Tamburat is a modern construction material that consists of two outer sheets and a filler. The idea to create slabs with a honeycomb structure appeared back in 1943, but implementation began only 20 years later. For a long time, developers searched for the ideal filler. They eventually settled on compacted cardboard.

The outer layers are made of wood-containing material or plasterboard with surface veneer. And the middle is made of thick cardboard and is located in the shape of a honeycomb with dimensions from 15 to 25 mm. The vestibule does not have strict dimensions. Companies producing this material offer quite a variety of sheet sizes. Thickness ranges from 30 to 240 mm, length from 2400 to 3000 mm, and width from 600 to 1300 mm.

Pros of tambourate

Today, not all consumers know about this material, but its popularity is steadily growing. These slabs received all their positive qualities due to their specific hollow design. The main advantages include:

- easy processing. Furniture board can be easily cut with any tools. Therefore, it can be used to create parts of various shapes and complexity.

- possibility of hidden installation. Cardboard filler makes it possible to create hidden wiring and install fasteners inside the slab. At the same time, vestibule furniture does not lose its visual appeal, but only becomes more functional. Hidden wiring is in great demand in the production of computer desks and various pieces of office furniture.

- fastening materials. Accessories for tambourate have similar properties and design as for other similar materials. This means that choosing fastening elements will not be difficult for you. At the same time, for the thinnest sheets it is worth using built-in fittings, which are purchased from companies specializing in this. Tamburat can be bonded to chipboard or laminated chipboard

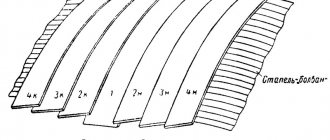

- high level of strength. Thanks to the presence of honeycombs made of thick cardboard, the material is able to withstand fairly high pressure in the horizontal plane without significant deformation. The vertical load allows the slabs to bend. At the same time, the original rigidity and strength of the sheets is not lost. Very often, convex structural elements are created from thin vestibule slabs

- many different coatings. A wide selection will help you choose products from this material in almost any color scheme. This is why designers really like the material.

- small mass. Due to the specific composition, the external dimensions of the vestibule do not coincide at all with the mass of the slabs. Thus, tambourate has unique qualities and is used in large-scale structures with the ability to move intermediate parts

- price. Tamburat is one of the most affordable materials in its class. Finding a similar ratio of cost and quality of slabs is almost impossible. Items made from these slabs are several times cheaper compared to analogues. At the same time, the level of quality and wear resistance is very high.

Main characteristics and advantages of tambourate

Tamburat (Eurolight) - frameless lightweight slabs with three separate layers, designed for the manufacture of modern, eye-catching furniture. Its appearance in the 2000s was a real surprise for manufacturers of headsets and interior items. Since then, the popularity of this material has been steadily growing throughout the world, including Russia. Tamburat made it possible to reduce the cost of respectable furniture, and at the same time significantly reduced its weight. Thanks to these plates, it was possible to establish in-line production of previously exclusive models, making them available to a wide consumer audience.

Tamburat has another name - “honeycomb slabs”, which reflects its structure. To reduce the weight of furniture made using this material, lightweight cellular cardboard is used for the internal filling of double-sided boards. Traditional HDF, laminated chipboard or MDF boards with a thickness of 3 are used as outer layers for the production of tambourate; 4 or 8 millimeters. This design allows, without compromising performance characteristics, to reduce the weight of furniture by 40%.

The thickness of the vestibule slabs varies between 38-100 mm, which removes almost any restrictions in the manufacture of visually massive furniture, which in reality is no heavier than products made from 16-18 mm laminated chipboard or MDF. The idea of creating such slabs was borrowed from door manufacturers. The strength of tambourate products is beyond doubt, since all technologies have been tested for many years on interior door leaves. “Honeycomb boards” (Eurolight) have proven themselves excellent in the production and operation of furniture due to the following advantages:

- availability of all methods of classical processing - sawing, edging, veneer finishing, milling, drilling, as well as insertion of built-in elements

- Possibility of hidden cable installation and installation in any area of the furniture structure

- compatibility with traditional furniture fittings and easy installation of auxiliary mechanisms

- pressure strength, as well as excellent deflection performance of workpieces under high vertical load

- the ability to maintain the original shape of workpieces unchanged in all planes

- a wide selection of finishing decorative coatings from EGGER and other well-known chipboard manufacturers

- low weight in relation to the dimensions of the workpieces

- versatility and wide range of applications

- favorable price in comparison with other materials of similar thickness.

