Products called sleepers are used as supports for rails for various purposes. The following materials are used for their manufacture: concrete, wood, metal, modern synthetic materials. Wooden sleepers are considered the cheapest to produce. They were the first to be used for laying railway tracks. Wooden sleepers have a number of advantages that allow them to be used quite widely. They are used to fasten rails on main and secondary tracks. Various types of wood are used for production. The production technology and final cost depend on this. Currently, they have been replaced by railway sleepers made of other materials. However, wooden products are still used in various fields.

Classification by type

In modern standardization, wooden sleepers are classified according to the following criteria:

- form of manufacture (edged, half-edged, unedged);

- quality;

- presence of impregnation (impregnated or unimpregnated);

- scope of application

According to the first sign, wooden sleepers may have an additional sign. This includes the so-called deeply split timbers. On the surface, such railway sleepers have special notches that promote deeper penetration of the antiseptic liquid. In terms of quality, wooden sleepers are available in two grades. First-class products are used on the most important sections of the road. Second grade sleepers are installed on secondary tracks.

Based on the third and fourth characteristics, wooden sleepers are divided into types. Type 1 is used for main paths of the first and second class. They are allowed to be used for third class tracks with a load load exceeding 50 million t×km gross/km. Usually this is an impregnated sleeper of type 1. Type 2 is allowed for installation on main tracks of the third and fourth class, access and marshalling tracks. The third type is used for any fifth class paths.

Standard requirements

Reinforced concrete sleepers are manufactured in accordance with regulatory documents with strictly observed shapes and sizes. Strength and other indicators of reinforced concrete sleepers are reflected in GOST 33320–2015. These are products whose performance characteristics are subject to the following requirements:

- Strength parameters. The force transmitting pre-tension occurs immediately after the product is manufactured.

- Concrete parameters. The mixture must have the highest degree of uniformity of consistency.

- Exact shapes and sizes. Compliance with these parameters is typical for these designs. There are strict tolerances on sleeper elements, and compliance with specified standards of connection points with rails is verified.

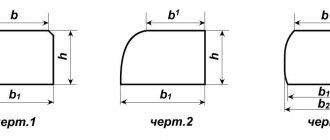

Table. Types of wooden sleepers.

| Sleeper type | Thickness h, mm | Height of sawn sides h1, mm | Width, mm | Length, mm | ||

| upper surface no less | bottom layer | |||||

| b | b' | b1 | ||||

| I | 180±5 | 150 | 180 | 210 | 250±5 | 2750±20 |

| II | 160±5 | 130 | 150 | 195 | 230±5 | |

| III | 150±5 | 105 | 140 | 190 | 230±5 | |

Sleepers according to their purpose are divided into three types: I - for main tracks of the 1st and 2nd classes1, as well as for tracks of the 3rd class with a freight load of more than 50 million t.km gross/km per year or train speeds of more than 100 km/h II – for main tracks of the 3rd and 4th class, access tracks with intensive work, receiving and sorting tracks at stations; III – for any 5th class tracks, including station tracks, inactive access roads and other tracks with shunting and export traffic. The dimensions of wooden sleepers are established for wood with a moisture content of no more than 22%. With higher wood moisture content, sleepers must have allowances for shrinkage in thickness and width for coniferous species in accordance with GOST 6782.1-75, and for deciduous species in accordance with GOST 6782.2-75.

READ What is lumber?

Overall dimensions and weight of wooden railway sleepers

The accepted standard establishes the geometric dimensions of a wooden sleeper. For all types, the sleeper length is set to 2750 mm. The permitted tolerance is 20 mm. The weight of the wooden sleeper will depend on the other dimensions. The height varies from 150 mm for the first type to 105 mm for the third. The width is determined by the shape and design. These parameters determine the purpose of the railway sleeper and its operating conditions. How much the railway option weighs depends on all the listed parameters. After impregnation, the weight increases slightly. The weight of one sleeper depends on its design. The mass of a wooden sleeper of the first type is 85 kg. It must withstand the heaviest loads. The weight of the second type does not exceed 80 kg. The dimensions of wooden sleepers in the standard are specified taking into account the condition of the wood. Humidity should not exceed twenty-two percent. Therefore, sleeper sizes may differ in one batch, but within tolerance. Before production begins, the dimensions of future products are set. Particular attention is paid to this parameter thickness. It must be constant along the entire length.

Standardized sizes

We have given the geometric characteristics of supporting structures of types 1 and 2 in the tables above (and also looked at how much an impregnated wooden railway sleeper weighs - we remind you, 85 and 80 kg). So now let's look at the third category.

a) edged;

b) semi-edged;

c) unedged.

| Parameter | Indicator, mm | ||

| Length | 2750 ± 20 | ||

| Width across face | |||

| Lower | Upper | 230 ± 5 | 140-190 |

| Climb | 160 | ||

There is another important element in the design of the VSP, which must also meet a number of standards - we suggest you pay attention to it.

Dimensions of railway sleepers according to GOST

Geometric characteristics (sizes of sleepers) and classification are given based on the requirements established by the state standard. For example, GOST 78-2004 wooden sleepers for broad gauge railways combines all the characteristics of finished products. For special routes, their own standards have been developed. GOST 22830-77 wooden sleepers for the subway specifies the individual parameters necessary for their operation in these specific conditions. Each standard is consistent with other guidance documents consistent with the operating rules of the various tracks. GOST imposes certain restrictions on wooden sleepers regarding their area of application. Particular attention is paid to the choice of coating that is applied to the surface to improve their technical characteristics.

GOST 78-2004 Wooden sleepers for broad gauge railways. Specifications

1 file 462.81 KB

GOST 22830-77 Wooden sleepers for the subway. Specifications

1 file 586.90 KB

Technical requirements for wooden sleepers of standard size and weight

The approved documents provide detailed requirements for the parameters of finished wooden products. There are separate requirements for unimpregnated and impregnated (treated) sleepers. High requirements are necessary, as this is related to the safe operation of rolling stock.

Requirements for unimpregnated sleepers

After sawing, unimpregnated sleepers must meet established standards. The main technical requirements for unimpregnated sleepers are:

- choice of material (the use of coniferous wood is allowed, in some cases it is allowed to manufacture unimpregnated products for railways from birch);

- the number of permitted defects when choosing wood is established by GOST 78-89;

- the size of the deep tattoo should be 10 mm;

- The impregnated wooden sleeper must have a smooth surface without bark and bast with cut knots;

- When compiling a batch, they should be separated by wood species.

Each class has its own individual requirements.

Requirements for impregnated sleepers

Such products must meet the following requirements:

- the quality of impregnation must comply with GOST 20022.5-93;

- impregnated sleepers must have holes for fastenings in strictly established places;

- impregnation is carried out only with approved antiseptic solutions in compliance with technology;

- Impregnated wooden sleepers type 2 are manufactured with greater tolerances than type 1;

- Railway sleepers impregnated with antiseptic agents must have the depth of impregnation specified in the instructions for the specific antiseptic agent.

Exact compliance with the requirements for unimpregnated samples ensures a long service life.

GOST 20022.5-93 Wood protection. Autoclave impregnation with oily protective agents

1 file 96.43 KB

Scope of use

Depending on the material and production technology, the following are used:

- Reinforced concrete.

- for separate rail fastening (type I is used);

- for continuous rail fastening (types II and III are used).

- Wooden.

- on main tracks of the first and second class at permitted speeds of no more than 100 km/h (type I);

- main tracks of the third and fourth class and access roads (type II);

- for fifth class tracks, access roads, rarely used (type III).

- Steel.

- on access roads of blast furnace and steelmaking production;

- on sections of track with increased axle load (up to 60 tons);

- in some countries of northern Africa and Saudi Arabia.

- Composite with polymer coating.

- on heavy-duty sections of a short-radius track;

- in turnout designs;

- in climatic zones with prolonged exposure to high temperatures (up to 50 ° C);

- in areas with weak and unstable soils.

Specific products are selected based on accepted standards and established norms and rules for laying railway tracks.

Average service life

This indicator is determined by several parameters:

- type of wood used;

- quality of processing and antiseptic used;

- compliance with storage conditions (specified in the relevant standard);

- applied loads and operating conditions.

If all requirements of state standards are correctly observed, the average service life of sleepers made for large gauge is approximately sixteen years. This period can be extended by five to six years during repair and restoration work, which allows you to get a good amount of savings.

Delivery

| Delivery type | Price, rub |

| Delivery across Russia | Check with the manager |

| Delivery throughout the CIS | Check with the manager |

We will deliver in a short time to any region to your facility or production. We will transport using our own vehicles. We also arrange railway freight transportation. If necessary, we insure and accompany the cargo.

Attention! Contact the manager and receive an INDIVIDUAL and FAVORABLE offer by phone: +77 +7 (49234) 333-78 +7 (49234) 218-67 +7

Technology for the production of wooden sleepers

The production of sleepers differs in the following characteristics:

- cutting method;

- the equipment used;

- the material used.

According to the cutting method they are divided:

- for edged ones;

- not edged;

- semi-edged.

In the first case, trimming is done on all four sides. In the second, the cut is carried out on two sides and in the third on three sides. Production begins with the choice of material, that is, what to make them from. Wooden sleepers can be made from hardwood or softwood. The production of sleepers is carried out in the following sequence:

- selection of lumber of the required size;

- marking the ridge onto wooden sleepers;

- direct sawing (production of wooden sleepers);

- treatment (impregnation) in antiseptic;

- drying impregnated wooden sleepers;

- sorting of finished products and labeling;

- preparation of technological holes for fasteners.

The result is wooden products of the required type for use on specific sections of the railway.

Sawing sleeper ridges

This technological operation (sleeper cutting) is carried out on the basis of GOST 8486-86. Depending on the size of the ridge, appropriate cutting schemes have been developed. Production productivity largely depends on the diameter of the log and the chosen pattern. The main task of choosing the right scheme is to reduce the amount of waste when cutting. Currently, seven basic and more than forty modified rational cutting schemes have been developed. They are designed for the use of sleeper logs with a diameter of 255 to 700 millimeters. These schemes can be changed depending on the specific conditions of the cut being made.

GOST 8486-86 Softwood lumber. Specifications

1 file 440.08 KB

Wood for sleepers

The choice of tree largely depends on local conditions. These can be coniferous or deciduous trees growing in a given area. Coniferous species used: spruce, pine, larch, cedar. The hardwoods used are birch, oak or ash.

Sawing equipment

For high-quality sawing of harvested logs, circular saws or band saws are used. Each of them has a well-developed methodology that allows you to obtain high-quality workpieces.

The most common machine for sawing, including bridge and transfer beams, are Russian-made machines of the TsDT6 series. Structurally, they consist of the following main elements:

- ridge fastening mechanism;

- feed devices;

- navigation systems;

- sawing mechanism (consists of a welded frame, saw shaft, riving knife and excessive vibration damping device);

- roller conveyor for cleaning sawing waste;

- saw;

- fencing mechanism.

In different machine configurations, the designs of individual elements may differ. By special order, the manufacturer can produce an additional unit with a mounted saw as additional equipment. It allows you to cut logs up to 1000 mm in size. Modern machines are equipped with mechanization equipment, which includes a hydraulic system for securing, rotating and feeding the workpiece, an automatic centering system, and an automatic sleeper with a support and end clamp.

Impregnation of wooden railway sleepers

The low cost of production of such products for railway tracks does not provide a full economic effect. This is due to their short service life. To increase this indicator, finished workpieces must be impregnated with special solutions that can give them strength and resistance to destruction and prevent premature rotting. For this purpose, sleepers are processed on an industrial scale. Depending on the scope of application, the manufacturer decides how to process railway sleepers. By the quality of the applied antiseptic and the resulting color, you can determine what the sleepers are treated with.

Impregnation compositions

To understand how sleepers are processed, you need to understand where they will be used. Currently, manufacturers offer various liquids for impregnating sleepers. Each of them has its own specific properties and is used for specific operating conditions of laid sleepers on the railway. The main tasks that are solved during impregnation are:

- resistance to negative environmental factors;

- protection of wood from rotting;

- improvement of mechanical characteristics (strength, elasticity);

- ensuring a long service life.

For impregnation of sleepers the following is mainly used:

- creosote, obtained from coal;

- coal tar;

- anthracene oil;

- various solutions of mineral salts.

The first two solutions prevent cracking of finished products when exposed to the atmosphere. Workpieces treated with oils are not susceptible to wood destruction by various pests. The variety of means for impregnating sleepers allows, with the correct use of the solution used, to solve all the necessary technical problems.

Large enterprises use the autoclave impregnation method. It allows you to create conditions so that a certain number of sleepers are impregnated with the same quality. To improve the effect of the impregnating liquid, special notches are applied to the wooden surface during processing. They will be impregnated to a great depth and completely get rid of rot. Depending on what the sleepers are treated with, it is necessary to follow the established safety measures. The flow chart of the technological process depends on the composition of the liquid used. Carrying out processing is dangerous for operating personnel. This is especially necessary when individual areas of finished workpieces or the entire surface are coated manually.

Elemsept

This antiseptic is used for treating wood in industrial conditions. An aqueous solution is prepared from Elemsept, in which the treatment is carried out. It is produced in two grades: A30 and A60. Each of them contains oxides of copper, arsenic and chromium. The versatility of the antiseptic allows it to be used in any climatic zone, which is confirmed by technical specifications 2157-107-00194429-2016.

ZhTK

This thermal condensation liquid is a petroleum refining product. Each manufacturer has its own patent for the production of this antiseptic. The basic requirements are set out in GOST 20022.5-93. Today it is the most effective substitute for coal sleeper impregnation oil. ZhTK belongs to the fourth hazard class. A significant advantage is the fairly low pour point. It varies from minus two to minus thirty degrees. Impregnated sleepers are odorless and do not produce toxic emissions.

GOST 20022.5-93 Wood protection. Autoclave impregnation with oily protective agents

1 file 96.43 KB

Types of wooden sleepers. Why does wood continue to be the best material for sleepers?

Sleepers are horizontal supports that allow the rails to be positioned at equal distances from each other. Meanwhile, maintaining the specified distance is critically important.

Today sleepers are made from various materials:

- tree;

- metal;

- plastic, etc.

It should be noted that despite the significant development of industry, wooden sleepers continue to be the most preferred in use. After all, they have all the necessary technical parameters and are as affordable as possible.

Wooden sleepers can be divided into the following classes: edged, half-edged, unedged.

Among the disadvantages of using wooden sleepers, only one can be noted. They rot where they meet the rails. However, there is a simple way to avoid this problem - the use of antiseptic solutions.

In Russia, pine is considered such wood. The fact is that this is the most common wood, which means it is the cheapest. In Western countries, cedar, maple and even eucalyptus can also be used to produce sleepers.

The main property that wooden sleepers should have is plasticity. When a train passes along the rails, they must keep them at the same distance from each other.

However, if hard metal is used instead of wood, vibration will occur in it (malignant). Wood dampens vibration without any problems. More precisely, it passes through it, but there is no negative impact.

The only thing you should pay attention to is local rotting of the tree. If this happens, it is strongly recommended to replace the sleeper with a new one.

Unedged sleepers rot the least. However, they are much more difficult to install. It will not be possible to replace them within ten minutes. Meanwhile, plastic sleepers are being actively introduced in Europe. They are more durable than wooden ones, but also much more expensive.

Despite this, in the long term (tens of years) they turn out to be more practical.

The video will demonstrate how sleepers are made today: