high-quality plywood. Separate parts of the dark core are used in inlays, and lighter wood is used to make furniture.

Paduk is a particularly resistant wood, but is easy to process. Due to its beautiful texture, the species is most often used for making furniture, parquet flooring, carvings and knife handles, as well as in the production of veneer.

Brazilian rosewood is a hard, dense and heavy wood characterized by high decorative properties. Thanks to this, for 200 years, Brazilian rosewood has been used in cabinetry, for cladding furniture, grand pianos and pianos.

Indian rosewood is a durable wood species that is highly decorative due to its exquisite coloring. Indian rosewood is used to make beautiful veneer that is used to decorate luxury interiors. The wood is also used in cabinetry and furniture making.

Sycamore is a reddish-brown wood with an exquisite speckled lace pattern. In many respects, the species is similar to oak, but plane tree is less durable. The wood has a fine texture and can be easily processed with various types of tools. Plane trees are used to create magnificent mosaic panels and many types of artistic and decorative items. "Lace wood" is used as a raw material for the production of decorative veneer and in interior decoration.

Rosewood - characterized by dense and hard wood of a beautiful violet-red hue with bright orange touches. The breed presents certain difficulties in processing, but allows you to obtain a high-quality finish. Due to the unique color of the wood, rosewood is of particular value. Used in turning and cabinetry work, in the design of stylish interiors. Rosewood is used to produce parts for musical instruments, artistic and decorative items, and mosaics.

Sapele - wood has a clear pattern of uniform stripes of reddish-brown color. The fiber structure is very dense. Sapele is heavier and harder than African mahogany wood, one of the most valuable types of materials in the wood industry. Despite its durability, the rock can be easily processed with various types of tools and is easily polished. It is used as a raw material for the production of lumber and decorative veneer, as well as for the manufacture of furniture and flooring.

Sequoia (California redwood) - the wood has a soft red or reddish-brown color. The contrasting pattern of tree rings creates a stunning effect. Sequoia wood is heavy, dense and resistant, but in all respects it is inferior to pine. The rock is not difficult to process, but requires caution due to the possible splitting of fibers. The wood is characterized by its durability, which is why sequoia is used to make roofing parts and various elements of exterior decoration. The breed is also used in the production of decorative veneer and plywood. Sequoia can also be used for interior finishing work.

Pine - has a pleasant wood color from bright cream to yellow. The rock is moderately hard, but dense and durable. Easy to machine. Widely used in construction work, in the production of plywood and veneer, as well as for the manufacture of furniture and joinery.

Tigerwood (tiger wood) - durable and dense wood is characterized by exquisite coloring in the form of violet-brown inclusions on a light yellow or pink background. It is easy to process, and after sanding it gives a surprisingly smooth surface. Due to its antiseptic properties and ability to resist insect pests, the breed is used in shipbuilding. Tigerwood is used in finishing luxury interiors and in cabinetry.

Teak is considered one of the most valuable wood species. The color of the wood is light brown with characteristic dark inclusions. The breed is moderately dense, strong, durable and at the same time easy to process. The scope of application of teak is extensive: production of lumber, plywood and veneer; manufacturing of furniture, flooring and cladding panels; high quality carpentry work, etc.

Tineo - has a bright wood color in red-brown tones of varying degrees of intensity. A distinctive feature is the presence of dark, uneven strokes that create a unique pattern. The breed has a medium degree of resistance and strength. In terms of processing complexity, it is similar to birch. Tineo wood is used for carpentry work of any complexity. It is used in the production of decorative veneer for facing work.

Poplar - wood color from beige to light brown. The breed is relatively strong and durable. It is processed quite easily, depending on the variety. Sands and polishes well. Poplar wood is best suited for carpentry and decorative veneer production. An unusual and very impressive texture is obtained from veneer, made from growths on a tree trunk.

Thuja - root - woody mass obtained from growths (burls) on a tree trunk. For thuja, the appearance of growths is a fairly rare occurrence, so the resulting material is considered especially valuable. The structure of the burl thuja is distinguished by the presence of small knots and curls, which form a unique, spectacular pattern. The wood is soft and can be processed well. During processing it emits a pleasant aroma. Thuja - the root is used to make small pieces of furniture, souvenirs, decorative items and boxes.

