Plywood for flooring is a natural, multi-layer wood material, characterized by durability, reasonable cost, and the best option for work in the home.

Manufacturing takes place using the method of firmly gluing layers of natural wood veneer together. Due to the perpendicular direction of the fibers, it is a durable material: resistant to fracture, stretching, cracks, chips.

At the moment, in construction stores you can find a large number of sheets of different thicknesses, individual sizes, and many varieties of material have appeared.

Plywood sheets of different thicknesses

Modifications

Before purchasing, you must know the texture, types, cost - choose the best option. According to the state standard, five types of plywood are manufactured, the only difference being the presence/absence of defects during manufacturing:

- E – First grade. Has no defects.

- I – cracks, defects are 16-20 mm.

- II - has cracks, defects up to 190 mm, unnoticeable wood inserts.

- III – there are up to nine cracks and surface defects. The size 1x1m should have no more than 9 wormholes.

- IV – material of below average quality. Wormholes can be up to 50 mm, defects can be up to 5.5 mm deep.

Subfloors – II, III, IV type.

Finishing floor coverings - E, I.

What is plywood

First, let's figure out what plywood is. This is a sheet construction and finishing material in which thin cuts of wood (veneer) - a millimeter or so thick - are glued together using a synthetic binder (glue). The number of veneer layers is three or more. The more layers, the greater the thickness of the sheet and the higher the strength of the material. But the strength characteristics also depend on the type of wood (deciduous or coniferous) and the type of glue used to glue the layers of wood together.

Plywood is a sheet construction and finishing material that consists of sheets of wood veneer glued together.

In wood, the fibers are arranged in a certain direction. When producing plywood, layers of wood are arranged so that the direction of the fibers in adjacent layers does not coincide. Moreover, on the outer layers the wood fibers are directed along the long side of the sheet (as a rule). The number of layers and layered structure are clearly visible on the side sections of the material.

Plywood varieties

It is made of thin layers pressed together, the number of which is odd. The thickness depends on the size, load, strength.

Types of plywood used for the floor: moisture-resistant laminated, plywood + urea-formaldehyde glue, increased water resistance (birch).

Varieties:

- FBA. The sizing is done with albumin-casein glue, a clean material, not moisture resistant.

- Highly water-resistant plywood (FSF). The sizing is done with a synthetic resin from the group of phenolic resins. This gives moisture resistance, strength, long shelf life and use.

- Plywood + urea-formaldehyde glue (UF). Widely used in installation and repair work inside houses and buildings (birch material).

- Veneer + bakelite glue (FB). The highest moisture resistance, can be used in hot, humid climates, with plywood of medium thickness.

- BS. The material + bakelite adhesive composition is applicable in 90% of aviation structures and in the construction of ships. Good characteristics, strength, resistant to corrosion, fungi, moisture (coniferous type of plywood).

- BV. Not moisture resistant, has good strength.

Knowing the grade and type of material, you can decide on the purchase of plywood for flooring.

Highly water-resistant plywood (FSF) - used on all types of floor surfaces, except baths, saunas, swimming pools, bathrooms, kitchens. The composition contains a toxin that is not acceptable for these types of rooms.

FC - used in 95% of types of floor coverings in houses, apartments, and offices.

Moisture-resistant laminated (FOF) - used in industrial repairs.

Laying plywood on the joists

Laying plywood on joists is the most popular method to obtain a flat surface for finishing the floor with laminate, linoleum and other finishing floor coverings.

Instructions for leveling the floor with plywood sheets along the joists:

- Before laying plywood on the joists, you need to do some preparatory work. If there is an old coating, then remove it.

- We purchase timber for the joists, for the frame on which we will lay the plywood sheets. Unplaned boards of 2-3 grades made from healthy coniferous and soft hardwood wood are optimally suited for them.

- It is better to buy logs at least 2 weeks before using them, so that they are dry by the time you work with them. The bars and leveling pads under them must be impregnated with an antiseptic.

Advice! It is better to immediately lay the logs across the direction of light from the windows, so that after possible subsequent dismantling of the plywood onto the plank floor, the cracks are located along the direction of the light flow.

- We mark the floor and cut the logs to the required length. The length of the joined logs must be at least 2 meters.

- We leave a gap of about 20 - 30 (mm) between the joists and the walls.

- It is recommended to make a soundproofing layer between the walls and joists. The soundproofed joists must touch each other without any gap.

- The uneven surface of the floor slabs, old cement screed (if it was not previously leveled with a self-leveling repair mixture) is leveled with wooden pads - bosses. The height of the space above the ceiling must be at least 1 cm.

- The frame itself is attached to the bosses, which are pre-sewn to the floor with anchors.

Fastening the joists to the leveling pads - bosses

- The frame joists are attached strictly in one horizontal plane, which is constantly checked with a long slatted level in all directions. The rail should touch all frame bars without gaps.

- After attaching the bars to the bosses, we make the sheathing. We make the lathing using crossbars, placing them across the joists and attaching them to the bosses with self-tapping screws. The size of the sheathing must correspond to the size of the plywood sheet. The crossbars are placed at least 50 cm apart.

