Where is fiberboard used?

Answering the question about what fiberboard is, we can say that it is a fairly affordable material that varies in density and thickness. The literal meaning of fiberboard is fibreboard. Dense ones are distinguished by their strength, thinner ones bend well and are used when finishing and covering curved surfaces.

Sheets are also used in frame construction to eliminate unevenness in walls and floors. Passenger carriages on trains are also made of fiberboard sheets. Due to its structure, this material serves as good sound insulation due to the chaotic arrangement of wood fibers. Therefore, when looking for cheap material for sound insulation, they purchase fiberboard. For high-quality finishing, the sheets are painted, laminated and even covered with decorative film.

This material is also popular among furniture manufacturers. Typically, it is used for auxiliary parts - the back wall or bottom.

Fiberboard of different thicknesses Source tss71.ru

Advantages and disadvantages

Many users are interested in the properties of fiberboard, what kind of material it is and what its pros and cons are. The following advantages of fiberboards are known:

- strength;

- cleanliness for the environment;

- ease of processing;

- maintaining appearance for a long time;

- ease of painting or varnishing.

High-quality fiberboard retains its appearance and properties even at high humidity, and does not swell after being in water. With all the advantages, the material retains its low cost.

The main disadvantage of the material is its production limitation. The slab cannot exceed a certain thickness, which prevents the use of sheets in many areas of construction. Low-quality fiberboard swells when in contact with moisture, diverges after drying and takes on a wavy shape.

Technological process for manufacturing fiberboard

Natural wood is an expensive material that is not used for leveling floors and walls. At the same time, waste remains in the forestry and wood processing industries that can be used in the production of fiberboards.

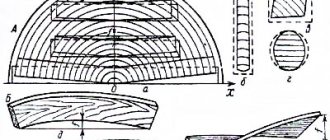

Fiberboard, or fibreboard, is produced by pressing wood processing residues. There are two pressing methods: dry and wet.

The fiberboard manufacturing technology consists of separate stages.

- Obtaining wood residues: sawdust, wood chips.

- Grinding wood waste into small fibers, steaming.

- Cleaning and removing debris from the material.

- Washing the resulting mass, processing and impregnation with resins and paraffin, which increases the moisture resistance of the slab.

- The formation of an even layer for pressing occurs at a pressure of 3 MPa and a temperature of approximately 300°C.

The dry pressing method is faster, cheaper, and technologically more economical. But such fiberboard loses in strength, moisture resistance and fire safety.

Historical reference. Fiberboard was officially patented and introduced into industrial production in 1858. In 1924, the wet pressing method was developed and used.

The wet version of production is characterized by preliminary soaking of the material before pressing. After drying, the fibers bind together more tightly.

The wet method does not require additional inclusions in the form of synthetic additives for bonding fibers. This indicates a high class of environmental friendliness. The slab gains strength, lasts longer, and is less susceptible to deformation from moisture.

The process is more labor-intensive, more time is spent on making the board, and therefore the cost of the sheet is more expensive than in the dry method. For soldering, binding components can be used that increase the fire resistance of the material. This expands the scope of application of the material, making it safe in everyday life.

Types of material

The construction industry uses different types of fiberboard, depending on its properties, production method and application method. Not only the scope of application, but also the price depends on the density indicator.

Wood fiber sheets Source gkstrong.ru

Soft slabs

The thickness of the soft board ranges from 8 to 25 mm. The density indicator is indicated within the limits of 100-350 kg/m³. This material is not particularly strong, conducts heat poorly and has an overestimated porosity.

Basically, such slabs are used for thermal insulation of floors and ceilings and are not used as the main material in construction. Soft fiberboard is similar to drywall, but more comfortable to handle and lightweight. Installation of sheets is simpler and cheaper than drywall.

Soft slabs are also used to form the underlay for parquet. The material is also useful for eliminating unevenness in floors. It is completely environmentally safe and harmless for people with allergic reactions.

Semi-solid fibreboards

The density of the semi-hard sheet is around 850 kg/m³. Average thickness – 10 mm. In general, the material is quite durable due to its density and is widely used for assembling furniture. It has proven itself as external and internal walls, shelves and drawers. It is also used when laying flooring. Packaging material can often be seen from semi-solid sheets.

Fibreboard packaging box Source yandex.net

See also: Catalog of companies that specialize in reconstruction, finishing and insulation of houses

MDF

Medium-pressed fibreboards, or MDF, have a density in the region of 700-800 kg/m³. This indicator makes it possible to effectively use MDF during construction and for furniture.

