Wood has been and remains one of the most popular materials used by humans.

It is difficult to find a field of activity where there would be no place for products made from it. Wood processing inevitably generates waste that needs to be processed or disposed of.

Professional processing of wood waste is a profitable business that allows you to take care of the environment and make good money from it.

Types of wood waste

Modern technologies make it possible to use wood to the maximum, however, it is simply impossible to do without waste. They appear at every stage of work, from cutting down the forest and cutting it up to the final stage of processing the finished product. Main wood processing waste:

- leaves or needles;

- bark of tree;

- stumps with rhizomes;

- sawdust of different fractions;

- wood chips and shavings.

Foliage and small branches left after felling trees are often left to rot on the ground, which is far from the best solution. Rotting wood is a breeding ground for forest pests. In some cases, such waste is burned, but this is an ineffective method of disposal. Burning untreated wood pollutes the atmosphere, and in hot, windy weather, a small fire can cause a full-blown forest fire.

Waste recycling seems much more rational, during which a number of useful materials can be obtained from rejects. The list of things that can be made from wood scraps is extensive, including various types of fuel, stoves, chemicals and, of course, plain paper.

What is wood waste, its types

Forests are a valuable resource on the planet. They are called the “lungs of the Earth” and are essential for the preservation of flora and fauna. In addition to wood, they provide a lot of useful raw materials in the form of berries, mushrooms, and medicinal herbs.

And although trees are considered a renewable resource, the increasing use of wood makes their rational use relevant.

In the process of all types of activities, from logging to wood processing, waste is generated.

Wood waste is separated according to size and structure:

- Lumps – tree branches, trimmings, slabs, small pieces.

- Small – wood shavings, sawdust, wood dust, wood chips.

- Bark.

In the Federal Waste Classification Catalog (FWCC), wood waste is listed in several blocks.

Pure wood, such as sawdust and shavings, belong to hazard class V (almost not dangerous). Waste from fiberboard and chipboard was assigned hazard class IV (low-hazard).

Chemical processing

By treating wood waste with various chemical compounds, it is possible to isolate the substances included in its composition and obtain a mass of valuable industrial materials. Actually, this is what chemical wood processing is all about. Using this method, it is possible to produce various products; a number of technological processes are based on this:

- pulp and paper industry;

- wood hydrolysis;

- distillation by pyrolysis;

- production of rosin and turpentine.

Chemical processing of wood is carried out by specialized plants using sophisticated equipment and technologies. The result of processing is a number of different materials, from paper and cardboard to acetic acid and complex protein compounds.

Of particular note is the production of paper. Cellulose is the most important thing that a tree can give to humanity. Paper is used everywhere: notebooks for schoolchildren, books for lovers of reading, among other things, paper is the most reliable carrier of information. The use of wood waste in the production process of this useful product in all respects allows for significant savings and rational use of forest.

What can be produced from wood waste

Sawmill and wood processing waste in our country has been used for quite a long time to manufacture new products and materials. However, competition in this industry is still low. Therefore, using waste as raw materials for production is a promising business idea.

What can be produced from wood waste? Let's look at the most popular destinations.

Briquettes

One of the most promising industries is the business of producing fuel briquettes. This is due, first of all, to the fact that when burning these briquettes, almost the same amount of heat is released as when burning coal.

When burning coal, wood briquettes and simple firewood, 22 MJ/kg, 19 MJ/kg and 10 MJ/kg of heat are released respectively.

In addition, as a result of the combustion process of briquettes, there is not a large amount of ash left and a relatively low volume of carbon dioxide is released.

The briquetting line consists of a crusher, a drying apparatus, a mechanical impact press, a loading unit and a briquette cooling unit.

It is believed that the production of fuel briquettes is a business that pays off in a short period of time.

The technological process for producing fuel briquettes and the equipment used in this process are described in the following short video

Pellets

Fuel pellets are used for heating not only private houses, but also industrial premises. The most popular material for making pellets is sawdust. This production will require equipment, including filling and packaging units, coolers, granulator presses, drying machines, and crushers. You can purchase devices from Europe, which are initially focused on the production of pellets from sawdust. Moreover, in this case, the sawdust can be wet, because installations carry out their simultaneous drying. To operate such devices, diesel fuel and gas are used.

