The myth that the lightest wood is cork is firmly rooted in our heads. This is not true, the lesser known balsa is lighter, its density in the dried state is 120 kg/m. cube Balsa (balsa, balsa wood, ochrome) belongs to the mallow family. The natural habitat is the countries of South America. The tree got its name from the Spanish word for “raft”, as the South American Indians made their boats from it. The main supplier on the world market is Ecuador.

In this article you will learn:

- Characteristics of balsa

- Usage

- Treatment

What is the name of the lightest tree?

This is Balsa, whose name comes from the Spanish word for raft. It is a member of the Malvaceae family and the Bombaxaceae subfamily. Forms the only species of Ochroma pyramidale.

Balsa tree trunk

It also goes by the names “Balsa”, “Ochroma” and “Balsa tree”. Belongs to a monotypic genus of plants. It has the rarest wood. When freshly cut it contains up to 95% water, which gives it heaviness, and when dried it becomes unusually light and soft, but retains its strength.

Balsa wood: uses

The wonderful properties of the lightest wood in the world were appreciated by the Incas, who made canoes and rafts for long voyages from balsa (from Spanish “balsa” means raft). The balsa tree arrived in Europe relatively recently. Wood began to be exported on a large scale during the Second World War as a replacement for balsa wood.

There are many more examples in history of the successful use of balsa wood: the British used it to build a multi-purpose bomber aircraft, and the Norwegian Thor Heyerdahl sailed across the Pacific Ocean on a raft made from balsa!

Physical and mechanical properties

This is the lightest durable tree, which after felling weighs quite a lot, but when dried it quickly loses moisture, reaching a density of a maximum of 150-160 kg per cubic meter. For comparison: for northern spruce this figure is 400 kg per cubic meter, for dry birch - 600 kg per cubic meter.

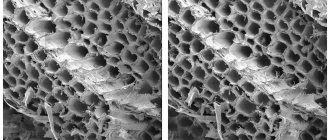

Balsa wood structure

In the core and in the butt area the wood is quite strong, the easiest is young sapwood. The fibers instantly swell with water because they are highly absorbent. At the same time, they are incredibly weak and wrinkle quickly.

Properties of wood

Balsa is a very practical, lightweight wood that is extremely easy to process. These qualities make it a very valuable tree. To understand how light wood it is, it is necessary to compare its mass with other known trees. In 1 cubic meter of balsa - 100 kg of wood, and 1 cubic meter. meter of the same pine is about 850-900 kg. Even balsa wood is 2 times heavier than balsa. The average man can easily lift and carry a log over 5 meters long and 0.5 meters in diameter. But this property is characteristic only of dry wood.

Living wood is very saturated with moisture. The moisture content of freshly cut wood is 400%. It is very heavy and soft. It is incredibly difficult to chop, since the ax practically gets stuck in the wood, as if in some kind of hard rubber. In order to process fresh balsa logs, you need to have great dexterity and strength.

If a cut tree is left lying on the ground, then within just a few days it begins to rot. To prevent this from happening, the logs are placed in special dryers, where they are kept in a vertical position. In this position, the pores of the wood are quickly freed from water and it begins to become lighter.

But if during chamber drying you rush to dehydrate the wood and set a higher temperature, then the wood can twist, warp and crack. A more gentle method is used in Puerto Rico. Before chamber drying, the logs undergo initial processing in the open air. To quickly remove moisture, stacks of logs are equipped with special gaskets. This method is longer, takes about a month, but it is more effective and safe.

Balsa is the lightest wood

It is extremely easy to process using any of the familiar methods: it is perfectly cut, chopped, sawn, nailed. At the same time, it is poorly painted with paints and varnishes. But it is acceptably susceptible to the influence of alcohol mordants and tinting with water dyes. For best results, you need a special tool with a thin blade and a small sharpening angle. Hence the amazing and easiest wood carving that is possible.

At the Balsa logging site

Where is balsa wood used?

The lightness of balsa wood is our use. Thus, various boats, canoes, and rafts are made from balsa. Floats, fishing gear, surfboards, model airplanes and boats are made for the masses.

In addition, they produce sound-proofing and heat-insulating materials and use them in interior design. It is very comfortable to work with balsa. The wood is excellent for sawing and cutting. It is easy to chop and cut by hand. Holds fasteners well and accepts them just as well.

