Externally, wood looks like a dense fibrous material that is part of the trunk, roots and branches of trees of any species. Different types of wood differ in mechanical properties, thermal conductivity, ring pattern, and color.

Despite the differences, almost any type brings its own benefits to humans; it is used in construction, for heating, home decoration and for many other purposes.

Wood species and their use

Certain types of trees and their species are classified according to a number of characteristics. The most well-known division is into deciduous and coniferous species. There are species that grow on the territory of our state and other countries. From an economic and geographical point of view, this is a very important division, since the cost of imported wood may be higher than domestic wood in some cases.

Deciduous species, in turn, are divided according to their shape: ring-vascular and diffuse-vascular. And the latter can be distinguished by soft or hard wood.

Ring-vascular wood (ash, acacia, elm, oak, pistachio) received this name because the largest vessels are located closer to the center, in the early zones of the growth rings. In scattered vascular rocks (beech, hornbeam, rowan, maple), large vessels are dispersed more or less evenly. This changes the grain of the wood.

Both deciduous and coniferous trees are widely used in house building and other areas of construction technology. They are traditionally used to make such elements of building structures as walls, frames, partitions, rafters and other roofing elements. They are widely used in the manufacture of fences, porches, verandas (terraces), gazebos and a number of ancillary buildings.

Soft and hard rocks

Softwoods are easy to work with, making them versatile. Soft wood mainly includes coniferous species such as pine, fir, and spruce. But hardwoods such as poplar and linden can also be found. These trees grow quite quickly and are available in our latitudes - hence their availability and relatively low price.

Hardwoods, in turn, are divided according to their degree of hardness. So, oak and walnut are medium-hard wood, ash or teak are hard, hornbeam is very hard. One of the hardest species is ebony. All hardwoods grow fairly slowly, making them more expensive than softwoods.

Valuable wood

Speaking about different species, it is worth mentioning valuable species that are distinguished by their hardness, beautiful texture and other positive qualities, but are less common than other types of trees in a particular region. Valuable wood includes oak, walnut, alder, Karelian birch, maple and many exotic species. They are traditionally used in finishing decoration, as well as in the manufacture of furniture and shipbuilding.

Note! Fruit trees (cherry, black cherry, pear, apple, plum, persimmon and others) have an interesting texture and special physical and mechanical properties, so their wood is also considered a valuable species.

Certain types of cherries, for example, make wonderful inlaid souvenirs (snuff boxes and other attractive crafts). Finely chopped apple wood chips are traditionally used for smoking meat and fish. Pear is very popular among wood carvers; parquet, furniture, panels, and souvenirs are made from it.

Wood structure

All trees growing on earth can be divided into two types: deciduous (angiosperms) and coniferous (gymnosperms) - with leaves in the form of needles.

Coniferous species include pine, cedar, spruce, fir, larch, juniper, and yew. Deciduous trees are very common and are represented by many species (birch, linden, oak, walnut, beech, ash, maple, apple, elm, willow, etc.) The tree has three parts: root , trunk and crown (Fig. 1). Wood carvers primarily use the trunk, which contains the bulk of the wood. The remaining parts of the tree can also be used to make various products. For example, the crown is used as a raw material for the production of fibreboards, baskets and wicker furniture are made from willow branches, and the roots are used in arts and crafts (root plastic).

Rice. 1. Wood parts

The transition point between the trunk and the root is called the butt part or butt . The wood in the butt part has a beautiful texture and iridescent shine, which is highly valued in the production of artistic wood products.

To better understand the properties of wood, you need to have a good understanding of its structure. It is most convenient to examine the structure of wood in three main sections of the trunk (Fig. 2 and 3):

- transverse, or end, when the plane of the cut runs perpendicular (across) the trunk;

- radial, when the cut plane runs along the axis of the trunk (parallel to the wood fibers) through the center;

- tangential, when the plane of the cut runs along the axis of the trunk, but at some distance from the center and tangentially to the growth rings.

Rice. 2. Trunk cuts

Rice. 3. Wood structure

In the very center of the trunk there is a core , consisting of loose, fragile tissues formed in the first years of the tree’s life.