Framir - the color of the wood is monochromatic, light yellow or pale brown. The breed has an average level of strength and durability, and is easily processed with various tools. Framir is used in construction and finishing works, used for the manufacture of floor coverings and window frames.

Ceder is the trade name for Central American Cedar. However, cedar is a deciduous species and has nothing in common with coniferous species. The wood is characterized by a pleasant pinkish-red or red-brown tint. In terms of strength, cedar is slightly behind red mahogany wood. Used for the production of decorative veneer and plywood. Zeder is ideal for making furniture, blinds, musical instruments and parts for small boats.

Ebony - The color of the wood varies from rich black to brown shades with a striped pattern. The breed is very heavy and resistant, difficult to process. Due to its high decorative value, glossy black ebony wood is used to create inlays and mosaics, make artistic and decorative products and musical instruments.

Eucalyptus - the color of wood can vary from golden-yellow to pink-ocher shades. The breed is characterized by insufficient resistance. It lends itself well to various types of processing and gives a smooth surface during polishing. Eucalyptus wood is used to make furniture and flooring, and is also used to produce veneer.

Eucalyptus pomele is widely cultivated in many countries due to the high cost of the wood and its exceptional aesthetic value. The growths on eucalyptus wood do not appear in the form of individual burls, but are a characteristic feature of tree growth, in which the burl texture appears due to the wavy structure of the fibers. Burls rarely appear in eucalyptus trees, so this type of wood cannot be used in mass production. The breed is easy to process, but is not highly resistant. Eucalyptus pomele is used to make flooring and furniture, and is also used in construction work and in the production of veneer.

Jacaranda (jacaranda) is the trade name of the Dalbergia nigra tree, the wood of which has high decorative properties. Its color has many variations - from violet-brown to chocolate shades with dark veins. The wood is hard, dense and heavy, with an oily appearance. During processing it releases a pleasant aroma. Due to its hardness, the rock is difficult to process, but for more than two hundred years it has been considered one of the rarest and most valuable materials in cabinetmaking. Jacaranda is used to make decorative veneer, which is used for cladding furniture, grand pianos and upright pianos. Jacaranda wood is used to make inlaid parquet, artistic and decorative items, parts of acoustic instruments and knife handles.

Yarra is the trade name for Australian eucalyptus wood, which is characterized by a rich red-brown color. Yarra is used in shipbuilding, furniture making, flooring, and window frames and doors.

Ash - about 60 varieties of this species are used in the woodworking industry. The wood is characterized by a very beautiful texture, strength and flexibility. Ash is widely used for the manufacture of bent and carved furniture, parquet flooring and various interior elements.

White Ash - Ash wood is almost identical in strength to oak, and has even greater resistance to longitudinal splitting. The breed is strong, durable and dense. At the same time, there are no difficulties in processing both manually and on a machine. White ash is used to make beautiful bent furniture, as well as various interior decorative elements. Beautiful light ash wood is used in the production of decorative veneer, which is successfully used in interior decoration.

Far Eastern ash (Manchurian) - the wood is hard, strong, viscous and elastic, and has a pronounced texture pattern. The breed is very wear-resistant and durable. Far Eastern ash is easy to process and polish. Solid ash wood is widely used for the manufacture of furniture, joinery, in the production of plywood and veneer, as well as in shipbuilding.

Jatoba is a dense, durable and hard wood, superior to oak in many mechanical properties. Jatoba is difficult to process and polish, but all products are characterized by high wear resistance. It is used for the manufacture of expensive furniture, as well as for covering floors and stairs.

Of course, this is not a complete list of all tree species that are used for making furniture, carpentry, interior decoration and the production of modern materials. However, the wood of the above species is the most valuable, in demand and popular among consumers.

Features of preparation

Choosing wood is the initial stage. After the master has decided on the breed, he will need to prepare the material. This measure is necessary in order to prevent early damage to the product and deformation. How to prepare wood for carving, what methods exist?

