What is wood density

Wood density is the ratio of wood mass to wood volume, that is, density is determined by the mass of wood substance per unit volume.

Density is expressed in kg/m³

Usually, in construction, the value of wood density is needed in order to calculate the mass (weight) of wood.

The density of wood directly depends on its humidity - the higher the humidity, the higher the density value.

Just like all other indicators of the physical and mechanical properties of wood, density is determined at a humidity of 12%. When determining the density of a wood substance, its mass is determined by weighing, and the volume is calculated by the difference between the volume of the wood sample and the volume of liquid that filled the voids in this sample.

A very close relationship exists between the density and strength of wood. Denser (heavier) wood is generally stronger.

Based on the density of wood at a moisture content of 12%, all species are divided into three groups:

- with low density (540 kg/m³ and less) - spruce, pine, poplar, balsa, fir, cedar, juniper, aspen, willow, linden, alder, chestnut;

- medium density (540...740 kg/m³) - larch, birch, beech, oak, maple, ash, walnut, rowan, apple, pear, elm, hazel;

- high density (750 kg/m³ and more) - acacia, hornbeam, iron birch, oak, ash, keruing, boxwood, pistachio.

It is worth noting that almost all wood from coniferous trees, with the exception of larch and some types of pine, has low density.

The effect of humidity on the weight of wood

The weight of wood does not always have the same value. What does it depend on? First of all, from the moisture content of the wood. If we compare, for example, oak and birch, it turns out that a cubic meter of oak weighs 700 kg, and a birch weighs 600 kg. But it could be different. Weighing a cubic meter of birch, we get 900 kg, and oak will show the same 700. Or in both cases it will be 700 kg. Why do we get such different numbers? In this case, the moisture content of the wood plays a role.

There are four degrees of humidity: dry (10-18%), air-dry (19-23%), damp (24-45%) and wet (above 45%). Thus, it turns out that different rocks with the same humidity have different weights, as in the first example above. If the humidity is not the same, then the weight may fluctuate in one direction or another. The standard humidity is 12%.

Classification of wood by density

Based on the density of wood at a moisture content of 12%, all species are divided into three groups:

- with low density (540 kg/m³ and less) - spruce, pine, poplar, balsa, fir, cedar, juniper, aspen, willow, linden, alder, chestnut;

- medium density (540...740 kg/m³) - larch, birch, beech, oak, maple, ash, walnut, rowan, apple, pear, elm, hazel;

- high density (750 kg/m³ or more+) - acacia, hornbeam, iron birch, ash, kerwing, boxwood, pistachio, as well as the density of oak wood.

All coniferous tree species have low density. The only exceptions may be larch and several rare species of pine.

Heat transfer from wood

In addition, there is another indicator - heat transfer. It will come to the aid of those who use wood as firewood for heating. The higher the hardness, i.e. The density of the wood species, the higher its calorific value. Of course, no one will heat a room with boxwood, but when choosing between linden and pine or birch and acacia, you can get much more heat if you know which of these species is the hardest. Information about the density of each tree can be gleaned from the tables, since all this information is systematized for ease of use.

Weight of a dense cubic meter, kg

| Breed | Humidity, % | |||||||||||

| 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | |

| Beech | 670 | 680 | 690 | 710 | 720 | 780 | 830 | 890 | 950 | 1000 | 1060 | 1110 |

| Spruce | 440 | 450 | 460 | 470 | 490 | 520 | 560 | 600 | 640 | 670 | 710 | 750 |

| Larch | 660 | 670 | 690 | 700 | 710 | 770 | 820 | 880 | 930 | 990 | 1040 | 1100 |

| Aspen | 490 | 500 | 510 | 530 | 540 | 580 | 620 | 660 | 710 | 750 | 790 | 830 |

| Birch: | ||||||||||||

| - fluffy | 630 | 640 | 650 | 670 | 680 | 730 | 790 | 840 | 890 | 940 | 1000 | 1050 |

| - ribbed | 680 | 690 | 700 | 720 | 730 | 790 | 850 | 900 | 960 | 1020 | 1070 | 1130 |

| - Daurian | 720 | 730 | 740 | 760 | 780 | 840 | 900 | 960 | 1020 | 1080 | 1140 | 1190 |

