The term “wood” is usually understood as the inner part of a tree trunk, located under its bark and freed from branches, bast and roots. The main physical and technical characteristics of this material include: strength and wear resistance, attractive appearance, high thermal conductivity, etc.

Application and use of wood

Wood has been used for the manufacture of engineering structures and products for various purposes since ancient times. For example, a bridge across the Tiber River in Ancient Rome was made from this material, in which there were no metal fastening components. It was built in 614 BC. and stood in its place for 24 years!

Wood is a completely renewable resource, which makes it a universal raw material for creating many types of products.

So what is made from wood:

- Various types of furniture, including cabinet, upholstered and lattice.

- Products for carpentry and construction purposes (window and door blocks, parquet and floor boards, milled moldings, etc.).

- Musical instruments, including: violins, guitars, cellos, grand pianos, etc.

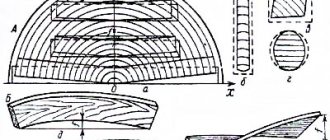

- Wooden vessels (boats, yachts, canoes, etc.).

- Sports equipment (skis, bats, skis, clubs).

- Fine mechanics instruments and radio engineering products (cases for radios, microscopes, etc.).

- Dishes and art products.

- Containers (boxes, barrels, etc.). etc.

Wood as a structural material is used in the automotive industry, where it is used to create parts and assemblies for trucks, agricultural machinery and interior fittings for luxury cars.

Areas of wood use

The main group of building materials used for the construction of structures of varying complexity is made from natural wood. These are laminated veneer lumber, rounded logs and dry profiled timber.

For this purpose, softwood raw materials are used, which are characterized by a more pronounced straightness of the fibers and the presence of a larger amount of resinous substances in their composition. These substances prevent the development of rotting and decomposition of the wood core.

Wood of softer, deciduous species is used in the manufacture of furniture, decorative and household products.

Types of wood building materials

All types of materials can be divided into solid and composite. Solid ones are made from solid wood - these are timber, slabs, edged boards, rounded logs and other materials that are actively used in modern environmentally friendly construction. Load-bearing structures are made from solid wood due to its high strength.

Common composite materials:

- Glued laminated timber – several dried lamellas connected to each other with glue. Thanks to special processing and structure, this material practically does not shrink and is resistant to biological threats.

- Plywood is sheets of veneer glued together. Plywood board is indispensable for covering walls and floors; it is used in the manufacture of furniture, construction of formwork, and many other works.

- Chipboards are chipboards that are obtained from wood processing waste. Sawdust and shavings are combined using an adhesive composition.

- Fiberboard – wood fiber board. Sawdust and larger shavings are joined together with a binding adhesive.

- OSB – oriented strand board. This material consists of large chips, which, using sophisticated equipment, are sprayed in a certain direction and compressed under pressure. OSB is used for sheathing frames, building roofs and many other works.

This is only a part of the building materials widely used for building and finishing a house. Wood is used as a heat and sound insulator; it looks beautiful and lasts a long time if properly processed.

Surely, many people have encountered a situation where cooking in the kitchen ended with something burnt, while the entire home was…

If you translate this word from Finnish, then sauna means nothing more than a bathhouse. For example, in Finland the sauna is a kind of cult. ...

Owners of cottages or summer cottages have ample opportunities to improve the area around their home. Landscape design…

Any ventilation system for private use must include fire and smoke protection components. In industrial ventilation...

Why is powder coating so popular today? Powder coating is often used in industries that produce products for which aesthetic appearance is one of the mandatory considerations…

Independent cladding of the facade with siding is an affordable and feasible task. This finishing material consists of panels with special fastenings…

Human activity is killing nature more and more every day. Therefore, now it is important, and not fashionable, to think about the results of our activities. This is to…

Are you planning a move? So you need wooden packaging! Moving is sometimes compared to a fire, because many things get damaged, broken or simply lost during transportation. And the reason lies in the wrong organization...

In suburban towns and rural areas, where there is no properly constructed storm sewer system, the problem of drainage and drainage of storm water, t...

The most popular, practical and in-demand storage method is placing products in a warehouse. The organization of the storage method should be limited...

