Today, various construction processes, decoration and finishing works are very difficult to imagine without the use of moisture-resistant wood-based panel materials. It is moisture-resistant plywood that allows you to solve many problems during these works due to its high technical characteristics, resistance to moisture and reasonable price.

Peculiarities

Moisture-resistant plywood consists of several sheets of veneer glued together. Their number depends on the required slab thickness. Plywood has significant strength due to the fact that the direction of the fibers in the veneer sheets is mutually perpendicular. A high level of moisture resistance of the product is achieved through the use of special glue based on synthetic resins.

Moisture-resistant plywood can withstand exposure to moisture for a long time due to its dense structure, high quality wood and strength of joints. All types of moisture-resistant plywood correspond to an operational humidity of 80%, which is suitable for interior work.

From us you can buy moisture-resistant plywood at the manufacturer's price.

Labeling nuances

At woodworking factories, the standard marking method has long been sticking labels on which all the information about the material is written.

Special signs and barcodes provide the buyer with all the necessary information. Special signs, which include the company’s trademark, transportation rules, etc., are pre-copied onto the label in the form of a preprint. In production, marking makes it possible to keep records and control the movement of material at all stages of production.

Characteristics of plywood.

The classic designation for plywood includes:

- Name.

- The grade of wood from which the exterior veneer is made.

- Compatibility of outer layers specified in GOST.

- Emission type.

- Surface treatment method.

- Sheet dimensions.

Sheets can have several grades, it all depends on the presence of veneer defects. Each variety is marked with letters that show the side of the shirt. Each grade of veneer used for the production of shirts is marked with a letter designation, type A, B, and so on.

A/AB. In this fraction, the numerator shows the front part of the veneer, the denominator shows the back part of the shirt. The average value is marked with numbers.

This material is very widely used in industry, as it has high manufacturability. Plywood is used for installing partitions, installing load-bearing structures, and so on. Moisture-resistant plywood is used when it is necessary to make formwork during concreting operations.

Scope of use

Various brands of moisture-resistant plywood are used in different areas of human activity. Most often it is used in construction. Depending on the moisture resistance grade, slabs are needed for the following purposes:

- Moisture-resistant plywood for interior use is usually used in interior decoration.

- The reasonable cost of moisture-resistant plywood and its aesthetic appearance make it possible to use this material to create decorative elements.

- You can also buy moisture-resistant plywood for laying various floorings and subfloors.

- The thickness of moisture-resistant plywood allows it to be used for cladding walls, roofs and other building structures.

You can buy moisture-resistant plywood in Moscow at retail for the manufacture of a fishing boat, which will be stored dry, for the production of garden furniture, as well as all kinds of auxiliary elements for household use.

Special aviation waterproof plywood is in particular demand, which can be purchased from us. It is made from high quality birch veneer and is characterized by increased strength and low density.

Birch plywood

Birch plywood is used in conditions of increased load, where it is necessary to take into account the strength characteristics of the material. Waterproof FC plywood is made mainly from birch. Due to the high physical and mechanical properties of birch in combination with the multilayer structure, birch plywood is very durable. This property is highly valued in construction, automobile and carriage building, as well as in other industries where the strength of the material plays a decisive role. Birch plywood is also used in the manufacture of containers and packaging. Also, birch plywood has warm shades and a beautiful wood structure, which, along with excellent surface quality, have made it popular in furniture production, interior and exterior design.

Differences between moisture-resistant and waterproof plywood

Moisture-resistant plywood, the price of which is quite reasonable, is somewhat different from water-resistant boards. Thus, any glue-based plywood can be considered moisture resistant. However, water-resistant products can withstand exposure to moisture for a longer period of time. It is more difficult to buy waterproof plywood in Moscow inexpensively, since additional materials and substances are used to produce such boards:

- it is impregnated with drying oil;

- has a paint coating;

- the slabs are puttied with PVA-based substances;

- Fiberglass can be used in the composition.