| - iron | 960 | 980 | 1000 | 1020 | 1040 | 1120 | 1200 | 1280 | — | — | — | — |

| Oak: | ||||||||||||

| - petiolate | 680 | 700 | 720 | 740 | 760 | 820 | 870 | 930 | 990 | 1050 | 1110 | 1160 |

| - eastern | 690 | 710 | 730 | 750 | 770 | 830 | 880 | 940 | 1000 | 1060 | 1120 | 1180 |

| — Georgian | 770 | 790 | 810 | 830 | 850 | 920 | 980 | 1050 | 1120 | 1180 | 1250 | 1310 |

| - Araksinian | 790 | 810 | 830 | 850 | 870 | 940 | 1010 | 1080 | 1150 | 1210 | 1280 | 1350 |

| Pine: | ||||||||||||

| - cedar | 430 | 440 | 450 | 460 | 480 | 410 | 550 | 580 | 620 | 660 | 700 | 730 |

| - Siberian | 430 | 440 | 450 | 460 | 480 | 410 | 550 | 580 | 620 | 660 | 700 | 730 |

| - ordinary | 500 | 510 | 520 | 540 | 550 | 590 | 640 | 680 | 720 | 760 | 810 | 850 |

| Fir: | ||||||||||||

| - Siberian | 370 | 380 | 390 | 400 | 410 | 440 | 470 | 510 | 540 | 570 | 600 | 630 |

| - white-haired | 390 | 400 | 410 | 420 | 430 | 470 | 500 | 530 | 570 | 600 | 630 | 660 |

| - whole leaf | 390 | 400 | 410 | 420 | 430 | 470 | 500 | 530 | 570 | 600 | 630 | 660 |

| - white | 420 | 430 | 440 | 450 | 460 | 500 | 540 | 570 | 610 | 640 | 680 | 710 |

| - Caucasian | 430 | 440 | 450 | 460 | 480 | 510 | 550 | 580 | 620 | 660 | 700 | 730 |

| Ash: | ||||||||||||

| - Manchurian | 640 | 660 | 680 | 690 | 710 | 770 | 820 | 880 | 930 | 990 | 1040 | 1100 |

| - ordinary | 670 | 690 | 710 | 730 | 740 | 800 | 860 | 920 | 980 | 1030 | 1090 | 1150 |

| - acute-fruited | 790 | 810 | 830 | 850 | 870 | 940 | 1010 | 1080 | 1150 | 1210 | 1280 | 1350 |

The table shows average mass values. Possible maximum and minimum mass values are 1.3 and 0.7, respectively, from its average value

How is wood density measured?

The average density of wood is measured using a certain algorithm:

- The wood sample is kept to a moisture content of 12%

- The size of the sample and its weight are measured.

- Based on the obtained parameters, the volume of wood is calculated. The workpiece is placed in distilled water for three days until the thickness increases by 0.1 mm.

- The previous parameters are re-measured and the maximum volume of moistened wood is calculated.

- The workpiece is dried and re-weighed. The mass of the dry sample is divided by the maximum volume. The result of the calculations will be the basis density.

- The mass of the dry workpiece is measured again. Based on these values, the specific gravity of wood is calculated.

This algorithm for calculating specific gravity is prescribed in GOST 16483.1-84. The recommendations indicate that measurements are best carried out on blanks that have the shape of a rectangular lens. The edges of the sample must be well processed. The dimensions of the workpiece should be as follows: length - 20 mm, width 20 mm, height 30 mm.

Artificial and natural drying

Ideally, lumber should be dried in natural conditions, that is, in a ventilated room with a roof or in the open air under a canopy.

Since dry lumber is in greater demand than material with natural moisture, accelerated drying methods are used. The question of how safe this is for the material remains controversial. There is an opinion that artificial drying leads to too rapid evaporation of moisture, which causes a change in the geometric dimensions of the boards. Due to microscopic damage to the fibers, curvatures and unevenness are formed. In particularly advanced cases, cracks appear.

However, drying using forced air, including warm air, performed without fanaticism, is unlikely to lead to such obvious negative consequences.

The moisture content of the wood should be taken into account when organizing transportation. Let's say you bought dry boards, but during storage they were exposed to rain and did not dry completely. Their weight, naturally, will no longer be the same as upon delivery.

engages in the procurement and processing of coniferous wood - Siberian larch, cedar and Angara pine in the Krasnoyarsk Territory. We are a full-cycle wood processing company: from logging and sawing round timber to the production of lumber and supply of finished products to St. Petersburg and the Leningrad region.