Work clothes are clothes designed for work, especially manual work. Often those who are employed in trade industries choose equipped…

The advantages of choosing pressure sewers, as well as comparison with other types. Of course, any sewer system https://www.standartpark....

Design is an initial and, at the same time, extremely important set of works that helps reduce certain risks during the actual construction...

Wood materials and products

Through mechanical, mechanical-chemical and chemical processing of the trunk, roots and crown of a tree, so-called goods are obtained. According to the method of production, forest products are divided into seven groups: timber; modified wood; composite wood materials; raw materials for wood chemical production; pulp, paper and wood fiber materials; hydrolysis and yeast production products; products of wood chemical industries.

For construction purposes, mainly goods of the first group are used - timber, as well as composite wood materials and modified wood.

According to the method of mechanical processing, timber is divided into: round; sawn materials; peeled; milled (planed); split, produced by dividing wood along the grain with a wedge-shaped tool; crushed (chips, sawdust shavings), obtained in the process of conventional sawing and milling or special wood processing.

Composite wood materials (sheets, slabs and other types) are produced using binders (astringents) from wood previously divided into parts (plywood, wood panels, particle boards, laminated plastics, fiberboard, etc.).

Modified wood is solid wood with directionally modified properties (pressed wood, plasticized with ammonia, modified with synthetic resins, etc.).

Round timber.

The trunk of a fallen tree, sawed off from the root part and cleared of branches, is called a whip. The process of dividing the logs into parts is called bucking. When bucking logs, you get pieces of different lengths - logs, ridges and logs. In construction, logs are mainly used, both in round form and as raw material for the production of lumber.

Round timber is divided into small, medium and large by thickness (diameter of the top cut). Small ones, often called subtovarnik, have a diameter of 6...13 cm, medium ones - 14...24 cm, large ones - 26 cm or more. Builders call thinner parts of the trunk or thin wood (3...7 cm) poles. The length of the logs is 3...6.5 m, with gradation every 0.5 m.

Depending on the quality of the wood and processing defects, round timber is divided into four grades. In construction, logs of 2nd and 3rd grades are mainly used.

Lumber and blanks.

According to their geometric shape and cross-sectional dimensions, lumber is divided into plates, quarters, beams, whetstones, boards, and slabs.

The beams have a thickness and width of more than 100 mm; bars - thickness up to 100 mm and width no more than double thickness; boards - thickness up to 100 mm, width more than double thickness. According to the nature of processing, lumber is divided into edged and unedged. Unedged lumber has unsawn edges. According to the degree of processing, lumber is divided into unmilled and milled (planed). When the thickness of materials is up to 32 mm, they are called thin, and when thicker, they are called thick. Thin boards are also called planks.

| Fig.1. Lumber and types of boards : a - plate; b - quarter; c - croaker; g - double-edged beam; d - four-edged timber with wane; e - clean timber; g - three-edged beam; h - edged board; and - semi-edged board with wane; k - unedged boards; 1 - edge; 2 - ribs; 3 - left or inner side; 4 - right or outer layer; 5 - bypass; 6 — sorbet board; 7 - side boards |

Softwood lumber

manufactured in lengths of 1...6.5 m with a gradation of 0.25 m. Boards and bars are divided into five grades (selected; 1, 2, 3 and 4th); the bars are not of selected grade. All grades are used in construction, and 1st and 2nd grades are used in carpentry. The width of the lumber is linked to the thickness and the maximum can be: for boards - 250 mm, for beams - 200 mm, for beams - 250 mm.

Hardwood lumber

They are manufactured in lengths of 0.5...6.5 m with gradations of 0.25 m. Based on quality, these lumber are divided into three grades.

| Softwood lumber | Hardwood lumber |

Glued laminated timber

. The tree is complex in structure and is formed biologically. As a result, when drying, wooden parts noticeably change in size, crack, bend, and defects and defects appear that reduce strength. The emergence of high-strength adhesives allows us to solve this problem.

