When gluing wooden surfaces, there is no need to pre-degrease them.

It is enough to choose the right adhesive composition. In this case, possible errors will be minimized. Modern manufacturers offer an impressive range of products for gluing wood. There are many adhesive compositions for working with this type of material. To know which glue is best for gluing wood, you should carefully study the available range. It is also important to know the characteristics of adhesives.

Which brand of wood glue is best to choose?

To know how to buy waterproof wood glue, you should carefully study the composition information. Today on the construction market there is a large selection of excellent adhesive compositions that provide high performance parameters for joints. After drying, a moisture-resistant wood adhesive often turns out to be more reliable than the base coating. When choosing a product, you need to have information about the product’s ability to glue wood of various species and change its color. The most famous brands:

- Moment . The Russian manufacturer produces glue in the form of an aqueous dispersion. It firmly connects wood species, as well as various building materials. Experts note the availability of glue, its reliability, and quick drying.

- Kiilto . Finnish company producing paint and varnish products in various directions. Adhesive compositions are distinguished by the absence of toxic components.

- Titebond . The product is produced by a well-known brand from the USA. Wood furniture glue holds the structure together perfectly. The manufacturer regularly works to improve technology, so the range is constantly increasing.

- Kleiberit . The brand from Germany offers various adhesive compositions for furniture, which are designed for different types of coatings. All products are of high quality.

- UHU . A German brand that is a leading developer of adhesives in terms of quality parameters and assortment. The company strives to take a leadership position in environmental protection issues.

- Akfix . A young but well-known brand from Turkey. Focused on the production of environmentally friendly paint and varnish products and technologies in order to find solutions that best meet the needs of consumers.

- Tex . Well-known developer of paint and varnish products. Adhesive compositions are used in industry and in everyday life. Suitable for plywood, cardboard, paper, they are resistant to moisture and serve as an additive.

- Lakra . One of the largest domestic developers of decorative paint and varnish products. Adhesive compositions from Lakra are manufactured in accordance with international standards of quality, safety, and environmental friendliness.

Each manufacturer is considered a well-known representative on the market and produces good quality products. Considering that the companies in question have positive criticism, the consumer will have no problem finding the best wood adhesives.

Wood in our life

Nature has endowed wood with such a unique set of qualities that no other material on earth has: environmental friendliness, wear resistance, richness of textures, etc. It is impossible to list all the areas of its application. Here's just a short list:

- construction;

- furniture;

- paper production;

- musical instruments;

- toys;

- home stuff.

Despite the fact that this material is quite durable, it also tends to break, crack and split into pieces. In order to bring a damaged item back to life, wood gluing is necessary.

Rating of wood adhesives

Users often have a question about how to glue wood. When looking for a reliable adhesive for wood objects, the user must evaluate its ability to firmly join coatings of different types of wood. During selection, emphasis is placed on the following indicators:

- Purpose;

- Reliability of gluing;

- Speed of setting, drying;

- Resistance to moisture, temperature, solar radiation;

- Price;

- Feedback from specialists;

- Customers' opinions;

- Comfort of use.

The question often arises as to which glue is best to use for wood. Each brand provides an impressive range, so finding a high-quality composition is difficult. In view of this, a review of the best wood adhesives has been compiled, which have been selected taking into account the opinions of experts, buyers, and tests.

The best wallpaper adhesives

One- and two-component PVA adhesives

Application area . One-part polyvinyl acetate (PVA) resin adhesives are a versatile option for a variety of indoor wood projects. Due to their high moisture resistance, two-component compositions (with the additional inclusion of a hardener) are considered the best option for gluing wooden products used outdoors (garden furniture, elements of external doors, window structures).

Working properties . If used rarely, the composition may separate and form sediment. Therefore, it is recommended to shake or stir thoroughly before use. The glue is extremely easy to use.

Compatible with finishing compounds . Traces of dried glue appear under the stain and varnish layer.

Open time : 3-5 min.

The best polyurethane adhesives for wood

If the adhesive composition requires increased reliability, long-term resistance to mechanical load, resistance to moisture and negative climatic conditions, then it is advisable to use a polyurethane composition. When comparing 7 products, it was determined which one is better. The list contains 3 of them.

Akfix PA370 D4

Akfix PA370 is a ready-to-use 1-component polyurethane product that can reliably connect wood-based objects to metal, concrete, and plastic in the shortest possible time. Effective for repair work on wooden boats due to its immunity to moisture and external factors. It must be remembered that when it hardens, the product will increase slightly in size, improving the quality of the joint.