In the fuel pellet production business, you can use straw and grain waste, but the quality of the product will be reduced. Pellets without impurities are used for heating private houses, while pellets with impurities are used for heating industrial premises. Also, pellets with a high content of additional components are sold in the form of cat litter.

Fiberboard

Fiberboards are widely used in construction, finishing work and furniture manufacturing. The process of producing fiberboard from waste consists of the following stages:

- purification and crushing of raw materials;

- steaming;

- re-grinding;

- drying;

- molding;

- carrying out pressing, grinding and decorative finishing.

To start a business, you can purchase both Russian and foreign equipment.

Fuel

To implement a business idea for fuel production, you will need a pyrolysis plant. It consists of three main units: a unit where wood is prepared, a boiler for pyrolysis and a gas piston power plant. The production of such installations has been carried out in our country for about 80 years.

Other products

Note! For a successful business, you can use more than just sawdust.

For example, the bark and needles of coniferous plants can be boiled to obtain useful and valuable condensate. The presence of many biologically active substances, vitamins, organic acids, etc. determines its use in the production of cosmetics, medicines and animal feed. Also, the remaining needles themselves can be processed into feed additives in the form of flour, the value of which lies in its bactericidal properties.

Among other things, wood waste can be used in the fertilizer business. For this purpose, they resort to a method of destroying organic residues such as composting. As a result of the decomposition of raw materials placed in compost trenches, a fertilizer similar to humus is obtained.

Mechanical processing methods

Much simpler, but no less useful, is mechanical recycling. The method is that the waste is crushed using special equipment. Processing wood into chips is considered the simplest and most useful way to turn wood scraps into new building material, prepare them for transportation or subsequent chemical processing.

Wood chopping does not require complex technologies and can be implemented in a country house or on a personal plot. Depending on the amount of work, this could be a disposal of scraps left over from clearing the garden, or a profitable business. In any case, before starting work, you need to acquire a shredder.

There are various devices for shredding wood. They have their own design features, differ in power, productivity, and acceptable waste parameters. You can buy a device with the desired characteristics or make it yourself.

Types of Shredders

The purpose of this type of device is to grind branches, slabs, trimmings, and wood with serious defects to produce chips of a given size. There are devices with horizontal and inclined loading. Based on the design features, we can distinguish drum, knife, disk, and rotary devices.

Most models are intended for stationary use, while some (mobile) can be used directly at the deforestation site.

Hammer crushers

The working tool of the crusher is several hammers movably mounted on a rotating disk. The crusher crushes by applying a series of blows to the material to be processed. Thanks to the rotational energy of heavy hammers, it is possible to break not only sawmill waste, but also whole trunks. Some models can chop logs up to half a meter thick or more.

The use of a hammer crusher in the household is justified due to such advantages as versatility, unpretentiousness and ease of maintenance, high power, and complete absence of waste.

It is also worth noting the high quality of the resulting chips; it can be used in any technological processes without additional processing.

Knife crushers (shredders)

The shredder crushes the wood with rotating knives, which makes it possible to obtain chips with precisely specified geometric parameters. This device can work not only with clean wood, but also shred construction waste, including those replete with metal fasteners. There are vertical and horizontal shredder types.

A shredder for a particular production is selected based on the list of work it performs and the volume of waste that needs to be processed.

Production of fuel briquettes

Wood burns well, which is why many people use wood waste to make fuel cells. Excellent results are obtained by briquetting - pressing sawdust, wood chips, branches into briquettes of a standard size. This fuel is ideal for domestic and industrial solid fuel boilers with automated fuel supply.

Of course, it is basically impossible to make a briquette using a press alone. The briquette will simply fall apart. To connect the chips into a single whole, resins or binders from petroleum products are used. It is also worth noting that the ash obtained from the combustion of such fuel is itself a product of wood processing. This is an excellent fertilizer.

In addition to briquettes, which usually have the shape of a regular parallelepiped, many boiler models use fine fraction fuel - granules. They are made in a similar way. The main advantage of pellets is that by adjusting the supply to the firebox, you can accurately control the boiler temperature.