The result is a new material - laminated veneer lumber, which has all the advantages of planed boards: strict geometric dimensions, absence of internal stresses, absence of defects affecting load-bearing capacity, the possibility of automatic processing, pleasant appearance. Since the number of lamellas (glued boards) can be very large, the cross-section of laminated timber reaches impressive sizes. Glued laminated timber also does not change its shape during operation, has lower thermal conductivity compared to wood, greater strength, and minimal height shrinkage

Blanks

- these are boards and bars, cut to specified dimensions and quality of wood used for the manufacture of parts with allowances for machining and drying. Blanks are distinguished by type of processing: sawn - obtained by sawing; glued - made by gluing together several smaller pieces; calibrated - for decorating corners between the floor and walls, and platbands for decorating door and window frames and closing the gap between the frame and the wall.

| Round timber, that is, the trunks of a fallen tree, already cleared of branches. Depending on the wood quality indicators (presence of defects and processing defects), round timber is divided into 4 grades | Lumber is divided into bars, plates, quarters, boards, slabs and beams. Boards and beams of coniferous trees are divided into 5 grades - selected, 1st, 2nd, 3rd and 4th. Lumber from deciduous trees is divided into 3 grades. For the production of individual parts of finished products (plinths, cornices, platbands, fillets and others), blanks are used - beams and boards, cut according to specified sizes |

| Wall laminated profile timber. This is a glued thick beam, on the upper and lower sides of which ridges and depressions are formed, which connect individual beams to each other when assembling log walls. One of the options for such timber is a profiled carriage. A new product for our country is laminated veneer lumber made from LVL veneer - an innovative high-tech product based on glued layers of veneer with parallel fibers. | Block house lining imitating timber. This type of lumber is planed boards with a tongue-and-groove profile. They are used in frame wall structures as cladding, as well as for making interior partitions, bay windows and pediments |

| Floor tongue and groove board 28mm thick | American paneling. Beautiful, neat American houses are covered with such clapboard. It is often painted in different colors. The peculiarity of this lining is its unusual profile |

Joiner boards

With

consist of an internal board made of narrow slats (base) and veneer glued to the board on both sides in one or two layers (front and back layers). Slab panels are made from coniferous and soft deciduous wood (birch, etc.), widely using production waste (slabs, slats, etc.). Wood slabs can be processed to specified sizes. In construction, blanks that have a special cross-sectional shape after milling (plinths, platbands, sheathing, handrails, etc.) are also widely used.

Construction parts and wood products

Milled wooden parts

(molded parts) for construction are elements of a small cross-section, processed by milling on machines: boards and bars for flooring, skirting boards, platbands, handrails, cladding and layouts. Floor boards and bars have a groove on one edge and a ridge on the other, which ensures the density and rigidity of the floor.

| Fig.2. Wooden parts and products for construction : a - platbands; b - skirting boards; c - handrails; g - boards for laying clean floors; d - bars for laying clean floors; e - boards for cladding wooden houses; g - tongue and groove connections of boards: 1 - with rebate; 2 - straight spike; 3 - segmental spike; 4 - trapezoidal spike; 5 - triangular spike; 6 - lath into tongue; 3 — parquet boards; and - parquet panels; k - parquet plank on a “rigid lath” | |

Parquet products

divided into piece parquet, parquet boards, parquet panels and mosaic (composited) parquet.

Piece parquet consists of individual planks (planks) with tongues (groove and tongue) at the edges and ends for connecting to each other. It is easy to manufacture, but requires significant consumption of raw materials and labor for manufacturing and installation, which affects its cost.

Parquet

boards

are two-layer products. The bottom layer (base) consists of milled bars or boards, the top layer (face covering) is made of identical parquet strips. Both layers are firmly glued together with waterproof glue. The edges of the parquet boards in the lower layer have grooves and ridges, with the help of which the boards are connected to each other. Parquet boards are produced in lengths of 1200...3000 mm, widths of 145 and 160 mm and thicknesses of 25...27. mm. Parquet boards have a number of advantages compared to piece parquet: less consumption of valuable wood, durable sticking of parquet strips, the possibility of mechanization and automation of their production, labor intensity is sharply reduced and the process of laying parquet flooring is accelerated. The disadvantage of flooring made from parquet boards is the monotony of the pattern.

