Bakelized plywood is a building material consisting of layers of hardwood veneer glued together with bakelite varnish - a special phenol-formaldehyde thermoactive resin. During the process of impregnation and pressing of the layers, the pressure is increased to 6 atmospheres, and the temperature is increased to 270 C⁰. As a result, the plywood is fire-resistant, moisture-resistant and comparable in strength to low-alloy steel.

Such exceptional qualities of this building material allow it to be used in many areas of production: shipbuilding, the automotive industry, as well as in professional and private construction.

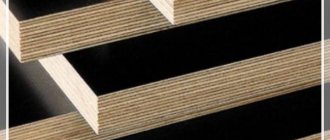

A pack of sheets of bakelite plywood, fire-resistant and moisture-resistant

Specifications

If we talk about the characteristics of bakelite (bakelite) plywood, we can especially highlight the following:

- Strength – twice that of ordinary wood;

- Water resistance - can be used in shipbuilding, mechanical engineering, etc.;

- Lightness (compared to other building materials);

- Corrosion resistance;

- Fire resistance - at temperatures above 350 C ⁰ it just chars and the smoke is not toxic;

- Resistance to temperature changes within 100 degrees (from -50 to +50 C⁰);

- Resistant to environmental conditions - fungi, microorganisms, humid/hot climates, as well as to the action of many alkalis, acids, salt water, etc.;

- Wear resistance - retains its properties for at least 10 years.

To enhance all of the above qualities, laminated bakelized plywood is produced, which has a glossy surface on both sides or on one side (so that it can be used on objects where slipping needs to be reduced).

Laminated bakelized plywood has a glossy surface on both sides

Here is a table of product parameters produced by Russian manufacturers:

| Length x Sheet width, mm | 5700x1250 2850x1250 2500x1250 2440x1220 |

| Thickness, mm | 7, 10, 12, 15, 18, 21, 24, 27 |

At the same time, laminated has other characteristics:

| Length x Width, mm | 2440x1220 2500x1250 3000x1500 |

| Sheet thickness, mm | 4, 6, 9, 12, 15, 18, 21, 24, 27, 30 |

The moisture content of bakelized wood depends on the thickness: with a thickness of 5-7 mm - 6%, 10-18 mm - 8%.

Bakelite plywood covers the floors of vans

Weight is determined based on an average density of 1217 kg/m3:

| Sheet thickness, mm | Weight of one sheet, kg |

| 7 | 25 |

| 10 | 35,6 |

| 12 | 42,8 |

| 15 | 54,54 |

| 18 | 64,17 |

| 21 | 75 |

| 24 | 85 |

Because each sheet has a certain volume, the weight of bakelite plywood relative to its density is very important, and if you know the density, you can easily choose the right brand and thickness of the product.

What is bakelite plywood?

This material is usually classified as universal, since its scope of use is not limited only to construction work. Such plywood has several common names - “aviation”, “Finnish”, “ship” or “deck”, “delta wood”.

The characteristics of this variety are close to those of low-alloy steel. Such qualities are achieved through a special manufacturing technology, which includes impregnation with special alcohol- and water-soluble resins. The resulting coating is hard and visually resembles plastic or carbolite products.

Bakelized boards (FB) are made on the basis of birch veneer, like other brands of plywood, but have the best performance properties.

The combination of peeled birch veneer with bakelite varnishes and resins produces a material with the highest performance characteristics

Material Features:

- Water resistance. The exception is options made using water-based glue.

- Immune to the influence of microorganisms. The treatment completely eliminates the threat of mold, mildew and insects.

- Wear resistance. Combined with high strength, the resulting skin is able to withstand constant severe mechanical stress and withstand sudden temperature fluctuations in the range from -50 to +50 degrees.

Such parameters allow long-term use of products in various aggressive conditions without loss of properties.

On a note! Due to the high price, slabs are rarely found in stores and are mainly delivered to order.

Varieties and brands

Bakelite plywood has two grades, depending on the resin with which the wood is impregnated:

- Bakelized plywood grade FBS contains alcohol-soluble resins (letter C);

- Bakelized plywood grade FBV contains water-soluble resins (letter B).

Bakelite plywood is widely used in construction in the manufacture of formwork.