The main method is drying. This procedure helps remove excess moisture that accumulates in the wood. It is optimal if the material is dried in fresh air. It is important to reduce humidity to a level of 15–20%. The drying procedure itself can take a long time - several months if the workpieces are large.

As soon as the humidity reaches the required levels, the wood is brought into the room (away from heating devices). This is necessary in order to further dry the fibers of the material. It is advisable that the moisture content in the workpiece does not exceed 8–10%.

How to prepare wood for carving using alternative methods? Masters can use the digestion method. This method is suitable for preparing small-sized workpieces. To do this, they are placed in boiling water, boiled over low heat for several hours. This procedure helps to quickly and effectively eliminate intracellular moisture in the fibers of the material. After such heat treatment, the workpieces must be dried for a week (on average).

If you don’t know what kind of wood is suitable for carving with chisels, or how to properly prepare the material, but at the same time you want to become the owner of original products, the craftsmen will help. Our specialists are experts in the production of unique carved furniture, souvenirs, and figurines that connoisseurs of exclusive items can order.

Wood carving materials

Wood carving is rightfully considered one of the most ancient arts. In the most ancient times there were masters in this art. Wood carving reached a particularly high development in Kievan Rus, where the facades of all houses were decorated with carved elements. Fortunately, materials for wood carving grew everywhere. At that time, skill in this matter reached its peak. It was wood carving that gave Kievan Rus its special unique style. Some secrets of the masters of that time have been lost, others, on the contrary, have been carefully preserved by masters of many generations. Many of the secrets concern carving materials. What types of wood are best for the job? How is wood prepared for work? How old should a tree be for its wood to be of the best quality? What should the wood moisture content be?

Wood selection

Not every wood is suitable for cutting.

Therefore, its choice is a crucial stage, which determines such points as:

- Ease of processing the workpiece;

- Ability to make complex patterns;

- Durability of the finished product;

- Appearance of the product.

It should be noted that there are no clear instructions on the choice of material, since experienced carvers use different wood for different purposes. However, there are some general rules that must be followed. Next we will take a closer look at them.

Breed

So, in order to choose the right material for wood carving, of course, first of all you need to pay attention to the type of wood.

Since ancient times, hardwoods were most often used for carving, such as:

- Linden is the most popular among carvers, as it lends itself well to processing with a chisel. Moreover, thanks to the fine-fiber structure, which is unique to this breed, it allows you to create complex and delicate designs. In addition, carvers are also attracted by the appearance of linden, namely its even white color.

Cutting board made from aspen

- Aspen has a homogeneous structure, however, it is rarely used for artistic carving. This is due to the fact that aspen has a greenish tint that is resistant to external influences. Therefore, this wood is often used to make all kinds of small kitchen utensils with your own hands, such as spoons, bowls, cutting boards, etc.

The photo shows an example of alder carving

- Alder is widely used by carvers. Experienced craftsmen use its ability to change color for their own purposes. The fact is that freshly cut alder is white, but if it is left in the fresh air, it will turn red very quickly, after which it will begin to turn pink until it acquires a light pink tint. If alder is insulated in time, you can get the desired color.

Birch carving

- Birch – has a pale yellow tint and a viscous, homogeneous structure. Maple is similar in color to birch, however, it has a beautiful texture and high hardness. This wood is more difficult to process, but the products made from it are very durable. Therefore, since ancient times, spoons and other utensils made of maple were valued much more than those made of linden or birch.

- Oak is an ideal material for making wooden utensils, spoons and other products. The only drawback of this breed is the high price and difficulty of processing.

Advice! If you are a beginner, it is best to start with sugar pine or American basswood, as these species are the easiest to process.

As for conifers, they are too soft for these purposes, however, in some cases they are still used.

For example, if you need to get a special color or texture that hardwood cannot provide, use:

Walnut carving

Note! Carvers often use not only the wood itself for carving, but also burls or suvels - these are growths that are found on a tree trunk. Their main feature is their varied, intricate texture.