We sell waterproof plywood, the sheet sizes, price and thickness of which may vary depending on the degree of its moisture resistance. So, if you need waterproof plywood, you can buy products in Moscow based on the following moisture-resistant components:

- Urea compounds. This type of waterproof plywood, whose thickness and resistance to moisture are considered low, is the most affordable.

- Phenol-formaldehyde resins. This is external waterproof plywood (you can check the dimensions and price with our manager).

- Laminated boards have the highest resistance to moisture. From us you can buy laminated plywood in Moscow inexpensively.

Laminated waterproof plywood, the price of which depends on the use of special synthetic resins and laminates, has characteristics not found in wood products. As for the texture and appearance, they also bear little resemblance to wood.

Softwood plywood

Softwood plywood is lighter in weight. This type of plywood is made mainly from pine, the properties of which provide not only an attractive and harmonious appearance of the surface, but also excellent strength indicators with low weight, which is successfully used in house construction (wall cladding, base for floors, roof coverings, construction of partitions in residential premises and etc.). Coniferous plywood is highly resistant to rotting and fungal infection. Coniferous plywood has these qualities because the needles are impregnated with resins and are glued using phenol-formaldehyde glue. The natural beauty of the texture and colors of wood make coniferous plywood indispensable in furniture production, interior and exterior design. Coniferous plywood is used for roofing work; it will last the entire service life of the “soft” roof. During operation, coniferous plywood changes its original dimensions in thickness by 0.03%, in length and width by 0.02%.

Classification

Moisture-resistant plywood – moisture resistance grade:

- FBA are sheet products made using albumin casein glue. FBA is a moisture-resistant plywood, its moisture resistance characteristics are the lowest, but in terms of environmental friendliness the material is superior to its counterparts.

- FC is made from birch veneer. This multi-layer moisture-resistant plywood has an average moisture resistance rating. Used in interior work. It is environmentally friendly and non-toxic. The most in demand is moisture-resistant plywood 25 mm x 152 cm x 152 cm.

- Moisture-resistant plywood FSF, its price is slightly higher due to its increased resistance to moisture. For production, glue based on phenolic resins is used, as well as birch wood. The thickness of such moisture-resistant plywood is from 4 mm to 30 mm. We sell moisture-resistant FSF plywood (you can check the dimensions and price with the manager), which is used in exterior finishing and construction work. Due to toxicity, it is not used indoors.

- FOF is a moisture-resistant laminated plywood, the price per sheet of which is higher than that of previous products. We sell Finnish moisture-resistant plywood (check the price per sheet in Moscow with the manager), which has improved performance characteristics.

- FB – bakelized slabs. If you need heavy-duty, moisture-resistant plywood, you can buy it in Moscow from our company. The moisture resistance of the product is much higher due to the use of phenol-formaldehyde resins. These grades of plywood are used in the aviation and shipbuilding industries.

If you need moisture-resistant plywood, you can buy products in Moscow with the following technical characteristics:

- Moisture-resistant plywood: sheet dimensions 1220x2440 mm or 1250x2500 mm.

- The thickness of the slabs is from 9 mm to 4 cm.

- Product density is from 680 to 700 kg/m³.

- Humidity not less than 10%.

Laminated moisture-resistant plywood (you can find out the dimensions and price in Moscow from our manager) is used for the following purposes:

- Automotive industry.

- To carry out construction work.

- Car manufacturing.

- Finishing and construction work.

Bakelized moisture-resistant plywood - dimensions and technical characteristics:

- Slab length: from 1500 to 7700 mm.

- Sheet width: from 1200 to 1550 mm.

- Thickness: from 5 mm to 1.8 cm.

- Density: 1200 kg/m³.

- Humidity no more than 8%.