The average values of the specific gravity (SG) of larch, at twelve percent relative humidity, are considered to be the standard indicator, and without any connection to the grade of wood. The value in undiluted form has no practical significance, only taking into account humidity and grade. That is, the statement that a carbon fiber can have any effect on the quality indicators of a product is simply unfounded. Moreover, it is impossible to accurately calculate a stable indicator, taking into account only a cube of dry larch; this is not plastic and the humidity (and therefore the hydrocarbons) in it is constantly changing.

Specific gravity has practical application only when calculating the (again, average) mass of a specific batch of larch. It is extremely rare for an experimental carpenter to refer to this indicator in order to calculate the possibility of gluing wood of different species.

Our position on this issue is somewhat different from the established one: if the project is carried out by specialists, and cargo transportation is also not accessible to amateurs, then why stuff the customer with data about what the dry weight of larch might be, because the potential client is interested in completely different indicators.

To satisfy the direct interest in our products, we can do a lot: harvest timber in the Krasnoyarsk Territory, and process it there in our own production. After which, bring a varied assortment to St. Petersburg and sell it at prices below the city average. If you decide to buy dry larch or natural moisture from our company, then we can even deliver the timber you purchased to any point in the Leningrad region and, if necessary, provide assistance in the implementation of the wooden project.

But attempts by a curious client to independently connect the strength and specific gravity of dry larch into a single whole will only lead to mixed feelings (due to the fact that the proportions of changes in moisture content in wood are not unambiguous and depend on a wide variety of factors). In the best case, there will be a desire to thoroughly study the physical characteristics of wood in order to accurately know the specific gravity of larch natural moisture, depending on the grade of specific wood.

As in the case of hydrocarbons, the customer’s use of information about how much dry larch weighs is very rarely justified. For example, if you carry out an independent calculation of the foundation. But do not forget that larch itself will not remain exceptionally dry for very long (both outdoors and indoors). And design and estimate documentation is best prepared by highly specialized specialists. Accordingly, the dry weight of a cube of larch has no practical meaning, since the timber can be delivered and installed by us, and in the shortest possible time.

How much does a cube of pine weigh - how does humidity affect it?

The same pine tree can have different weights. This is directly related to the amount of moisture in it. Depending on the percentage of water in wood, dry, air-dry, wet and wet species are distinguished.

- Pine whose humidity is from 10 to 18% is called dry and the weight of one cubic meter is 505-510 kilograms.

- If the humidity is 19-23% , then the mass of one cube is 520 kg.

- At 24-45%, the pine is considered raw and its weight will be about 550 kilograms.

- All wood whose moisture content exceeds 45% is called raw; its cubic meter weighs from 550 to 730 kilograms.

- A cube of freshly cut pine can sometimes reach up to 820 kg, since its humidity exceeds 90% .

More specific information can be found using special tables that show the correspondence between the percentage of humidity and the mass of a pine cube.

The weight of wood also directly depends on its density. Density, in turn, is directly proportional to the moisture content of the wood. Dry pine has a density of 0.50-0.52 g/cm3, and its cubic meter weighs approximately 515 kilograms .

Completely dried pine wood with a density of 0.48 g/cm3 has a weight of 480 kg, if the wood is raw, then the density is 0.64-0.85 g/cm3, 600 - 700 kg per cubic meter.

In general, the higher the moisture content of the rock, the higher its density, and, accordingly, the greater the mass of one cubic meter of wood.

Information about the exact weight of pine (pine lumber) can be useful when transporting it and choosing the carrying capacity of a vehicle.

In general, there are two types of wood weight:

- Specific.

- Volume.

The specific gravity is approximately 1540 kg/m3 and is defined as the mass of one cubic meter without taking into account various indicators such as the type of wood, its humidity and density.

The volumetric weight depends on the moisture content of the tree and its species. The unit of measurement for this weight is g/cm3 . It is worth noting that it is customary to calculate it only at normal humidity, namely 15% .

Determine the volumetric weight according to the following formula:

уw=y0(100+w) / (100+(Y0-Yw))

W – wood humidity;

Уw – volumetric shrinkage;

У0 – volumetric weight in a completely dried state;

уw – volumetric weight of wood.