Construction materials from wood waste

At all times, wood has been considered as a building material, so it is not surprising that wood chips and sawdust are used to create slabs with different strength characteristics. On a modern construction site it is difficult to do without OSB - oriented strand boards. They are a multilayer material made of laminated wood chips. Characterized by high strength and durability. To make them, large thin wood chips are used, each layer of which is laid perpendicular to the previous one.

Fine sawdust is used to make fiberboard - fibreboard. Such a product is indispensable not only in construction, but also in furniture production. For the same purposes, chipboard is used - chipboard. It is characterized by high strength and ease of processing.

Options for using sawdust

By-products remaining during the processing of wood raw materials - shavings and small sawdust - are materials used in many industries. They are used in agriculture, construction, in the production of fuel, etc., as a material for smoking meat products. There is special equipment for processing and producing pressed sawdust.

Fuel production

The climate features of most of Russia make it necessary to install a reliable heating system in country houses. And it requires suitable fuel. The best option would be to use coal, firewood or pressed briquettes from wood waste.

Fuel pellets are cylindrical granules made from compressed sawdust. They are used to light a home fireplace, stove, sauna boiler, barbecue, barbecue. The process of producing such fuel from sawdust includes a number of stages:

- Crushing large sawdust into smaller fractions.

- Drying.

- Complete removal of existing impurities.

- Hydration. The moisture content is adjusted to 12%.

- Pressing using special equipment. For this purpose, form-forming binders are not used.

- Cooling.

- Repeated drying.

- Packaging of finished pellets.

The use of wood pellets as solid fuel has a number of advantages compared to firewood or coal. Fast ignition, high combustion rate, convenient storage, etc.

Manufacturing of building materials

Manufacturers of building materials use organic fillers in the production of concrete blocks, wood blocks, wood concrete, and fiberboard. These materials, like laminated veneer lumber, are used for the construction of low-rise monolithic buildings, outbuildings, and garages. They have high thermal insulation and sound insulation properties, and vapor permeability. Such indicators ensure a healthy indoor microclimate. Due to these properties, additional thermal insulation of the walls is not required. Wood processing products are also used as insulation and screed.

When producing building materials with wood sawdust, mixtures are made that include sand, cement, and antiseptic substances to increase fire resistance and repel pests - insects, rodents, etc.

Wood boards - chipboard, fiberboard, plywood - are made from sawdust and shavings. To produce such boards, the method of pressing a mixture of wood processing products with special chemical compounds that serve as a binding component is used.

These materials from wood waste are used in the production of furniture and finishing construction work. They completely retain the properties of natural wood, and are superior to it in a number of indicators. Slabs made from sawdust and shavings are not subject to rotting and cracking, the effects of parasitic fungi, and warping. They do not deform and retain their original size. The cost of furniture made from such boards is lower, which makes it more affordable. In terms of strength, such products are superior to items made from ordinary wood. The water resistance of boards made from sawdust and shavings is higher due to the natural and synthetic resins included in its composition. It is easier to process such boards: paint, saw, glue, etc., than materials made from ordinary wood.

Household and Agriculture

Wood processing waste is used in agriculture and animal husbandry. They can be used to make fertilizers and compost. They are used to mulch the soil to protect plant roots during severe frosts or hurricane winds. To produce effective fertilizers, special components are added to sawdust - urea, etc., to prevent nitrogen from being sucked out of the soil. Wood waste containing nitrogen compounds is suitable not only as a fertilizer, but also as a mulching agent. Sawdust from coniferous, mainly pine, wood is a means to combat the Colorado potato beetle. Sawdust fertilizers do not contain weed seeds and retain moisture in the soil. They are sprinkled on garden paths for convenience and aesthetics. They are also used for growing mushrooms and germinating seeds.

Wood shavings and sawdust are used on farms as bedding for housing animals. They have hygroscopicity - the ability to absorb moisture and reduce odor in the room, and antibacterial properties. Pressed sawdust is used to fill cat litter trays. Processing wood waste makes it possible to obtain valuable products for agriculture.

Sawdust is used for crafts - interesting figurines, dishes. To do this, prepare a mixture of raw sawdust with starch, water, and PVA glue. Such products are safe for human health.

Repair and construction work

Wood processing waste: sawdust, shavings, wood chips are used in construction, repair and finishing work. They are used as insulation for one-story buildings. This budget material, mixed with gypsum, lime, and cement, is suitable for any type of structure. They are pre-treated with antiseptic solutions. This repels rodents, insects and other pests and eliminates the risk of fire in the structure. The finished mixture is poured into the walls and compacted. This method of insulation is effective and meets environmental requirements.

Wood chips are wood processing waste crushed using special equipment. It is used for decorating lawns, mulching the soil, producing building materials - wood concrete, woodchip cement boards, etc., and solid fuel. Wood chips are used in the food industry: for smoking food, for infusing alcoholic beverages.

Charcoal production

Perhaps the best way to dispose of wood waste is to make charcoal. As a result of pyrolysis (combustion in an atmosphere without oxygen), it is possible to create fuel with a fairly high heat transfer coefficient. Coal is primarily used in domestic and industrial boilers, but its scope is not limited to this. Coal is used in medicine and in the metallurgical industry.

There are three classes of charcoal.

A - made from branches and solid waste of deciduous trees.

B - created by mixing hard and soft waste.

C – a mixture of hard, soft and coniferous species.

The prepared waste is loaded into ovens, in which the pyrolysis process occurs at a temperature of about 450 degrees. As a result of processing, the wood is divided into three fractions: gas, liquid and solid residue - charcoal.

A feature of the pyrolysis process is the fact that each resulting fraction undergoes additional processing and is used for various purposes. Solid coal is stabilized, cooled and packaged in bags and bags. The liquid residue is drained and undergoes several stages of processing, resulting in the production of methyl alcohol, aldehydes, and acetic acid. The gas released during pyrolysis does not disappear either. Chemically, it is a mixture of various flammable gases, mainly methane, which contains impurities of carbon monoxide. The gas is purified and reused to heat the next batch of waste or for heating premises.

Classification of wood waste

Wood waste consists of the following materials:

- Coniferous, deciduous

- Lump

- Logging waste at a logging site

- Trunk fragments, brushwood, dead wood

- Crown waste

- Stumps and roots

- Logging waste in timber warehouses

- Crown waste

- Bucking waste

- Sawmill waste

- Trim the logs

- Croaker, lath

- Lumber pieces

- Wood waste

- Slats, end cuts

- Lumber pieces

- Wood waste

- Coniferous, deciduous

- Lump

- Plywood production waste

- Pencils

- Log pieces

- Veneer flaw, veneer and plywood trims

- Cut my hair off

- Soft

- Sawmill waste

- wood chips

- Sawdust

- Wood waste

- Sawdust

- Shavings

- Sanded dust

- Bark

- Debarking waste, bark on wood

- Bark

- Wood waste

- Coniferous, deciduous

- Woody greens

- Logging waste

- Foliage (needles)

- Small branches

In large cities, the problem of recycling wood waste generated during tree maintenance and sanitary felling in the process of caring for green spaces on streets, parks, public gardens, forest parks, etc. will be a problem. – this is low-quality wood of medium size, tops, branches, butts of coniferous and deciduous species. In addition, wood waste released during the sorting of solid waste - lumber waste during the renovation of buildings and premises, disused wooden products, containers and furniture - also pose a problem.

An attempt to classify waste according to industry principles was made in the 80s - TU 13-539-85 “Wood waste” was developed and approved. Technical conditions". Currently, GOST R 56070-2014 “Wood waste. Technical conditions".

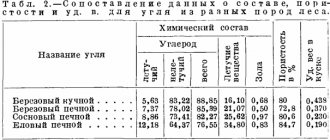

Wood production waste is waste from logging, sawmilling and woodworking. Wood waste is classified according to three main characteristics: type of wood waste (species composition, type of waste, size), industry and area of application.

The greatest value for wood waste is large-piece waste (more than a meter long) in the form of trunks of low-value wood, slats, slabs, cuttings of lumber and blanks, and pencils.

Less valuable are lump fines and soft wood waste. Their use as raw materials is limited.

The total volume of production of wood waste in the Russian Federation is estimated at 15-20 million dense cubic meters, and the volume of use is 8-13 million m3, mainly due to the use of large lump waste.