Wood is one of the most popular materials for construction, common in many industries. The scope of application of the products is agriculture, construction of individual country estates (dacha or small house), construction of warehouse-type premises, etc. But what is the difference between several types of wood? The product differs in properties, has a certain classification and features. The above factors determine where the part will be used, and the approximate service life is also calculated. The type, properties and characteristics of the wood will determine the longevity of the construction, the amount of costs for the construction of a building or country estate, and, of course, the appearance of the object.

Wood in construction

Since ancient times, wood has been used as a building material for the construction of walls and log houses. Although metal-plastic windows and doors have been installed recently, wooden products are still not inferior, and even superior in their properties.

And a natural wood floor will create a warm microclimate in your home. A wooden staircase will also look unsurpassed.

In the design field, wood material is used for cladding the walls of houses, saunas, and for the production of furniture.

Why do builders and designers choose a natural material - wood?

Main directions

Wood can serve as a raw material for many products. The producers know all these indicators, I just write all the truths on paper. Let's look today at the criteria by which we can evaluate wood as a raw material for obtaining products; this is necessary when wood is purchased from suppliers. At the same time, when purchasing and agreeing, you can save good money for production. So here are some areas of wood processing:

- Use of wood waste and further production of products from this waste.

- Like wood fuel.

- Using wood for sawing.

- Using wood to produce wooden moldings.

In order to get maximum profit in production, you need to correctly distribute what wood you need, what part of the wood, what species, and then purchase what you need from suppliers. Let's say you cut wood into lumber, and for this you use round wood with rot, you will not receive high-quality products and, accordingly, profit. Or another case, wood has a high percentage of foreign inclusions, where is it better to use it?

Advantages

- — has a low weight (when compared with reinforced concrete, wood material weighs 5 times less and 16 times less than steel);

- — high strength;

- - it is easy to obtain;

- — does not require complex technologies for processing;

- — wooden structural parts are easy to assemble, disassemble, transport and remodel individual wooden buildings and entire structures;

- — wood has a low thermal conductivity coefficient, so it is valuable as an effective insulation material;

- — the material is characterized by durability, provided, of course, that the rules of operation of the structure are followed;

- - wood can be renewed, this provides ample opportunities for the manufacture of many types of products;

- — goes well with other building materials;

- - acts as a moisture-regulating and filtering component (wooden walls purify the air, and in both directions they slowly pass it through the structures of their fibers);

- — wood is an environmentally friendly material.

Wood for the production of panel products

The criteria by which we will evaluate wood as a raw material for process chips or shavings for panel production:

- The presence of rot has a negative effect because when transporting rotten round wood or rotten chips, you buy a volume of wood for one volume of slab; as a result, you end up with a much smaller volume of slab from rotten wood. The consumption rate of wood with rot per cubic meter of finished slab will be much higher. This should be used when you purchase timber externally.

- The presence of bark, on the one hand, bark is not counted in the total cubic capacity and is about 11% in excess of wood, therefore, when purchasing wood with a large amount of bark for slab production, it is not bad, the rate of wood consumption per one cubic meter of slab is reduced. On the other hand, the quality, or rather the presentation of the slab, decreases. Ultimately, it is up to the manufacturer to decide what is more important to him.

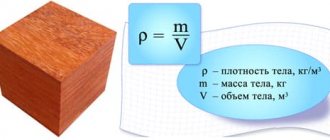

- The density of wood affects the rate of wood consumption per cubic meter of slab. Of course, purchasing birch will be more profitable than purchasing aspen under the same conditions; more slabs will be produced from birch. According to the same properties, the wood obtained from the first cut is better than from the third. As a rule, wood is sold in cubes, for us it is better that in this case the cubic meter has a large mass.

- The moisture content of the wood affects the cost of drying, so it is better to dry the wood, or to dry it yourself if possible.

- The presence of foreign bodies increases the rate of consumption of cutting tools for products; to reduce the impact of foreign bodies, it is necessary to introduce magnets and stone catchers.

Flaws

- - heterogeneous structure. So, if wood is cut incorrectly, the compressive strength can drop by almost 5 times;

- - knotty;

- - creep. When a load is placed on wood for a long time, it becomes deformed;

- - subject to rotting and insect damage;

- - moisture absorption. With increased humidity, the strength of wood in almost all types of work with it drops sharply;

- - drying of wood. May cause severe cracking;

- - exposed to combustion.