Polyurethane wood glue has proven itself excellent in carpentry, in the manufacture of furniture frames, doors, and in joining multilayer elements in complex structures. To obtain the strongest possible connection, the ambient temperature cannot be less than +5 degrees, and the elements to be glued are slightly moistened. Undried fragments of the product can be easily removed using acetone. The maximum temperature values at which the seam will not lose its qualities are in the range of -40+100 degrees.

Advantages

- Convenient use;

- Low viscosity;

- Reliable grip;

- Fast drying;

- Immunity to moisture;

- Heat resistance.

Flaws

- Fire hazard.

Based on reviews, the tool will allow you to create reliable connections. Users note that the temperature range makes it possible to glue any material that is of wooden origin.

Titebond Polyurethane Wood Glue 2300

The best wood adhesive for polyurethane wood, which is a breakthrough in the field of adhesive technology. The composition in question from a US brand occupies one of the leading positions in this segment. The developer was able to maintain a balance between the speed of hardening (45 minutes) and the time of preservation of its qualities (20 minutes).

The product firmly glues all materials of wood origin, from ordinary wood to objects made from wood shavings. The scope of use is not limited to this: metal, plastic, stone and other materials are firmly glued together. It is moisture resistant, however, in conditions of excessive humidity or under water, the resulting units cannot be left. The glue is not afraid of cold, but before use it must be thoroughly warmed up to +12 degrees.

Advantages

- Fast setting;

- Versatility of use;

- High connection strength;

- Resistance to moisture;

- Environmental friendliness of the material.

Flaws

- Applicable only at +10 degrees.

Users note that the product is suitable for damp rooms, is specific, and does not dissolve in water. Not for use on products that come into contact with food. It foams well, which means it will fill the space between parts. Firmly glues wood to brick.

The best paints for wood

PUR-adhesive Kleiberit 501.0, D4

One of the best universal adhesive compositions is considered to be products from the German brand Kleiberit 501.0. The basis of the product is polyurethane, which gives the material resistance to moisture and resistance to temperature changes. The 1-component composition is easy to use; it can be used to connect 2 wooden elements, as well as other combinations, for example, polyvinyl chloride, mini-slabs, ceramics, concrete, etc.

Operation of the formed units is possible indoors and outdoors, in rain or scorching heat. Excellent gluing quality is confirmed by international standards. The connection hardens completely after 24 hours.

Advantages

- Ease of operation;

- Short hardening time;

- Elasticity;

- Versatility of use;

- Resistance to aggressive environments;

- Resistant to temperature changes.

Flaws

- Long drying;

- Pungent aroma.

Reviews from domestic buyers mainly note positive characteristics. This composition is easy to use, will not drip, and the seam will be reliable. However, it is difficult to wash your hands after work; it is necessary to ventilate the room during the gluing process.

TURBO FIX 805

At production they advised me exactly this composition. Simply because it works quickly, the quality of gluing wood (and not only) is excellent, and its cost is relatively low (when compared with analogues).

Therefore, I will tell you using his example (since I bought it). The cost from the official website is about 300 rubles, for a large package of 400 ml

What does TURBO FIX 805 consist of? A set of two substances:

- The glue itself comes in liquid (gel) form, volume – 100 ml

- Activator, comes in a can, sprays – 400 ml

As the manufacturer assures, with a certain application, it glues wood to wood, really in seconds

The best resin wood glues

The composition of various resins has many useful qualities. It will not change the shade of the wood being processed, has excellent adhesion, high strength and electrical insulating qualities. However, when working with adhesive composition, proper room ventilation and the use of personal protective equipment are necessary. When comparing 7 products, it was determined which one is better. The list contains 3 of them.

Moment Joiner

Composition based on epoxy resin, an excellent product from domestic manufacturers. Using the composition, it is possible to combine various types of wood, plywood, MDF, fiberboard, chipboard, plastic with paper inclusions. The surfaces to be glued need to be pressed for a quarter of an hour using a clamp or vice. The complete drying time for the elements before use will be 1 day. The product does not change the shade of the processed material, which will increase the scope of its use. The product can be used at positive temperatures from +5 to +30 degrees.

Experts and amateur craftsmen note the following characteristics of Moment Joiner: short drying period, reliability, accessibility, transparency after hardening. The disadvantages include sensitivity to moisture and low temperatures.

Advantages

- Transparency after drying;

- Convenient use;

- Quick drying;

- High initial grip.

Flaws

- Poor resistance to moisture.

It is made on the basis of epoxy resin, therefore it is not toxic to the user. It is economical in use and is effective for all types of wood.

