Modern cutting boards for the kitchen are made of wood, glass, plastic, silicone, natural and artificial stone.

They come in round, square, rectangular, in the shape of fruits, vegetables and fish. Preparing salads, first and second courses, slicing appetizers and bread is indispensable without this kitchen utensil. The laziest housewife should have at least three boards in her arsenal. Learn how to choose the right accessories, which ones to choose, what to consider when purchasing.

In this publication:

The history of wood carving

Wood carving's roots go back centuries. Many such products served as a kind of talismans; they were believed in and worshiped. Echoes of those times remain today. Beautifully made carved wooden souvenirs are available in abundance in the market. They are especially widespread in the tourism business. And in household use, carved products are in great demand.

In the old days they thought that every living creature has a spirit that controls it, this creature. There were forest spirits, house spirits, horse spirits.

To appease such a spirit and so that it would protect the horse for a year, it was necessary to make an idol (a figurine of a horse). But it had to be done only in 365 touches of the knife to the tree (how many days in a year) and while casting spells. If you make an idol in 360 touches, then the owner's horse will remain defenseless for 5 days a year. And if you touched the idol with a knife even one more time, the spells lost their power altogether.

And such an idol, shown in the picture, guarded the entire village. It was performed with 52 touches of the instrument (according to the number of weeks in a year) and placed on a high pole (4 - 5 meters) at the entrance to the village, “in order to protect its inhabitants from natural disasters, diseases and robbers.

Each family member only owned his own spoon, so it had its own distinctive design. This was done to maintain hygiene.

In this regard, you might be interested to know that Peter 1, when going on a trip to Europe, always took personal cutlery with him (spoon, fork, knife). The hosts who received the noble and honored guest were offended by this, but the king put his health first and did not want to risk it in vain.

That back in the 10th century there were workshops in Kyiv that were engaged in decorative finishing of homes and household items.

And at the beginning of the 16th century, special palace workshops were organized in the Kremlin, which marked the beginning of the creation of the armory.

In the 18th century, a large number of master carvers took part in the construction of St. Petersburg and the work of decorating palace ensembles.

Vasily Petrovich Vornoskov becomes the most famous carver. During the Soviet period, he organized several personal exhibitions in our country and abroad, created the Renaissance carving artel, which has now been transformed into the Abramtsevo Art and Industrial School, where masters of folk art crafts are trained.

In addition, Vornoskov’s name is associated with the creation of the so-called Kudrin carving, which is a type of relief carving. Wood products with a weak texture were most often painted or decorated with carvings.

Popular manufacturers

Among the popular manufacturers whose products rank first are the following companies:

- Atlantis. The products of the German company combine versatility, durability, wear resistance, and ease of use. Cutting boards are made from the following materials: high-strength steel, zinc, vanadium, molybdenum.

- Tramontina. In addition to producing various types of knives, the factory produces kitchen sets, dinner sets, non-stick frying pans and various accessories for cooking, including cutting boards.

- Joseph Joseph. The materials used are tempered glass, which is resistant to elevated temperatures. The products are easy to use, as the rubber feet prevent the products from slipping when slicing.

- Gipfel. A leading manufacturer of high-quality tableware and kitchenware. Very popular in European and Asian markets. The company designs and produces comfortable and practical products, distinguished by a strict style. The product range includes more than 3 thousand kitchen items.

- Tescoma. The country of manufacture of kitchenware is the Czech Republic. Exclusive design, high-quality materials, versatility, functionality of products meet modern quality standards. Warranty service is provided for 3 years for inexpensive products, 5 years for products that are in greatest demand among users, 10 years for prestigious models.

It is ideal if there are 4 types of boards in the kitchen, since it is not recommended to use one product to cut all the products. It is important that they fit in the dishwasher and do not deform under the influence of temperatures and moisture. It is also desirable that the boards do not require special care and have an antibacterial coating.

Atlantis

Gipfel

Joseph Joseph

Tescoma

Tramontina

Types of wood carving

There are the following types of wood carving: flat-relief, relief, geometric (triangular-notched), contour, slotted, applied, volumetric.