Laying on joists

- After the frame with sheathing is ready, construction waste is removed.

- Plywood is laid on the frame. Its sheets should not touch each other so that there is no creaking afterwards. The gap between the sheets is 2 - 4 (mm).

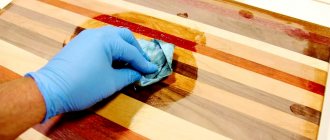

- The flooring material is attached to the sheathing in increments of 50 - 100 (mm) and again covered with an antiseptic using a roller.

- Now this smooth plywood surface can be used to cover any surface, from staining and painting to carpet or parquet flooring.

Step-by-step instructions for laying construction plywood on adjustable joists are shown in the video in this article.

Note! When there is a need to lay logs under plywood in a cement screed, followed by filling them with self-leveling mixture, it is recommended to use a modern power tool - a wall chaser.

Advantages and disadvantages of laying plywood on the floor

The advantages of the material include:

- Natural material. OSB and fiberboard are industrial waste products.

- Moisture content - 11-15%.

- Under load, it remains unchanged; the canvas may receive a minimal number of cracks that do not affect the general condition of the flooring.

- Long service life, thanks to the good interaction of wood with any floor covering.

- Saving time and money during use.

- Laying and laying plywood does not require much effort and takes a small amount of time.

- Used for finishing rough flooring.

- In 70% of cases it serves as an excellent heat insulator (in the case of concrete flooring).

Appearance of a floor covered with plywood sheets

Disadvantages of use include:

- Not suitable for rooms with high humidity levels (saunas, baths, bathrooms), for temporary cottages, summer cottages.

Advantages and disadvantages

Like OSB boards, it is most often used as indoor flooring. Each of them has its own advantages and disadvantages, which must be taken into account when deciding what is better to choose: plywood or OSB for floor screed. In this case, you should be guided by a number of indicators: resistance to deflections, water resistance, environmental friendliness, etc. The main advantages of plywood are the following.

- Plywood flooring is very strong and durable. One of its main advantages lies precisely in this. Therefore, it can be safely used as a bottom covering before laying materials such as laminate, carpet, linoleum.

- Environmentally friendly. Plywood consists of veneer sheets joined together using special glue. It contains formaldehydes, but their concentration is low. Therefore, there is no threat to human health. In addition, other non-toxic agents can be used for the connection.

- This material can be installed much faster and easier than others, since the plywood sheets are large in format.

- Low cost, due to which large expenses for such work will not be required.

- There are moisture-resistant varieties of plywood. They are suitable for renovating rooms with high humidity.

- Plywood is a good insulation and sound insulator.

- When laying plywood on a concrete floor, no screed is required.

But for all its advantages, plywood also has some disadvantages. The main one is the ability to expand under the influence of changes in external factors: humidity and temperature. Therefore, you should not lay ceramic tiles on top of a plywood flooring, or use a concrete floor screed, as it will not be durable. Due to this property of this wood material, it is necessary to leave gaps between the boards during installation.

Selection of plywood for laying on the floor

To make the right purchase, you should remember the following important factors:

- Type of flooring. This is an important issue when purchasing material; the wrong approach to the situation can affect the quality of the resulting coating. You should know the nuances of the floor on which installation will be carried out.

- Room type. Children's - only material with urea-formaldehyde glue. Production premises with an optimal level of ventilation - only increased water resistance of the first class.

What to attach plywood to?

Depending on the type of subfloor to which the plywood is mounted, it can be attached in different ways:

- Polyurethane foam. Increases the heat and sound insulation of the floor, gives additional rigidity to the plywood. The foam significantly bends the plywood sheets, so this method of fastening is very labor-intensive; you need to carefully monitor the height difference during the installation process.

- Self-tapping screws. The most common method of attaching plywood. It is important to recess the screw heads into the wood.

- Glue. It is used when the base surface is flat and it is not possible to use hardware, for example, on a concrete base. To attach plywood, use mastic, bustilate, water-based glue, assembly adhesive or liquid nails.

Plywood parameters

In addition to the qualities and types of material described above, you should also know the parameters of the material:

- Brand. As presented above, FC is used for permanent residence rooms.

- Class. For any floor covering (concrete, wood) class E – I is used.

- Variety There are 4 varieties in total. Subfloor - III, IV. Finishing - I, II.

- Moisture content. A good level of veneer has a moisture content of no more than 15%.

- Number of layers. It has a thickness of 1.6 – 1.9 mm. More layers – higher level of strength. Rough floor – up to 19 mm, finishing floor – up to 13 mm. Production work – from 24 mm and above.

- Slab parameters. Three types: small-format, large-format, format slabs. Difficult work when installing large-format slabs.

Advice! When cutting plywood, during installation, each one should be numbered, and laying should be done with a shift!

- Manufacturer. There are many negative reviews about the Chinese quality of the material.