The operation of furniture made from tambourate has proven in practice that products made from Eurolight are not inferior in reliability and durability to analogues made from paired laminated chipboards. The cellular board used to fill the internal cavities is shaped like a hexagonal endless honeycomb, providing outstanding mechanical and flexural strength. Tamburat sheets have a format of 2800x2070 millimeters and, depending on the thickness and type of facing slabs, have a mass of 70 to 80 kg, which is slightly greater than the weight of laminated chipboard (16-18 mm). Tamburat organically combines physical, technological and economic indicators. This material can easily withstand loads from 1.3 to 3.5 kgf (kgf), thanks to which tambourate furniture has an additional margin of safety, which is more than enough to protect products from mechanical damage: dents, cracks, etc.

Kinds

Tamburat differs from each other not only in dimensions and sheet thickness. Today, several different types of slabs are available. They differ in the coating characteristics of the outer layer and require different types of additional processing. The slabs are:

- uncoated. The use of such material requires a top layer of laminated paper or veneer

- with slab coating. Such boards are finished with natural wood veneer, laminated paper or PVC film.

- standard decorated. These slabs are completely ready for further use thanks to the presence of a factory lining made of special types of varnished paper, veneer or plastic. You just need to choose an edge that matches the color.

Most often, tamburat slabs are created to resemble wood or simply in dark shades.

EXCLUSIVE

The latest trends in the design of premises and interiors require the use of thick materials in order to emphasize the modernity of design solutions and the high quality of furniture and materials. When clients require exclusive execution of interior designs, massive-looking but light furniture, impressive work surfaces of tables, racks and shelves with large spans - in such cases TAMBURAT is suitable like nothing else.

Massive furniture in large, spacious rooms looks much more organic than its analogues made from conventional slabs, and the possibility of applying matte, semi-matte or glossy varnish to the front surface makes it possible to produce luxury, premium class furniture.

Usage

Tamburat has a narrow focus; it is most often used to create furniture. Two ways of using this material have been developed:

- the first is the use of slabs to create three-dimensional structures. In particular, tambourate is often a replacement for chipboards in open areas of the finished product

- the formation of furniture collections that are entirely made of these slabs. Such pieces of furniture are easier to create than items made from other wood-containing materials. However, such furniture is distinguished by the most sophisticated forms and level of practicality.

Tambour slabs are used in almost all types of furniture.

However, this furniture is not the best option for the bathroom. The thickness of the plate affects its area of application:

- 32mm. Such slabs are used to create interior doors and cabinet doors.

- 38mm. Such slabs are great for shelving and bedside tables. However, the shelves should not be long, approximately 50 - 100 cm

- 50mm. This material is used to create executive-class furniture, shelving with long shelves, tabletops, tables for conference rooms, retail and banking equipment. The length of the shelves can be over 1.5 places.

The thickness of the outer layers of lightweight chipboard furniture boards can be 3, 4 or 8 mm. With a thickness of outer layers of 8mm, the processing methods are similar to those for chipboard.

Features of sandwich furniture

The technology for producing sandwich panels appeared relatively recently and quickly gained popularity in the construction industry. Gradually, this technology began to be used in the manufacture of furniture, which is explained by the characteristics of the material.

Advantages

At the moment, there is a wide variety of building materials that are suitable for the manufacture of furniture and various interior items. All of them have both advantages and disadvantages.

When drawing up a housing project, it is worth familiarizing yourself with the advantages and features of various materials, which will allow you to make the right choice.

The sandwich design is characterized by the following advantages:

- Ease of processing. Any person can cut a tambourate slab, and no special tools are needed for this.

- Possibility of hidden installation. Explained by the density of the filler. In addition, the fastening elements are easily hidden inside the furniture without spoiling its appearance.

- Ability to combine with other materials. The design assumes classic fasteners. However, if very thin sheets are used, they should be mounted using special recessed fasteners.

- Strength. This characteristic largely depends on the characteristics of the filler. Its design involves many stiffening ribs that can easily withstand increased loads.

- Resistance to bending. Thin products bend easily, while remaining strong and rigid. Due to this, rounded or concave elements are often made from the material.

- Decorative coatings. They are available in a wide variety so that the final product can have a unique look.

- Light weight. Despite the large volume of parts, the products are not heavy. This feature allows the panels to be used to produce impressive structures that will not create difficulties during transportation.

- Availability. The cost is low.

