What is flaxseed oil

The modern building materials market offers a fairly wide range of protective compounds for wood. Many of them surpass linseed oil in their technical characteristics. But the latter does not give up his positions. The reasons are the environmental friendliness of the material, high antiseptic properties, plus the ability to emphasize the natural texture of the wood.

The advantages include properties such as filling microcracks that form between the fibers. And it is known that it is in cracks of this type that moisture accumulates, which reduces the quality of the tree itself. At the same time, linseed oil, penetrating deep into the wood structure, increases the elasticity and plasticity of the top layer. And this is protection against the formation of microcracks.

Linseed oil is an excellent water-repellent layer Source impra.de

The resulting protective film is an excellent water-repellent layer. At the same time, the molecular structure provides high adhesive properties. That is, the oil easily lays on the wood without peeling off from it. Let us add that after drying, the formed film does not support combustion, which is an important quality for finishing wooden products and structures. And another plus is low consumption. On average 60 g/m². Of course, taking into account the multi-layer application, the material consumption increases. But this depends on the porosity of the wood. The softer and more porous it is, the greater the oil consumption, because it is absorbed and fills the pores.

The flax impregnation itself is obtained by squeezing flax seeds. Technology can be cold or hot. In the first case, the seeds are simply pressed. In the second, they are first exposed to temperature.

There is a certain classification of this material depending on the amount of impurities in it:

- refined with the amount of impurities up to 0.05%;

- unrefined with the amount of impurities in the range of 0.05-0.15%.

It is the second one that is used for processing wooden structures and products.

Processing wooden products with linseed oil Source ytimg.com

The market today offers two modifications of this material: pure oil without additives and with additives. The latter type is called drying oil or impregnation. The second differs from the first in that the oil undergoes a heat treatment process, and then chemical additives are added to it. The latter are necessary in order to reduce the polymerization time of the material. In ordinary words - the drying process. Sometimes drying oil is called boiled oil or boiled oil.

Treating wood with flax oil is a simple process. But it is necessary to take into account the low polymerization of the impregnation. Firstly, the protective material is applied in 5-7 layers, depending on the porosity of the wood. And each layer can dry for several days, which increases the time for carrying out protective measures for the tree. Secondly, the impregnation is actively absorbed into the wood structure, hence the number of layers.

Thirdly, linseed oil that has penetrated deep into the body of a wooden structure takes a long time to dry. And the surface layer quickly. Hence the oil stains that constantly appear on the surface. Fourthly, the dried material is afraid of mechanical stress. That is, it has high abrasion. Scratches also often appear on the treated surface.

Attention! The oil layer dries well in the sun. This only takes a few hours. But the material becomes darker from sunlight. Not everyone likes this.

Treating a wooden floor with linseed oil Source allegroimg.com

See also: Catalog of companies that specialize in paints and finishing materials and related work.

In this regard, drying oil is better. It is practically not absorbed into the wood structure, leaving a durable film on the surface. Quick drying is another important advantage. And thirdly, even under the sun, drying oil does not darken. By the way, it dries within 24 hours if the temperature is within +20C and the air humidity does not exceed 80%.

Despite a fairly large number of shortcomings, craftsmen still use linseed oil to impregnate wood. It is used to treat external and internal surfaces of wooden walls, ceilings, wooden dishes, furniture, windows and doors, toys, etc. Products and structures made of valuable wood species are especially impregnated with this type of oil. In this way, the natural qualities and properties of expensive wood are preserved for a long time.

Impregnation of wooden furniture with linseed oil Source roomester.ru

Flaxseed oil and drying oil. It is the same?

In short, no. Flaxseed oil and natural drying oil have the same base, but these are two different compositions with very different characteristics. Now let's talk about everything in order.

Linseed oil

– a natural substance obtained by cold or hot pressing of flaxseeds. Pure oil can be used as a stand-alone finishing coating, but in its untreated state it is ineffective due to its low polymerization (drying) ability.

Natural drying oil

is linseed oil modified by heat treatment. Therefore, drying oil is often called “boiled” or “boiled” linseed oil. Drying oil also contains a small proportion of driers - chemical additives that accelerate the polymerization process.

Important! This article is about natural linseed oil.

. This is a formulation that consists entirely of processed natural flaxseed oil and contains no solvents. The share of oil drier here should not exceed 3%. This is important to know, since along with natural compositions there are synthetic drying oils.

Rules for applying linseed oil

Like most construction processes, impregnation of wood with linseed oil is divided into two stages: preparation and application itself. Processes included in preparation:

- sealing cracks and cracks with repair compounds;

- primer, preferably alkyd;

- surface grinding;

- dust removal, preferably with a compressor, that is, a stream of air under pressure;

- cleaning - usually treated with white spirit;

- If a log house is treated with linseed oil, it is pre-treated with an antiseptic.

Attention! Wood moisture content should not exceed 15%. Otherwise, linseed oil will not be absorbed into the structure of the product and will take a long time to dry.