There is another concept - conditional volumetric weight . It is defined as the ratio of the weight of a completely dry piece of wood to the weight of the same freshly cut sample. The overall humidity does not matter, so it is more convenient to use. It is calculated using the formula:

U0=y conv/(1-y)

Where Y0 is the weight of dry wood, and y is the shrinkage of the rock, shown as a percentage.

You can do all the calculations yourself, or you can turn to special online calculators that will give you the exact answer in a few seconds.

Table of weight of 1 m3 of pine depending on its humidity.

It is very difficult to determine the percentage of moisture using improvised means. And this is a very important indicator for determining such a parameter as the specific gravity of a cubic meter of pine. Typically, these procedures are carried out in special technological laboratories.

The easiest way when purchasing a material is to check the moisture content from the manufacturer. Then, using the table presented, find out the weight of a pine cube with a flag from 5% to 90% and the density of the material:

Specific gravity and density of pine depending on humidity

| Pine moisture percentage | Specific gravity (kg /m3) | Density (g /cm3) |

| Standard, 10 to 12% | 500 – 505 | 0,5 – 0,505 |

| 1 – 5 % | 480 | 0,48 |

| 12 % | 505 | 0,505 |

| 15 % | 510 | 0,51 |

| 20 % | 520 | 0,52 |

| 25 % | 540 | 0,54 |

| 30 % | 550 | 0,55 |

| 40 % | 590 | 0,59 |

| 50 % | 640 | 0,64 |

| 60 % | 680 | 0,68 |

| 70 % | 720 | 0,72 |

| 78 – 90 % | 750 – 820 | 0,75 – 0,82 |

| 80 % | 760 | 0,76 |

| 100 % | 850 | 0,85 |

Physics problem - 1151

HOME » SOLUTION GUIDE

2016-10-20 Dry firewood with a density of $\rho_{1} = 600 kg/m^{3}$, brought from a warehouse, was dumped in the open air and not covered with anything. The firewood got wet, and its density became equal to $\rho_{2} = 700 kg/m^{3}$. In order to heat the house to room temperature in cold but not frosty weather (at a temperature of $T = 0^{ \circ} C$), you need to burn $M_{1} = 20 kg$ of dry firewood in the stove. Estimate how much wet wood needs to be burned to heat the house to the same room temperature? Specific heat of vaporization of water $L = 2.3 \cdot 10^{6} J/kg$, specific heat capacity of water $C = 4200 J/(kg \cdot ^{ \circ} C)$, specific heat of combustion of dry firewood $ q = 10^{7} J/kg$.

Solution: In order to impart a certain amount of heat to the house (stove, pipes, etc.) and at the same time convert a certain amount of water contained in wet wood into a vapor state, it is necessary to burn more wet wood than dry wood. The smoke comes out of the chimney at a temperature slightly exceeding $100^{ \circ} C$. For simplicity, let’s assume the temperature outside is equal to $0^{ \circ} C$, and the temperature of the exiting smoke is equal to $100^{ \circ} C$. Then, when burning a mass $m_{0} = 1 kg$ of wet wood, it heats up by $\Delta T = 100^{ \circ} C$ and a mass of water $m = m_{0} \frac{ \rho_{2} evaporates \rho_{1}}{ \rho_{2}} = \frac{1}{7} kg$. In this case, dry wood with a mass of $M = m_{0} - m = m_{0} \frac{ \rho_{1}}{ \rho_{2}} = \frac{6}{7} kg$ burns. The amount of heat $Q_{1} = m(C \Delta T + L)= m_{0} \frac{ \rho_{2} — \rho_{1}}{ \rho_ is spent on heating and evaporating a mass of water $m$ {2}} (C \Delta T + L) \approx 0.39 \cdot 10^{6} J$. When a mass $M$ of wood is burned, an amount of heat is released $Q_{2} = Mq = m_{0} \frac{ \rho_{1}}{ \rho_{2}} q \approx 8.57 \cdot 10^{6 } J$. Consequently, when heating a house when burning mass then = 1 kg of wet firewood, the amount of heat $Q_{3} = Q_{2} - Q_{1} = m_{0} \frac{ \rho_{1}}{ \rho_{ 2}} q — m_{0} \frac{ \rho_{2} — \rho_{1}}{ \rho_{2}} (C \Delta T + L) = \frac{m_{0}}{ \ rho_{2}} ( \rho_{1}q — ( \rho_{2} — \rho_{1}))(C \Delta T + L) \approx 8.18 \cdot 10^{6} J$, that is, the specific heat of combustion of wet firewood is equal to $q_{3} = \frac{Q_{3}}{m_{0}} \approx 8.18 \cdot 10^{6} J/kg$. Therefore, in order to heat a house, you will need either a mass $M_{1} = 20 kg$ of dry firewood, or a mass of wet firewood $M_{2} = \frac{M_{1}q}{q_{3}} = \ frac{M_{1}q \rho_{2}}{ \rho_{1} q — ( \rho_{2} — \rho_{1})(C \Delta T + L)} \approx 24.5 kg$ .