What kind of plywood to lay

Before laying plywood on the floor, you need to familiarize yourself with its characteristics:

- The brand for residential premises must be FC. This is the safest option, although its moisture resistance is not very high. Laminated products are also used, but they are more expensive;

- For safety reasons, choose E1 or E0.5 class;

- Inexpensive grades 3 and 4 are suitable for subfloors; for finishing floors, you need to take a higher grade. The designation of grades 2/2, 2/3, 1/2 and the like is often found. This is how the grade of veneer is indicated from different sides;

- the humidity of the sheets should be no more than 15%, the lower it is, the better;

- plywood used for the subfloor must have a thickness of at least 12 mm; for finishing, a value of 10 mm is allowed. Laying in two layers is possible. In workshops, workshops, and public spaces with high traffic, the thickness can reach 2.5 cm;

- For subfloors, unsanded plywood, designated NSh, is suitable. It can also be polished on one side - Ш1.

Laminated plywood with a mesh texture is used primarily for transport floors. It is suitable for finishing on terraces, country houses, outbuildings.

The dimensions of the sheets are chosen in accordance with your own needs; they are not of fundamental importance for installation. It must be taken into account that the larger the leaf, the greater its mass. The process of transportation and manipulation during installation becomes more complicated. To avoid tension in the material under load, large sheets are sometimes cut. When gluing to a screed, it is convenient to work with squares of 75 x 75 or 60 x 60 cm. Elongated strips are suitable for joists. In large rooms they may not be cut.

Domestic manufacturers offer good quality plywood, which is quite suitable for flooring. The same applies to Western European brands. As for Chinese goods, you need to be careful when choosing, because there are products that do not meet the standards. For example, the declared thickness may be greater than the actual thickness.

Plywood thickness for flooring

This material can be used for leveling floors and for laying subfloors (using logs). When choosing to purchase plywood for the floor, you should know (see) the condition, the range of levels.

Plywood sheets of different thicknesses

Production of non-foreign plywood: 4, 6, 7, 8, 9, 10, 12, 15, 18, 21 mm.

- Floor coverings with small defects are covered with a thickness of 6 mm. Compensation of vibrations is possible, but with the appearance of relief after installation.

- To level the flooring, 9, 10, 12, 15 mm veneer is used. Subsequently, all defects of non-conformity of the even surface will be removed, the floors will be dense and stable.

- If uneven joints appear, a second layer should be laid, with an offset in the seams, which will give an excellent result and smooth out all the unevenness.

When used in several stages, screws of the maximum suitable length are used, screwing in every 16-22 cm. A good screwdriver should be used.

Important! If you already have laid out joists, you should know the step width. At 0.5 - 0.6 m, a plywood thickness of 15 to 21 mm is used. The thicker the plywood, the stronger the floor will be.

How to lay it correctly

Using plywood for flooring will be a smart solution to eliminate uneven surfaces. Sometimes, with accurate measurements, you can find that the difference in floor level is more than a few centimeters; the figure can even be more than ten. Therefore, you will definitely need to level it.

There are different methods and types of installation. The choice depends on the characteristics of the room, and on what exactly needs to be done: simply level the floor, or lay it on boards or wooden logs. In the first case, plywood is the most suitable option. It will hide all the differences in height that would otherwise have to be sealed.

Before you start covering the floor with plywood sheets, you need to make preparations. The concrete floor needs to be cleaned: remove all debris, dirt, dust. Cleaning should only be done dry. Otherwise, moisture will begin to accumulate on the concrete, and this should not be allowed. Then apply primer. When it dries properly, you can begin to cover the floor with plywood boards. If you lay them on old boards, or directly on concrete, then one layer will be enough. But on the logs you will definitely need to lay two layers. If you take sheets 1.2 cm thick for this, then the amount of costs will be lower than for plywood 2.1 cm high. But the work time and fastener costs will increase.

Working with rough coating

Laying plywood on the floor as a subfloor is not difficult. If it has a high-quality concrete screed, even and smooth, then the sheets are simply glued to the surface. Their thickness should be 1-1.2 cm. And small gaps must be left between them. Their width should be approximately 3 or 4 mm. The same gaps are left near the walls. Sheets 1.2 cm thick are laid on the logs. This method is acceptable in cases where floor insulation is required. It is quite labor intensive. But with the help of adjustable logs, differences in height are eliminated, and then the surface is covered with plywood, on top of which the material for the finishing coating will be laid.

In order for the rough coating to properly fulfill its purpose, there are several recommendations. After flooring, all sheets must be reliably strengthened, taking into account any gaps. In this case, all the caps of the fastening elements will completely recess the surface of the sheets. Use a grinder or sandpaper to remove surface irregularities. And also fill all the depressions and cracks with putty.

Leveling the floor with plywood

This type of work does not require professional skills or complex equipment; installation is carried out quickly. This is much simpler than screeding and requires less expense. For this purpose, you can use cheap varieties of plywood sheets, because appearance does not matter.