Example of a carving blank

Wood qualities

In addition to the type of wood, there are a number of other factors that influence the suitability or unsuitability of using a material for carving. These factors include:

| Options | Requirements |

| Humidity | It largely depends on the area of application of the carved product. For example, for external threads the humidity should be 15 percent. If the product is located indoors, then the workpiece must be dried to 8 percent. In some cases, for example, absolutely dry wood is used for ornamental carvings, i.e. 0 percent. It should be noted that freshly cut wood is completely unsuitable for carving, as over time it deforms and cracks. |

| State | Some growths, knots and other inclusions can significantly spoil the work or lead to certain problems. For example, twisted fibers can make the tool difficult to point in the desired direction, especially when moving across the grain. Therefore, when choosing materials for wood carving, you need to carefully examine them. |

| Weight | As a general rule, the heavier the wood, the more difficult it is to work with. In addition, it should be taken into account that weight indicates the moisture content of the material - the lighter the workpiece, the drier it is. |

Advice! If you are unable to find material of the required dimensions, you can glue several boards together.

Here, in fact, is all the basic information on the choice of material. Of course, this is not all that is needed for wood carving, however, as mentioned above, the final result largely depends on the quality of the wooden blank.

Coniferous and deciduous wood

Coniferous wood is most often used as a material for wood carving.

Its advantage is resin, which is found in large quantities in wood and gives it resistance to weathering. Coniferous wood can be used at any age. It is possible to use hardwood. This is a linden tree over 70 years old, a poplar tree over 50 years old, and a maple tree over 90 years old. The wood of alder, rowan, ash, oak and other trees is also used. The wood chosen for wood carving should be good quality. There should be no oblique layers on it, there should be no knots. Only under such conditions will wood on wood not break or chip.

What is the best wood to use for carving?

I think that if you want to learn how to carve wood, it’s still better to choose a softer wood to start with. In Siberia, cedar wood is often used for this purpose. It cuts very well, and the texture of the wood itself is beautiful. So I recommend it.

Before choosing a tree for carving, you first need to decide what you want to carve; it will be a painting or small crafts in the form of roses, an ornament, a toy. Also, a lot depends on whether you are picking up a chisel for the first time, or are already a professional in your field.

Wood carving is a decorative art, thanks to which you can create beauty not only for your friends and loved ones, but also beautifully decorate your room thanks to wooden crafts, furniture, and stairs.

Very often, deciduous tree species are used for wood carving, for example, the following tree species are very popular: linden, aspen, alder. Also, very often other trees such as fir, pine, and larch are used for wood carving.

If you want to make beautiful spoons and bowls, then I advise you to pay attention to a tree like aspen, it is perfect for this work.

Aspen is rarely used for artistic carving, since this type of tree can leave behind a slightly greenish tint.

Alder is perfect for artistic painting on wood, as it can change color, and this is suitable for making beautiful paintings and framing wooden products.

Birch is also suitable for wood carving as it is a very durable and reliable wood for such decorative arts.

Maple is also suitable for carving, as this wood can be used to make beautiful decorative tabletops. Don't pass by oak if you decide to make beautiful wooden dishes or jewelry. Oak is perfect for this.

In addition to wood, they also use burls, as well as suveli, which make very beautiful jewelry.

For me, birch, oak, aspen, ash, kapo - root are closer, from which I make various wood crafts.

So it is impossible to say which wood is best suited for wood carving, since everyone has their own tastes and preferences, because a lot depends on what you want to make from wood, and what tools you want to use, and how long you have been doing it carving or just a student starting out.

Many factors influence the choice of wood for carving.

Color, texture, wood species, grade, wood density and so on.

Even the availability of a tool and the ability to work with it can affect the choice of wood.

I can give linden as an example, the material is soft and pliable, but you need experience working with this wood and a high-quality tool (especially sharp), otherwise the linden will not be cut, but will wrinkle under the tool.

In general, the wood should be “aged”, dry, without cracks and woodworms.

The texture of the wood is an important point, it can be a brightly crafted texture or a uniform one, that is, it all depends on the product we are making.

Hardness, softness, and moisture resistance are also selected specifically for a specific product.