Production of tambourate

Tamburat production is carried out in three directions:

- frameless slab

- a slab with embedded strips (slats), which are attached along the length of the slab on both sides. Such slabs are sold already cut to the manufacturer’s standard dimensions. In addition, a number of companies offer vestibules with embedded strips and a supporting edge (for example, EGGER). Typically, the thickness of the embedded strips ranges from 10 to 70 mm, however, if the client wishes, the thickness can be changed

- a slab with embedded strips (slats) along the entire perimeter of the slab - a slab with a frame. Sold cut out in standard sizes. At the customer's request, embedded elements can be of any size, for any technical specifications.

Tamburat is able to withstand loads from 1.3 to 3.5 kgf. This parameter depends on the size of the cells of the honeycomb filler and the material from which the filler is made. It is worth noting that there is no single definition of what a lightweight panel is. However, in the generally accepted understanding, a design with parameters of 500 kg / cubic meter is called lightweight. m or less.

Sandwich furniture: features of its production and varieties

The furniture market is constantly evolving, new trends and ideas are emerging, design and functionality are changing. Recently, a return to massiveness has been observed in this area. Once upon a time, the price of furniture depended on the material from which it was made. Now design is also taken into account, that is, compliance with modern trends. Products made from laminated chipboard will surprise few people, but sandwich furniture has distinct features.

Edgebanding and fittings

If the thickness of the outer layers of chipboard is 8 mm, then a regular edge can be used except for melamine; the use of a supporting edge in this case is not necessary. But if the thickness of the outer layers is less than 8 mm, then it must be used. The support edge is a flexible ABS foam strip. Its thickness reaches 3 mm. It is used as a base for decorative edges.

Accessories for the vestibule are:

- standard. Such fittings are used for chipboard. It is used if the thickness of the outer layers is more than 8 mm

- specialized is used if the thickness of the outer layers is less than 8 mm. In addition, it can be used on thicker sheets. In this case, it will provide additional reliability of the product.

Specialized fasteners are designed to compensate for voids in the honeycomb core of the slabs. The most famous manufacturer of accessories for vestibules is the German company Hafele, which produces all the necessary elements for high-quality furniture assembly.

Experts note that Maxifix ties, self-tapping screws with special threads and Aerofix adhesive couplings help ensure a high level of reliability of connections of all types, which in terms of strength will not be worse than the assembly characteristics of blanks made of laminated chipboard or MDF with a thickness of 16-32 mm. The use of such specialized elements makes it possible to equip the body of tambourate products with guides, retractable baskets, pantographs and other additional mechanisms that are designed for standard loads.

Decorative inserts in tambourate panels

To improve the aesthetics of a number of products, inserts are made into tambourate panels using other materials. Glass and acrylic plastic are mainly used for these purposes. The presence of a variety of decorative corners and MDF profiles allows such integration to be carried out accurately, thanks to which the places where decorative elements are inserted look great even up close.

A good example is modern interior doors, the glazing of which is carried out using a similar technology. Integration of decorative inserts can be carried out in the side racks of shelving or cabinets, as well as the side and front panels of tables, reception desks, exhibition equipment, display cases and bar counters. If desired, glazed areas can be additionally equipped with internal decorative lighting.

Conclusion

The cost of tambourate sheets is on average 2 times more than the price of laminated chipboard sheets (18 mm) of a similar format. Accordingly, the cost of furniture made from this material will exceed the price of similar models made from 18 mm thick laminated board. However, all the advantages of products made from Eurolight panels, listed at the beginning of this article, more than cover the client’s material costs. If you compare the prices of similar products several years ago and today, it is quite obvious that high-quality furniture made from vestibule has become accessible to a wide range of buyers.

Employees of the Stiver-100 company will develop for you original author’s design projects for any furniture made from lightweight Eurolight honeycomb panels. If necessary, we can carry out this work together with experienced Moscow architects, thanks to which you will become the owner of not only an elegant fashionable set, but also an exclusive interior in which literally everything is organic - from furniture to wall decoration.

Compatibility with other materials

Tamburat fits perfectly with all known components used today in the process of designing and creating furniture. A wide selection of fastening materials guarantees the compatibility of the component elements of the product, even when they are created from different raw materials - chipboard, MDF, plywood, natural wood, glass, mirrors, aluminum and MDF profiles, acrylic plastic, postforming, perforated metal, decorative relief plastic.

In addition, experts advise using parts made from simple laminated chipboard as vertical partitions and horizontal shelves to create closed areas of the body. As a result, it is possible to reduce the cost of the final product without compromising the performance and aesthetic qualities of such furniture. The open parts of the body will create the effect of massiveness, and the internal components of the closed areas of the structure have absolutely no effect on the appearance.

UNIQUE

Due to its specific hollow design, TAMBURAT is unique in its simultaneous combination of two qualities - strength and lightness. TAMBURAT expands the possibilities of furniture manufacturing and creates the visual effect of a thick-walled solid mass.