It adheres well, accepts mordants and other means of protection and decoration. The only negative point is the porous structure of the wood. Which absorbs a lot of processing agents. This means that their consumption significantly increases.

To work with balsa, use thin, sharp blades. Moreover, the wood does not dull the blades at all.

Subscribe to our Yandex.Zen channel

Where is it used?

It has considerable economic importance. Most often used in modeling gliders and airplanes. It is also used to produce bars of various sizes, table tennis rackets, surfboards, layouts, any decorations, fishing baits, buoys, floats and all kinds of life-saving devices (on the water).

In addition, wood is in high demand in:

- finishing works;

- construction;

- aviation;

- design;

- vibration, noise and heat insulation.

The heartwood of the tree is used in the production of composite fiberglass hulls of yachts and ships. And the fibers are used to make coarse fabrics and stuffing mattresses or pillows.

The strongest wood

The strength and hardness of timber is determined by several methods. Experts have long compiled a list of all trees by density. Thanks to the results of this check, craftsmen use timber strictly for its intended purpose.

Strength of wood species

The first line of this list is occupied by white acacia, widespread throughout Europe. Brazilian cherry, or jatoba, ranks second in hardness. Products made from this wood have a beautiful structure. Amaranth can be found in Central America. Timber products are characterized by dense and flexible wood. The raw material has a red-violet hue and an interesting structure. The strongest amaranth wood is difficult to process, but it is from it that luxury pieces of furniture are produced.

Next on the list is ash, followed by oak. These types of lumber are very heavy and durable. In our country, Schmidt birch is distinguished by the greatest hardness. Bullets fly off it, it sinks to the bottom in a few seconds in water, and is distinguished by its self-preserving property. Products made from it do not rot and are stronger than cast iron.

Solid grades of timber are used in various fields. For example, Brazilian cherry is an excellent material for creating canes, furniture, and parquet. The durability of acacia parquet is higher than that of oak, and over the years it acquires a more beautiful texture. After steaming, the raw material can be easily bent, which is why it is so popular when creating Viennese chairs.

Iron trees are used to make nails and bearings. These include: Schmidt birch, Amazonian tree, azobe and several others.

Lightweight, durable wood

Balsa tree, which has very light and durable wood, grows in South and Central America. Many people believe that the lightest tree is cork. However, they are very mistaken - it is almost 2 times lighter than balsa. The density of the boards of this tree is 120-160 kg/m3, and the density of cork boards is over 210 kg/m3. Products made from balsa are 9 times lighter than water, and 6 times lighter than oak.

It is worth noting that a freshly cut tree is quite heavy, because the timber contains a lot of fiber cells, which are filled with cell sap. If the wood is not dried immediately after cutting, it will rot within a few days.

These trees are characterized by a colossal growth rate: within six months after seed germination, they reach 3.5 m in height and 25 cm in diameter.

Felling is carried out in 6-10 years. At this time, the tree grows 25-30 meters in height, and the trunk diameter is 1 m (sometimes up to 6 m).

After felling, the timber is dried vertically. During drying, fiber loses moisture and becomes deformed, the cells shrink. Balsa wood is very porous, spongy, but not brittle - 6% of moisture remains in them.

Another advantage of such raw materials is the ease of processing. Craftsmen value it because, despite its low weight, the structures are quite rigid - stiffer than oak or pine. The spongy structure allows this material to be successfully used as a noise and sound insulator. The tree came to Europe relatively recently. Mass exports began during the Second World War, when they replaced balsa wood.

Today they make from balsa:

- wind turbine blades

- sport equipment

- decorations, layouts

- aircraft models

- fiber pillow filling.

Wood tensile strength

It is known that certain qualities of lumber appear under the effect of mechanical work. This:

- strength

- deformability

- technological and operational properties.

The parameters of the mechanical qualities of timber are calculated using:

- sprains

- compression

- bending

- shift

Strength is the ability of timber not to collapse under the influence of mechanical work. It is directly proportional to the structure and physical state of the raw material. Strength testing is carried out using standard methods on healthy and small (section 20X20 mm) specimens under static loads using special devices. Based on the results of most processes, maximum strength is recorded, which is the maximum stress that does not destroy the raw material.

Compressive strength is calculated on specimens of a prismatic configuration. The specimen is slowly loaded until there are signs of destruction. After this, the force meter of the testing apparatus is calculated using a special formula. The average value of the maximum compressive strength along the fibers for all Russian varieties at a raw material moisture content of 12% reaches 50 MPa. When testing timber for static bending, specimens in the form of small bars are used. The average maximum strength reaches 100 MPa.

Mechanical strength of wood

During short-term loads, mainly elastic destruction appears in lumber, disappearing after the load is removed. This indicator is also calculated by specialists using special formulas.

Due to the fact that polymers with elongated chain molecules predominate in the composition of timber, their deformability is directly dependent on the time of loading. The science of rheology studies the mechanical properties of lumber. She studies the general patterns of destruction of timber under load, taking into account the time factor.

The strength coefficients of timber under long continuous loads must be studied because they are used in building structures. Experts call maximum long-term resistance a characteristic of this quality. For almost all types of load it is equal to 0.5 - 0.6 levels of maximum strength under short-term static loads.

When drawing up a project for building structures made from timber, craftsmen in their calculations use not the maximum strength of small specimens of timber, but much lower coefficients - calculated resistances.

Specific viscosity is a characteristic of the ability of a raw material to absorb work during an impact without breaking. It is determined during bending tests. This indicator for coniferous timber is two times weaker than for deciduous timber.

Hardness is the limit of lumber’s resistance to indentation of harder bodies. To determine hardness, a device with a punch is used, the tip of which is pressed to the depth of the radius. At the end of the procedure, a trace remains in the raw material. Hardness is determined by the size of the mark. Impact hardness is calculated by dropping a metal ball with a diameter of 25 mm from a height of 50 cm onto a specimen.

The ability of lumber to resist wear is called wear resistance. It has long been known that wear on the side parts is much higher than on the end cuts. As hardness increases, wear decreases. Wet timber is more susceptible to wear and tear than dried timber.

Perhaps the most unique quality of lumber is the ability to hold fastening materials such as nails, screws, and staples. When driving a nail into the raw material, elastic destruction is created, providing the necessary friction force. It is this that prevents the nail from being pulled out. With increasing density, the resistance of timber to pulling out of fastening material increases.

Oak and ash lumber is much easier to bend than, for example, beech. Coniferous varieties are characterized by even less bending ability. It is much easier to bend timber when treated with steam. Such conditions make the raw material more pliable and make it possible, as a result of the formation of frozen destruction during further cooling and drying under load, to fix a new shape of the sample.

To compare the qualities of timber of different grades, experts use specific coefficients of mechanical properties, i.e. coefficients of their mechanical properties, proportional to the unit of density.

These lumber indicators are very important if increased strength with low weight is required from an object or structure. All this is necessarily taken into account in transport engineering, aircraft construction, and shipbuilding.

From the history of the use of Balsa

The unique properties of this plant have been known since ancient times. For example, the Incas made rafts and canoes from it for long trips.

The same wood was used to make Kon-Tiki, the famous raft of the Norwegian traveler Thor Heyerdahl, who sailed to the Polynesian islands across the Pacific Ocean.

The famous raft of Thor Heyerdahl

Its wood was also used in the construction of the Mosquito, the famous high-speed bomber of World War II. The balsa panels with which it was finished significantly reduced the need to use metal parts that were in short supply at that time.

This plant also served as the beginning of the production of layered sandwich panels, in which balsa was gradually replaced by other structural components - modern carbon fiber and aluminum honeycombs.

Application on the farm

Balsa wood is widely used on the farm. It is very easy to process. To do this, you just need a thin blade with a small sharpening angle. But balsa practically cannot be colored - it is best to use water-based dyes, which will quickly absorb into the wood. But it is better not to use varnishes and oily substances. They will not stick to wood.

The distinctive qualities of balsa were discovered by the ancient Incas. It was they who began to plan canoes from wood and make light and stable rafts. Wood is considered ideal for making calligraphy brushes. But in shipbuilding, balsa wood is used to construct decks and sides for small pleasure boats (usually not exceeding 30 meters in length, the size of an adult tree). Balsa is also used to make blades for wind turbines. It is probably difficult to come up with a more convenient and lightweight material.

Pink tree

The Brinell hardness of rosewood is 4.4. Grows exclusively in Brazil. Rosewood wood is characterized by its color - from yellow to pink with a red pattern. There is also a rose scent. The wood is very dense and hard and polishes well. Rosewood is often used to make furniture for small other objects. For example, for humidors or for creating musical instruments.