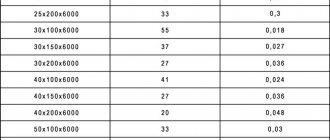

NUMBER OF BOOTS, BOARDS AND LINING IN 1 CUBIC. M

The number of pieces of any lumber or molded product in 1 cubic meter depends on its dimensions: width, thickness and length.

Data on the quantity of lumber in 1 kb. m are presented in the table. — 58.50 Kb Carrying out calculations of waste from cutting down trees and shrubs

Initial data for calculation

According to the act of inspection, preservation (demolition), replanting of green spaces and calculation of the amount of their replacement cost dated July 26, 2011, case 197/11 falls within the work zone and is subject to demolition:

Trees – spruce (up to 20 years) – 13 pcs.

Free-growing bushes of various species (up to 15 years) -172 pcs. The agreed act of the USPH has been provided (see Appendix).

Waste from stump uprooting accounts for ~ 16.0% of the trunk volume

Density of raw wood - 0.72 t/m3

Full wood ratio:

- for twigs, branches, and crowns - 0.12;

- for trunks and stump uprooting waste - 0.57.

The calculated folded volumes of trees, the volumes of above-ground phyto-mass of trees (trunk diameters, tree heights, volume of twigs and branches) are taken according to TERR-2001-68. Collection No. 68. “Improvement. Technical part" according to reference table 1.

Table 1

| branches | branches | crown | general | ||||||

| 10-30 | 11,2-13,3 | 0,304 | 0,022 | 7,4 | 0,45 | 0,15 | 0,89 | 1,04 | 1,49 |

| 30-50 | 13,39-18,90 | 1,079 | 0,109 | 10,1 | 1,59 | 0,47 | 2,63 | 3,1 | 4,69 |

| 50-70 | 18,91-24,20 | 2,481 | 0,283 | 11,4 | 3,65 | 0,99 | 5,29 | 6,28 | 9,93 |

| 70-90 | 24,27-28,10 | 4,567 | 0,571 | 12,5 | 6,71 | 1,98 | 8,78 | 10,76 | 17,47 |

| 90-110 | 28,15-30,60 | 7,510 | 0,999 | 13,3 | 11,04 | 2,89 | 13,25 | 16,14 | 27,18 |

| 110-130 | 30,67-33,20 | 11,253 | 1,587 | 14,1 | 16,54 | 3,7 | 18,56 | 22,26 | 38,8 |

| 130-150 | 33,28-35,30 | 13,8 | 2,029 | 14,7 | 20,29 | 4,44 | 23,15 | 27,59 | 47,88 |

Calculation of cutting and uprooting waste

Waste of twigs and branches from logging 00 5)

According to the act of inspection, preservation (demolition), and replanting of green spaces, 13 trees with a height of 13 to 20 years and a height of 2.0 to 10 m are subject to felling. and bushes of various species up to 15 years old in the amount of -172 pcs. This type of waste includes: waste of trunks, twigs, branches and crowns of trees to be demolished, without their selective collection.