Titebond joinery moisture resistant

1-component adhesive for gluing wood materials. It has a high class of water resistance and can be effectively used for outdoor work: assembling garden furniture, birdhouses, mailboxes. The composition is characterized by a strong initial setting, rapid hardening, creates a reliable seam, and is easy to process. The downside will be susceptibility to moisture and negative temperature parameters.

Advantages

- Connection reliability;

- Versatility of use;

- Fast setting;

- Holding period in clamps;

- Cutting tools do not deteriorate when processing the joint.

Flaws

- Weak water resistance;

- Big expense.

Users note strong adhesion of the adhesive composition in a short period. The disadvantage is that the funds are spent quickly.

Uhu Plus Endfest 300

Two-component universal wood adhesive has good gluing properties. It is made of epoxy resin, which will allow materials of different origins to be glued to the wooden object being processed. The exception will be glass items. The composition hardens within 1.5 hours, the joints are fully ready for use within 12-24 hours. The seam will become impact-resistant, wear-resistant and moisture-resistant.

To make a working solution, you need to mix 2 ingredients, following the developer's instructions. Then the components are thoroughly mixed until a homogeneous consistency is formed. The finished composition is applied with a brush or spatula. Among the advantages of glue from a German brand, the emphasis is on high strength, resistance to mechanical influences, and moisture. It is characterized by reliable initial setting and high adhesion.

Advantages

- Reliability;

- Immunity to moisture;

- Durable grip;

- Connection of any objects with wood;

- Does not conduct current.

Flaws

- Proportions must be observed;

- You need to prepare a working solution.

Based on reviews, the adhesive composition has increased strength, immunity to mechanical influences and moisture.

The safety of the mixture, which is used both for home and industrial purposes, is noted.

General gluing rules

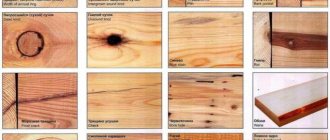

There are rules for gluing wooden parts that must be followed regardless of what adhesive composition is chosen.

Before you glue wood to wood, you need to thoroughly clean the surface. This can be done using sandpaper or a file. After this, dry the parts and apply a thin layer of adhesive using a brush and rub in lightly. All surfaces intended for connection are lubricated with glue, then they are pressed tightly against each other using a press or other method until the composition is completely cured.

When working with any glue, mandatory precautions are required, since even the most harmless composition can sometimes cause a severe allergic reaction. Therefore, gluing wood must be done with rubber gloves. If glue does get on the skin, you need to carefully wipe it off and thoroughly wash the affected area with soap. If the composition gets into your eyes, rinse them immediately with running water.

If you carefully understand how to glue wood to wood, and strictly follow the instructions for using the adhesive composition, then the place where the parts are joined can turn out to be much stronger than the wood itself.

Which wood glue is best to buy?

To choose the strongest glue for wood, you need to consider its purpose and type. There are specialized products that are used directly for items of wood origin, and there are universal ones. Despite the variety, experts choose narrow-profile compounds that are suitable directly for wood and its derivatives. However, the characteristics of the wood in a particular situation also need to be taken into account when purchasing. Among the products reviewed, experts focus on the following nominees:

- Moment Super PVA D3 is moisture resistant – suitable for gluing wood in a humid environment;

- PUR adhesive Kleiberit 501.0, D4 – a universal product with fast setting;

- UHU Plus Endfest 300 is the most reliable product made from epoxy resin;

- Titebond carpentry is moisture resistant – suitable for carpentry work.

The rating includes the best adhesives for wood-based materials. It is impossible to answer the question which one is better. The choice of wood glue should also be based on the recommendations of specialists, builders, and positive and negative user opinions.

How to apply it?

TURBO FIX 805 has two application methods (hence two gluing methods):

FAST. Of course, we clean the surface of various irregularities or residues (as in my case of the old composition). I took sandpaper and simply sanded the surfaces, then wiped them with a cloth to remove any wood dust.

Next, apply the gel (from a small bottle) to one surface (spread it thoroughly).

And the activator, on another surface (just spray it). More details can be seen in the video below.

Then we press, observing the dimensions! IT IS IMPORTANT! Gluing occurs in seconds, and there is practically no time to fix it

We count to 10, the tree, in our case it is the balcony of the capital, just “grabbed” tightly.

LONG. The method is relatively long, it works not in seconds, but in minutes. Used so that you can adjust the size or fit.

We apply the gel on both sides, that is, on one and the other. We press them (combine the sizes), if necessary, adjust them - hold them. Next, spray the activator into the cracks (top and bottom). We hold it for a minute so that it initially sets, then leave it for a couple of hours (so that the activator penetrates inside) for final gluing. According to observations, after an hour, it can’t be torn off