MDF boards are in demand in the manufacture of the following parts:

- platbands;

- fillets;

- furniture facades;

- skirting boards;

- window sills;

- ceiling sheathings.

Interior door leaves are also made from it. The decorative function of the slabs is used for elegant decoration of the walls and ceiling of the room. Laminate in some cases is made from MDF.

Hard fiberboard boards

Solid sheets are produced with a density from 750 to 1000 kg/m³. Average thickness – 4 mm. Almost always used in the production of doors. There are several grades of hard fiberboard, depending on the density and external structure. Most of them are painted with waterproof paint to protect them from deformation when in contact with water.

Solid white slabs have gained popularity in kitchen decor. Among all the colors of the material, white is the most affordable and practical.

Solid white fiberboard Source bosscdn.com

Super-hard fibreboards

Super-hard sheets are of high quality and easy to install. The density indicator is not much different from solid fiberboards, but, unlike them, superhard ones are impregnated with pectol to achieve additional strength. Arches, doors and partitions are made from this material. Used for covering floors. Super-hard fibreboards have high electrical insulation, which is why electrical panels and panels are made from them.

Treated fiberboard

Fiberboards can be treated with varnish or special paint to achieve high moisture resistance. The treatment also protects the slabs from mechanical stress and gives them a pleasant appearance, due to which they are widely used for decorative purposes.

During manufacturing, an initial layer of primer is applied to the surface, onto which a design is applied. Subsequent processing does not take much time. The most popular are sheets with wood imitation - such designs can often be found on furniture. Laminated fiberboard floors, which are treated with a special mixture of resins, are especially in demand.

Room with fiberboard interior Source yandex.net

Types of fiberboard sheets

Fiberboard sheets come in a variety of densities. The main classification of the material is associated with this indicator.

Soft

Low density slabs - up to 350 kg/m³, up to 12 mm thick . The material is quite porous, therefore it has low thermal conductivity - up to 0.07 W/(mK). The mechanical strength of the sheet is minimal: it can be pressed with your finger. Due to its high porosity, fiberboard strongly absorbs moisture, so it is not suitable for finishing bathrooms and kitchens.

There are 3 types of material: M1, M2, M3 . The higher the number, the greater the density of the sheet. You can distinguish them by their appearance: the softer the material, the more wood fibers stick out from the edge.

The material is used as an analogue of plasterboard: for covering frames and walls, soundproofing partitions, and interfloor ceilings.

Semi-solid

Its density is up to 850 kg/m³ . The strength, especially in bending, is also noticeably higher - from 15 MPa. The dimensions of the fiberboard sheet are standard, but the thickness ranges from 6 to 12 mm. The material bends well and retains its shape. It is mainly used in the manufacture of back walls of furniture. The slab is also suitable as a substrate.

The water absorption of the material is 40%, so fiberboard is not used for finishing in damp rooms.

Solid

Density reaches 950 kg/m³ . Thermal conductivity is naturally lower, since the material is slightly porous. The sheet thickness is small - up to 6 mm . Fiberboard is used mainly for the manufacture of panel doors, much less often for the back walls of cabinets.

Solid fiberboard has a decorative surface: smooth, matte, imitating aged wood.

Super hard

Density up to 1200 kg/m³. Maximum hardness: bending strength is 47 MPa. Water absorption is low - only 12%. These qualities are due to the inclusion of petcol in the original mixture. The material is used to make doors, interior arches, sheathe walls and partitions. Can be used as a floor covering; the slabs can withstand quite significant loads.

Super-hard fiberboard is an excellent electrical insulator and is often used in the installation of electrical panels.

Laminated

Special cladding material with high aesthetic characteristics. Such slabs are small in size, usually from 30*30 to 100*100 mm . The sheet is covered on both sides with a film that imitates the color and pattern of wood.

They produce several options: tiled - for finishing floors, walls, under lining and sheet. The second option has tongues and grooves at the end, which makes assembly of the trim easier. Sheets are offered in standard sizes.

Laminated fibreboards and their areas of application

The main advantages of laminated fiberboards are increased strength and protection from water. There are several types of this material:

- Laminated tiles. It has a huge range of sizes from 40x40 cm to 110x110 cm. Every year many slabs are produced in a wide range of colors and with different patterns.

- MDF paneling. It is extremely water resistant and is used for finishing walls and floors.

Due to their sound insulation, laminated boards are used in the construction of sound studios and in rooms where it is necessary to isolate sound as much as possible. In addition, laminated fibreboards look aesthetically pleasing due to processing, which is why they are widely used for finishing offices and classrooms. It is universal and is perfect for installing partitions, arches, finishing facades and even making suspended ceilings. Furniture made from laminated fiberboard looks elegant, and its use for walls will eliminate the need for subsequent cladding.

Laminated fiberboard Source medioplit.ru

Laminated sheets are considered the most affordable material for construction relative to their analogues. The price is determined depending on the size of the slab and its processing.

Sheet sizes

According to the standard, the sheet width is from 1220 to 2140 mm, and the length is 1220 to 3600 mm. In reality, the sizes may vary depending on market demand.

The thickness of the material is determined by the density:

- Low or medium density HDL can be 8, 12, 16.5 mm thick;

- semi-solid varieties are produced in thicknesses of 6, 8, 12 mm;

- extra hard and hard sheets reach 2.5, 3.2, 4.5 and 6 mm.

The weight of the product depends on the density.

How to choose

The dimensions of the fiberboard are determined by the purpose and characteristics.

Soft fiberboard is used mainly as a soundproofing material, so the thickest sheet is preferable for finishing an office or studio. The dimensions of the stove depend on convenience. It is more convenient to cover a large area with large ones.

To make the back walls of furniture, it is better to take semi-solid ones of minimal thickness: they are lighter, but still durable. Solid slabs, up to 6 mm thick, are used for finishing the room, covering the frame and partitions. Thin hard material – 2.5 mm is also suitable for the back wall of high-quality furniture.

The dimensions of decorative laminated fiberboard are selected according to their intended purpose. For cladding the ceiling or walls in a small room, tiles with different textures or lining are more suitable. For finishing large halls - sheets.

Differences between fiberboard and chipboard

The variety of wood composites on the materials market has created their branching into different subspecies. It is important to understand the difference between fibreboard (fibreboard) and particle board (chipboard).

The difference lies in the material and production technology. The mechanical properties of fiberboard and chipboard also differ. In the production of fiberboard, wood fiber is used, and in chipboard, chips and shavings are used. The difference for an inexperienced user is small, but essentially these are two different materials.

The composition of particle boards allows them to be produced without high costs. The cost of a chipboard board is lower than that of fiberboard. However, the technical characteristics of fiberboards are much higher. The difference in quality becomes noticeable when it comes to surface treatment. Chipboard begins to disintegrate and crumble when secured with self-tapping screws and large bolts. Moisture negatively affects particle boards - the material begins to delaminate due to its heterogeneous structure.

Construction materials from forest waste

It was originally intended that the shavings and fibers remaining after sawing wood would be used to make slabs that could be used for some rough elements in construction. It was immediately clear that this material cannot be used where there is high humidity.

However, it had and now has a number of undeniable advantages:

| Advantages | Flaws |

| Low cost | Fear of water and humidity |

| High heat and sound insulation properties | Low service life |

| Minimum weight, ease of handling | Toxicity of some species that contain formaldehyde |

In general, we can say that fiberboard, when used for its intended purpose, is a fairly good building material. It has also found good use in furniture production. But even the most dense slabs with constant high humidity will lose all their positive parameters. Therefore the rating is a solid 4.

The nuances of working with the material and repairing fiberboard

An inexperienced specialist may unknowingly encounter problems processing fiberboard and chipboard. Few people know how to properly glue materials, because even heavy-duty adhesives and liquid nails do not always cope with this. Granular bone glue used in construction is ideal for gluing wood fiber and particle boards.

You can cut slabs at home using a mounting knife or a hacksaw. The cutting technology must be followed. The blade needs to be sharpened; it is best to do the work using a metal ruler. There is no need to rush - according to safety rules, you should cut the material smoothly and carefully to save your fingers. There are many tools for cutting fiberboard and chipboard that make the job easier and do not require special skills.

Super hard fibreboards

Super hard (not less than 950 kg/m3) - for floor coverings. super-hard (grade ST-500 with a density of 950 kg/m3). During the manufacturing process, superhard slabs are painted or primed on the front side. They are most often used to cover floors. They can be widely used in building products and structures - doors, partitions, floors, containers, temporary structures, etc. The boards are made using wet fiberboard technology using traditional equipment... The boards are very dense, their front side is glossy, primed or painted. Fiberboard of increased hardness is obtained by impregnating the source material with a by-product of tall oil processing - pectol. When using it, the strength of the slabs increases by 20%.

Video description

The process of painting the material is shown in the video:

If a through hole has formed in the floor, wall and door made of wood-fiber material, you need to prepare the necessary tools and materials for self-repair. First of all, you will need a sharpened mounting knife, a piece of material, putty, hardening filler and mounting foam.

First, you need to trim the concave and uneven edges of the hole so that the hole is smooth, without cracks or third-party damage. Afterwards, pieces of bars are installed inside to create a partition. Fibreboard pieces, cardboard or thick paper will do. Next, along the edges of the partition, the hole is filled with polyurethane foam. After drying, it is necessary to trim off excess pieces of foam so that they do not protrude beyond the surface.

The next step is to putty around the sealed hole. Epoxy resin is perfect for this. The treated surface, after drying, is treated with fine sandpaper to achieve evenness. The appearance and cladding of the material is restored using paint or decorative film simulating wood structure.

The main advantages of fiberboards

Due to their high degree of moisture resistance, these boards can be used for cladding exterior and balcony doors. Fiberboard has a high level of sound and heat insulation. The material is easy to process, has a long service life and is lightweight, which simplifies its further installation. The low price of fiberboard, depending on the type, dimensions and thickness of the product, significantly reduces the total cost of all construction and installation work, without compromising their quality.

Related article:

MDF wall panels: prices, catalog of photo ideas and main technical characteristics

Prices for different options. Advantages of using this material. Types and colors of MDF panels. Various uses.

The fiberboard surface is light and easy to maintain on a daily basis. To clean, simply wipe the material with a damp cloth without using powder. Cladding walls using slabs does not require preliminary leveling.

Helpful advice! Without compromising the quality and structure of the material, it can easily be decorated using decorative plaster or paint.

Disadvantages of the material

Each type of fiberboard, except MDF, has a narrow scope of application. Some types of panels contain toxic compounds. Therefore, work on processing this material should be carried out in personal protective equipment and in well-ventilated areas.

Fiberboard slabs can vary in thickness, sheet size and density

The fiberboard sheet cannot withstand significant lateral loads due to the small thickness of the product. Therefore, installation of the material must be done carefully, without leaving air cushions between the wall and the panel, which can cause the slab to break.

Fiberboard is one of the most common building materials. For finishing the interior elements of a house, fiberboard has a number of advantages over other similar building materials. This practical, inexpensive, easy-to-process material allows you to achieve several goals at once: thermal insulation, good ability to absorb all external noise, resistance to temperature fluctuations and humidity changes.

Video description

The following video shows how to seal a hole using a door as an example:

When laying wood composite material on a wooden floor, protruding boards can also create a through hole. If the defect is too extensive and cannot be repaired, it is best to completely replace the slab, while eliminating unevenness on the floor using a plane. In case of minor damage, you will need to carefully cut the hole with a mounting knife to the size of the inserted part of the material. A patch made of wood composite is installed into the resulting nest. It is best to secure with glue or self-tapping screws.

Thus, having studied the nuances in detail and prepared the appropriate tools and materials, you can independently repair fiberboard and chipboard at home without special skills.

Size, thickness and cost

A standard fiberboard sheet has overall dimensions of 1220 * 2700 mm, 1700 * 2700 mm. In some cases, the manufacturer reserves the right to change the size of the slab.

In case of careless transportation, damage to the corners or edges of the sheet can sometimes occur. This must be remembered when calculating the number of sheets.

- Thickness ranges from 4mm to 40mm.

- The thickness and size of fiberboard depend on the purpose of the material: there are boards available for sale with sizes ranging from 300x300mm.

- There are three types of fiberboard according to the size range: for tiles, for lining and standard sheets.

The price of one sheet of fiberboard is quite affordable compared to OSB board or plasterboard. It depends on its density, production method, size, thickness and finishing. Treated laminated sheets are more expensive than simple options.

Briefly about the main thing

Fiberboard is common and popular among materials for construction and interior decoration. Used in the production of furniture. It has a number of advantages over construction analogues, but at the same time it is considered the most affordable. Fiberboard is a high-quality, durable and easy-to-process material that can be used to achieve both heat and sound insulation in a room. The variety of types allows you to choose fiberboard for every taste and for many purposes. Processing and repairing fiberboard does not require special skills and is accessible even to an inexperienced user.

Ratings 0

Hardboard, fiberboard, MDF, HDF - the name of one material

All of the names listed refer to fiberboard slabs of varying degrees of density. Hardboard is a material of medium density.

MDF refers to the semi-solid class of fibreboard. It is produced by wet pressing. MDF lends itself well to milling, is easy to sand and is suitable for painting with enamels. It is used for the manufacture of facades, doors, decorative panels, and grilles.

HDF, or High Density Fiberboard in English, means high-density fiberboard. It is more in demand in construction.

In the modern world, fiberboard is indispensable for finishing and construction work, in the production of furniture, doors, and packaging containers. In order for the stove to serve for 10 years or more, you must take a responsible approach to choosing the right material based on its functional characteristics.