1) Waste from cutting down spruce trees

V = V total ´N, m 3

V = 1.49 m 3 /pc. ´ 13 pcs. = 19.37 m 3

B = V ´ ρ ´ (k 1 ´ m 1 + k 2 ´ m 2), t

B = 19.37 m 3 ´ 0.72 t/m 3 ´ (0.178 ´ 0.57+ 0.822 ´ 0.12) = 2.791 t

Where:

V (m 3) – storage volume of waste, trunks, branches, branches and crowns of trees to be demolished, without their selective collection;

B (t) – mass of waste, trunks, branches, branches and crowns of trees to be demolished, without their selective collection;

N (pcs.) – number of trees with a height of 2.0 to 10 m to be demolished;

V total (m 3 /piece) - the volume of waste, trunks, twigs, branches and crowns of one tree with a height of 2.0 to 10 m, subject to demolition;

to 1 (shares of units) – the share of trunks in the total storage volume of trees to be demolished;

k 2 (shares of units) – the share of twigs, branches and crowns in the total storage volume of trees to be demolished;

m 1 (fractions of units) – full wood coefficient for trunks and waste from stump uprooting;

M2 (fractions of units) – full wood coefficient for twigs, branches, and crown.

2) Waste from cutting down bushes

V = V total ´N, m 3

V = 0.15 m 3 /pc. ´ 172 pcs. = 25.8 m 3

B = V ´ ρ ´ k 2 ´ m 2, t

B = 25.8 m 3 ´ 0.72 t/m 3 ´ 0.822 ´ 0.12= 1.832 t

Where:

V (m 3) – storage volume of waste, twigs, branches and crowns of bushes to be demolished, without their selective collection;

B (t) – mass of waste, twigs, branches and crowns of bushes to be demolished, without their selective collection;

N (pcs.) – number of bushes to be demolished;

V total (m 3 /piece) - the volume of waste, twigs, branches and crown of one bush to be demolished;

ρ (t/m 3) - density of raw wood;

k 2 (shares of units) – the share of twigs, branches and crowns in the total folded volume of bushes to be demolished;

m 2 (fractions of units) – coefficient of full wood for twigs, branches, and crown.

The total amount of waste of twigs and branches from logging will be 45.17 m

3 or 4.623 tons.

Waste from stump uprooting 00 5)

This type of waste includes waste from uprooting tree stumps to be demolished without selective collection.

V = V std.d ´ k 3 ´ N d + V std.d ´ k 3 ´ N k, m 3

V = 0.304 m 3 /pcs. ´ 0.16 ´ 13 pcs. + 0.15 m 3 /pcs. ´ 0.16 ´ 172 pcs. = 4.76 m 3

B = V ´ ρ ´ к 1 ´ m 1 , t

B = 4.76 m 3 ´ 0.72 t/m 3 ´ 0.57 = 1.953 t

Where:

V (m 3) – storage volume of waste from uprooting tree stumps to be demolished, without selective collection;

B (t) – mass of waste from uprooting tree stumps to be demolished, without selective collection;

N d (pcs.) – number of trees with a height of 2.0 to 10 m to be demolished;

N d (pcs.) – number of bushes to be demolished;

V stem.d (m 3 /piece) – the volume of the trunk of one tree with a height of 2.0 to 10 m, subject to demolition;

V stem.k (m 3 /piece) – the volume of the trunk of one bush to be demolished;

ρ (t/m 3) - density of raw wood;

to 1 (shares of units) – the share of waste from stump uprooting in the total storage volume of trees or bushes to be demolished;

to 3 (shares of units) – the share of waste from stump uprooting is equal to the volume of the trunk to be demolished;

m 1 (fractions of units) – full wood coefficient for waste from stump uprooting.

Short description

According to the act of inspection, preservation (demolition), replanting of green spaces and calculation of the size of their replacement cost dated July 26, 2011, case 197/11 falls into the work zone and is subject to demolition: - spruce trees (up to 20 years) - 13 pcs. — free-growing bushes of various species (up to 15 years) - 172 pcs. The agreed act of the USPH has been provided (see Appendix). Waste from stump uprooting accounts for ~ 16.0% of the trunk volume

When organizing timber transportation, the density of the tree is an important indicator when selecting a timber truck and calculating the cost of transportation. This will help avoid overloading, which will consequently prevent you from being fined.

The density of the material has a special significance on the weight of m3 of wood; accordingly, to correctly solve the questions posed, it is necessary to determine the value of the density. There are two types of density: volumetric weight

(density of the structured physical body) and

specific gravity

(density of the wood substance).