Geometric carving is the most ancient way of decorating wood products. Wooden ships, huts, furniture, dishes, looms, spinning wheels and much more were decorated with carvings. In flat-relief carving , a low relief image, usually of a silhouette nature, is located in the same plane as the background.

According to the technique of execution, flat-relief carving is divided into carvings with an oval contour, a cushion or a selected background. Relief carving is characterized by a recessed background and protruding image forms above it - low-relief (bas-relief) and high-relief (high-relief). Geometric (championed) carving creates a pattern embedded in a smooth background.

It is represented by two main techniques - triangular-notched and stapled. The trihedral-notched one is characterized by a pattern, while the bracketed one has nail-shaped or moon-shaped elements of the image. Contour carving is done with deepened lines on a smooth background. Reminds me of engraving. A slotted (openwork, through, kerf) thread is created by through sawing or drilling out the background.

It is a thin, light, openwork composition that allows light to shine through. With overlay carving, the cut-out image is placed on a smooth surface, which allows you to get an even background without laborious sampling. Volumetric carving usually means a small three-dimensional image - a sculpture. In carving, to achieve a bright decorative effect, different types are sometimes combined: applied carving with through carving, flat-relief carving with contour carving, etc.

Original options

Modern manufacturers offer customers unusual and multifunctional board models. There are many options. It is up to the housewife herself to decide which cutting board is best for the kitchen.

- To cut the loaf, oblong boards are made, with special slots.

- For bread, they offer round tabletops with a shelf for storing a knife.

- Products with built-in containers for chopped products and herbs are popular.

- A practical option is a multifunctional sink attachment. In addition to the cutting surface, a colander and a container with a hole for waste are built into it.

- A kitchen board-tablet that exactly resembles a brand new iPhone will help you prank your friends; it even has LED backlighting.

- Experienced cooks will love the cutting surface equipped with scales. After cutting the product, you can instantly determine how much it weighs.

- An interesting solution from the designers is a transformer board. It folds along the folds, allowing you to carefully pour out the chopped product.

For the loaf

On the sink

With scales

With container

Transformer

Tablet

Wood and its properties

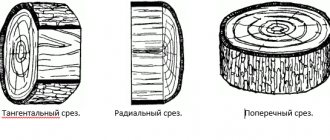

Wood is a material that has been cleared of bark and branches and is used in production.

Wood is a widely used construction and ornamental material. It has amazing properties, is easy to process, and can be used to make a wide variety of products.

Depending on the type of tree, where it grows, external conditions and processing, wood can be white and dark (almost black), light and heavy, soft and hard.

All tree species are divided into two groups: deciduous and coniferous. Deciduous trees are birch, maple, oak, chestnut, poplar, etc. Coniferous trees are spruce, pine, yew, larch. Hard wood is oak, maple, ash, larch, soft wood is spruce, pine, poplar, aspen, linden.

Wood is an elastic material. Its elasticity depends on the type of wood. In skillful hands, wood is transformed into a variety of crafts. Any wood product is made taking into account its properties, which depend on the type of wood. For example, matches are made from soft wood of aspen and poplar, coils are made from birch, parquet is made from hard wood of oak or ash, pencils are made from cedar.

Wood has a property that other natural materials do not have - splitting (or splitting). By splitting, blanks for matches, etc. are obtained.

Constantly encountering wood in everyday life, people involuntarily studied its properties and discovered more and more new possibilities of this wonderful material. It is also important that the production of wood products can be organized without much difficulty at home.

For carving, choose well-dried, uniform wood of all deciduous species without a pronounced texture (birch, linden, aspen, poplar, alder, willow, etc.).

Miniature carvings are performed on hard wood of boxwood, pear, apple, maple, hornbeam, etc.

Carving with large elements is used on coniferous wood.

To work with wood, you need to know the secrets it holds. Common tree species must be identified by their structure, leaf shape, bark, and wood.

Linden has yellowish, soft wood. Used for making furniture, wooden utensils, toys. Linden bark is very valuable, from which bast is obtained and bast is made. Easily processed with hand tools.

Aspen is used to make matches, wooden utensils, and barrels. The wood is white, soft, chips well, and can be easily processed with hand tools. The shavings are used as packaging material.