Applying oil with a swab Source ales-spb.ru

Video description

The video shows the process of treating wood with linseed oil:

Today, manufacturers offer a wide range of mineral oils for wood based on linseed components. They are classified as professional impregnations. They differ from pure oil by additives. Usually these are wax, resins, plasticizers, antiseptics, fire retardants, drying accelerators, pigments, etc. These impregnations are classified into two groups: for external and internal work.

Impregnations with the addition of wax are especially popular among craftsmen. This is actually a high quality material among its kind. They are usually used to treat the surfaces of wooden structures that are subject to intense loads. For example, stairs, floors, doors and some types of furniture.

And one more point that can be attributed to the advantages of impregnations of this type. Wood coated with linseed oil wears out over time, loses its original color, and scratches and other minor defects appear on the surface. These shortcomings can be easily corrected. To do this, the old treated surface is sanded with fine-grained sandpaper and a layer of oil is applied. The latter will hide all the unpleasant moments and give the wood a new attractive appearance.

Restoration of old furniture with linseed oil Source wp.com

Waxing technology

To work, you will need tools: sandpaper with different grains, a construction knife, a brush, a stiff brush, a soft cloth.

If the wood is processed for the first time, the wax material is easily distributed on the surface and is well fixed to it. Before applying wax or oil mixture to a previously painted surface, it is prepared.

Cleaning phase

The old coating layer is thoroughly cleaned from the wood.

- Begins with solvent treatment . A layer of paintwork or varnish is impregnated with an organic liquid. After this, the residue is removed quickly and easily.

- Leave the treated wood for a while to allow the solvent to evaporate.

- The wood is wiped with water at room temperature and then dried.

- Poorly removed paint residues are removed with a knife. The surface is protected with sandpaper. Remove paint from cracks with a brush.

Smooth wood is ready for waxing.

Useful video on the topic:

Application stage

Only dry products can be waxed.

- The mixture is distributed with a soft cloth, moving from the central area to the edges, corners, and curly elements.

- The liquid consistency composition is applied with a brush.

The hand moves in the direction of the fibers. Otherwise, the material does not fit well and is fixed on the surface. Soon the coating will peel off.

- The coating is left to dry when all the wood has been treated. In a dry and warm room, the layer will dry within an hour.

- By lightly touching an area hidden from view, you can check the degree of drying.

- Excess wax material (it is poorly absorbed even after the entire surface has dried) is removed with a cloth. These places are wiped with light movements.

Repeated application of wax or oil mixture will make the decorative surface even more beautiful.

At the finish the surface is polished.

Interesting video on the topic

Polishing

A special device with an electric drive is used. A rotating shaft connected to an electric drill quickly polishes the treated wood.

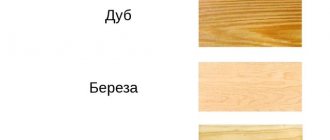

To preserve the natural appearance of the wood, it is covered with a transparent wax material. Toning is performed with a color composition. It is necessary to take into account the type of wood and the desire of the owners to obtain a specific shade of its surface. For example, brown and black impregnations are applied to dark oak. Wax in shades of the same color is applied to mahogany.

Other types of oil impregnations

Linseed oil for impregnating wood is not the only thing that manufacturers offer. There are other varieties.

Tung oil

This ancient product is known as a protective impregnation for wood against various bugs, rot and moisture. Therefore, in the old days they treated not only floors and walls, but also furniture and wooden utensils.

Today, tung oil is sold in all hardware stores and is in demand. The method of application is practically no different from linen. Namely:

- application is possible at temperatures not lower than +15C; at low temperatures it thickens, which complicates the impregnation process;

- the material is applied with a brush, then allowed to sit for about twenty minutes and rubbed on the wooden surface with a sponge, evenly distributing it over the entire area;

- It is allowed to dilute the oil with white spirit up to 40%, this increases the absorbency of the material.

Tung oil for wood processing Source nojinsk.ru

Features of materials

- Veneer is a thin sheet of wood, its thickness is 0.4–1 mm, and the length depends on the type of wood and the processing method. There are three types of material: sawn, planed and peeled.

- Plywood is a board glued together from several sheets of veneer. Most often, the number of layers is odd (3, 5, 7). On the outside there are layers of higher quality wood, and on the inside there is peeled veneer from scraps.

The procedure for making materials has been improved over many centuries; today the industry offers 6 grades of plywood and 6 grades of veneer, suitable for a wide variety of jobs. But it was not possible to get rid of one drawback of these materials.

Today, veneer can be made in different colors, textures and qualities; oil is suitable for processing any type

Veneer and plywood are porous and quickly absorb moisture, so they require additional protection from getting wet, mold and destruction. Oil compositions cope with such tasks perfectly - they create a beautiful colored (if necessary) film on the surface, strengthen the internal structure and improve the tactile sensations from contact with the material.

Briefly about the main thing

Linseed oil is used to treat wooden surfaces to create a moisture-proof film and cover minor defects.

Apply the oil to the prepared surface: sanded, clean and dry.

For application use brushes, rollers or sponges.

To treat large surfaces, use a spray bottle. The main task of the work manufacturer is to apply the material evenly.

In addition to linseed oil, manufacturers offer tung, teak and tar oil.

Ratings 0