The core is surrounded by growth rings - layers of wood growth during one year of the tree's life. On a radial section, the annual layers are visible in the form of parallel stripes, and on a tangential section - in the form of winding lines. In the annual ring, there are inner layers of large light cells that appear in the spring, and outer layers of small dark cells - this is the area of late, summer and autumn wood.

In some tree species, in a transverse (end) section, you can see a darker central part - the core and a lighter part around the core - sapwood . The kernel is distinguished by greater density, hardness and lower moisture content, since it is the oldest wood, consisting of dead cells that do not take part in the exchange of nutrients.

Sapwood is the youngest part of the wood; it serves to conduct water and other nutrients along the trunk from the roots to the crown. Sapwood is less durable than heartwood, it dries out and cracks more, so carvers do not use the sapwood of some tree species in their work, but use only the heartwood.

Depending on the presence of core, sapwood and mature wood, tree species are divided into the following types.

Heartwood - such species have both a core and sapwood. Soundwood species include pine, cedar, larch, juniper, oak, ash, apple and others.

Mature wood - in this group of trees, the wood in the central part of the trunk almost completely dies, but does not differ from sapwood in color. Such wood is called mature. Mature tree species include spruce and aspen.

Sapwood is a tree species in which there is no difference in color or moisture content between the central and rest of the trunk. Sapwood species include birch, linden, maple, pear, etc.

At the border between wood and bark there is the cambium - a thin layer consisting of living cells that, as they develop, form a new layer of wood every year.

The bark consists of two layers - cork and bast. The cork layer located on the outside protects the wood of the trunk from frost, sunlight and mechanical damage. The bast layer of bark ( bast ) conducts water and organic substances produced in the leaves along the trunk.

On the end surface of the tree trunk of some tree species, light shiny stripes are clearly visible, directed from the core to the bark - these are medullary rays . They conduct water horizontally in the trunk and also store nutrients. In all coniferous trees and in such deciduous trees as birch, aspen and pear, the medullary rays are so narrow that they are almost invisible; oak and beech, on the contrary, have wide rays and are clearly visible in all sections.

Mechanical properties

Each of the rocks has certain physical properties, among which their ability to actively resist deformation and other mechanical influences is of particular interest.

The mechanical properties of wood are traditionally understood as its hardness, density, strength and elasticity to bending. The complexity of wood processing and the functionality of the future product depend on these qualities.

Strength and elasticity

The strength indicator refers to the ability of a material to resist deformation stresses leading to fiber rupture (for bending deformation, the strength indicator corresponds to the elastic modulus of wood).

The strength of the material critically depends on the following factors:

- direction of external force (along the fibers or across) and its speed;

- type (species) of wood;

- its density, humidity and the presence of obvious flaws (knots and cracks).

The presence of flaws in wood blanks significantly reduces their strength, but to a greater extent it depends on the vector of external loads.

With stresses along the grain, the maximum tensile load for most types of wood is 130 megapascals. The same parameter for compressive loads corresponds to 50 units, and for bending deformations it has a value of the order of 100 (note that for shearing effects it is only 0.5 megapascals).

Hardness

This indicator is directly related to the previous one and is understood as the resistance of wood material to the penetration of another dense body into it. It has been practically established that hardness in the longitudinal direction (along the fibers) always exceeds the same parameter in the cross section by approximately 30-40%.

For wood pieces dried to 12 percent moisture content, it is 1.5-2.0 times the hardness of the rawer material. As this indicator increases, the complexity of processing products also increases.

The hardness of a particular rock is determined experimentally using the Brinell method, and the data is entered into a table. The result is a hardness scale. At any time you can look at this indicator and draw conclusions about the hardness of the rock. There is a method and, accordingly, the Janka scale, as well as other methods named after the researchers who introduced them, but they are less common.

Plastic

When considering the characteristics of the structure of wood, its ability to hold various types of metal fasteners and hardware in the body of the material, as well as its resistance to impact splitting, is taken into account.

When assessing this property, it was found that to remove nails driven into wood across the grain, it is necessary to apply a force approximately 1.5 times greater than that driven into its end.

Important! It should be noted that the ability to hold nails and other fasteners increases in proportion to the increase in the density of a particular type of wood material.

Plasticity is directly related to resistance to splitting, that is, resistance to the separation of raw material when driving a wedge. The resistance of the material to this influence increases with increasing viscosity, and the presence of flaws such as knots, on the contrary, reduces it.