Weight of wall materials and concrete

| Name of building material | How much does a bucket weigh, kg (weight of building material placed in one 10-liter bucket, kg) | How much does 1 cube weigh, kg (kg/m3) |

| Asbestos concrete | 21 | 2100 |

| Lightweight concrete based on granulated slag | 11-12 | 1100-1200 |

| Lightweight concrete on expanded clay | 5-18 | 500-1800 |

| Lightweight concrete with coke | 12 | 1200 |

| Lightweight concrete made from boiler slag | 13,5-14,5 | 1350-1450 |

| Lightweight concrete on pumice crushed stone | 8-14 | 800-1400 |

| Large-porous concrete, sandless, acid-resistant | 21,5-25 | 2150-2500 |

| Large-porous sandless fire-resistant concrete | 14,5-17,5 | 1450-1750 |

| Plain concrete on gravel or crushed stone | 22-25 | 2200-2500 |

| Regular concrete on sandstone | 21-25 | 2100-2500 |

| Aerated cement dry thermal insulating concrete | — | 400-700 |

| Dry cement aerated structural concrete | — | 1100-1200 |

| Porous clay brick | — | 1100 |

| Semi-dry pressed clay brick | — | 1800-2000 |

| Clay brick of plastic pressing | — | 1700-1900 |

| Clay iron ore brick | — | 1800 |

| Semi-dry pressed hollow clay brick | — | 1400-1500 |

| Clay hollow brick of plastic pressing | — | 1250-1450 |

| Rubble concrete masonry | — | 2200-2300 |

| Rubble masonry made of soft limestone | — | 1970-2000 |

| Rubble masonry made of dense limestone | — | 2200-2300 |

| Sandstone rubble masonry | — | 2200-2300 |

| Clay brick masonry with cement mortar | — | 1600-1900 |

| Fireclay brick masonry | — | 1800-2000 |

| Porous brick masonry | — | 1100-1500 |

| Hollow brick masonry | — | 1000-1450 |

| Sand-lime brick masonry | — | 1800-1900 |

| Sandstone | — | 2200-2700 |

| Adobe | — | 1200-1500 |

.

Lumber Tables

Below are detailed data that will immediately allow you to determine the required amount of lumber from 3 to 6 meters in length. It is very easy to use these tables - we find the required product sizes and see the amount of material and the volume of one element.

Helpful information.

Please note that these tables are approximate results. Doing your own calculations is more accurate. In addition, different manufacturers approach the stacking of lumber in their own way, so the density of the products can vary greatly. Therefore, make a reserve of about 10-20%, otherwise you will have to pay for delivery again.

Table 1.

The number of boards in 1 cubic meter of materials.

Table 2.

The amount of timber in 1 cubic meter of materials.

Table 3.

The amount of lining in 1 cubic meter of materials.

Practical meaning and importance.

Among coniferous building materials, wet, dried, dry and damp pine trees are valued. However, these terms do not give a specific exact value for humidity, so knowing clear numbers is essential. For example, requirements for the use of fallen pine are not provided for by legislative acts. But, when performing certain work, GOST sets humidity standards, for example:

- in the manufacture of structures and products intended for placement in an open area, wood with a moisture content of 11 to 14% is used;

- for the manufacture of residential structures and products, wood with a moisture content of 8 to 10% is used;

- for parquet – wood with a moisture content of 6 to 8%.

Concept of material moisture

Before we tell you how much natural moisture edged boards and other lumber weigh, you need to understand the basic concepts. Different types of wood are used to make tongue-and-groove, decking, planed and edged boards. Each rock has its own specific hygroscopicity, that is, the ability to absorb moisture from the air.

Depending on the absorption of moisture, porosity and the structure of cell membranes, each type of wood has its own absolute humidity. The maximum value of this indicator is 30.

In addition, a board with natural humidity can absorb water through direct contact with it during precipitation or when the room is flooded. Dampness in the room also causes wood to absorb moisture. If the surrounding air becomes very dry, it releases moisture.

Important! Most often, moisture loss occurs through the ends of the product.

The normal process of wood absorbing and releasing moisture is called “breathing.” Equilibrium moisture is a condition in which there is a balance of water between the environment and the internal space of the wood.

The indicator of natural saturation with water depends on the location of the fibers in the structure. Moisture evaporates faster in the longitudinal direction of the fibers, rather than in the transverse direction. That is why a floor made from planks of natural moisture releases moisture faster at the ends of the floorboards.