It requires less effort during transportation, carrying and installation compared to solid materials of similar sizes.

The low weight makes it possible to create suspended ceiling structures, and installation of dimensional products becomes possible on various walls, including those with weak load-bearing capacity.

IN TAMBURAT it is possible to carry out hidden wiring and even lay communications in the middle layer - the honeycomb filler. This is convenient when arranging various accessories and equipment in modern furniture. Now it is easy to place sockets, lamps, chargers and even speakers in the panel. TAMBURATE are also made hidden . The shelves look especially impressive.

Tamburat or furniture board

Tamburat or furniture board is a composite material with a honeycomb structure. Consists of two layers of MDF, chipboard, plywood or other wood-containing panel materials. Kraft cardboard, made in the shape of a honeycomb, runs through the center. The cell size varies. From 15 to 25 mm.

The furniture board or tamburat took a relatively long time to develop. About 20 years, starting in 1943. This is due to the fact that it was necessary to find the ideal filler. Meeting all material requirements.

Of course, there is hardly a person who does not like solid wood furniture. But, unfortunately, not everyone can afford this kind of furniture. Tamburat is very close in its characteristics to solid wood. But much cheaper.

Furniture fittings in the MDM assortment for vestibules

Companies developing and producing accessories have not remained aloof from this process. Entire lines of special accessories for vestibules have been created. Below we will talk about components used in furniture made from standard materials, which can also be used in products made from vestibule.

For vestibule without embedded strips and outer layers of 3mm and 4mm

For vestibule with embedded strips from 30mm thick and outer layers 3mm and 4mm

- Confirmat (for connecting embedded slats and depending on the thickness of the vestibule)

- Shelf tie (including FLIPPER and PK2)

- Conical tie (for thickness 30mm)

- Intersectional coupler (for connecting embedded slats and depending on the thickness of the vestibule)

- Furniture corner

- Dowel (for connecting embedded slats)

- Without fixation

- With fixation (including UNICO, SPRING)

- TRIADE XXL

- KAIMAN and KAIMAN MAXI (depending on the thickness of the vestibule)

- Decorative shelf holder

- Standard four-joint hinges

For vestibule with embedded strips and outer layers 8mm, 10mm or more

- Confirmat (for connecting embedded slats and depending on the thickness of the vestibule)

- Shelf tie (including FLIPPER and PK2)

- Conical tie (for thickness 30mm)

- Intersectional coupler (for connecting embedded slats and depending on the thickness of the vestibule)

- Bed tie

- Screed for tabletops (with embedded strips from 38mm)

- Furniture corner

- Dowel (for connecting embedded slats)

- Without fixation

- With fixation (including UNICO, SPRING)

- TRIADE XXL

- KAIMAN and KAIMAN MAXI (depending on the thickness of the vestibule)

- Decorative shelf holder

- Standard four-joint hinges

- All guides

- PVC and ABS 2mm thick (glued like on chipboard with a vestibule thickness of less than 50mm)

How to make tambourate or furniture board

So, we have already figured out that tambourate is a frame slab with light weight. The production of furniture boards or tambourates is simple.

So, to make a tambourate, take two sheets of plywood (MDF, fiberboard, chipboard and others), 3.4 or 8 mm thick. Craft filler with a honeycomb structure is placed between the sheets. The entire structure is glued together. A protective edge is glued to the sides. The protective edge is usually made of PVC. Has a thickness of no more than 3mm. An embedded strip made of foamed ABS or plywood is placed under the protective edge. This is done so that the edge holds better.

Tamburat or furniture board. Kinds

There are three types of tamburat. Each type of furniture board differs in the way it is processed. So there is uncoated, coated and standard decorated.

- The standard-decorated tambourate is finished in lacquered paper, plastic or wood veneer

- Coated tambourate usually has a final finish in the form of wood veneer, film or paper-laminated coating

- Uncoated tambourate requires additional processing before use. You can cover it with PVC film, paper or veneer

Tamburat: properties of honeycomb furniture boards

- Advantages of tambourate

- Slab options

- Application

Tamburat is a construction material consisting of two outer sheets and a filler. The outer layer can be made of wood-containing material or plasterboard with surface veneer. The middle is made of hard cardboard and is arranged in the form of a honeycomb with dimensions ranging from 15 to 25 mm. Tamburat does not have specific dimensions. Manufacturers offer different sheet sizes. Thickness - from 30 to 240 mm, length - from 2400 to 3000 mm, and width - from 600 to 1300 mm.