There is no universal breed

There really is no one type of wood that is right for every project. It all depends on what needs to be done.

There are other interesting woods in the furniture industry such as elm, alder, acacia and birch. There are also many exotic wood species, it is impossible to list them all.

In general, hardwoods dominate over softwoods in the furniture industry. This is because these woods are harder and have a more interesting grain.

Which wood will be chosen should depend, first of all, on the type of product, its purpose and the place where it will be located. This should be taken into account when choosing wood of different species.

Main conifers

Of the coniferous species, pine should be especially highlighted, which occupies about 16% of the area of all forests in Russia. The most widespread is the so-called Scots pine, which mostly grows in the Crimea and the Caucasus. Wood of this species is classified as a soft material that can be easily processed and is most often used for the manufacture of windows, doors, and other building elements (staircases, for example).

Note! This easy-to-use type of wood material is often used in the manufacture of some furniture and household utensils.

Another representative of this group, spruce (fir), occupies up to 12 percent of all forested Russian areas and is widely used in the national economy. Coniferous spruce material, due to its increased knotiness, can be processed with great difficulty, but despite this, it attracts the user with its uniform structure, pleasant white tint and low content of resinous substances.

This grade is often in demand in the manufacture of building blocks, floorboards, platbands and baseboards. Selected spruce wood can also be used in the production of household furniture for the purpose of decorating residential interiors. From its bark they learned to make tanning materials widely used in the leather industry.

Larch is very common in our country and occupies most of the forest plantations. Its material has excellent physical characteristics and is noticeably superior in density and strength to those of pine. In addition, larch fibers are practically resistant to rotting and provide products made from this material with high strength properties.

The areas of use of larch wood are wide. It is used in the construction of hydraulic structures, in the manufacture of piles, sleepers, telephone poles and support posts for mines. Another representative of coniferous species (cedar) is very similar in its properties to spruce and can be used to make sleepers, racks, furniture and pencils.

The yew wood material is valued for its attractive appearance, which allows it to be used in the manufacture of luxury furniture, as well as in the decoration of interiors. The familiar juniper should also be included in the category of coniferous wood.

What is the strength of wood and what does it depend on?

Strength is the ability of wood to resist destruction (separation into parts) under the influence of mechanical forces.

The strength of wood depends on the direction and speed of the load, the type of wood, its density, humidity and the presence of defects: defects, especially knots and cracks, greatly reduce the strength of wood; as the density of wood increases, its strength also increases; Humidity reduces the strength of wood. Strength depends on the nature and direction of the loads. For example, the strength of wood along the grain under tensile loads is about 130 MPa, and under compressive loads - about 50 MPa; strength under bending forces is about 100 MPa, shear strength is about 0.5 MPa.

Exotic wood species

Exotic wood species for our latitudes include sequoia, ebony and mahogany, as well as buckout and rosewood. Sequoia is a family of the largest and most durable woody plants and is found primarily in North America.

There are known examples of these trees with a height of almost 120 meters and a girth diameter of up to 15 meters (their estimated age is about 6 thousand years). Sequoia is successfully cultivated in the southern extremities of Crimea and in other areas of the Black Sea region. In its properties it resembles Russian spruce, but unlike that it is more resistant to rotting. It, like African abacha, is often used in the production of furniture and pencils, as well as in interior decoration.

The name “mahogany” in the generally accepted classification refers to a number of durable wood species (including merbau) that have a characteristic reddish tint.

Additional information: the most popular and unsurpassed variety of mahogany in color and beauty is American mahogany, found only in Central America.

One of the varieties of exotic wood called African padauk is widely used in the production of luxury furniture. Due to its strength characteristics (high hardness), trees of this variety are used for finishing carriage interiors and cabins.

Black refers to species that have a characteristic dark shade of fibers (these include elite varieties of ebony from India, in particular). This type of “colored” wood is used for the manufacture of piano keys, wind instrument bodies, and also for inlaying luxury furniture.

Buckout is an evergreen woody plant, often found in the subtropics, with a dense and hard structure with a vanilla scent. It is very difficult to machine and is most often used for the manufacture of especially durable parts of machine tools and machines. Somewhat similar to backwood, rosewood is very hard, but easy to polish. It is in demand in the manufacture of luxury furniture, parquet sets and musical instruments (pianos, in particular).