Willow has a soft, flexible, lightweight wood. Good material for making wooden utensils and weaving. Easily processed with hand tools.

Pine is a widespread coniferous tree. The wood is light. Used for making furniture, sleepers, telegraph poles. Turpentine and rosin are obtained from pine. Processed with hand tools. You can make many different crafts from pine wood.

Spruce has light, soft, resinous wood. Easily processed with hand tools. It is used as a building material, paper is made from its wood, and musical instruments are made.

Larch is used in construction. The Olympic cycling track in Moscow is built of larch. The wood is dense, heavy, fragile, and resistant to decay. Difficult to process with hand tools. Small parts crack when nails are driven into them.

Birch is a widespread tree with white, yellowish-tinged wood of medium hardness. Used for making skis and wooden utensils. A good ornamental material is birch bark - birch bark, which is removed from dried or cut down trees.

Oak has hard, heavy, light brown wood that is resistant to decay. After lying in water for a long time, it becomes black and durable, like stone (bog oak). Oak is used for making furniture, parquet, etc. It is difficult to process with hand tools.

Humanity has long learned to use natural materials. Wood provides great opportunities for the manifestation of craftsmanship. It is relatively easy and well processed.

Reasons for the popularity of end products

End boards are products made from pieces of wood glued together. They have a number of advantages that make them popular with professional chefs:

- Hygiene. The products are carefully polished and impregnated with wax. It prevents food particles from getting into the wood fibers. Bacteria also do not penetrate deep into the wood, which makes the board safe for health. Moisture and juice are well repelled from the cutting surface, it does not get wet.

- Sustainability. Often products are equipped with rubber feet to prevent sliding on the kitchen table. A heavy work surface is difficult to accidentally brush off with your hand or towel.

- Presentable appearance. End products remain smooth and shiny for a long time, without cracks, and are not subject to drying out.

- Long shelf life of knives. The blade does not dull on the vertical fibers of the wood, the board remains smooth and even after sharp cutting objects.

End products are the best cutting boards for the kitchen, but they require special care. They need to be waxed every 10-15 days; soap and detergents should not be used when washing with water.

When choosing a product from the end, pay attention to some details:

- A large number of wooden blocks are distinguished by high-quality expensive products.

- the vertical arrangement of wooden fibers will last longer than the perpendicular one;

- high-quality models are made from hardwood: oak, elm, hornbeam, ash, maple.

Tools and accessories for making a cutting board

Wood has no equal in its variety of uses. With the help of an ax, a knife and some other auxiliary tools, a person made everything necessary for life: a home, outbuildings, boats, sleighs, carts, furniture, dishes, toys and much more.

The ax was the most versatile tool. An old proverb says: “The ax is the head of everything.” But where the work was delicate, another ancient universal tool came to the aid of the ax - a knife. They planed, cut, and split wood with a knife. A good knife and ax were the master’s pride; they were treasured and even passed down from father to son.

Nowadays special carpentry tools are used for wood processing.

Sawing is carried out with saws of different design and cut of teeth. They are available for longitudinal, transverse and mixed sawing. It is better for children (junior schoolchildren) to use a small, fine-toothed hacksaw for transverse and mixed sawing.

Planing is done with various tools. There are also many of them, and they are intended for different jobs. But for now, a plane is enough for me to plan small parts.

For sawing at different angles, a device is used - a miter box , which consists of three planks knocked together in the form of a trough. Cuts were made on the vertical planks at the desired angle (45 – 50 degrees)

Marking is done with a carpenter's square and a ruler. For drilling, a brace, drill, or auger are used. Clean and sand the wood with a file or emery cloth.

Criterias of choice

Convenience, like beauty, is a relative and very individual concept. So you don't have to agree that a good cutting board is:

|

|

But some of these parameters, you see, are important to you and will help you decide on the choice of material and shape of the cutting board.

We specifically did not indicate such a factor as cost.

Everything is obvious here: you will have to fork out for a good thing, but a high price does not always indicate the same quality. To avoid mistakes, use the experience of friends and acquaintances, listen to word of mouth, reviews and our recommendations.