Knowing the characteristics of timber is very important when designing, constructing and operating wooden structures.

As a building material, wood is used in two forms:

- - original (round timber, logs, etc.)

- - secondary (board, timber, plywood, veneer, etc.).

Properties

Wood has a number of characteristic properties. The structural features are the reason for this. The strength of wood is quite high, and among building materials in this indicator it occupies an intermediate position. And given its low specific gravity, it is comparable in this regard to metal. The weak point of wood is that it is an anisotropic material. The ability to resist fracture depends on the direction of the force relative to the arrangement of the fibers. The best strength indicators are visible when the material is exposed along the fibers.

The rigidity of wood is low, the reason for this is its specific structure. Wood is a porous, flexible material. Beams are able to restore their shape after a short-term load. But residual deformations, due to prolonged exposure, remain forever. A wooden beam will not be able to regain its shape after long use.

The hardness of building materials is determined by the load required to press a steel ball of a certain size. For the hardest types of wood, it is only 1000 N. Moreover, low hardness is one of the main advantages of the material. Wood is easy to process and holds nails, screws, and self-tapping screws firmly.

Wood moisture content is determined by the specific moisture content in the pores. In a freshly cut tree it reaches 100%. Depending on the purpose, freshly cut wood is dried to the required levels of 40 to 15%.

What type of wood should I choose for construction?

1. Coniferous species are the most popular wood material. Compared to deciduous trees, it is the most affordable. And, of course, it has high technical properties.

- Pine. On the scale of use it is at the highest position. Why? Firstly, this material is strong, dense, resistant to cracking, drying out and rotting, and wear-resistant. Secondly, pine is a light wood, not knotty, and this greatly facilitates the processing process. A disadvantage is the “blue” property; this spoils the appearance of the log house.

- Spruce. It is flexible and therefore widely used for the manufacture of bent parts. Spruce, like pine, is very durable (when dry). But it is not so rich in resinous substances, so it needs to be further processed. Spruce is knotty, and this complicates the processing process, and also narrows the scope of application.

Compared to pine, spruce does not lose its color palette for a long time.

- Larch. It has high density and strength, especially after drying, and is also resistant to decay. Therefore, it is used for the manufacture of main load-bearing structures. Has a low degree of water absorption. It is also practically not knotty and does not warp. Disadvantages include: easy to split and difficult to process.

- Fir. It has low elasticity and low strength. It pricks easily and is also processed. This species is much more susceptible to rotting than pine because it does not have resin passages. Fir is not suitable for the manufacture of basic external structures. It has found its application in the manufacture of windows, doors, floors and other internal structures.

- Cedar. Highly durable material, but at the same time flexible and soft. It is lightweight, rot-resistant, and easy to process. External structures are made from cedar. The advantages of cedar include its antiseptic properties, which is why it is successfully used in green construction.

2. Hardwood Many hardwoods are not as strong and resistant to decay (they do not have resin passages) as conifers, so they are not used as widely in the construction industry.

The following hardwood species are most widely used in the construction industry:

— Oak. It has a very beautiful texture, so it does not require additional coloring. Practically not susceptible to fungal influences. Oak wood is very durable, it is a very hard material. It is used in the manufacture of external structures, and also as a finishing material (windows, doors, floors).

- Nut. The material is heavy, durable and hard. It is well processed and can be polished very well. The texture of the walnut is very beautiful.

- Ash. Elastic and durable material, has a light color. Ash is very difficult to split. Due to the increased viscosity, it is difficult to process wood manually. It does not have the same properties as oak, so it is rarely used in external structures. It is most actively used as a finishing material.

- Elm. Rot resistant. The material is distinguished by density, viscosity, hardness and strength. It is difficult to prick, but it is perfectly processed. In terms of its technical characteristics, it is inferior to many coniferous species, therefore it is not used for building houses. Mainly used in furniture production and shipbuilding.

Tree trunk structure

The tree trunk consists of:

• bark

• cambium

• wood

• cores

A tree trunk consists of bark, cambium, wood and pith

Bark of tree

The bark covers the entire surface of the tree and serves to protect it from damage and harmful environmental influences. It consists of three layers, of which only two are visible to the naked eye: the outer cork layer and the bast layer facing the inside of the .