Physical properties of wood

The physical properties of wood include those that determine its appearance: texture, color, shine, moisture content, shrinkage, swelling and density.

The texture of wood is the pattern formed on its surface when cut. The more complex the structure of the wood, the richer and more interesting the texture. The nature of the texture is affected by the following:

- direction of the cut (radial or tangential);

- part of the tree caught in the cut (trunk, butt, burl, burl);

- wood structure (location of fibers and pith rays, width and shape of growth rings).

Texture determines the decorative value of wood. Deciduous trees have a richer texture than conifers. Oak, ash, and walnut have particularly beautiful textures.

The color of the wood depends on its species, age, climate and conditions under which the tree grew. Color is determined by the dyes, tannins and resins found in wood. The type of wood can be determined by the color and texture of the wood. Most often, yellowish-brown and reddish-brown tones of wood are found, but there are species with almost white wood (birch, aspen, hornbeam, fir) and black wood (ebony).

The shine of wood is the ability of its surface to reflect light. The shine is especially visible in a radial section. The shine of different breeds varies in nature:

- poplar, linden, aspen, rowan, and pear have a matte (satin) sheen;

- silky - cedar, pine, elm, ash, bird cherry.

- moire (irridescent) – birch, gray maple, cherry laurel.

Wood moisture content is the ratio of the mass of moisture contained in a given volume of wood to the mass of absolutely dry wood, expressed as a percentage. Humidity has a great influence on the properties of wood as an ornamental material. Products made from raw wood are easily affected by mold and rot; when dried, they change size and shape, warp and crack. Humidity is measured with a special device - a moisture meter. According to the degree of moisture content, wood is divided into the following types:

- wet – having been in water for a long time (100%);

- freshly cut (50…100%);

- air-dry – lying in the air for a long time (15...20%);

- room-dry – (8…12%);

- absolutely dry – (about 0%).

The humidity at which the product is operated is called operational or working humidity of wood. Thus, the operational humidity of the wood from which indoor (interior) furniture will be made should be 6...12%; The humidity of wood products that will be used outdoors (wooden benches, steps, railings) should be 15...20%. It is important that the moisture content of the wood matches the humidity of its environment.

Shrinkage and swelling are properties associated with changes in wood moisture content.

Wood shrinkage is a decrease in the linear dimensions and volume of wood when it dries, that is, when moisture evaporates from it. The reduction in size during drying is not the same in different directions; for example, in the tangential direction the shrinkage is stronger than in the radial direction. Uneven shrinkage in different directions leads to wood deformation and even cracking (Fig. 4).

Rice. 4. Shrinkage of wood in various parts of the trunk

Deformations of wood associated with its shrinkage are called warping (Fig. 5). Warping can also occur due to improper mechanical handling of dry wood, such as unsymmetrical planing or improper storage of lumber. There are transverse and longitudinal warping. To prevent warping, it is necessary to properly lay, dry and store wood.

Rice. 5. Shrinkage and warping of edges: I – edges of wood that have not been dried; II – edges of dried wood; a, b, c, d – diagrams of shrinkage of wood edges depending on their place in the trunk

Swelling of wood is the opposite property of shrinkage. Swelling is an increase in the linear dimensions and volume of wood with an increase in its moisture content. Swelling occurs due to the ability of wood to absorb and absorb moisture from the air around it. Just like shrinkage, swelling occurs unevenly in different directions.

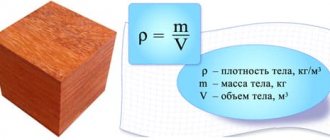

Wood density is characterized by the ratio of wood mass to its volume and has the dimension [kg/m3] or [g/cm3]. The density of wood depends on its species and humidity. As the moisture content of wood decreases, its density decreases and it becomes almost twice as light.

Based on density at a humidity of 12%, wood can be divided into three groups:

- low-density species (up to 510 cedar, poplar, linden, willow, alder, chestnut;

- medium density species (550...740 kg/m3): pine, spruce, fir, kg/m3: larch, yew, birch, beech, elm, pear, oak, elm, elm, maple, sycamore, rowan, apple, ash ;

- species with high density (from 750 hornbeam, boxwood, saxaul, pistachio, dogwood. kg/m3): white acacia,

Hardwood

Particular attention should be paid to deciduous trees. After cutting down the coniferous forest, they fill the empty area. Deciduous types of wood are used most widely and variably.