Combined plywood

Plywood (plywood board) with layers of veneer made from wood of various species, located symmetrically relative to the central layer. For example, Combi Twin plywood - outer layers of veneer - birch, inner layers: sublayer - birch, inside - alternating pine needles and birch. Combi - outer layers of veneer - birch, inside - alternating pine and birch. Twin - outer layers of veneer - birch, inner layers - pine. An attractive appearance along with an economical price (due to alternating layers of coniferous and birch veneer, it is cheaper than just birch plywood) make it advisable to use combined plywood in furniture production, interior decoration of premises and gyms, and design of structural solutions. Not much inferior in strength to birch plywood, combined plywood is at the same time cheaper, while simultaneously combining the best properties of coniferous and deciduous wood.

Varieties

Before writing an ad “I’ll buy moisture-resistant plywood,” you need to decide on the type of product. How much moisture-resistant plywood costs depends on this. So, according to the appearance of the outer layer, all slabs are divided into the following grades:

- Products of the first grade may have no more than 3 small knots. There may be cracks on the surface no longer than 20 cm. A slight change in the color of the surface is allowed. Before you buy such moisture-resistant plywood, check the dimensions and price with our manager.

- Second grade slabs may have knots up to 25 mm in size. Drop-out elements no larger than 0.6 cm in size are also allowed. There may also be cracks no longer than 20 cm. The color may be slightly changed. Small fragments of wood may be present.

- Third grade plywood may have loose knots, ripples, discolorations, waviness and cracks up to 0.2 cm wide and no more than 30 cm long.

- Grade 4 can contain an unlimited number of drop-out elements up to 40 mm in size. There may be multiple cracks, ripples, waviness and wood particles.

You can buy moisture-resistant plywood from us; check sheet sizes, thickness and price with the manager. To do this, you need to call the numbers listed on the website. If you need 6 mm moisture-resistant plywood, you can buy it from different companies, but our company offers the best prices and a wide range of plywood of different brands and grades.

User reviews

According to consumers, waterproof plywood is a high-quality material that is not afraid of moisture and weather conditions. They also note the high strength of the material.

In addition, ease of installation and processing is noted. You can hammer nails into the slabs, tighten screws, make holes in them, and so on. And all this does not cause any difficulties.

Among the disadvantages, consumers note the difficulty of transporting plywood. This is due to its large dimensions. The dimensions of waterproof plywood are always more than one meter. Due to this, the slabs do not fit all types of equipment. Therefore, it is necessary to look for suitable transport to transport the material.

Parameters of products from a domestic manufacturer

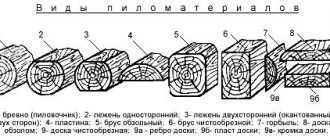

All plywood produced today by domestic enterprises is conventionally divided into materials of regular format and large-format products.

Today there are the following standard sizes (in mm):

The photo shows large-format slabs

Large format:

- 1830*1525;

- 2440*1220;

- 2500*1250;

- 3050*1525;

- 3000*1500.

Regular format slabs

Regular format:

- 1525*1525;

- 1525*1475;

- 1525*1350;

- 1525*1270;

- 1525*1220;

- 1475*1475;

- 1270*1270;

- 1220*1220.

In addition, according to GOST 3916.1-96 and GOST 3916.2, sheet plywood can be produced in accordance with an agreement between the manufacturer and the customer.

Parameters of waterproof plywood

What are the dimensions of laminated plywood? Plywood is a material around which many useful questions are asked that would not hurt to know. This suggests that this particular product is most relevant both in industrial construction and in private households.

Laminated plywood

Laminated plywood of the FK and FSF brands is a multilayer building material made using wood, mainly birch, veneer of a certain thickness. The product is manufactured in accordance with the requirements of GOST 3916.1-96.

Important: When choosing plywood for construction or renovation work, first of all, pay attention to the grade, which is determined in accordance with the appearance of the outer layers. The products of most manufacturers are divided into five grades, including E (elite grade), I, II, III and IV grade. The grade designation includes two numbers, one of which characterizes the front layer, and the other the back layer.

The dimensions of FSF laminated plywood depend on several parameters, including:

- standard sizes of veneer used;

- thickness of the adhesive layer (phenol-formaldehyde resin brand SFZh-3014);

- number of layers in a sheet.