Since the cork layer is located on the outside of the tree, its main task is to protect the wood from drying out, mechanical damage, frost, overheating, sudden temperature changes and other external influences.

Just like the inner part of a tree - wood, the bark grows in thickness every year, but this increase is very small, and besides, the outer layers in the form of scales gradually fall off, since the cork is dead cells filled with air. Therefore, the bark never reaches the same thickness as wood.

The bast layer (bast) of the bark consists of small tubes, invisible to the eye, through which water and nutrient organic substances produced in the leaves and needles move down the trunk to the roots.

Cambium

Between the dead bark and living wood is the cambium - a very thin succulent layer of living cells, invisible to the naked eye. This living part of the trunk, feeding on the descending sap of the bast layer of the bark, directly participates in the growth of the tree.

The growth of a tree in thickness occurs as a result of the division of cambium cells. As a result of the division of the cambium cell, one of the daughter cells remains cambial, and the other goes either to the formation of wood elements or to the formation of bark. The division of cambium cells towards the wood occurs ten times more often than towards the bark, as a result of which the wood grows much faster than the bark.

The inner part of the cambium cells (about 90%) forms xylem - special conductive vessels through which minerals and water rise from the roots of the tree, along the trunk to its top. Thus, sapwood is formed from the internal cells of the cambium - a new annual layer of wood.

The outer part of the cambium cells (about 10%) goes to the formation of other vessels - phloem . Through these vessels, organic substances formed in leaves and needles travel down the tree. Thus, the bast layer of bark is formed from the outer cells of the cambium.

The cambium is active only in spring and summer, when a lot of juices appear in the trunk, which it feeds on. The result of the activity of the cambium is the formation of new layers around existing wood, the so-called annual layers of wood , the number of which determines the age of the tree. In winter, the work of the cambium fades so much that tree growth stops.

Transverse, tangential and radial cuts of wood

In the annual layer of wood, thin-walled cells of early wood are first formed, which in coniferous trees are noticeably lighter than cells of late wood, whose walls are thicker. Early wood must quickly transport nutrients from roots to leaves; latewood cells serve mainly to strengthen the trunk.

In tropical areas, growth zones form during periods of alternating drought and rain. Here growth is not observed every year. Tropical evergreen trees, whose growth is not interrupted by a dormant period, do not form annual rings.

The width of the growth rings varies from 1 to 10 mm, and this depends on the age of the tree, climatic conditions, soil conditions and pest pressure. The proportion of early and late wood in the tree also depends on these conditions. As a rule, fast-growing trees form wide annual rings, while slow-growing trees form narrow ones.

However, if we consider the overall cross-section, it is clear that the late wood plays the most important role in the annual ring.

Wood

For construction, the main industrial value is wood , (consisting of sapwood and heartwood), which occupies most of the trunk in a growing tree.

Sapwood (or sapwood) is a young, not yet dead part of the wood, located closer to the surface of the tree. Consists of living, physically active wood cells. Serves to conduct water from the roots up the trunk into the crown and to deposit reserve nutrients.

The core is the oldest part of the wood, located closer to the core, consisting of dead cells that do not take part in the life of the tree. However, this is the strongest and most stable part of the wood, containing the largest amount of resins, gums, etc. The core has a darker color, and in freshly cut wood it has less moisture than sapwood.

All young trees, regardless of species, have wood consisting only of sapwood. In some tree species, over time, dying cells, deposits of resin and tannins form the core. Nucleation begins at different ages in different breeds. In oak, for example, this happens quite early - at the age of 8-12 years, in pine much later - at 30-35 years of the tree’s life.

The transformation of wood into sound wood begins when a sufficiently wide sapwood is formed in the trunk, capable of supplying moisture from the roots to the crown. The inner part of the trunk is freed from performing this task, the living elements of the wood die off, the moisture-conducting channels are blocked, and the moisture content in the wood decreases.

Substances such as dyes, resins, fats, tannins and rubbery substances are deposited in the dead cells of the nucleus. The wood is impregnated with tannins and dyes, as a result of which it darkens, becomes heavier, harder, and is better able to resist pests. Its resistance to rotting increases, and its density increases slightly.

Blockage of the water-conducting pathways of the core wood has both a positive meaning, since it becomes practically impenetrable to water and air, and a negative one, since when wood is impregnated with antiseptics, the core is usually not impregnated.