To clearly show the methods of using various subtypes, we use a table (brands are listed in order: from the highest quality to the standard):

| Brand | Characteristics | Application |

| FBS | All layers of veneer are completely impregnated. Chips, dents or untaped areas are not acceptable. | Construction of ships, cars, stadiums, ports and other special-purpose structures that require lightness and, at the same time, the highest strength and resistance to the external environment. |

| FBS-1 | The resin is applied not by impregnation, but by coating, so the strength is lower. | Construction of podiums, stages, shopping centers, small ships, cars, etc. |

| FBS-1A | Only the longitudinal layers are coated; poor resistance to environmental influences; The advantage is the price. | Finishing works. |

| FBV | Complete impregnation of the outer layers, the inner layers are only coated. Weak water resistance and resistance to environmental conditions. | Units and connections inside machines, interior decoration of buildings, can be used in exterior work only after additional processing with special means. |

| FBV-1 | The layers of wood are only coated, without the use of an impregnation process. | Recommended for use only as a durable material, not intended for outdoor use, and without additional requirements for resistance to environmental conditions. |

It is worth noting that, despite the different properties, all varieties and brands of bakelite plywood comply with GOST 11539-83 and are subject to mandatory quality control during production and release of products, as well as certification by the manufacturer. So that the buyer does not have any doubts about the quality of the product, each sheet is marked in production - the manufacturer’s label is pressed in, as well as the designation of the grade and type. The warranty period for bakelite plywood is at least 5 years.

Areas of use

Plywood is used as a structural material in mechanical engineering, shipbuilding, and construction. It is made from:

- body parts and elements of internal equipment of cars and buses;

- details of the power set and equipment of ship hulls;

- reusable formwork for concrete work;

- light building structures, frame cladding;

- containers of increased reliability.

For the outer layers of the material, veneer of grades II and III is used, impregnation with resin gives its surface a high quality.

What does the price depend on?

The price of bakelized plywood, due to its exceptional qualities, is much higher than regular plywood, but, as professionals advise, it is better to use it.

Manufacturers of bakelite plywood in Russia, when setting prices, primarily focus on:

- Brand (since different types of resins are used);

- Reliability of the veneer used in production and its processing;

- Plywood sheet thickness and format: the larger, the more expensive.

But, you can always find the optimal price-quality ratio, for example, buying a thicker sheet will cost less than two thin ones.

Mode of application

For interior and exterior wall decoration, bakelite plywood is attached to pre-plastered concrete bases using various mastics, for example, definol.

- To ensure longer service life of plywood sheets, they are coated with special varnishes or waterproof impregnations.

- Before starting this procedure, all existing joints are covered with thin beams, and uneven areas and cracks are primed. This type of treatment helps protect the wood product, as well as the walls underneath it.

- To ensure that this material does not disappoint you, you must be very careful in choosing it. In particular, ensure that the product contains the manufacturer’s label, plywood markings, and the mark of conformity.

You can find out how boats are made from bakelite plywood in the video:

Application

Bakelized plywood is indispensable in the construction of boats, yachts, sea containers, and ship hulls. Also, it can easily be used in ports, docks, in the construction of stadiums, stages, and car podiums. Particularly noteworthy is the use in the external and internal decoration of industrial facilities, factory buildings, shopping centers, private houses, especially in unfavorable climates.

Moisture-resistant bakelite plywood is used in the construction of boats and yachts

Bakelite plywood is very popular for the production of vans, floor coverings in vehicles, as well as for the construction of garden houses, summer kitchens, and temporary shelters.

Having so many extraordinary qualities, moisture-resistant bakelite plywood can be used wherever such material properties as lightness, strength, and resistance to external environmental conditions are required. The only drawback is the rather high price, so it’s worth thinking in advance whether it’s really necessary to use baked plywood, and then carefully plan the costs.

Did the article help you? ( 16 ratings, average: 4.63 out of 5)

Bakelite plywood: sizes, characteristics, markings and prices

If bakelite plywood is to be purchased, the dimensions of the slabs have linear dimensions of 244x122 cm. A variety of technical characteristics are provided for by the different dense thickness of the panels. Based on the purpose, you can lay FBV on the floor, walls and ceiling. This will increase the level of resistance to physical and chemical stress.

