A circular saw is a useful power tool for cutting lumber during repair or construction work. The main difference between a circular saw and an electric jigsaw is the shape and diameter of the saw. A circular saw can provide an even cut, without distortion to the sides, which will create a perpendicular edge.

Circular saws for wood are equipped with different accessories. Discs may differ in the number of teeth, the presence of additional soldering and slope, which determines the speed, quality and cleanliness of the cut.

There are several specifications of wheels designed specifically for a specific material. That is why you need to know the main characteristics and types. They will help you choose the right circle for specific tasks.

Parameters of circular saw blades

A disk is a metal circle with teeth on the end. Wood saw blades for circular saws are designed for different tasks, which is something you need to consider when purchasing. Incorrectly chosen equipment will lead to an uneven cut, it will be difficult to cut, with expected damage to the consumables.

When cutting, be sure to monitor overheating. Steel is characterized by an increase in body temperature with constant friction, especially against wood. During this process, the metal expands, which leads to a “figure eight” distortion. The deformation begins to manifest itself in a small beat that has not previously been experienced. Often, an increase in temperature is caused by small bulges on the metal body that are not visible to the eye, but are noticeable to the touch. Over time, they begin to expand and become even more noticeable. Operating a circular saw with such a disk will lead to engine wear and breakdowns in the armature.

When purchasing, you need to take into account the likely expansion, since even a disk that matches the characteristics of the tool can begin to expand due to temperatures. To eliminate this defect, there are thermal compensators. These are slots that take over the expansion and prevent it from deforming. In addition, for safety reasons, you need to take periodic breaks to ensure the engine and wheel cool down.

An indicator of cut cleanliness is the number of teeth. Productivity models have fewer and larger teeth. They also have a positive slope. They are much faster at cutting wood board or wood, but the edges become covered with debris and uncut fibers. You will have to clean them yourself using a chisel.

A saw blade for wood for a clean cut has a larger number of teeth (from 42) with a negative slope. Their productivity is reduced, but in return they give a clean end, without protruding fibers.

It is important to look at the purpose of the disk. The circular machine has equipment for:

- Metal;

- Trees;

- Wood boards (fibreboard, chipboard, MDF, plywood, OSB);

- Plastic;

- Aerated concrete and foam blocks.

They have different cutting edge shapes, which changes their purpose.

The best saw blades for wood

Such equipment is used on woodworking machines, circular machines, and format-cutting equipment. The presented discs are used when dissolving logs and boards, creating blanks from plywood, chipboard, etc.

Irwin Pro 10506819

5

★★★★★

editorial assessment

100%

buyers recommend this product

The teeth of the Irwin Pro disc are made of industrial-grade tungsten carbide and are resistant to chipping and intensive sawing. The kit includes adapter rings that allow you to install the disc on mounting sizes of 25, 20 and 16 millimeters.

The diameter of the circle is 250 millimeters, the cutting width is 3 mm. Expansion slots effectively dissipate heat, reduce the risk of disc warping and minimize vibration.

For additional strength, the material of the circle is hardened. Anti-corrosion coating reliably protects surfaces from adverse environmental factors.

Advantages:

- versatility - suitable for different types of saws;

- high strength and corrosion resistance;

- convenient installation;

- rapid heat dissipation;

- long service life.

Flaws:

- high price.

The Irwin Pro 10506819 can be mounted on a circular saw, miter saw or circular saw. A reliable solution for working in any conditions.

Makita M-Force B-31360

4.9

★★★★★

editorial assessment

95%

buyers recommend this product

The front and top sides of the M-Force teeth are beveled, creating six working edges. This increases the cutting surface, reduces the likelihood of rapid wear and ensures accurate sawing. For smooth entry into the wood, the elements are inclined at an angle of 15°.

The diameter of the disc is 210 millimeters, thickness - 1.2 mm. The main material for its manufacture is steel of increased hardness, resistant to wear and deformation, which ensures a long service life of the equipment.

Advantages:

- long service life;

- durable material;

- vibration reduction;

- neat cut;

- reinforced teeth.

Flaws:

- difficult sharpening.

Makita M-Force B-31360 is recommended for fast and high-quality cuts. The disc is suitable for working with pressed boards, laminated wood, plywood and other loose materials.

Bosch Construct Wood 2608640633

4.9

★★★★★

editorial assessment

92%

buyers recommend this product

The disc has a reinforced design, is not afraid of intensive use and maintains quality when sawing at speeds of up to 8000 rpm. The wheel is not subject to overheating and is resistant to vibration, which makes cutting hard wood easier.

The number of teeth is 12, diameter is 190 millimeters. The sharpening of the main elements does not deteriorate with prolonged use of the disc, and the special shape of the teeth guarantees precise and accurate work.

Advantages:

- high blade strength and reinforced teeth;

- long service life;

- reduced vibration;

- easy sharpening.

Flaws:

- lack of protective coating.

Bosch Construct Wood is good for making fast and precise cuts in structural wood, chipboard, aerated concrete and other similar materials.