The boundary between the heartwood and the sapwood usually does not extend entirely along one annual ring. Based on the difference in color between sapwood and heartwood and the formation of the latter, trees are divided into the following groups:

1. Trees with sound wood (oak, pine, larch). In these trees, the dark core is separated from the lighter sapwood by a color line.

Cutting down a pine tree

2. Trees with a predominance of heartwood (spruce, red beech, fir). In these trees, the moisture content in the heartwood is lower than in the sapwood, but they do not differ in color.

Spruce cut

3. Trees without heartwood, with only sapwood - with a drier central part of the trunk. These are mature wood, sapwood species (maple, hornbeam, linden, birch), in which the entire course of the trunk is colored evenly

Cutting down a birch

Core

The core is the inner, central part of the trunk, consisting of loose, low-strength tissues formed in the first years of the tree’s life.

Types of lumber

When building wooden structures and choosing lumber, you will come across names of types of lumber, the meaning of which you need to know:

- ridge - a thick tree trunk, freed from bark, or a segment of it of sufficiently long length (but not more than 25 cm);

- garter - the same ridge, but with a diameter of less than 25 cm;

- pole - a thin tree trunk (less than 9 cm in diameter), cleared of bark;

- plate - a tree trunk sawn along the grain;

- quarter - ½ plate, which is sawn along the grain;

- a log is a log in a horizontal position, hewn on both sides;

- timber - a log that is hewn on all four sides with a cross-section of at least 100x100 mm.

- whetstone - the same as timber, but smaller in size.

- Treated wood

In the construction industry, so-called refined wood has recently become popular - wood plastics obtained from processed wood materials.

Types of wood plastics:

- plywood;

— Fiberboard (fibreboard);

— Chipboard (chipboard);

— OSB (oriented strand board);

- wood-laminated plastic.

General information

Wood is a natural material that consists of tightly packed plant cells. Due to its physical characteristics, the substance has an elastic, dense structure. Thanks to the cellulose it contains, the wood is very strong and durable.

Wood retains heat well. There are voids between the cells that accumulate energy. The resource resists dynamic and static loads, while remaining lightweight. When compressed along the fibers, the strength of the substance is not inferior to cement.

Substance in boards Source stroy-podskazka.ru

Wood is easy to process. Raw materials can be cut, sawn, glued and pressed under pressure. The material holds solid fasteners (staples, nails). Wood is used to create both durable structures and decorative items.

Due to its cellular structure, wood can “breathe”. Constant air exchange allows you to maintain a favorable indoor microclimate. Due to the presence of oils and resins in the composition, the raw materials have a specific aroma. The substances help the tree fight tissue destruction.

The decorative value and value of wood often depend on the plant species. All varieties are divided into two large groups - coniferous and deciduous. Additionally, monocotyledonous crops are distinguished, which include bamboo and palm trees.

Sawn wood Source zen.yandex.ru

Due to its structural features, wood burns easily and rots in humid conditions. The material has many defects that reduce its grade and limit its use. Due to its high hygroscopicity, the substance swells, warps or cracks. The consequences of deficiencies are minimized by changing operating conditions and special protection during processing.

When choosing timber for construction, what should you consider?

- Strength. The stronger the material, the lower the destruction rate. Each type of wood has its own strength. It is also affected by humidity, density and its defects.

- Density. Weight, ease of processing and resistance to rotting depend on it.

- Wearability. The harder and denser the wood, the greater the degree of wear resistance.

- Resistance to cracks. It depends on the degree of drying of the wood: during the drying process, moisture from the wood material evaporates unevenly, this leads to internal tension and the wood cracks. Low-drying species are fir, cedar, and pine.

- Susceptibility to rotting. Under the influence of various fungi, wood is destroyed. It is believed that coniferous trees are less prone to rot than deciduous trees. This can be explained by the presence of resinous substances.

- Texture. What is important here is how it manifests itself after being coated with stain, wax or varnish. This is very important in a design decision.

- Ability to hold metal fasteners (nail or screw). Density and humidity are important here - the higher the density, the more difficult it will be to pull out the fastener.

- Presence of knots. The more wood material has knots, the lower the strength. This will result in additional processing costs.

- Weight

Innovative wood processing technologies make it possible to produce any product.

Anatomical structure of wood.