Bakelite Plywood Sheet

The table below shows the main parameters that bakelite plywood has - dimensions and price are interrelated.

| Layer, cm | Number of slabs in 1m3 | Cost up to 1m3 | Price per slab from 1m3 and above | Cost per panel from 5m3 | Number of panels per package | Panel weight, kg |

| 0,7 | 48 | 1 890 | 1789 | 1756 | 58 | 2 500 |

| 1 | 33,6 | 2 534 | 2478 | 2434 | 40 | 3 560 |

| 1,2 | 28 | 3 149 | 2987 | 2987 | 34 | 4 280 |

| 1,5 | 22,4 | 3895 | 3659 | 3536 | 27 | 5 454 |

| 1,8 | 18,6 | 4 587 | 4409 | 4278 | 22 | 6 417 |

| 2,1 | 16 | 5 278 | 5078 | 4954 | 20 | 75 000 |

| 2,4 | 14 | 6 059 | 5657 | 5634 | 18 | 85 000 |

5mm bakelite plywood is very popular - sizes and prices are indicated in the table. The cost is displayed in rubles.

Bakelite Plywood Panel

Purpose and application

The material is used for the construction of advertising installations, for example, billboards. When creating cars, this type of plywood is used for laying floors and upholstery of vans. Its strength characteristics allow the panels to be used in construction. They are used for laying subfloors followed by placement of parquet or laminate.

Moisture-resistant characteristics ensure the right choice in creating formwork. Among the main advantages is the ability to uniformly distribute the temperature of the concrete composition and the external environment. This allows you to increase the quality of hardening. Many builders practice repeated creation of formwork. The coating of the slabs is even, which eliminates additional leveling after removing the formwork.

Bakelite plywood board

When cutting or drilling plywood, exposed to water, the ends and slots can be coated with protective materials:

- Enamel PF-115 (for FBV).

- Bakelite varnish (for FBS).

When varnish penetrates into the cuts, the plywood swells.

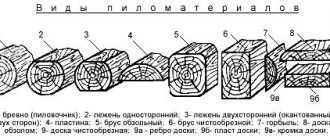

Rock massif

Birch veneer is used to make the boards. When sizing, its fibers create a perpendicular arrangement of fibers in the adjacent cut. For the outer layers of the FBS, -A, -K and -B series, veneer sheets of grade I are used. The internal placement is represented by grade II (GOST 3916.1-89). Other brands have grade II veneer inside the slabs.

Bakelite veneer series

Marking of plywood boards

- FBS. The outer layers of plywood panels are impregnated with phenol-formaldehyde alcohol-soluble resin. Internal surfaces require the application of resin. The products are used in the industrial and construction sectors.

- FBS1. Phenol-formaldehyde alcohol-soluble resin is applied to the outer and inner layers of plywood boards.

- FBV. The outer layers of the slabs are impregnated with a phenol-formaldehyde resin composition.

- FBV1. A resinous agent is applied to the external and internal layers of plywood panels.

- FBS-A. Also treated with surface application of alcohol-soluble resin. Used for interior equipment of cars.

- Fig 5 – Bakelite laminated birch veneer

- FBS1-A. On the outer and inner layers of plywood (except for two transverse layers that form a symmetrical arrangement), phenol-formaldehyde is applied from the central one.

The mass of a given number of plywood boards is calculated by the formula: number m3 x 1.1 = weight. Laminated and conventional panels are subject to calculation.

Price

The table below lists the companies that sell bakelite plywood, the sizes and prices of the sheet material, and a list of contacts for communication.

| Sheet thickness 1220*2440 mm | Price rub./sheet |

| 7 | 2 154 |

| 18 | 5 273 |

| 30 | 8 830 |

- Location:

st. Academician Kargina 25, Mytishchi - Call here:

(495) 58 877 99 - Find out more:

https://www.fantorg.ru/

5mm birch bakelite plywood on sale. Dimensions and price:

| Sheet thickness 1250*5700 mm | Cost, rub.) |

| 5 | 3 900 |

| 18 | 10 300 |

| 24 | 16 500 |

- Location:

st. Alexandra Matrosova 10, St. Petersburg - Call here:

(812) 67 653 89 - Find out more:

https://st-monolit.rf/