Sometimes it is necessary to update the plank floor. The boards themselves may be in quite satisfactory condition, but lose their visual appeal. In these cases, it can be used as an intermediate floor, which is necessary to make the surface level and lay the final covering. Mount plywood sheets using self-tapping screws. If the floor is to be covered with parquet boards, you will need to lay an underlay.

Finish plywood floor

Not everyone likes covering their floors with plywood sheets. Many find it unaesthetic. That’s why they are used only for the inner layer. However, if you choose decorative high-quality sanded or laminated sheets for this and lay them on the floor, then it will look great. This finish will cost much less than laminate.

You can cut the sheets into small plates and lay out the original pattern. To do this, a sketch is first made. Here you can give free rein to your own imagination or find an interesting example on the relevant sites. The sheets are then cut into slabs of the required size. This can be done using a circular saw or jigsaw. Then sanding and chamfering should be carried out, as a result of which the plywood boards acquire a solid appearance. When using laminated plywood, sanding is, of course, not required. Laying is done in exactly the same way as laying boards. The slabs can be glued to the subfloor, or nailed, or reinforced with screws.

If the drawing contains parts of different sizes, then it is recommended to number them according to the chosen scheme. Sometimes plywood is laid out in a “herringbone pattern” or squares like on a chessboard, imitating parquet. To finish such a floor, you can use stain. It is applied in several layers. Each of them must dry before the next coating. When the last layer is completely dry, the surface is varnished. It is also applied in at least two layers.

Before laying plywood boards on a previously leveled floor, it must be coated with a primer. This is a necessary procedure when processing both plank surfaces and concrete floors. Thanks to this, the grip will be reliable and durable.

Features of installing plywood under parquet and laminate

A finishing coating can be laid on the floor on top of the inner layer, since the floor is perfectly level. If you need to lay parquet, then thanks to the plywood layer it will lie flat and the floor will not creak or deform. The design will be reliable and will last a long time. In addition, thermal insulation and noise insulation are also significantly increased. This is very important for apartment buildings.

Laminate is a very popular floor covering material nowadays. It is made from a mixture of paper, wood flour and a special film by pressing.

Of course, in terms of technological characteristics, this material is significantly inferior to wooden parquet. This concerns, first of all, thermal insulation properties. Therefore, most builders recommend that you always use plywood before laying laminate flooring on a concrete floor. For such work there is no need to use expensive materials.

It is permissible to begin laying plywood during this type of work only after priming, and until it has completely dried. You can verify this using plastic film. It must be laid tightly over the entire area of the room. So it should lie for three days. If there is complete absence of condensation, further work can begin.

For flooring under parquet, the sheets are cut into squares (50x50). This is done so that the internal tension is lower. Typically, plywood is used with a thickness that is equal to 2/3 of the thickness of the parquet itself. It is preferable to choose the FC brand for this. If reinforcement is carried out on joists, all seams between the slabs must be on the beams. Gaps should be left 0.9-1 cm. Plywood boards should be placed like brickwork. They are secured using construction adhesive, dowels or self-tapping screws. The surface of the subfloor must be cleaned before laying parquet, preferably with a vacuum cleaner.

Proper use of plywood for flooring will save both money and time. Not only the appearance, but also the service life of the flooring depends to a large extent on the choice of the most suitable material.

Installation work

After cutting the plywood into sections, they will need to be laid out on the floor surface to adjust to the area of work. It is extremely important to take into account the gaps (between the sheets inside - up to 10 mm, between the sheet and the wall - up to 20 mm).

Screed flooring is carried out on both wooden and concrete floors. The flooring should be slightly offset to avoid grouping all four seams in one place.

After preparing the plywood sheets for the floor, each one is numbered - installation will be faster and more convenient.

For better installation, a plywood sheet 1.25 m X 1.25 m should be cut into pieces of 0.60 m. If, when cutting the sheets, a large number of delaminations are observed - the first sign of poor-quality material, the floor should not be laid with such plywood.

Working with rough coating

One of the fastest and most effective types of work with plywood. Has several types of styling:

- On a concrete type screed.

Plywood up to 12 mm thick must be glued onto the screed. The flooring is smooth. Expansion joints - 4 mm between sheets, 3 mm - between the wall and the plywood sheet.

Installation of plywood on a screed

If there is a difference in level in the room, special fasteners will be required, which will be located under the sheet. Such floors do not require logs.

Fastenings that allow you to adjust the level of the flooring

- Laying on joists

Before the flooring, a base of logs is installed. The sheet thickness must be more than 12 mm. Working with this type of installation is difficult, time-consuming, and durable. Required for insulation and raising the floor to the required height. The correct placement of logs and plywood sheets will allow you to cover differences in the height of the room.

Laying flooring on joists

Leveling the floor with plywood

In 90% of cases, floors made from a wooden base lose their appearance over the many years of their existence, but do not lose their evenness and do not require tearing off the floor. There is a solution in this case - laying a covering on top of the wooden floor.

In order not to worsen the condition of the finished floor, plywood sheets (intermediate covering) are laid on top of the wooden covering, which is used to level the floor for subsequent finishing work.

Leveling the floor with plywood sheets

Laying plywood on a wooden floor using self-tapping screws is simple, cheap, quick, and without much effort or investment.

If the finished floor is not made of wood, then you should adhere to the rules of overlay:

- When cutting the material, during installation, each one should be numbered, and the laying should be done with a shift.

- During installation, the sheets must be firmly fixed and not “walk” on the floor.

- Deformation gaps should be taken into account.

- It is good to “drive” the screw heads into the plywood so that the surface is smooth.

- Fill the identified depressions with putty.

- Use a backing.

Flooring is not required for subsequent finishing of natural wood. Due to its mass, the board can be laid on concrete or wooden logs.

Plywood finished floor

Wide-ranging specialists can create an indescribable beauty of finished flooring from plywood. To do this, only first grade plywood is taken for the floor, and the surface is sanded to perfect condition.

If desired, for a better appearance of the coating, it is covered with varnish, stain, and all kinds of patterns and designs.

Here are some installation options for your finished floor

Decorative plywood floor

How to choose plywood for flooring

To choose the right OSB board or plywood for your floor, consumers should consider several factors. First of all, this is what kind of gender, or more precisely, its type. Finishing and rough finishing require materials of different quality. Next, there is the question of the purpose of the room where the floor needs to be laid. For rooms in the house, especially children's rooms, you should use sheets of plywood of the FK brand. They are completely non-toxic, because formaldehyde is not used for their production. This type of plywood consists of birch veneer sheets. It is highly durable and moisture resistant, but cannot withstand constant, prolonged exposure to water.

When choosing a material, the user must know which brands and grades of plywood are suitable for the floor. Different brands represent materials with different physical properties. The letter E is used to mark plywood of the highest quality. Latin numerals from I to IV indicate a decrease in quality. Low grades are used for internal coating. The final finishing is made with high quality materials that have a beautiful appearance.

You cannot cover the floor in residential premises with FSF plywood, although it is a durable and reliable material, resistant to wear and tear and not afraid of water. But for gluing veneer during its production, phenol-formaldehyde glue, which is toxic, is used. The FBA brand is often used in rooms with low humidity. Its main advantage is its high environmental friendliness, since the veneer is joined with non-toxic glue.

Recently, moisture-resistant laminated plywood for flooring has become popular. It is often used as an auxiliary material. But they are also used for finishing.

Laminated plywood can be used to cover floors in rooms with high humidity. The retail chain has different color options for laminated plywood. You can perform a single-color finish, or combine different colors and shades. But you need to take into account its fairly high cost. Waterproof FB plywood is also suitable for wet rooms.

Thickness of plywood for flooring

Plywood sheets produced by manufacturers in our country are of uneven thickness. It can be from 0.3 to 2 or more cm. As for those varieties that are used for flooring, the choice must be made based on the purpose for which they are planned to be used: leveling the floor, finishing or rough coating, when the sheets laid on wooden logs. For the second option, it is advisable to take sheets with a thickness of 1.8 cm. This depends on the location of the beams. If they are located at a distance of 5-6 cm, then the optimal thickness will be 1-1.5 cm. The installation option and the height of the coating also matter. When choosing the appropriate thickness for the floor covering, you must also take into account the future load on the floor. If it is high, thicker sheets will be required. Sheets with a height of 2.2 cm are suitable for industrial premises, and 1 cm for residential premises.

It is also important to consider what will be used for the outer layer: other materials, or it is necessary to install a finished plywood floor. For example, if the final covering is parquet, then the dimensions are selected depending on its thickness. For parquet 1.6 cm, sheets 1 cm high are suitable. If the parquet is thick - up to 2 cm, then the suitable thickness of plywood for the floor will be at least 1.2 cm.

Features of laying plywood under parquet and laminate

For laminate and parquet, you should know what kind of plywood to buy. The main task of laying laminate or parquet is to have a perfectly flat floor. Only moisture-resistant plywood should be used. There are several variations of installation under laminate and parquet:

- On the screed. The concrete must be dry, the surface smooth, clean, free of debris and unevenness.

- On the logs. Among the advantages we can highlight: the possibility of insulating the floor, hiding installation communications.

- On a wooden floor. One of the simple and effective styling methods.

Subfloor laying options

Plywood is easy to lay on a flat concrete screed in an apartment. Sheets 12 mm thick are glued to the surface, having first checked its horizontalness. The height differences should be no more than 2 mm, otherwise you need to fill it for leveling and wait until it dries completely.

Note! For any installation, gaps of 2.5–3 mm must be left at the joints of sheets, and 1–1.5 cm away from the walls. This will avoid deformation due to changes in temperature and humidity, and there will be no creaking or sagging.

Plywood sheets are laid with a slight offset so that there is no clear joining of the four corners. This installation increases the strength of the floor covering.

The most common installation method is on wooden joists. It can replace the screed. The surface is perfectly smooth and can be used for any finishing. The logs can be adjustable. How to perform such installation will be discussed below.

When there is a difference in height on a wooden floor, fastenings in the form of studs or screws are used, which allows you to level the surface without the use of joists. This is an interesting installation method in which fasteners (screws, self-tapping screws, studs) are drilled over the entire area at the same distance from each other. The height of their heads should be at the same level. You can check this using a laser or a regular level. The hardware must be screwed in evenly. Foam is squeezed out between the fasteners and a thick plywood sheet is laid on top.

Protection, operation, storage

In order for plywood to serve for many years, you should know some of the nuances of working with it:

- The material should be acclimatized. 24 hours - with minimal temperature deviation in the store and the room for working with it. 4-6 days – with a difference of 9-12 °C, taking into account the humidity in the room. More than 7 days - with significant differences in temperature conditions, with defects in sheets, and high humidity.

- The damp atmosphere will destroy the material. Use in a damp area is prohibited.

- Laying is carried out only at 19-29 °C.

- Auxiliary processing of the material improves wear resistance and protection against fungi. The use of varnish improves strength, and the use of glue improves moisture resistance.

According to the above data, we can say with confidence that this is the best material for laying on the floor.

Plywood over wood floor

Plywood is widely used in the construction industry. It can be used to create partitions, cladding walls and ceilings in a wooden house, it is used to build formwork, and it is often used to level floors before laying coverings that require evenness of the base.

Plywood structure

Stages of plywood production

This material is a layered “pie” created from wood veneer. To create it, an odd number of veneer sheets (from 3 pieces) are glued together, which are connected in such a way that the wood fibers in different layers are perpendicular to each other. Due to this, the strength of the material increases.

Plywood sheets

For installation in warm and dry rooms, for example in residential buildings, plywood is a material that is ideal. It’s easy and quick to work with, which is what attracts many builders and novice craftsmen to use it. If necessary, sheets that have lost their strength and reliability can be easily replaced with new ones.

On a note! Plywood makes an excellent option for a dry screed; you won’t have to wait 30 days for it to dry (unlike a regular cement screed) - you can begin laying the topcoat almost immediately after installing the plywood. Using this material will save not only time, but also money during renovation of the premises.

Installation of logs with plywood ceiling

Do I need sanded plywood for the floor?

4/4 grade plywood sheets are usually not sanded, so they are not used when it is necessary to obtain a high-quality surface. The material NSh (unsanded) is suitable for rough flooring in undemanding structures.

There is no point in using Sh2 material (polished on both sides) for installing floors, since one of the surfaces will still be completely hidden.

It is obvious that in terms of the cost/practicality ratio, Sh1 plywood (with one sanded plane) for floors will be the most optimal.

About the size of plywood floor board

FC plywood is available in sizes 1525X1525 mm. Such square dimensions are considered classic; they are well suited for working with indoor floors, especially when the underlying layer is made from plywood, for example, under block parquet.

Large-format slabs with sides of 1220, 1250, 2440 or 2500 mm are mainly FSF grade material, which is usually used inside and outside the house. Such plywood can have a sheet length of up to 3050 mm, which allows you to complete the flooring faster and with fewer joints.

By the way, according to GOST 3916.1-96, plywood with dimensions of 1525X1525 mm should have errors in length or width of no more than 3 mm. And plywood of larger formats can have a tolerance of up to 5 mm.

Gluing plywood to a concrete base

Sanding - leveling plywood

Laying the finishing coating on a plywood base

Prices for FC 4/4 plywood

| Product name | The price of the product |

| Plywood 4 mm birch FK 4/4 1525x1525 mm | RUB 470.00 |

| Plywood 6 mm birch FK 4/4 1525x1525 mm | RUR 800.00 |

| Plywood 8 mm birch FC 4/4 1525x1525 mm | RUB 1,030.00 |

| Plywood 9 mm birch FC 4/4 1525x1525 mm | RUB 1,130.00 |

| Plywood 10 mm birch FK 4/4 1525x1525 mm | RUB 1,350.00 |

| Plywood 12 mm birch FK 4/4 1525x1525 mm | RUB 1,530.00 |

| Plywood 15 mm birch FK 4/4 1525x1525 mm | RUB 1,980.00 |

| Plywood 18 mm birch FC 4/4 1525x1525 mm | RUB 2,480.00 |

| Plywood 21 mm birch FC 4/4 1525x1525 mm | RUB 2,630.00 |

Prices for FSF 4/4 plywood

| Product name | The price of the product |

| Plywood 6 mm birch FSF grade 4/4 1220x2440 mm | RUB 1,600.00 |

| Plywood 9 mm birch FSF grade 4/4 1220x2440 mm | RUB 2,150.00 |

| Plywood 12 mm birch FSF grade 4/4 1220x2440 mm | RUB 2,700.00 |

| Plywood 15 mm birch FSF grade 4/4 1220x2440 mm | RUB 3,100.00 |

| Plywood 18 mm birch FSF grade 4/4 1220x2440 mm | RUB 3,500.00 |

| Plywood 21 mm birch FSF grade 4/4 1220x2440 mm | RUB 4,500.00 |

Types of plywood

Plywood is divided into types based on its scope of application: construction, furniture, structural, industrial, packaging.

The type of plywood is determined based on the glue used during production:

- FC is a water-repellent type of plywood. Its sheets are glued together using urea glue;

- FSF is plywood with enhanced water-repellent properties. In this case, the layers are glued with phenol-formaldehyde glue;

- FBA is ordinary plywood, the sheets of which are glued with albumin casein glue. Such plywood is afraid of moisture, but it is chosen because of its harmlessness to humans;

- FB is plywood created for use in particularly wet conditions, even in water. Such qualities are acquired by the material due to its impregnation with bakelite varnish.

Listed above are only the most famous types of plywood. There are additional classifications depending on the thickness, wood used, and surface quality.

Which one to choose

Which plywood to choose? Among all the variety, FC plywood sheets are most often used for flooring before finishing coating. They are less moisture resistant, but much cheaper than similar materials and have high mechanical properties, perfect for these purposes.

From the article you can understand the difference between FSF and FC plywood

Plywood sheets are also distinguished by the type of raw material used. If plywood sheets made from softwood are practically the standard, then the “hardwood version” is distinguished by a higher price and use in finishing work.

Using “birch” plywood for flooring will not be a very economical idea, and besides, its properties will be no better than the “spruce” version.

This article indicates the dimensions of one sheet of moisture-resistant plywood.

Assortment of plywood sheets

- The first grade means the use of exclusively high-quality raw materials; there are no knots or irregularities on the surface; as a rule, it is produced sanded on both sides.

- The second grade allows for a certain number of minor veneer inserts, knots and minor defects. All this does not interfere with its trouble-free operation in a wide variety of areas of construction, including as a rough version of flooring.

- The third grade, accordingly, has a greater number of flaws, as well as worse quality of raw materials. Despite the presence of defects and manufacturing defects, the quality of gluing the sheets together does not allow for negligence, so the slab has all of the above advantages, except for appearance.

- Fourth The grade is usually used for industrial purposes and for most low-cost projects. The use of such material is advisable only as a completely insulated layer.

The type of material also determines its cost. As mentioned earlier, plywood sheets are an inexpensive analogue of fibreboards, superior to them in moisture resistance and strength parameters.

You can learn what FSF plywood is from this article.

Judging by the physical characteristics, it is more advisable to use plywood sheets of the second or third grade for the flooring. The first grade will be too expensive for this type of work, and the fourth may create a poor-quality layer and affect the further operation of the finishing coating.

This article describes the characteristics of moisture-resistant bakelite plywood.

In addition to all the above characteristics, plywood boards can also be sanded, according to which the following types of sheets are also distinguished.

Additional markings

Additional marking of plywood:

- “N” - unpolished, suitable exclusively for rough work, industrial and non-residential premises.

- “Ш 1” - sanding was performed on only one side of the sheet. It is ideal for flooring; installation is done, quite naturally, with the layers sanded upward.

- “Sh 2” - this plywood is distinguished not only by improved performance characteristics, but also by visual appearance. Sanded on both sides, it is perfect even as stationary partitions or for finishing work.

Plywood for the floor does not have to be sanded, especially on both sides. This will mean an increase in the cost of repairs, which is not always acceptable. On the other hand, if linoleum is laid on an unsanded surface, sooner or later, the natural deformation of the top layer will reveal all the unevenness and defects of the rough surface.

Video showing floor leveling with plywood:

For those who choose a building material, you can choose Petrovich plywood, which is described in this article.

Some information about plywood

Plywood is included in the list of the most durable, best-suited building materials for eliminating unevenness in rough foundations. She is preferred for her harmlessness. Plywood does not contain very harmful volatile carcinogens, which cannot be said about chipboard (for more details: “Chipboard or plywood for the floor - pros and cons of materials”).

Versatility and durability make this material an excellent solution for the following work:

- elimination of unevenness of the old floor laid on logs;

- use as a base for dry screed;

- creating a clean floor covering;

- use as thermal insulation for rough foundations.

This relatively lightweight and wear-resistant material does not place excessive load on the floors, which makes it possible to lay it on an old floor with joists. Very often, plywood is used in multi-story buildings, where there are weak floors between apartments (read: “How to make a plywood floor in an apartment”).

Prices for FC 3/4 plywood

| Product name | The price of the product |

| Plywood 4 mm birch FC 3/4 1525x1525 mm | RUB 750.00 |

| Plywood 6 mm birch FC 3/4 1525x1525 mm | RUB 850.00 |

| Plywood 8 mm birch FC 3/4 1525x1525 mm | RUB 1,130.00 |

| Plywood 9 mm birch FC 3/4 1525x1525 mm | RUB 1,380.00 |

| Plywood 10 mm birch FC 3/4 1525x1525 mm | RUB 1,430.00 |

| Plywood 12 mm birch FC 3/4 1525x1525 m | RUB 1,650.00 |

| Plywood 15 mm birch FC 3/4 1525x1525 mm | RUB 2,030.00 |

| Plywood 18 mm birch FC 3/4 1525x1525 mm | RUB 2,530.00 |

| Plywood 21 mm birch FC 3/4 1525x1525 mm | RUB 2,680.00 |

Laying rules

Laying plywood sheets should be carried out based on a number of rules. The service life of not only the rough, but also the finished floor covering will depend on how well the material is laid.

Basic installation rules:

- The sheets are divided into pieces of a certain size.

- Laying is carried out offset to reduce the load on the seams.

- For cutting, it is better to use a jigsaw or circular saw.

- When installing the sheets, 10 mm gaps should be made between them to allow for expansion.

- There should be a gap of 20-30 mm between the sheets and the wall.

- To secure the sheets, you need to use not only glue, but also self-tapping screws.

Types, grades and markings of plywood

Plywood is a sheet material made from several layers of veneer glued together. The number of layers is always odd; the contacting layers are located perpendicular to each other, which ensures the rigidity of the sheet and its high resistance to deformation.

Plywood differs in the material it is made from. The use of coniferous wood (usually pine, but spruce and larch wood can be used) increases resistance to rotting, but such material has a looser structure.

Deciduous trees (primarily birch) make it possible to produce plywood with increased strength properties. Plywood sheets intended for general construction work most often have front layers made of dense hardwood, and inner layers made of coniferous veneer.

The grade of the plywood sheet indicates the degree of resistance of the material to moisture. This indicator depends on the substance with which the wood is impregnated. Before choosing plywood for the floor, it is recommended to familiarize yourself with the features of each type of material.

FB – bakelite (bakelized) plywood, the second name is “Finnish”. The wood is impregnated with bakelite varnish, which makes it resistant to moisture, aggressive environments and high temperatures. This is the most durable, but also the most expensive plywood.

BS – aviation plywood, alcohol-soluble bakelite glue is used for impregnation. It is characterized by increased flexibility, resistance to moisture and fungal damage.

BV - veneer is glued together with a water-soluble bakelite composition. Plywood is highly durable, but its moisture resistance is low.

FC – urea adhesives are used for gluing layers of wood veneer. The moisture resistance of this material is low, but it is environmentally friendly and suitable for interior work. To increase the resistance of plywood to moisture, it can be additionally treated with an appropriate composition for wood when installing the flooring.

FBA – albumin casein adhesives are used as an adhesive. This is also an environmentally friendly and safe material, but it is afraid of moisture.

FSF is plywood made using phenol-formaldehyde resins. The material is waterproof, but is only suitable for roofing and exterior work, as it emits substances harmful to humans.

Paste a VALID AdSense code in Ads Elite Plugin options before activating it.

There are 5 grades of plywood - from E (elite) to grade IV.

- Material of the lowest (IV) grade is characterized by low surface quality; the manufacturer only guarantees the reliability of the adhesive connection.

- Grade III plywood also has surface layer defects and is used for hidden work.

- Grade II is suitable for external work, provided that a few acceptable external defects are repaired.

- Small dark-colored veins and isolated small knots are allowed on the surface of grade I material.

- Grade E material is characterized by an ideal appearance.

On the plywood marking, the grade is indicated for the front and back sides, for example, III/IV or I/II. To lay flooring under laminate or parquet, it is enough to use grade II – III material. If plywood is intended to be used as a finishing coating followed by the application of a decorative protective layer, the highest grade material is selected.

Sheet sizes and thickness, scope of application

As already mentioned, plywood is a sheet material that has a rectangular shape. The size of the plywood sheet can be height/length from 120 cm to 360 cm. Plywood thickness - from 4-5 mm to 36 mm. The most popular is 10-14 mm. The sheet size is selected so that waste is minimal. It is often more convenient to work with small-format sheets - they are easier to transport. But when installing small plywood, more fasteners are required. But such a floor is less susceptible to thermal and humidity deformations (more seams, which compensate for changes in size).

The dimensions of the plywood sheet are chosen so that it is easier to work with them and there is less waste

In general, plywood is a popular material. It is used in construction - in the construction of panel houses, for leveling floors and walls, and for constructing floors. It is also used in the production of furniture, in the construction of passenger cars, in the finishing of ships, and in aviation. Cheaper varieties are used to make containers, packaging, and removable formwork for concrete or reinforced concrete products. So the scope of application of plywood is very wide.

Laying plywood on the floor began in the last century

Although there are cheaper sheet materials available, plywood is still one of the most popular options for flooring. Moreover, there are several ways to make a plywood floor:

- laying plywood directly on the joists;

- lay on top of the subfloor made of boards;

- level the old wooden floor;

- level the concrete floor.

Laying plywood over an old plank floor is the best choice. Due to rigidity and elasticity, differences in height are compensated, which, when using other materials, must first be sealed. Repairing an old wooden floor is done this way. And it is plywood (as a base) that is recommended by almost all manufacturers of finishing floor coverings - laminate, linoleum, carpet, etc.