Like any plant, a tree is made up of cells. Each young cell consists of a membrane and the protoplasm contained in it. Inside the protoplasm there is usually one nucleus (multinuclear cells are also found). During cell growth, protoplasm is consumed and cavities (vacuoles) 4 are formed in it, which are filled with cell sap. Subsequently, individual vacuoles gradually merge into one common one and push the protoplasm towards the cell membrane. In addition to protoplasm, nucleus and vacuoles with cell sap, cells also contain so-called plastids - colorless or colored formations.

Protoplasm is a granular, transparent, viscous mucus (plant protein). The nucleus is usually oval in shape, containing one or more shiny nucleoli and thin thread-like protein substances called chromatin. The nucleus, like protoplasm, consists of a complex protein compound.

Depending on their color, plastids are divided into leucoplasts - colorless plastids, chromoplasts - with yellow and orange pigments, and chloroplasts containing a green pigment called chlorophyll. Chlorophyll grains are found mainly in leaves and, under the influence of sunlight, convert carbon dioxide from the air in combination with cell sap substances into various organic compounds (carbohydrates, proteins, fats). Plants lacking chlorophyll cannot themselves produce the organic compounds necessary for plant life and are therefore forced to become parasites.

The cell sap that fills the vacuoles is an aqueous solution of various substances: carbohydrates, pigments, tannins and free organic acids.

The shell mainly consists of cellulose or fiber (C6HuO5). Layering is observed in the cell membrane. The shell material is formed due to the decay of protoplasm, therefore, as the cell grows, the amount of protoplasm in it decreases. Older cell membranes contain more minerals. As the cell grows, the membrane gradually thickens due to the growth of subsequent layers. Sometimes the thickening is so great that the membrane inside the cell has thin pores. The shell undergoes various changes in structure and composition, as a result of which it becomes woody, suberized, or mucused.

During lignification, a special substance is formed in the cell membrane - lignin, which contains a significant amount of carbon; Its strength and hardness also increases, but its elasticity, ability to swell, etc. decrease. The lignification of cells occurs mainly in the trunk.

Suberization is accompanied by the formation in the cell membrane of a substance poorer in oxygen than lignin. As a result of suberization, the cell resists rotting well and becomes impenetrable to water and gases. Cells on the surface of the trunk and branches of the plant are usually sampled.

Mucusing is accompanied by the transformation of the entire shell or part of it into gum or mucus, which dissolves in water. If part of the membrane is mucused, holes are created through which the cells are connected to each other, forming vessels.

Although the cells fit tightly to each other and are connected to each other by an intercellular substance, intercellular spaces are formed between them, filled with cell secretions (for example, in conifers - with resin). In addition to resin passages, there may be air-bearing intercellular passages. According to their shape, cells are divided into parenchymatic, having approximately the same size in three dimensions, prosenchymatic, elongated in one direction, and tabular, developed in two directions.

Wood fabrics.

The cells in the young growing parts of the tree are similar to each other, but as the tree continues to grow, they specialize, with groups of identical cells combining into tissues. Depending on the functions they perform in the life of the tree, tissues are divided into educational, covering, mechanical and conductive. Educational tissues are located at the growth point of the plant stem and consist of thin-walled (with a large amount of protoplasm) parenchyma cells. This tissue subsequently serves to form other tissues. The covering tissues of young stems and leaves are covered with epidermis, the cells of which are replaced by covering cork tissue as they grow.

Mechanical fabrics serve to give the plant element a certain mechanical strength. This tissue consists of woody cells and serves to increase the strength of only the young, still growing parts of the tree. The cells of this tissue have relatively high mechanical strength and are highly elongated, and therefore are called fibers.

Conductive fabrics are designed to conduct moisture with mineral and organic compounds dissolved in it. These tissues are composed of blood vessels and vascular cells. Tracheas are formed when vertical cells merge into one common vessel, and their transverse partitions completely or partially disappear. The vessels are characteristic of deciduous wood. Vascular cells are long cells whose cavities are not interconnected. Coniferous wood consists almost exclusively of vascular cells. Conductive tissues are filled with water with various substances and air dissolved in it. The tissues that conduct organic matter throughout the plant consist of sieve tubes and milky vessels. Sieve tubes consist of elongated cells, the partitions between which have small holes, like a sieve. Conductive tissues are collected in wood into special vascular-fibrous bundles, in which mechanical elements are located around the vessels.