Bank of ideas and suggestions for making a cutting board

Cutting boards of standard and unusual, fancy shapes, natural or decorative, with classical images or futuristic landscapes - such a variety of shapes and design solutions can satisfy the character and taste of any housewife or cook. And the material for making the cutting board is selected specially. Natural wood or high-grade bamboo keeps the knife sharper longer and responds well to temperature.

To make a cutting board, let's take one of the most versatile materials - wood. In terms of the variety of physical and mechanical properties, other natural materials can hardly be compared with wood. Wood can be cut, planed, split, bent, painted, fired.

The availability of materials, the availability of tools in the school workshop, and the relative simplicity of the technology for making the product allow us to conclude that the choice of project was successful.

Cutting boards can be very different: regular, plywood, in the shape of fish, animals, fruits.

Therefore, before starting the project, I decided to try myself as a designer and selected several of the most interesting options:

IDEA 1. A regular cutting board with a handle is simple and easy to use.

IDEA 2. Cutting board in the shape of a fish - less space for cutting

IDEA 3. A plywood cutting board is not aesthetically pleasing.

After working through all the options, I decided to choose option 1. In my project, I chose a traditional form in the old Russian style with the application of ornaments using paints. Linden boards are most suitable for work, as they are soft, easy to process, and do not warp.

The wood material used must be free from defects, cracks and knots. The cutting technique is familiar and simple to me.

The manufacturing process is accessible to me and allows me to use existing skills, knowledge and abilities. To make my product, I selected the necessary materials and tools.

When making a board, it is necessary to take into account the factors given below (Diagram 1):

The versatility of my project lies in the fact that it can be used for its intended purpose, that is, as a cutting board and as a kitchen interior.

The cost-effectiveness lies in the fact that all the materials for this project can be found in the workshop, among the production waste.

Constructiveness must be taken into account during manufacturing; it is beautiful, comfortable and durable.

Environmental friendliness lies in the fact that in the manufacture of this project, environmentally friendly material was used - wood.

From an aesthetic point of view, I used ancient traditions here.

How many boards do you need in the kitchen?

According to sanitary standards, it is necessary to have five cutting boards for cutting various groups of products. The quantity can be reduced if you cook very little at home, and increased if you are constantly working in the kitchen.

Active housewives should have separate cutting surfaces:

- For raw meat – durable, easy to clean, and can be disinfected. End or stone will do.

- For fresh fish - if you don’t chop it, you can use glass-ceramic or glass.

- For non-cooked products.

- For vegetables and herbs. A plastic or silicone one will do, as it will have to be washed frequently.

- For bread. Any material will do, the main thing is that it is compact and stored separately. Convenient options with a hanging loop.

Sets of cutting boards look beautiful, but they contain items made from the same material. If this is a wooden set, then buy a small silicone and glass set, they will not take up much space, but will be useful for “wet” work.

Methods and techniques for making a cutting board

Characteristics of the materials used.

We will need:

- Wooden block measuring 20*130*470 mm.

- Wood varnish (50 g)

- Acrylic paints, or watercolors.

In addition, we may need a jigsaw, a set of cutters and files, a small emery and drilling machine, a regular saw and a circular saw. You can set up a workplace at home, setting aside a room for a workshop, or set up in a warm garage. To work, you need a stable table, chair, and additional table lighting - bright enough, at least 75 W, otherwise your vision may suffer when working with small designs.

Safety precautions when making a cutting board

When processing wood:

- You should not work when you are very nervous or tired, when your attention is dulled and it is difficult to concentrate.

- The workplace must always be kept in order. There should be no unnecessary objects on the table surface.

- Lighting on the product should fall from the front, side, top, and the lamp should be at a sufficient distance from the carver.

- You should not be distracted and, if it is not necessary for carving, walk with the tool in your hands.

- The tool should always be kept in good working order.

- Place the tool on the workbench with the cutting edge facing away from you.

- Chisels and knives should always, without exception, be held with both hands - there are no deviations from this rule!

- It is not recommended to place the workpiece on the palm or knees when carving, or to cut while holding the product suspended without support.

- You should always have first aid supplies on hand.