Ring-vascular structures

The basis of deciduous species is made up of such ring-vascular representatives as elm, elm, ash, elm and oak. The last of this family - oak - is found in many places in European Russia, and also grows in the southern outskirts (in the Crimea and the Caucasus). The peculiarity of its wood is its high hardness, strength and resistance to rotting. In addition, common English oak is distinguished by its bending ability, very attractive texture and rich color.

Common ash is often found in most regions of the European part of Russia. The properties of this type of wood are very similar to the characteristics of oak already discussed above (it also has a high hardness index and bends well, that is, it has good ductility).

Due to its properties, ash is used in the production of various types of sports equipment (tennis rackets, skis and oars), as well as in the automotive, aviation and ship industries. In addition, it is often used to make stair railings and handles for various tools.

Disseminated-vascular soft rocks

Birch is the tree symbol of Russia and grows everywhere on its territory. It is widely used in the domestic industry for the manufacture of plywood, butts of hunting and sporting rifles, skis and veneer. In addition, wood boards of various classes, parquet floors and tar are made from birch.

Poplar, aspen, alder, willow and linden have a very similar structure and, due to their softness, are most often used as ornamental wood to satisfy household and construction needs. These wood structures are used to make troughs, shovels, household utensils and pulp.

In addition, some of them are used to produce box containers, viscose, wood shavings, toys and roofing tiles.

Types of wood and classification of species

Wood requirements vary greatly depending on the type of work. In some cases, you need a soft wood that can be easily and conveniently processed to obtain fine patterns and soft contours, while in another case you need the most durable and wear-resistant wood. Fortunately for woodworkers and builders, there are different types of wood. Lumber from different types of wood varies greatly not only in appearance and texture, but also in its properties. Each species has its own strengths and weaknesses, so when doing construction and carpentry work, professionals pay extra attention to choosing the right type of wood.

Classifications of wood species

In order not to get confused when analyzing wood species, let’s understand the theory: by what criteria and what types of wood are divided.

Separation by structure, core and sapwood

The structure of a tree trunk is relatively simple. Under the bark is an outer layer of living cells called sapwood, and around the core are dead layers of kernel. This creates a protective mechanism for most trees, thanks to which rot, fungus and insects cannot “eat” the tree from the inside in comfortable conditions.

But this does not happen in all trees, so in this category the breeds are divided into 3 types:

- heartwood species, trees with a pronounced layer of dead cells of increased density and darker shade;

- sapwood, trees without dead cells around the core;

- mature wood, trees with heartwood and sapwood of the same shade.

Hardness division

Simple classification based on wood fiber density:

- soft wood, density less than 540 kg/m3;

- hard wood, density ranges from 550 to 740 kg/m3;

- especially hard wood, density more than 750 kg/m3.

This classification is useful when selecting materials for wear-resistant products and when processing wood by cutting to select the appropriate tool. The higher the density of the rock, the more difficult it will be to damage. Soft wood is used primarily for carpentry work, while hard wood is used for construction work, for example, when laying floors.

Separation by leaf type

Perhaps the most common classification of tree species, familiar from school biology lessons by the type of leaves:

Conifers

Deciduous

The main difference between this classification is the structure of the wood and the presence or absence of tree resins. Thanks to resin, coniferous wood is resistant to moisture, deformation and shrinkage, which is why it is preferred in construction. Natural resin also repels insects and actively fights the effects of microorganisms. The only thing is that, due to the resin, the texture of coniferous trees is heterogeneous and may contain resin pockets, which in large quantities have a detrimental effect on the overall strength of the array.

Additional classifications

Wood can be divided into types according to many parameters, including resistance to decay and ease of treatment with chemical compounds. We talked more about these classifications in this article devoted to measures to protect wood from rotting.

Common wood species

There are a lot of wood species and their varieties according to place of origin, so we will consider the most popular ones for construction, carpentry and finishing work.

Oak

Deciduous hardwood.