These products are usually made using birch veneer with a thickness of 1.15-1.9 mm. Taking into account the use of phenol-formaldehyde resin SFZh-3014, which provides increased water resistance, FSF plywood is produced with sheet thicknesses: 9, 12, 15, 18, 21, 27, 30, 35 and 40 mm.

The dimensions of the standard sheet are 1250*2500 mm and 1220*2440 mm, with a relative density of up to 700 kg/m³.

Other characteristics that determine the choice

Among other characteristics of FSF laminated plywood, we note the following:

- humidity level is not higher than 10%

- formaldehyde emissions correspond to class E1;

- surface processed on both sides by grinding (Ш2)

- unpolished surface (NS)

- the appearance and strength of the surface is determined in accordance with the grade (I, II, III and IV grade).

In addition to standard sizes, the choice of waterproof plywood is significantly influenced by the strength characteristics of the outer layer and the adhesive connection:

- the outer layers have a tensile strength of wood fibers of at least 40.0 MPa;

- the outer layers have a bending strength along the fibers of at least 60.0 MPa;

- after 24 hours of soaking, the adhesive layer demonstrates a tensile strength of at least 1.5 MPa.

Among the main advantages of FSF plywood, we especially note:

- Increased moisture resistance;

- Optimal strength and wear resistance;

- Extremely tight geometric tolerances in width, length and thickness;

- The strength of veneer gluing corresponds to the strength indicators of the international standard DIN 68705 part 3 BFU 100;

- Ease of processing and, as a result, a wide range of applications;

- The plywood surface does not require protective treatment or maintenance;

- Possibility of combined use with a wide range of different materials.

Installation of plywood sheet on the floor

Installing sheet plywood on joists is one of the simplest and at the same time budget-friendly ways to install flooring.

The main advantages of this method include the following points:

- no need to level the screed;

- the possibility of laying insulation in the space between the screed and plywood;

- the result is a perfectly smooth floor covering;

- saving money and time compared to other flooring methods.

Installation on joists

When choosing material for flooring on joists, preference should be given to moisture-resistant plywood with a thickness of 15-20 mm. If the subsequent installation of linoleum, carpet or laminate is planned, it makes no sense to overpay for the high quality of the subfloor surface and it is quite possible to get by with grade 4 plywood, that is, unsanded.

Laying chipboard on joists

Installation instructions are as follows:

- The logs are installed at a distance of 50 cm from each other. For these purposes, you can use 50*50 mm timber. Columns are installed under the logs. By selecting the length of the posts, you can level the floor covering in a horizontal plane.

- Expanded clay is poured in between the lags.

- Plywood, even waterproof, needs appropriate waterproofing. For these purposes, a special film is purchased to cover the logs.

- Plywood is laid on top of the log with the sheets offset (in a checkerboard pattern).

- It is advisable to fasten the material with screws rather than nails, since as a result of mechanical stress on the coating and due to prolonged vibrations, nails can come out above the level of the plywood surface.

Tip: in order for the screw heads to be flush with the surface, it is necessary to drill holes 1-2 mm deep.

- After the slabs are laid and fixed in their final position, the joints between them are sealed with silicone sealant. Joints should not be puttied, since putty, even one intended for working with wood, can crack due to vibrations after complete drying.

Laying plywood on a plank floor

It often happens that you need to quickly and relatively inexpensively restore a wooden floor covering with your own hands before laying laminate and linoleum. In order not to disassemble the boards down to the joists, plywood can be laid directly on them.

Installation on floorboards

The technology is simple and the only problem is leveling the floor covering. If the boards in the floor structure are located at different levels, differences can be compensated by using strips of roofing felt cut to the required size.

Installation diagram for plank floors

In the event that the installation is carried out on a plank floor, it does not make much sense to use thick plywood, since slabs about 1 centimeter thick will be enough. To avoid distortions, the placement of each sheet must be checked using a water level.