When painting:

- Products should be painted only on the application board.

- Avoid contact of paint and solvents with the skin of your hands and face.

- Do not paint products and do not store paint near heating devices.

- Ventilate the room where painting is carried out.

- Wash your hands with soap after dyeing.

Technological part

Development of sketches, templates:

We carry out the drawing:

Technical drawing:

Exploitation

Proper care of cutting boards extends their service life and ensures food hygiene.

Recommendations for use and care:

- To prevent your cutting board from becoming a source of bacteria, careful care is required. Plastic, plywood and glass models should be washed in hot soapy water, then thoroughly wiped dry, then dried.

To disinfect wood products, you should regularly scrape them with a knife and scald them with boiling water. After two months, it is better to change the product to a new one.

It is not recommended to clean such boards in the dishwasher, as they swell from excess moisture. Protect them from high temperatures, do not store them near the stove, this will lead to cracking of the material.

- Use food vinegar to disinfect surfaces; Odors are removed well with lemon, salt and baking soda. Soak the product, sprinkle it with salt and leave for a few minutes.

This way you will get rid of foreign odors. It is recommended to carry out the disinfection procedure once a week.

- Do not store boards in a dish dryer; the best place is on kitchen shelves with compartments away from moisture and the stove. It is important that the products do not come into contact with each other; water accumulated under them will lead to the formation of mold.

- Immediately after purchase, clean the wooden surface of the board with sandpaper and thoroughly coat it with food-grade mineral or linseed oil and leave for three hours. This will protect the wood from bacteria and moisture.

- Plastic products are not suitable for cutting hot food; they emit elements harmful to health: phenol and formaldehyde, which are absorbed into the food.

- There should be at least two cutting boards in the kitchen: one for foods that are eaten raw, the second for cutting meat and fish.

Bacteria present in meat are removed after treating the product with warm water, but if you cut sausage or bread on it, you can get an infection.

Technological sequence of product manufacturing

| Select a blank from a board 15-20 mm thick | Ruler, pencil |

| Mark the outline of the product | Pencil, ruler |

| Cut out the outline of the product | Jigsaw |

| Drill holes | Drilling machine |

| Clean the product, round sharp edges and corners | Clean the product, round sharp edges and corners |

| Product finishing | Sandpaper |

| Draw a picture for coloring | Pencil, paints |

| Painting the product | Varnish, brush |

Decor options

Ordinary kitchen utensils are decorated in various ways; such models will be a good gift for any housewife. Wooden products are decorated with:

- Firing. Geometric patterns, silhouettes of animals, plants, and fruits are burned onto the surface.

- Using decoupage.

Option 1. Clean the wooden surface with sandpaper, moisten a paper napkin with PVA glue and place it on the board. If desired, the edges of the napkin are painted with acrylic paint, and after drying, everything is coated with varnish for wooden products.

Option 2 - decoupage using a file. The working surface is coated with acrylic paint. A pattern is cut out of a napkin that will be applied to kitchen utensils. Place a napkin into the file and smooth out any unevenness. The board is coated with glue and placed in a file under a napkin. The surface is smoothed through natural fabric, and the board is carefully removed from the file. Afterwards, the area with the decor is opened with varnish, applying 2-4 layers.

- Engraved. The name and initials of the owner are cut out or burned on the gift item.

You can often find ornaments and drawings on glass boards. Boards with photo printing are in demand, both to order and ready-made. Usually, they depict natural landscapes, flowers, and funny pictures. It is not customary to place portraits or photographs on a cutting board, because the housewife will work there with a knife.

Economic calculation for making a cutting board

Let's determine the cost of the materials needed to make the board. Let's determine the volume of wood in m3. First, let's convert the linear dimensions from millimeters to meters.

Product 20 mm = 0.02 m; 130 mm = 0.13 m; 470 mm = 0.47 m.

The volume of wood is 0.02*0.13*0.47 = 0.001222 m3.

Cost of wood = 0.001222*4000 = 5 rubles. 89 kopecks

You will need 50 grams of varnish.