In general, oak, beech, poplar, pine, alder, linden, apple tree, walnut, birch, larch, aspen and so on are suitable for wood carving.

The word “better” is not entirely correct here, depending on what the product is better for, if you are a novice carver and are just getting better at it, then birch is not a bad option

Birch is suitable for most types of wood carving, easy to sand, cut, etc.

In ancient times, they cut mainly from coniferous trees; each region had its own type of wood as a priority.

Why exactly coniferous species, because of the resin in it, which was then used to rub the products.

Although there are many wooden products with carvings made of walnut, oak, and linden.

Masters in books on applied arts also advise using coniferous species, but also give preference to some deciduous species, but with certain conditions:

- linden - must be over 70 years old

- poplar - must be over 50 years old

- maple - must be over 90 years old

- oak - must be over 70 years old

In addition to these four species, rowan, alder, oak, ash and others are also used in Russia.

Of the foreign wood species, ebony is famous, which in our country is better known as black.

The fashion for carving from American cherry came from America.

In the south, craftsmen use fruit trees such as peach, bird cherry, apricot, plum and almond.

Here is this ebony pig:

Only over the years, having worked with several types of wood, will the master tell you exactly which wood is the best for carving. Each variety has its pros and cons. When choosing wood, you need to take into account the age of the tree; it must be uniform, without oblique layers, without knots, well and properly dried.

Soft wood species (linden, birch, and aspen) are easy to cut. Good crafts are made from birch wood; it can be cut both along the grain and across it.

For beginners, it is recommended to learn carving on coniferous trees: juniper, spruce, and deciduous trees: birch, alder, linden, ash, aspen, pear.

We were doing wood carving. I believe that the best option for wood carving is aspen. Many craftsmen make platbands from aspen, with elements of wood carving. Aspen is most suitable for fine, openwork carvings. Well, if there is no aspen, you can use alder or birch, although aspen is the best option in terms of its structure.

Material

Different types of wood are used for wood carving. The choice of one or another species depends on the purpose and shape of the item being decorated and the type of carving.

Of the deciduous trees, linden is often used for carving. Linden wood cuts easily and cleanly, but is slightly susceptible to cracking and warping. Due to its low hardness, linden is not used for making furniture; therefore, its use is limited to small household products.

Alder wood is also easy to cut, warps a little, accepts finishing well and is imitated to resemble other species, say mahogany. All this makes it suitable for all types of work.

A beautiful material for carving is birch wood. It is harder than linden and alder and is more difficult to cut, but the quality of the carving is better. Birch wood is excellently painted and finished. Its disadvantages are the ability to easily absorb and release moisture, as well as its tendency to warp and crack, which prevents its use in large products. It is allowed to make unprofitable carved decorations and parts of furniture and other products from birch.

For carving small items - dishes, souvenirs - poplar and aspen wood is used.

Oak has long been used for huge decorative carvings and carved furniture. Oak carving is difficult and time-consuming due to the high hardness of the wood and its tendency to chip, but it is very colorful and decorative.

Beech wood is close to oak in hardness, but it chips less because it is more homogeneous. Beech can be easily painted with aqueous solutions of dyes and finished. Beech is used mainly for small carvings.

Walnut wood is an excellent material for carving work. It cuts amazingly in all directions, rarely chips and allows you to perform the most precise carvings. The walnut wood is beautifully finished and exceptionally polished. It is used in the manufacture of furniture, both for carving on solid wood and for unprofitable carving in combination with other species. For highly artistic carvings of small shapes and sculpture, walnut wood is also considered the best material.

Wood products

Ancient products made by wood carvers have long become antiques and have acquired enormous value. But even now many wooden products are part of our culture. Wooden spoons, wooden dishes, carved wooden furniture, inlaid wooden frames and mirrors. Russian-style wooden souvenirs are very popular.

Wooden boxes and wooden toys are highly valued. At the hand of the master, rough materials for wood carving are transformed into artistic panels and interior sculptures. In many villages in Russia, houses in the villages are decorated with carved decorations.