To understand what a normal humidity floorboard is, you need to understand the concept of absolute and relative humidity:

Important! Because hygroscopic intracellular fluid collects in the cell walls, it is more difficult to remove. In this regard, hygroscopic moisture has a greater effect on the geometry of the board, its weight and characteristics.

The weight of the edged board of natural moisture also depends on the unbound free liquid in the material, which collects in the intercellular spaces and inside the cells. Such moisture evaporates quickly and does not affect the characteristics of the product.

Natural moisture content is the moisture content in freshly cut wood that has not been dried. This non-standardized indicator can be in the range of 30-80 percent. The weight of 1 m3 of edged boards with natural moisture content depends on:

Density of different rocks

From the above, one could draw a predictable conclusion that the procedure for measuring and estimating the density of wood is a rather complex task and requires very accurate measurements. In most cases, all the complex work is done for the consumer by manufacturers and suppliers - all the basic properties of the material must be indicated on the packaging of the same edged or parquet board.

The situation is more complicated if a person even harvests different types of wood himself, because then there will be no informative packaging, but then you can find on the Internet approximate density indicators for each type of wood, from which entire tables are compiled. It is only important to remember that the moisture content of each individual bar is influenced by many factors, separately described above, which means that in a particular case, fluctuations in mass are very likely.

In some cases, another situation is possible: when the master is given only a task, but there is still no wood to implement it. You have to purchase the raw materials yourself, but at the same time you need to figure out which breed will be the most effective.

Considering that density affects many other practical qualities of wood, you can immediately weed out the majority of unsuitable candidates by focusing on a specific category of material. Specifically for this purpose, there are three main groups of wood types based on density.

Low density is practical, at least from the point of view that light wood is easier to harvest and transport, and loaders will be grateful to the consumer for choosing such a tree. According to the common classification, the upper density limit for low-density wood is 540, less often 530 kg/m³.

It is this category that includes the bulk of industrial conifers, such as spruce and pine, aspen and many types of walnut, chestnut and cedar, willow and linden. Cherry and alder, depending on the specific variety and conditions, can be classified as low- and medium-density species, with cherry more often classified as medium-density. Due to the relative ease of transportation, such wood is cheaper. Another obvious argument in favor of its cheapness and demand is that a significant part of domestic forests is made up of just such species.

Experts note that trees with low trunk density are most common in the northern regions . This is due to the fact that the regions in which forests of the corresponding species grow cannot always provide the plant world with a large amount of moisture.

Adapting to existing conditions, plants with low wood density form trunks with relatively low humidity, which ultimately affects the mass.

Medium-density wood is the “golden mean” when choosing a material , which does not have any obvious advantages, except for the significant point that it has no obvious disadvantages. Without being too heavy, such a material demonstrates good compressive strength without having the obvious disadvantages of dense rocks, such as good thermal conductivity.

The medium density category includes lumber from larch and birch, apple and pear, rowan and maple, hazel and walnut, ash and poplar, bird cherry, beech and elm. Cherry and alder have a significant difference in density, which does not allow us to confidently put all representatives of the breed into one category - both fluctuate between low and medium, with alder being closer to low density. Indicators that allow the breed to be included in the medium density category are 540-740 kg/m³.

As you can see, these are also very common tree species in our area, which are in significant demand in various fields of industry and can boast of high qualities not only in practical, but also in the decorative sphere.

The increased density of wood may seem like a disadvantage due to the fact that products made from it are very heavy and massive and cannot boast of good thermal insulation performance, and even split from impact.

At the same time, the material is able to withstand significant constant loads without deformation , and is also characterized by relatively low flammability and amazing durability . Among other things, such wood is also relatively little susceptible to rotting.

To fall into the category of dense wood, you need a wood density of at least 740 kg/ m³ . Of the common types of wood, oak and acacia, as well as hornbeam and boxwood, come to mind first. This should also include some species that do not grow in our latitudes, for example, pistachio and ironwood trees.

Please note: almost all of the listed breeds are classified as expensive and prestigious. Even their very significant weight does not prevent some types of material from being transported from another hemisphere, which only further affects the cost.

There is only one conclusion from here: for all its shortcomings, such wood has a number of advantages that are worth paying generously.