1 liter of varnish costs 120 rubles, because... 50 g = 0.05 kg, then the cost of varnish is 0.05*120 = 6 rubles, but since we coat the product with varnish 2 times, that means 6*2 = 12 rubles.

Energy costs

The power of the machine is 200 W = 0.2 kW, because cost of 1 kW = 2 rubles. 09 kopecks, then the cost of electricity is 2.09 rubles.

Total: cost of wood + cost of varnish + cost of electricity = 5.89 + 12 + 2.09 = 19 rubles 98 kopecks.

Ecological - economic justification for a cutting board

Our production must be such that environmental and economic problems are solved as a single task.

Looking at the product I made, I want to say that my work was not in vain. The board is made from an economically pure product, will decorate the kitchen interior well, and is worth the cost.

Advantages of this project:

- firstly, a necessary thing in the kitchen;

- secondly, it is universal;

- thirdly, it is easy to manufacture and economical.

Flaws:

- made of soft rock

Conclusion

Nowadays, when industrial goods have filled our everyday life, I propose to make your home with your own hands, introducing elements of creativity and individuality into the world around us. And the main thing is to get great pleasure from the thing made by your labor in combination with original imagination.

Centuries have passed, people's worldview and their way of life have changed. And the products of folk craftsmen today still delight us with their perfection. Nowadays, decorative art is not only preserved in museum halls, it lives among the people. We treat products that retain the warmth of human hands with a sense of reverence. After all, every thing contains a part of the soul, the heart of the master.

Woodworking brings joy, gives skill, makes our life more beautiful and richer.

In the process of completing a creative project using the “Cutting Board” technology, I learned how to choose a type of wood, make a workpiece, use tools, sandpaper, glue, and master simple wood turning.

Of course, almost every wooden item can be bought in a store. But then I would not have known how easily and cheerfully a plane moves along the board, removing thin, curled, golden shavings, how tenderly and cleanly the wood smells, I would not have felt the living warmth of this material with my palm, I would not have felt the joy when from under my hands, as if by magic, a beautiful and necessary thing in the house is born.

The photo shows the result of my work.

When preparing the project, I studied quite a lot of specialized literature on wood processing.

I tried myself as a designer. Having assessed the designer’s work, I realized how much it requires a creative approach and accuracy.

I am pleased with the result of my work and I think it will be appreciated.

Bibliography

- Buzkinov M., Potapov G., The art of wood carving. -M.: Antikva, 1998.

- Glikin M.S. Decorative woodworking on machines. M.: Iskona, 1999.

- Martenson A. We begin to craft from wood. M.: Education, 1979.

- Leontyev D.P. Do it yourself. – M.: Education, 1985.

- Logacheva L.A. Basics of wood carving skills. M.: Folk Art, 2002.

- Lebedeva E.I., Burgunova E.M. Wood carving. M.: Adelant, 2005.

- Abrosimova A. Artistic wood carving. M.: Higher School, 1989.

- Khvorostov A.S. Embossing, inlay, wood carving. M.: Education, 1977.

If you liked the page, share it on social networks:

Size and shape - according to purpose and preference

Deciding on the size of your cutting board is easy. Focus on the size of the products and their quantity.

- For cutting chicken, meat and fish, a 30 by 50 cm board with a thickness of 3-4 cm is recommended.

- For cutting vegetables for salads and various dishes - 20 by 30 cm.

- For bread – 20 by 30 cm.

- Small boards are suitable for cheese and sausages, sandwiches, and greens.

In addition to round, rectangular and square cutting boards, there are models in the shape of apples, tomatoes, fish, and crescents. Don’t rush to smile, the form helps you not to confuse the devices and avoid the need for a signature.

For everyday tasks, the most convenient shape is rectangular; it is also easier to store in the kitchen. Round ones are needed for pizza, pies, loaves, and cakes.

Cutting surfaces are not always smooth. Grooves are very common. They are needed to collect juice from products. Such models are suitable for vegetables, fruits, and meat.

Think about how you will store your kitchen boards. Sets are often sold with stands. It's beautiful and convenient, but it will require space on the table or in the closet. Hanging options with a hole or loop for hanging are convenient. In this form, the accessory dries faster and is not susceptible to mold.