It has a beautiful “fine” structure and a soft, rich color. Depending on where it grows, oak can range from delicate brown to noble dark brown. This is one of the strongest and most durable types of wood, but its properties are highly dependent on the age of the tree. Edged oak boards are an expensive material that is supplied for interior decoration and furniture making.

Beech

Deciduous hard mature wood.

The wood has beautiful colors ranging from bright yellow to reddish brown. Requires specialized steam treatment. Beech is often used for flooring; the result is both durable and beautiful covering with different color shades.

Ash

Deciduous hardwood.

Valued for its picturesque wood structure. Color ranges from light yellowish to soft brown. At the same time, the core is not always very different in shade from the sapwood. It bends well and takes a hit. It is used in finishing, furniture production and the manufacture of sports equipment.

Maple

Deciduous soft sapwood.

The wood has a beautiful almost white color with a yellowish tint. Maple flooring or lining is a highly valuable design material. A room decorated with maple looks extremely light and pleasing to the eye.

Cherries

Deciduous hardwood fruit tree.

The wood is valued for its color - a rich red-brown, pinkish-brown or red. At the same time, the wood releases moisture well and is almost not deformed when dried. Used for the production of veneer, parquet, exclusive furniture and souvenirs.

Alder

Deciduous soft mature wood species.

Wood with a light texture and a reddish tint. Darkens when exposed to light. When in contact with iron, it turns gray, and the iron itself quickly rusts. Used for the production of veneer, plywood and particle boards used for interior decoration.

Nut

Deciduous hardwood.

Walnut is valued for its unique wood structure and often beautiful yellow-brown color. Moreover, with a very soft color transition from the core to the sapwood. Wear-resistant and tough wood. Typically used as veneer or in the production of luxury furniture, it is rarely sold as lumber.

Acacia

Deciduous especially hard core species.

A very valuable breed due to its special strength and unusual texture with a play of various shades. Used for the manufacture of exclusive furniture and high-class floors.

Pine

Coniferous soft soundwood.

Depending on the place of growth, color, hardness and structure differ significantly. In Russia it is one of the least valuable wood species and the most common. Popular lumber for construction work, which is available in a large assortment in our catalog. Pine lining is used for saunas because of the subtle aroma of resin that it emits; you can also find it on our website.

Larch

Coniferous soft soundwood.

This wood is distinguished by the highest water resistance and beautiful texture. Floors, beams, tongue and groove, lining and much more are made from larch. Larch also makes excellent boards for covering terraces, which you can find in the catalog on our website.

Aspen

Deciduous soft heartwood.

This wood is lightweight, resistant to wear and moisture. It has a pleasant light shade and natural shine in the light. Aspen is a very specific material, primarily due to the peculiarities of primary processing. The core of the tree is often not suitable for any use due to high humidity and often actively rots during the growth process, so aspen is often processed into chipboard and plywood, lining and elements for interior decoration, as well as furniture and doors are made. Some aspen products are presented in our catalog.

Lumber is also made from cedar, cherry, elm, linden, poplar, spruce, teak, willow, rowan (depending on the location of the forest). But we recommend that for building houses you choose species that grow in your area, since they are more accustomed to their native climate and are much less likely to let you down.

And if you are interested in a more detailed analysis of the theory on the general physical and mechanical properties of wood, we recommend that you read this article.

Areas of application of various types of wood in construction

The choice in favor of one type of wood or another should be made depending on the purpose for which the material will be used.

For example, softwood is easy to process, but complex carving elements cannot always be made from it.

Vase made of aspen wood

Hard varieties must be used to create reliable, high-strength structures.

The most common types of wood and their standard areas of application:

- Spruce, fir - timber, flooring, rafter structures, laminated veneer lumber, middle panel board

- Pine timber, furniture, flooring, windows, paneling, doors.

- Larch timber, furniture, flooring, windows, doors

- Juniper, thuja - construction timber; blinds, façade cladding, shingle covering.

- Oak furniture, plywood, parquet, half-timbered wood (structural wood), windows and doors.

- Beech furniture, stair steps, parquet.

- Ash furniture, floors.

- Alder furniture, plywood.

- Maple furniture, parquet, table boards.

Cuts of various wood species

Having information about the characteristics and scope of wood species, it is easier to choose the most suitable material for a specific task.

Subscribe to our Yandex.Zen channel