READ ALSO

12 Best Sawing Machines

Vortex 73/10/4/9

4.8

★★★★★

editorial assessment

88%

buyers recommend this product

The cutting elements of the 48-tooth Whirlwind disc have carbide tips, which increase the service life of the equipment and ensure high-quality processing of the material.

Reliable tool steel is not subject to deformation and rapid wear. Special slots compensate for temperature increases to maintain a stable wheel shape when in contact with the workpiece.

The maximum rpm is 6600. The kit includes an adapter ring that makes it possible to use a disc with mounting diameters of 30 and 32 millimeters.

Advantages:

- reinforced teeth;

- vibration reduction;

- convenient installation with the possibility of using an adapter;

- durable material with a long service life.

Flaws:

- instability to corrosion.

Whirlwind 73/10/4/9 is suitable for sawing both soft and hard wood. A universal solution for continuous work.

Elitech 1820.055000

4.7

★★★★★

editorial assessment

86%

buyers recommend this product

Special compensating slots in the disc contribute to the comfort of long-term work and ensure an accurate cut. Elitech equipment is not afraid of difficult operating conditions and does not lose quality when rotating at speeds of up to 8000 rpm.

The bore diameter is 32 mm, the thickness is 1.8 mm. The main elements have an aggressive orientation, which guarantees ease during intensive sawing of wood of any hardness.

Advantages:

- the presence of an adapter ring;

- heat resistance;

- high strength;

- high-quality cut;

- long service life.

Flaws:

- unclear markings.

Elitech 1820.055000 is more suitable for occasional use in a home workshop.

Characteristics

There are two main indicators that you should pay attention to when purchasing.

Diameter is a characteristic that affects the speed of rotation of the motor shaft. The size of circular saws varies, and this changes the parameters of the wheel. The optimal ratio of size and speed can be presented in the tables:

| Diameter mm. | Rotation frequency |

| 80 | 23 800 |

| 100 | 19 100 |

| 120 | 15 900 |

| 250 | 7 600 |

| 350 | 6 300 |

As the diameter increases, the comfortable operating frequency always decreases. What you need to pay attention to when buying a tool. On a circular saw with a permissible diameter of 100 mm, it will not be possible to install an eightieth blade.

Each disc is designed for specific speeds allowed by the manufacturer. High speeds are the main cause of metal burnout, after which it changes its shape and becomes soft.

To find out the basic indicators suitable for working with equipment, you need to read the information on the disk. Next to the brand label, its main characteristics will be written:

- Diameter;

- Operating rotation speed;

- Additional information (low noise level, anti-temperature coating materials).

Purpose

Depending on the type of disk, the following can be processed:

- wood of various species;

- wood products - chipboard sheets, OSB, plywood, laminated flooring and other similar materials;

- polymeric substances and products made from them, for example, organic glass, polystyrene;

- natural stone material, such as marble;

- soft metals – aluminum, copper alloys;

- products based on iron alloys - pipes, corrugated sheets, etc.

A cutting tool has certain characteristics, parameters, dimensions, purpose, and properties of the material from which it is made.

Types of disks

There are no commercially available universal discs that can handle all types of materials. The main difference is the shape of the cutting edge. Even for one type of raw material, like wood, there are several wheels on sale that are designed for hard and soft wood. Some are designed to work with soft wood (pine, fir, spruce) and hard wood (ash, beech, cherry).

An indicator of durability is the presence of pobedite or diamond tipping on the teeth. These are small pieces of carbide minerals (tungsten carbite) that are much harder than metal and wood.

Conventional steel wheels have a shorter service life and are prone to frequent wear of the cutting edge.

Metal monolithic models are made of carbon steel. The cutting edges are thermally hardened, which increases their density and hardness. Thanks to this, they do not become dull longer and remain suitable for normal work. If the edge is dull, it can be sharpened using stones or special emery machines. Much cheaper compared to Pobedit ones. The metal used for manufacturing must not be overheated. As the temperature rises, tempering of the steel may occur. This will cause the metal to become soft and practically unusable.

Models with soldering have higher productivity, since the linings are much harder compared to ordinary metal. They do not require additional sharpening, which is why they can last longer. But cannot be restored if damaged. Diamond and will win is afraid of overheating.

If the technique of working with the disk has been violated, the soldering may crack or chip, which will lead to complete inoperability.

If the soldering wear occurs, they can be sharpened. This requires an engraver with a diamond disc and additional polishing using a vulcanite wheel or felt with GOI paste.

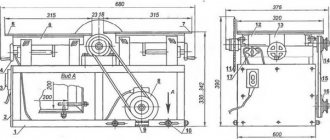

Design, principle of operation and use of a circular saw

At first glance, the device of a circular saw is as simple as possible - a powerful motor, on the shaft of which a cutting metal disc is mounted. In the case of stationary tools, the engine can be located separately and transmit force to the working shaft with a belt through a system of pulleys, but hand tools, of which the absolute majority among household ones, are made in one housing.

We recommend: Do-it-yourself vices - making a bench vice at home

Adding to the complexity of the device is the need to use high-quality materials, strict adherence to the alignment of parts, plus maintaining serious safety measures. The saw blade rotates at high speeds, so neglecting any of the above points will, at best, lead to damage to the tool.

As a result, an impressive number of mechanical-electronic protective and blocking devices are added to the engine and cutting wheel, the purpose of which is to instantly stop and de-energize the tool if something goes wrong.

The principle of operation of a circular saw is clear from its design - a rotating disk with teeth cuts a board along which the tool itself is pulled. In the case of a stationary saw, everything happens the other way around - the board is pulled through a circle fixed to the frame and divided into two parts.

There is one important note about the use of a circular saw - it is not suitable for figure cutting and is intended to cut boards and other materials only in a straight line. There are models with additional graduation of the leading sole, which allows you to set the blade not strictly perpendicular to the surface being sawed, but at a certain angle, but at the same time the saw is also driven strictly in a straight line.

1. Upper main protective casing. 2. Power button. 3. Power lock button. 4. Laser switch activation button.

5. Support handle. 6. Housing with motor. 7. Laser pointer. 8. Adjusting the cutting angle.

9. Saw blade. 10. Lower loaded casing. 11. Support sole.

1

How the tool works

The principle of operation of a circular saw is quite simple: a rotating toothed disk cuts a strip of material. If this is a manual model, the unit itself is pulled over the material. In tabletop versions, it “rides” through a cutting circle fixed to the base, dividing into two parts.

Such a saw is not capable of performing figured cutting and is intended to cut material exclusively in a straight line. There are models on the market with the ability to set the disc at a certain angle to the surface being cut, and not strictly perpendicular, but even then the cut is still made straight.

We recommend: Do-it-yourself wall chaser from an angle grinder

We recommend

Circular saw - main characteristics of the tool and features of its selection Miter saw - rules for choosing a tool Miter saw - rules for choosing a tool

Influence of tooth shape on cutting

The shape of the teeth has a significant influence on the quality of the cut.

- Flat top. A wood saw blade with this tooth shape is well suited for cutting hard wood. It breaks out tough fibers, allowing for productive movement when sawing. Best suited for ash, oak, beech, birch. The tooth is symmetrical, without setting.

- With pronounced wiring. Designed for strong biting into wood. Provides high productivity with messy cuts. The treated areas must be additionally sanded with sandpaper.

- Triple chips. This saw blade for wood is developed using a specific system that combines the two previous technologies. First comes the set tooth, which cuts large amounts of wood. The next tooth cuts off the marks from the previous one. This creates high sawing performance, but the cut itself is clean, without protruding fibers.

- Finishing. The most common technology for producing finishing discs is four teeth with a negative slope and setting and one for trimming. This technology even allows for finishing cuts. Suitable for cutting chipboard and MDF when making furniture.

Circular saw ergonomics

For household needs, a hand-held circular saw is most often used, which means that special attention must be paid to the issue of ergonomics. At the same time, it will not be possible to give any unambiguous recommendations, since everyone has their own concept of convenience.

Lefty-righty

About 10% of people on Earth are left-handed, and manufacturers must take this into account when producing mirrored models of instruments.

Handle shape and position

If the rear handle is more or less standard, then there are at least three varieties of the front handle: straight, mushroom-shaped and staple-shaped. The first is more suitable when working with a saw “from yourself”, the second is more convenient to drive the saw from the side, and the third is universal, but larger in size than a mushroom-shaped one.

Straight.

Mushroom-shaped.

Staple-shaped.

Rubberized handles

They do not slip in your hands and help you better control the work process.

Observation area

It depends on the design features of each tool, so before purchasing it is better to evaluate it with your own eyes.

Sawdust removal

This is done by blowing sawdust from the work area or by connecting an industrial vacuum cleaner to the saw.

Power cord

To prevent the wire from getting twisted, at least near the saw itself, the cable is taken out of its body through a long and rigid input sleeve.

We recommend: A cutter for metal profiles for drywall - a review of the most popular brands

Replacing carbon brushes

It is not required so often, but in any case it is better if there is a special window for this operation. Additionally, the brushes can be self-switching - when the graphite rod is ground off, the circuit breaks, and there may also be an indication of the status of the brushes.

Marking

As you can see in the picture, the disc markings can tell you about many technical characteristics. But there is a dependence that should not be neglected: the shape of the teeth directly affects the ability to work with a specific material.

The classification developed by representatives of the GASS divides discs into the following categories based on tooth shape :

GK and GS:p alternately beveled . Suitable for processing all types of wood and “clean” chipboards , without plywood and plastic coatings.

Read also: Blast furnace what is it

GM : direct . They can only cope with cutting soft wood.

GT : trapezoidal . They are useful in cases where you need to cut MDF or chipboard with lamination.

GR : conical . Cuts multi-layer coatings with double lamination.

GA : trapezoidal and straight . Same features as GT .

laser markings to high-quality saw blades . If the parameters are “written” with ordinary paint , it means that we are looking at an economy-class product that will quickly become unusable.