Preparing wood for work

Materials for wood carving must be well dried, humidity 15% or lower. If you carve on wet wood, the product, when it dries, will begin to crack and warp. Dry wood is more difficult to cut than wet wood, but products made from it are more durable. Working with wood requires a very sharp, well-sharpened tool.

There are hard and soft woods. On hardwood, the carvings are cleaner, even with less sharp tools. The bars used as materials for carving can be either radially or tangentially cut. With a tangential cut, the wood texture is more beautiful. And although in this case the wood resists the wood artist’s cutter more strongly, most craftsmen choose a tangential cut.

The beauty of the texture should be taken into account when coating wood with varnishes. It’s good when a beautiful texture shines through a layer of varnish. Soft woods are impregnated with a special composition. Canned. They are most often impregnated with anti-rot compounds.

It is not recommended to sand the workpiece with sandpaper. Abrasive grains enter the wood structure. Subsequently, when processing wood, the tool quickly becomes dull. This reduces the quality of work and slows it down. The wood needs to be cleaned using scrapers.

Choosing wood for wood carving

Specialists have to work with different materials for wood carving. And in addition to the objective characteristics of the varieties, there are also subjective assessments of the master. Therefore, to find your optimal option, you have to experiment.

- Pine. It has straight-grained wood with a yellowish tint, powerful and with a medium degree of drying out. It is easy to work with if the wood is not particularly resinous; it is excellent for gluing, but is not particularly convenient for finishing and painting. Almost unsuitable for small-relief carvings. But it is also used for carved decoration of buildings.

- Larch. Wood with the highest qualities. Heavy and durable, not the easiest to work with, but very durable. It will not rot from dampness. But more often it is used for building houses and making parquet.

- Tiss. Sound rock, its interior is dense and heavy, practically not rotting. A good choice for carpentry and turning needs. It is classified as a “red” breed.

- Juniper. And this is already a very interesting breed for carvers. Heavy and hard wood dries out little, it is not afraid of rotting, and retains a pleasant aroma for a long time. Excellent when cutting, good in touch-up and easy to polish. Dried juniper is considered an excellent base for carpentry. Wood is a suitable choice for fine flat-relief carvings, as well as for volumetric carvings.

- Cedar. Its structure is close to pine wood, which is why it is in demand in carving. Thus, wood looks advantageous in polished smooth products, in various kinds of crafts decorated with contour carvings.

- Oak. Dense wood with an elegant structure, medium drying and low cracking. Oak has to be processed with considerable force and with the help of high-quality, well-sharpened tools. Its wood is often used for carving and turning, and for mosaic operations.

- Bird cherry. Heavy and strong wood, it is afraid of moisture. If the tree is young, it will be white, if old, it will be reddish-brown. The material must be dried carefully. Bird cherry is distinguished by excellent cutting in all directions. This tree has always been actively used by woodcarvers.

- Apple tree. This tree has a hard, heavy material with a uniform structure. It is not easy to dry an apple tree, as it dries out a lot, but after drying it does not warp or crack. Wood behaves well in painting, sanding, polishing and glazing. Apple tree material is almost ideal for fine carving of mini-sculptures.

- Hazel. The material is simply excellent for small carving operations. Chess pieces have long been carved from hazel, as well as pencils and handles.

- Aspen. Soft, delicate wood, lends itself well to cutting with a chisel. It is used to make lightweight toys, dishes and various decor that can be decorated with carvings.

- Rowan. The reddish-brown base is not easy to process; it is strong and heavy. But for turning and carving operations, a dense and homogeneous composition is quite suitable. It was previously used for carving and chiselling crafts. Rowan root is considered an excellent preparation for sculpture.

- Alder. It is also used for carving work, and also for simulating more noble types of wood.

Separately, it is worth mentioning about birch . This is wood of medium hardness and density, its structure is uniform. It is easy to cut in different directions, drills and polishes well. But the material also has some disadvantages: birch has a high risk of cracking, warping and shrinkage. It is susceptible to wormholes and rot.

And, of course, maple - dense, bright and highly durable wood serves as the optimal basis for carving operations. Especially for applied threads.

More detailed information about wood can be obtained by watching this video: