Even at the beginning of the last century, this type of cladding, such as lining, was not known to anyone. Only after the widespread use of freight cars lined with this type of finishing did people learn about this method. And people began to massively use this profile to decorate and protect their homes. But in order for this coating to look beautiful and please the eye, high-quality installation is required. In order to achieve this, you need high-quality lining, the exact dimensions of which will be indicated in the table. Choosing such a coating is a very responsible step, but if you follow all the rules, the result will stun you.

Standard lining sizes

Lining is a thin cut of natural wood. Installation of the panels is simple, and the surface is beautiful. The standard thickness of these products varies from 12 to 20 mm. These values are enough to prevent the board from breaking or being pressed during installation. Size is also important when calculating the required volumes. Many people are interested in the question of whether there are standard sizes of lining. It is worth studying the features of the various types in more detail.

Types of lining profiles

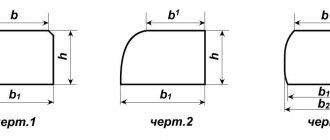

Since lining is used for cladding many surfaces, manufacturers take into account the desires of buyers to give their premises some individuality and produce several types of profiles that can be selected not only by appearance, but also for certain types of work. Profiles differ from each other in the presence or absence of chamfers, types of locks, shape and size of the front and back sides.

Traditional eurolining

On the front side of such a profile, near the tenon, an additional chamfer is selected, as a result of which, after installation, pronounced seams are visible on the wall. The chamfer can be angular or rounded. The rounded one is called Softline.

Lining "Softline"

Since this surface shape is devoid of corners, there is less likelihood of chips and burrs appearing during operation, therefore Softline is considered more suitable for rooms such as a sauna.

Lining "Calm"

The difference between this profile is the absence of a chamfer near the tenon, so the seams after installation are not as pronounced as when using traditional lining. This is used when necessary to create an imitation of a wall assembled from timber, so most of the Shtil lining is produced thickened up to 25 mm and can be freely used for cladding building facades.

Lining "Landhouse"

Lamellas, which include these types of wooden lining, are among the most expensive, since during their production the front side is subjected to milling or other processing methods that form complex patterns on the surface of the wood. There are even profiles with the effect of wood carvings, which are obtained using hot stamping under a press.

Blockhouse lining

If the “Calm” lining imitates walls made of timber, then the “Blockhouse” profile has a completely rounded front part. Thanks to this solution, after assembly the wall looks as if the house was assembled from rounded logs. Mainly used for cladding building facades.

American paneling

In this profile, the chamfer near the tenon is not simply removed, but a smooth transition is made from it to the middle of the front part. Thanks to this solution, an exact imitation of siding panels is achieved, but at the same time the house is lined with natural wood.

Double-sided lining

This profile does not have a back side - both of its parts are made front. This lining will come in handy if you need to make a thin wooden partition. Also, when covering a wall, it is possible to choose a more successful pattern or place small defects on the back side.

This lining is strongly not recommended for use in rooms with high and variable humidity, since it is the only one of all types of eurolining that does not have compensation (ventilation) ducts.

Peculiarities

The main dimensions of wood bases are regulated by standardization corresponding to GOSTs 8242-88 for profile parts made of wood for construction and 8486-86 for lumber of softwood. There is also a European parameter for industry - DIN 68126/86. There are no strict regulations on the length of the lining. Products are on sale from 2 to 6 meters. Buyers purchase goods that are more convenient to transport. There are also no strict parameters for the width, so it varies from 13 to 120 mm.

The standard allows a deviation of the size range by no more than 1 mm, and the deviation from straightness is no more than 3 mm per 1 linear meter of length.

The main features of the lining are its length and width. These indicators are taken as a guide when calculating the quantity of production. Regardless of the dimensions, laying any boards is carried out according to an identical principle. This is convenient for the consumer. Since, for example, if replacement or repair is necessary, it will not be difficult to find a similar part of the required size and with an identical fixation method.

To avoid any difficulties during installation, it is important to study the instructions supplied for a specific type of product. Usually it is included in the packaging with the product. Differences may be present if the lining is of European or domestic production. The differences lie precisely in the standard sizes of the varieties. Domestic lining of the first, second or third grade does not correspond to the standard dimensions of European-made products of class A, B, C. The same dimensions can only be found in products of the “elite” class. However, there is a difference here, since European-made products are usually more expensive.

By the way, the cost of the lining is very dependent on the dimensions. If we consider the length, then, as a rule, short boards are cheaper. Long boards are more expensive, since the blanks are usually needed for hemming roof overhangs and should not contain dead knots. If at the processing stage there are dead knots in a long board, then they are cut off and products of the same harvested grade are obtained, but shorter. If dead knots remain, they will fall out of the finished products at any time, resulting in defective finishing.

Experts also distinguish between living knots. They will not fall out when using the board, so in some grade categories they can be left on. Lining with live knots is suitable for finishing walls indoors. Inexpensive varieties are usually used for baths, hallways, and other similar rooms where a particularly sophisticated finish is not required. With proper processing, lining of exquisite varieties can turn into designer decor, so it is worth considering the varietal types in more detail.

Source

Spliced lining

This is the only type of lamellas that do not have tongue-and-groove ends. Its sidewalls are cut with a milling cutter and then glued together with thermoplastic adhesives during installation. The result is a solid fabric without seams, having the required dimensions. The spliced coating does not warp or change over time; In this way you can choose a beautiful, uniform pattern over the entire area.

Among the disadvantages of this type of material is the instability of adhesive joints to the influence of humid air and elevated temperatures, so it is definitely not worth laying ordinary spliced products in bathhouses. European standards provide for dividing the material into groups for possible long-term use in certain conditions:

- D 1 products are recommended to be installed only indoors with humidity not exceeding 15%;

- D 2 may be present in rooms where short-term, unintentional excess humidity is possible;

- D 3 can be used in rooms with a predictably high concentration of water vapor, for example in kitchens;

- D 4 can withstand dampness, water flows, and high humidity for a long time. This type of lining can be used to line the interior of a bathhouse, and after preliminary preparation, external cladding can be performed.

Spliced lamellas are used to cover any surface. At the same time, depending on the future location, experienced craftsmen give preference to different types of wood.

They try to lay oak paneling on the floor because it has very high hardness and abrasion resistance. For a bath, many owners try to buy aspen products in a light, preferably white, color.

Larch profiles normally withstand the influence of the street; they are laid on balconies, terraces, and verandas. After processing, larch profiles can be used to cover external walls; the adhesive joint becomes more durable under the influence of protective agents.

It is not easy to obtain high-quality material from coniferous wood because it has many knots. The cost of such planks for splicing can be higher than other wood profiles. The buyer needs to be prepared to pay a considerable price for this type of product; not a single manufacturer supplies the market with good and cheap jointed lining.

How to decipher the manufacturer's inscription

We read the marking as follows:

- Sheathing brand (see details below)

- Type of lining (see table below)

- ThicknessxWidthxLength

- GOST

- Sometimes manufacturers indicate the number of pieces per package

An example of a symbol for eurolining:

Grade C 12.5×96(88)x2000 mm 10 pcs. in unitary enterprise Eurolining grade C, 12.5 mm thick, 96 mm thick, 2000 mm long. Pack of 10 pcs.

An example of a regular lining according to GOST:

O-3-13x120x4000-GOST 8242-88 This means - Sheathing grade O-mm, 120 mm wide, 4000 mm long, manufactured in accordance with GOST 8242-88.

Choosing a type of lining

When purchasing lining, pay attention to the grade; the appearance of the future cladding and the durability of the structure directly depend on it. You will find a more detailed general classification of wood types and characteristics in this article.

Important! Inspect the lining upon purchase or acceptance to ensure that it actually corresponds to the declared grade.

Variety Extra

Expensive, as they say, elite lining without defects. The best samples are selected for it, which will have only a natural wood pattern. Often, to produce such lining, wood is longitudinally spliced using an industrial method. Outwardly, it will be almost invisible, since a microspike circuit and high-precision equipment are used.

The best option if your budget is not limited and you want to create the perfect finish for your living space without painting.

Grade A

Expensive, high-quality lining with a minimum number of defects. Without falling out knots, rot, blue stains, mold and wormholes. Shallow cracks are allowed, and the core should occupy no more than 20% of the board.

An excellent option for cladding residential premises without the use of paint; a varnish coating will be sufficient to highlight the natural texture and provide additional protection to the coating.

Grade B

Middle class lining with visual defects. Allowed:

- lack of stitching on the end part;

- chips, dents, potholes, wormholes and small cracks (no more than 3 cm per 60 cm linear meter);

- blueness and rot (no more than 10%);

- resin pockets, knots and core.

A decent budget option that is suitable for both interior decoration and facade work.

Grade C

Cheap lining of low quality. A large number of defects are allowed, which may interfere with installation and require additional effort for adjustment.

It may only be suitable for an extremely limited budget, arrangement of premises for temporary residence, utility rooms or rough work.

By the way! Some manufacturers may indicate a mixed class, such as AB. This means that the front side will correspond to grade A, and the back to grade B. However, for the lining this will not play a special role during installation, and such grades are slightly cheaper than pure analogues.

Varieties and varieties of eurolining made of wood

Wooden eurolining can be classified according to its manufacturing profile.

Today you can find two profiles on the market.

- A standard that can be referred to as ordinary lining, “collective farmer” or “classic”. A special feature of this finishing material is the minimum number of grooves, which are practically absent.

- Eurolining has a similar appearance to the previous profile, however, more stringent requirements are imposed on this material. In addition to them, when joining the lamellas in this case there is always a slight groove. In some situations it reaches up to 15 mm.

Let's present the most common types of eurolining, which are characterized by a vertical fastening method.

- Softline is a type where the boards are slightly rounded. The width and length of the material allows for quick façade finishing.

- Wave is a type of eurolining, the front side of which is slightly concave.

There are other types of wooden lining that differ in the horizontal method of fastening.

There are several varieties worth paying attention to here.

- American. Using this type of eurolining, you can simulate the laying of wooden boards. Most often used for exterior decoration. Eurolining is characterized by protection in the area of the joints, where moisture cannot enter. Since these panels can be purchased in different widths, cladding the house can be done as quickly as possible.

- Imitation of timber. In this situation, the lining has a standard profile.

- Block house. If you use this material to finish a building, it will look like a log house. They differ in different lengths and widths, so finishing is quite simple.

Details about eurolining

Let's consider the types of profiles that are considered the most popular on the market:

- Softline - this type of profile has a slightly rounded shape. The width and length of the panels make it easy and quick to complete the façade cladding;

- Wave - this profile has a slightly concave front side, which imitates the effect of a wave;

- American - this type of lining creates an imitation of finishing the facade with wooden boards. Well-protected joint areas encourage the choice of such material for façade finishing;

- Imitation of timber - in this case, the lining has a standard profile;

- Block house - when decorated with such panels, the house looks like a log house;

Some factors are considered the main advantages of eurolining:

- Guaranteed ecological beauty;

- The material has a beautiful appearance. The buyer has a wonderful opportunity to choose from a very wide range of structures and shades, which opens up unique possibilities for different design options;

- Perfectly heat and sound insulates the room;

- With proper care and proper installation, eurolining has a long service life, in some cases more than 50 years, while maintaining its unique, original appearance;

- Simplicity and ease of installation are characteristic of eurolining. Even a person without experience can easily cope with this task thanks to the tongue-and-groove connection system;

- Using this profile you can also perform auxiliary finishing;

Due to the wide variety of sizes, it is easy to calculate the required amount of material based on the surface area that will be finished.

The following indicators stand out from the negative aspects:

- During operation of the wooden profile, deformation is possible. This largely depends on the type and quality of wood you choose;

- This material is flammable and therefore extreme care should be taken during installation. Of course, this indicator largely depends on the selected raw materials.

These deficiencies can be easily corrected with the help of additional, special solutions and high-quality installation.

Advantages and disadvantages

Lining is a natural and pure material with an unforgettable smell of forest. The room sheathed with it preserves the natural microclimate. When there is excess moisture in the room, the wood absorbs it and releases it when it is very dry.

Conifers create a pleasant aroma that hangs in the air and creates a feeling of comfort and warmth. It has the best sound and heat insulation properties, ease of installation, the ability to hide uneven walls, hide electrical wiring and communications.

But it should be noted that when covering the interior, the area is reduced, and the price is much higher than artificial materials. In addition, the lining is susceptible to burning, although using special impregnations, this disadvantage can be avoided.

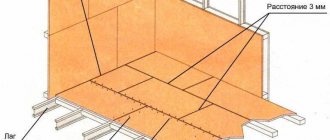

During installation, no expensive wall treatment is required; the main thing is to firmly secure the sheathing made of bars or metal profiles. And there is an opportunity to strengthen the insulation.

Lining quantity calculator

Block house

It is believed that such panels are more often used to decorate facades. However, they are no less popular among the owners of country houses, who prefer to decorate, if not the entire house, then some of the rooms with just such lining. Its peculiarity is that the front side is convex. When several boards are attached to a supporting frame, they successfully imitate the wall of a log house. See the main dimensions of the block house here.

American

This is an imitation of another lumber - timber. It is not used so often for interior decoration, but there are fans of this type of room design.

Wood species

What is the fundamental difference between them? There are only two points that any home craftsman should know about.

We advise you to study - Economical heating system for a country house based on a solid fuel boiler, from “A” to “Z”

Coniferous wood

The second feature is the specific smell in the room, which persists for a long time after finishing work is completed. From a medical point of view, microelements released by coniferous wood have a beneficial effect on the body. But not all people tolerate it.

Deciduous species

Difficulties with impregnation of the lining. The reason is the same dense structure. Any of the drugs used in such cases will definitely not work.

For example, the width for wooden lining is set from 45 to 120, and the thickness - from 13 to 16 (mm). The length is usually 2.5 or 3 m.

You can give the following advice - before drawing up an installation diagram, planning the interior decoration of the house, you should ask what kind of lining (taking into account the profile, type of wood) is available on the local market. Exactly in size.

Other Features to Consider

Grade

Everyone strives to save money wisely when decorating their home, and this is quite normal. But when choosing cheaper types of lining, you may encounter problems that will result in additional financial losses. Not to mention the time and your own nerves. Based on this, for interior decoration it is recommended to purchase lining of the highest grades (Premium, Extra, Prima) or first grade (A).

How are they different from cheaper products? Firstly, there is no so-called “core” of the tree (pulp). Consequently, the risk of rot developing in the lining structure is significantly reduced. This means that you won’t have to regularly replace individual panels. Secondly, there are fewer defects in the form of knots and “resin pockets.” And the cracks, if any, are insignificant, and no more than 2 per linear meter. By purchasing lining grades B and C, you will be able to save some money on lumber. But then you will have to think about how you can disguise the flaws in the boards. And any composition also costs money + time to work. So it turns out that when it comes to interior finishing, the savings on the type of lining are very illusory.

Specifics of the premises

If its humidity value is higher than normal, then the interior finishing should be done with eurolining. The reason is clear - wider grooves and tenons will ensure the reliability of the cladding.

Fastening technology

Only with hardware (nails, screws, staples) or special devices (clampers). All recommendations for “fitting” lining with glue (there are some on the Internet) do not stand up to criticism. Finishing panels of this type during operation partially absorb wood, swell, and deform under the influence of temperature changes. In other words, they “play.” Rigidly fixing the lining with glue will lead to the cladding “moving”. It will begin to warp, and it will no longer be possible to do without replacing individual panels (and this is putting it mildly). Actually, the issue of unscheduled repairs will be on the agenda.

On the market you can find a number of other panels, which are called lining. Plastic has already been mentioned. But there are also samples made from MDF, for example, with appropriate coating, and metals. The choice is yours, reader. But we should not forget that the original interpretation of the term lining was a finishing board made of solid wood of the correct shape. It is this type of panels, due to the characteristics of lumber (one of which is the ability to “breathe”), that allows you to maintain an acceptable microclimate in the house without additional effort and expense.

Good luck with your choice of lining for the interior decoration of your home!

Care and use

Modern manufacturers offer a huge amount of material for making lining from various types of wood - expensive and budget. Expensive species should not be painted, preserving the natural texture of the wooden paneling. But it is advisable to treat cheaper ones with paint or stain, giving a certain color to the lining and hiding defects that arise during manufacturing.

Do not forget also that lining made of coniferous wood can release essential oils and resins, therefore it is more resistant to high moisture and fungus and is not recommended for finishing baths and saunas. At high temperatures it can ignite spontaneously.

Lining made from hardwood has less strength, but can be used in any room and outside, but it is advisable to sometimes treat it with paint and varnish products.

It does not require special care, although it is not advisable to moisten and wash it generously with detergents. This type of finishing will bring warmth, comfort and coziness to your home. And it will last for quite a long time.

MDF

MDF is a mass of wood waste pressed at high temperatures.

Unlike chipboard, not cement is used as a binder, but melamine resin, which is much less harmful in production and use.

Often, MDF products are laminated with special decorative coatings to imitate valuable wood species, for example:

- oak,

- beech,

- maple,

- Oregon pine, etc.

Also, for decorating MDF, coatings are used that imitate various surface textures, made in a variety of colors. Various MDF products, such as laminate flooring, are increasingly used in construction.

The sizes of MDF linings are significantly more varied, especially in thickness, since this material, having sufficient strength, allows the production of thinner products. Dimensions: typical thickness of MDF lining is 5.5–7, with a width of 100–250 mm.

A little about the sizes of MDF profiles

MDF panels have recently gained popularity for interior decoration. Due to the low price and environmental friendliness, consumers are often inclined to choose just such a coating.

It is produced by pressing wood chips, gluing is done with lignin.

The main difference from a wooden profile is the size and shape of MDF products. Thanks to its low weight, it can be quickly and easily installed anywhere. It is used for finishing walls, ceilings, as well as loggias and balconies. Due to its environmental friendliness, it is often used even in bedrooms. Unlike wood products, MDF panels differ significantly in size: width - from 10 to 25 cm, length - from 100 to 300 cm, thickness - 0.55 cm to 0.7 cm.

Products made from such material do not tolerate high humidity well, for this reason you should not use it in baths, steam rooms, saunas and toilets.

Dimensions and other GOST standards of wooden profiles

Eurolining and domestic ones have a number of differences. For example, domestic panels do not have GOST, which is actively used by unscrupulous manufacturers, sometimes independently selecting the dimensions of finished products. Nowadays you can find different sizes on the market, for example:

- Thickness - from 1.2 to 4 cm;

- Width - from 7.5 to 20 cm;

- Spike size - from 0.4 to 0.5 cm;

- Length - from 20 to 600 cm;

And although errors are not included in the finished material, such defects are still quite common.

Eurolining has more specific parameters; when choosing such a profile, there is a limited variation in sizes:

- Thickness - 1.3; 1.6; 1.9 cm respectively;

- Width - 8, 10, 11, 12 cm;

- Length varies - from 50 to 600 cm;

- Spike - from 0.8 to 0.9 cm.

Errors are strictly regulated and can vary within the following limits: width - 0.7 cm, length - 0.5 cm, thickness - 0.1 cm, spike - no more than 0.1 cm.

Wooden profiles are made from different species. Most often, certain varieties are used to make panels, such as oak, alder, linden and aspen; these are deciduous; coniferous species are usually represented by cedar, larch and pine. The final price of your coating largely depends on the material you choose.

In order not to pay extra money, you should very carefully calculate the required amount of material. Here are several wood options, their parameters and characteristics.

Oak - as a rule, is used for cladding residential premises; it has a natural, beautiful appearance. Unlike other species, oak lining is very durable, although it is many times heavier; finishing with such material will last a long time due to its wear resistance. Oak profile parameters: width - from 5 to 10.8 cm (depending on the manufacturer), length - from 100 to 300 cm (the most common are 300 cm, 270 cm, 250 cm, 180 cm), thickness varies from 1.25 cm up to 1.5 cm (often 1.4 cm).

Aspen - panels made from this type of wood are used for interior decoration; special preference is given to this material when lining steam rooms and baths. There is material on the market from both foreign and domestic manufacturers. For samples of foreign products there are increased requirements for the quality of raw materials, as well as for humidity and size. For this reason, the imported profile is several orders of magnitude more expensive and complies with the European standard DIN 68126.

Our manufacturers do not comply with this standard, but often use GOST, in which the quality is significantly lower than in the European standard. But both foreign and our manufacturers use the following dimensions: total width - 9.6 cm, working width of the lining is 8.8 cm, length - from 100 to 300 cm, and thickness - from 1.25 cm to 1.5 cm (European standard - 1.25 cm).

Pine is the most popular and versatile type of coating; it is used more often than other types in interior decoration. This is mainly due to affordability and ease of processing. Such panels also have their own limits in size: width - from 5 to 10.8 cm, length - from 50 to 300 cm (200-300 cm is more common), thickness - from 1.25 to 1.5 cm (more often than usual - 1.25 cm or 1.3 cm).

Area calculation

The sequence for calculating the area of the surface to be covered is best calculated using the example of a house measuring 6x10, where the ceiling and walls will be sheathed.

Then we calculate the quadrature of the first room. Let's say the length is 6 m, width - 5 and height - 2.5 meters.

Then everything is extremely simple, as taught in school:

- Long side - multiply the height by the length 6x2.5 = 15 m2;

- The wall opposite has the same dimensions, for this reason we multiply the result by two 15x2 = 30 m2;

- Using the same principle, we calculate the square footage of the wall, which is smaller than 5x2.5 = 12.5 m2, multiplying the resulting result again by two 12.5x2 = 23 m2;

- To calculate the ceiling area, multiply the width by the length of the room 5x6 = 30 m2;

- We add up the data obtained and get the coverage area of this room 30+23+30=83 m2;

In the same way, we calculate the area of the remaining rooms, add the result together, and we will know the total quadrature of the entire surface.

We calculate the square footage of the balcony in the same way, except that in this case it is most convenient to divide each side into its constituent figures.

Selection of finishing material

Lamellas are produced in different sizes, manufacturers indicate all indicators in catalogs, and mark them on the products.

With the help of brochures, the user selects the appropriate material for his home. Standard strip sizes:

- thickness – 10 – 25 mm;

- length of lamellas - 0.6 - 3 m;

- width - up to 16 cm;

- the height of the spikes on the side edges is 4 – 8 mm.

Errors in thickness and width are allowed - 1 mm, in length they are allowed up to 5 mm at six meters.

Walls and ceilings in the country house

The dacha is located outside the city and is intended for recreation, so the interior space is decorated with natural materials as much as possible.

Selection tips:

- Coniferous types of lining are popular - the material has a pleasant smell and does not deteriorate for a long time;

- wild and simple oak and birch have a beautiful texture, so living rooms, children’s rooms, and bedrooms are decorated with clapboard of this type;

- For the bathroom and kitchen, choose larch, spruce, pine - species with high moisture resistance.

By type, preference is given to Softline, Eurolining, and Standard.

Decorating the cottage inside and out

High-grade material is used for the cottage; Extra and Premium grades are preferred.

Finishing features:

- rooms, an office, and sleeping quarters inside the house are lined with lining made of hardwood, using a beautiful pattern of fir, pine, birch, alder, and elm fibers;

- Conifers are used in damp rooms of bathrooms, kitchens, where there is a large accumulation of steam and moisture; larch is good, but it is more expensive.

Valera

The voice of the construction guru

Ask a Question

Outside they put pine, clapboard, spruce material, choose a block house or an American one. After installation, protective compounds are used to protect the surface of the wall from the action of aggressive atmospheric chemicals and ultraviolet radiation.

What deviations are optimal?

The following permissible deviations can be distinguished:

- a maximum difference of 5 mm is permissible in length;

- in thickness – 0.7 mm;

- in width – 1 mm;

- the spike size is 0.5 mm.

Thanks to the optimal sizes of the lamellas, no gaps will form when working with wooden eurolining. At the same time, the material will not lose its appearance, which is extremely important when it comes to wall cladding.

The existing dimensions of eurolining are designed to facilitate the process of covering the surface using panels.

The length of the lining is the most variable indicator

The widest range is observed in the length of the lamellas. The maximum length of the planks is 6 m; such lining is considered ideal and the most expensive. Solid boards are chosen for external and internal finishing work, when you want to avoid connecting seams on the lamellas.

Short lining strips are several times cheaper because they are a kind of production waste. They are used to design roof overhangs or cladding, where a connecting seam is provided. If you want to save money, the joint can be covered with a decorative plinth and the overall appearance of the finish will be no worse than when using solid, long slats.

Vote post

Dimensions of standard lining according to GOST

Classic lining, popularly known as “collective farmer”, is regulated by GOSTs with the name “cladding board” of the following sizes and sections:

Lining grade O-1

Lining grade O-2 (1st option)

Lining grade O-2 (2nd option)

Lining grade O-3 (1st option)

Lining grade O-3 (2nd option)

Lining grade O-4

It is made from various types of wood: pine, spruce (conifers are the cheapest), birch, alder, linden, aspen, ash, oak, larch, cedar.

Evolution has taken the dimensions of cladding boards beyond the limits established by state standards and today you can easily find products for sale in the following sizes: thickness from 12 to 25 mm; width—up to 150 mm; length - up to 6000 mm.

Types and characteristics

The lining can be either classic, made of wood, or created from materials of a completely different class, such as plastic or MDF. Plastic lining. The type of finishing applied with this material is also called panel finishing. This type of finishing material is extremely resistant to moisture, is very light compared to analogues and does not lose its appearance when exposed to sunlight, however, due to exposure to low temperatures it often becomes brittle and it becomes extremely easy to damage the panel.

Plastic lining is approximately 2-3 times wider than the ordinary wooden version. Its installation is simplified by the ability to bend it around corners, both internal and external - you just need to cut out a small number of stiffeners from the inside of the panel and heat it. In addition, such material can have any pattern, either stylized like wood, or some kind of pattern, or even a whole image that will be made up of panels.

MDF lining. Panels made from MDF are an absolutely environmentally friendly and clean finishing material that represents good competition with plastic panels or classic wooden lining.

MDF panels are produced by pressing small and dry wood chips under high temperature, using high pressure for molding. Bonding of the material is carried out through the release of a natural substance present in wood - lignin. Thanks to this, MDF is an absolutely safe material that does not emit harmful substances, since epoxy resins are not used in its production.

We advise you to study - How to choose a screwdriver - technical parameters and selection criteria

Wood lining is the most common type of finishing material. It was the very first to appear on the construction products market.

Wooden lining has many design styles, but according to its appearance it can be divided into two types:

- with a flat front panel;

- with a rounded front panel that imitates the structure of a timber.

Types of wood:

- Aspen is a light, hard wood that is not prone to cracks and is light in weight.

- Pine is a medium-strength wood, quite heavy, with a yellowish and sometimes red tint. It gets a little darker over time. When treated with specialized means, pine lining perfectly resists fungi and mold, as well as insects.

- Larch is a durable wood that practically does not change its size under the influence of external factors; the color range can vary: from light yellow to red-brown.

- Cedar is a very durable and expensive wood. It has a pleasant aroma and beneficial resins that are endowed with healing properties.

- Spruce is a light yellow wood, similar in properties to pine, but less common.

Calculation of required material

In order for us to correctly calculate the required quantity, we must know the dimensions of the panels. The size of the lining is not a mandatory standard, and this indicator has a wide range.

In accordance with GOST, the thickness of a standard board can vary from 1.2 to 2.5 cm, the average width is 15 cm, and the length is within 600 cm.

The profile for interior work is used with a thickness of no more than 1.6 cm, while the lining with a thickness of 1.8 cm is used for external covering.

Having the length and width values available, we can easily calculate the required area. Here's an example: let's say the length of the panel is 500 cm and the width is 15 cm, then the total quadrature of the profile will be 0.75 m2.

When calculating the required quantity, it should be taken into account that the width of the profile during installation will be less than the total width of each panel, due to the peculiarities of the fastening - tongue and groove.

Well, as a last resort, in any hardware store there is a consultant who will help, using a special calculator, calculate the required amount of material.

PVC lining and its dimensions

The most budget option is panels made of PVC. Due to the fact that this material is indifferent to moisture, its use is versatile. Used for finishing steam rooms, baths, bathrooms, as well as outside and inside.

A significant disadvantage of this coating is increased fragility, especially in cold weather; for this reason, when used outside, it makes sense to cover areas inaccessible to mechanical impact.

PVC profiles are produced in two types, thick - 0.8-1 cm and thin - 0.5 cm. With a panel width of 10 cm, the length, as a rule, corresponds to 300 cm. If the lining is wide - 20-37 cm, then its the length will be 260 cm, 270 cm and 300 cm respectively. PVC panel standards: width - from 10 to 50 cm (yes, such widths exist), length - 260, 270, 300 and 600 cm, respectively, thickness - from 0.5 cm to 0.8-1 cm.