Mosaic (composited) parquet

is a carpet made of planks of the same width in the form of mutually perpendicular squares and glued face-up onto paper, which is removed along with the glue after laying the parquet on the base of the floor.

| Fig.3. Parquet flooring | Fig.4. Mosaic package |

Plywood

is a layered sheet material, usually consisting of an odd number of layers, called veneers and obtained by peeling or planing sections of wood trunk (churaks). Adjacent veneers have mutually perpendicular fibers and are glued together by hot or cold pressing. This design of plywood provides it with a number of advantages over lumber. It has almost equal strength in all directions, warps little and does not crack; There are no through cracks in it, it bends easily

Fig.5. Plywood sheets

One of the most popular lumber in the construction process is building materials - boards. They are used not only for external construction of any objects, but also for many internal finishing operations.

Rough filing of ceilings (in cottages, in wooden houses), preparation of roofs for covering (for example, lathing system). Also, the manufacture of floors and partition frames is not the entire list that characterizes the entire scope of application of this material.

| ONLY THE BEST TIMBER | FREE LOADING |

| PROMPT DELIVERY IN MOSCOW AND REGION | PAYMENT BOTH IN CASH AND BY BIRTHDAY! |

| CAREFUL STORAGE GUARANTEE | DISCOUNTS FOR WHOLESALE BUYERS |

Various wood products

Thanks to its beautiful texture, optimal density, good flexibility in processing and fairly high mechanical strength, wood is a universal and practical material for the manufacture of construction carpentry, decorative products, furniture and goods for cultural and household purposes.

Under normal operating conditions, wood products can serve the owner for several decades. They are obtained by mechanical processing using various finishing methods, including joining individual elements into a finished product using glue or fasteners.

Products made from hardwood and softwood include a wide variety of small cross-sectional elements and milled and turned parts. This may include:

- Skirting boards, platbands, belts, handrails for stair railings, cornices, fillets, cladding.

- Parquet products, including piece parquet, panel parquet, parquet boards and mosaic parquet.

- Plywood thickness from 3 to 19 mm.

- Fiberboards.

This material is also used to produce carpentry products, for example, door and window blocks consisting of frames, wooden panels and window sashes, and building materials, including:

- Beams and floor panels;

- Partition panels;

- Elements of panel and frame houses, etc.

At the same time, the quality of the above products is determined based on many different parameters, the main one of which is the moisture content of the raw materials entering processing.

Basic wood building materials

Wood has always been used in the construction industry, even in the construction of pyramids and medieval granite castles. Today, wood materials are used no less widely, although with the invention of concrete, wood begins to yield to it its dominant position in the past. But even modern stone buildings cannot do without wood.

For example, not a single residential building today can do without a rafter system, which in 99% of cases is made of wood. It is also used for finishing work, and this is not to mention formwork, if any parts of the house are being concreted.

Yes, wooden house construction in our country is on the decline, and frame technologies have not taken root at all, and these are precisely those types of construction that require the use of large amounts of wood.

But even in stone house construction, wood is used quite a bit, so the woodworking industry today is developing at a fairly rapid pace. Many sawmills and factories produce a wide variety of lumber, the purpose of which is very wide. For each type of work, one or another type of material is used, in connection with this there is a classification of lumber. In addition to lumber, other wood materials are also used, such as plywood or particle boards, so we’ll talk about all of this.

Log

The most traditional lumber is a log, but today ordinary logs are used little, mostly builders give their preference to rounded logs. Such a log is lumber with an ideal round cross-sectional shape and is processed in factories.

All logs used to build a house have the same diameter, so there is no need to adjust them to each other; houses are built from such logs very quickly.

However, a rounded log is noticeably more expensive than a regular log, and a significant part of this difference is due to the preparation of the log for construction not only by carpentry, but by drying using not very cheap technologies.

Board

The most common type of lumber is board. A standard board is obtained by sawing a log, its length is within 2 meters, its thickness is up to 10 cm, and its width is up to 30 cm. The boards are used to lay floors in rooms, cover walls with them, and make ceilings between floors.

Boards vary by category, the most popular of which is unedged board, and the most elite is solid board, one of the options of which is lining. The difference is that solid boards are made from expensive types of wood, while lining is made from almost any kind.

They are united by the presence of tenons and grooves on the sides, thanks to which the laying of this material is done better than using nails or screws.

An unedged board is a board whose edges are not sawn, it is the cheapest, the only cheaper one is the slab, which is the outermost layer of cut logs with unprocessed edges. And if you can even make lining from an unedged board, then the slab is only suitable for sheathing or formwork, which, however, does not detract from its value when carrying out a variety of types of work, since formwork and sheathing are mandatory elements used in the construction of any house.

The industry also produces a wide variety of planed boards, which, however, are more often used not in construction, but in the furniture industry.

Boards are made from almost all industrial tree species, both deciduous and coniferous.

timber

The beam is also made from a solid log, and, in fact, it is a log, only its sides are not round, but cut. This lumber is mainly used for making rafters for houses of any type or for creating frames for frame houses.

There are different types of timber, the most popular is ordinary timber, which can have any thickness greater than 10 cm. The more expensive one is profiled timber. In a regular beam, all sides are smooth; in a profiled beam, the two opposite sides have a profile somewhat similar to the tongue-and-groove system.

Thanks to this profile, the installation of a log house from beams is of higher quality, but at the same time such timber is much more expensive.

https://www.youtube.com/watch?v=JJmav4eCsBY

Today, glued laminated timber has become quite widespread. Strictly speaking, this is not even a beam as such, but a wooden mass similar to a beam, made from boards glued together. However, such timber is much stronger and more durable than conventional types of timber, and it does not shrink or warp under high humidity.

You can also mention such a type of timber as a block. It is made mainly by cutting thick boards and is most often used in finishing and repair work. Its usual thickness does not exceed 10 cm, the length may vary depending on the application.

DIY crafts

Excellent external qualities, decorativeness and ease of use (according to these parameters, it can be assigned a “five” on the five-point rating scale we previously used), wood is one of the most popular materials used to create all kinds of crafts and souvenirs.

You can use it to make a huge number of interesting and original things: cabinet doors and tops for coffee tables, jewelry, decorative stands, boxes, etc.

What can be made from wood

Example No. 1

Example No. 2

Example No. 3

Example No. 4

Example No. 5

Example No. 6

Example No. 7

Example No. 8

Example No. 9

When working independently with various types of wood, you should keep in mind that it is most rational to use poplar burl as a facing material, which is characterized by its lightness, good sandability and high decorative effect. However, the disadvantage of this material is its rarity.

A much more accessible material for home crafts can be called firewood logs, among which there are very original “instances”. When cut correctly, they can be used for cladding countertops and cabinet doors.

Benches, figurines and other decorative items can also be made from natural wood, which can complement any interior.

Defects and quality of wood.

According to GOST, lumber is divided into grades, which depend on the quality of the lumber. So, the wood is divided into four, and the board into five classes.

For the construction and finishing of the main surfaces during the construction of a house, only the selected material or the first grade of lumber is suitable. Other lumber options can be used as auxiliary ones, since they have many disadvantages that are unacceptable for capital buildings.

So, when buying lumber, pay attention to the following disadvantages:

- Putrid spots appear as reddish and dark areas. The structure of rotten wood is fragile and loose.

- Fungal infections. If this defect occurs in wood, bluish or gray-black blurry spots of different sizes appear on its surface. The fungus itself does not weaken the strength of the wood structure, but creates favorable conditions for the development of humus. Small areas infected with fungus are treated with antiseptic impregnations.

- Sapwood or bark are young, actively growing layers of a tree trunk, characterized by high humidity, low endurance and low resistance to damage by parasitic microflora and insects. The presence of this layer on structural wood is considered a defect.

- Knomelos are a pronounced increase in diameter that forms in the lower part of the trunk, which differs in greater hardness and structure from the main wood.

- Wane is the remaining part of the bark along the edges of a wooden product, which makes its geometry imperfect and can lead to contamination of the material by fungi and flat wooden insects.

- Sprouts form in wood due to mechanical damage, due to which the bark grows in the structure of the trunk.

- Cracks can occur due to adverse natural influences or during drying of lumber, which leads to rupture of wood fibers.

- Wormholes – damage to a tree by a beetle. This defect significantly reduces the strength of the building material.

Now, having determined what defects may be present on wood classified as inferior, you should find out how products of the highest and first quality differ from it.

Premium or selected . These products include wood from selected raw materials. They may contain:

– a minimum number of small healthy nodes located in different areas of the product;

– end cracks of varying depths, but not more than 10% deep and 16% shallow.

The presence of wrinkled and rotten knots and fungal manifestations is unacceptable. The deformation and unevenness of the edges is set within 1 ÷ 2%. The core of the trunk is completely excluded as the weakest point of the wood.

First grade . This category includes lumber of regular geometric shapes. Unlike selected products, in first class the following is allowed:

– healthier knots by about 10%;

– fungal stains and mold, the total area of which should not exceed 10% of the total area of the product;

– sawing defects on surfaces and edges, not exceeding 1/6 of the total length of the product;

The presence of putrefactive manifestations that destroy the structure of the wood is not allowed.

Boards of this class are used in all areas of construction and finishing work.

Second class. The following defects are allowed for wood in this category:

– greater tendency of fibers when sawing;

– presence of resin pockets in softwood lumber;

– blue and gray-black color caused by fungi;

– significant reduction (cutting error).

This type of wood is used for preparatory work - for example, when assembling formwork, when constructing temporary scaffolding. This slab is also suitable for turning under roofs.

Third grade wood is used for attachments and temporary buildings, as well as for the manufacture of containers. The following defects are allowed in related products:

– significant tilt (annual rings on one side of the log are significantly thickened);

– resin bags – up to 4 pieces per meter of shoulder strap;

– wormholes in any part of the product;

– any number of sound nodes of any size;

– cracks in the tank, etc.

The fourth class , like the previous one, is used only for preparatory and auxiliary work. This wood can have many different defects, including wormholes, rot (10%), bluish tint, severe and dull fading, warping and winging.

So, to summarize, it is worth briefly highlighting the main parameters that you should pay attention to when purchasing timber for building a house:

The wood must have clear geometric shapes and a minimum number of the above defects. The annual rings should fit tightly to each other - this indicates the quality of the wood. Wood moisture content should not exceed 20 ÷ 22%. It is not recommended to buy wet lumber, since it is very difficult and often impossible to dry it properly without causing deformation. However, if for some reason such a decision is made, then it is better to lay the damp wood under a canopy or in a well-ventilated area.

In this case, each row in the stack is stacked from the adjacent one in columns of the same section. And exactly in a row, the boards (wood) should not touch each other. It is recommended to purchase lumber from a reliable supplier who, at the buyer’s request, can provide documentation for a specific batch of wood and demonstrate the quality of sorting.

Furniture

Wood is the main raw material for the production of furniture, including luxury furniture. At the same time, different types of wood are used to create different types of furniture:

- Softwood (cedar, spruce, pine, chestnut, alder, willow, poplar, etc.)

- Hardwood (apple, walnut, ash, rowan, birch, beech, etc.)

- Very hard species (boxwood, hornbeam, pistachio tree, acacia).

The hardness of the raw materials has a direct impact on the service life of furniture sets and individual products made from natural wood. However, furniture is made from wood of all listed types, and in all cases it can be of high quality. The main influence on the formation of the cost of the finished product is the finishing of the material and the final appearance of the furniture.

Raw materials used

Raw materials for the production of edged boards are selected depending on the purpose, as well as the determined requirements for the strength of the boards, moisture resistance and thermal conductivity. The best raw materials for producing edged boards are spruce and pine.

Do you want to know why exactly this is? Today, the offered range of edged boards, as a separate type of building material, is presented quite widely. The main price indicators for edged lumber vary. It most often depends on the type of wood, the number of completed processing processes, size, and so on.

High quality of offered products

Edged boards are made from wood of only the highest quality using modern equipment, which produces a minimum amount of waste; this allows us to maintain a low price level for such lumber, despite the high quality of the finished product.

Wood sawing can be cumulative (mixed), radial and tangential. Materials that do not have bark along the edges are called edged, and with the presence of bark, boards are defined as not edged. Sawing is the initial stage of wood processing. If after the first stage it is necessary for the wood materials to have a very smooth surface, they are additionally sanded and planed. There are various cutting methods.

Radial Cutting - In the radial cutting process, the cut line goes straight through the middle of the trunk. Semi-radial cutting - with this, the angle of inclination of the wood rings of the finished product is determined from 90 to 60 degrees. Tangential cutting - the cutting plane passes exactly at a distance from the core of the log.

Still, the most popular building materials, as before, remain edged boards. Hurry up to purchase at a favorable and affordable price.

Preface

Modern building materials made from wood differ in the method and nature of mechanical processing.

Contents

Modern building materials made from wood differ in the method and nature of mechanical processing. Boards, sheets and other composite wood building materials are obtained from the split portion of wood. They are quite economical, but have less strength. Wood materials for construction, obtained from solid logs, are more expensive and durable.

Timber

Wood materials and products are usually divided into several main groups:

- Timber produced by mechanical processing of wood. These include round, sawn, peeled, and planed materials.

- Chips and by-products: wood flour, sawdust, shavings, wood chips.

- Modified wood treated with synthetic resins, plasticized with ammonia, etc.

- Wood products (plywood, chipboard, wood panels, fiberboard, wood-laminated plastics, etc.)

Wood in the construction of houses and other structures

Wood is one of the main materials used in construction for the construction of buildings and structures of varying complexity. For this purpose, raw materials of both coniferous and deciduous wood are used, which have a certain set of specific characteristics that determine their use in a particular area.

For example, for the installation of formwork it is more rational to use coniferous material, since the wood of deciduous trees does not tolerate the load of the concrete mass. Coniferous trees are also the main raw material for the production of timber, from which residential buildings and bathhouses are built.

It is believed that for the construction of a bathhouse it is better to use pine growing in northern areas. Such raw materials contain a minimal amount of moisture, have high strength and resistance to cracking.

Types of wood

To solve various problems in construction, one or another type of wood is used, it is easy to purchase, for example https://bistrend69.ru/doska_brus.php, where there is a large selection.

All species are divided into deciduous and coniferous. The latter have a pungent resinous odor and have a pronounced macrostructure. The most common industrial species of coniferous wood are pine, fir, spruce, larch and cedar.

Pine is most often used in construction.

The color of its wood ranges from pale yellow to reddish yellow.

Pine is a light and durable material, simple and easy to process. Pine wood contains a large amount of resin, so it perfectly resists rotting and moisture. Thanks to its soft structure, it absorbs paint and varnish well. Pine almost does not warp when dried. Among the disadvantages of this wood, the only thing worth noting is the impossibility of high-quality finishing and painting of the surface.

Next in popularity is spruce.

Its wood contains little resin, so it is more susceptible to rotting and moisture. Spruce is a strong and lightweight material, but very knotty, which significantly reduces its quality and cost compared to pine. The advantages of this material include a pleasant light color and low resin content. Holds various types of fasteners well - bolts, self-tapping screws, screws, etc. In construction it is used for the manufacture of parts of minor importance.

Cedar, or Siberian pine.

Cedar wood, although soft, is very dense, resistant to rotting, and can be easily processed, in which it is much superior to spruce.

Fir in its characteristics is not much different from spruce: it is well processed and does not tolerate caustic chemical compounds.

Fir wood contains little resin, which is why it rots quickly without proper treatment.

Larch wood is valued primarily for its strength, hardness and resistance to rot. Larch is such a dense and hard material that it sinks in water.

As for hardwoods, they are divided into soft and hard. Deciduous wood has virtually no odor; the material only smells after it has been freshly cut. Hardwood species used in construction include: oak, ash, birch. Soft species: aspen, alder, linden.

Oak is a very durable and decay-resistant material, has a very beautiful texture and a pleasant color.

Oak wood is widely used for furniture, art and luxury items. Tannins contained in oak wood have strong antiseptic properties. The most beautiful and durable wood (bog oak) is obtained if it is kept in cold running water for one and a half to two years.

Expensive luxury furniture is made from bog oak. Stained wood has a rich dark color, almost black. This is an almost ideal material for making furniture, however, it is difficult to process, as it is very dense and hard.

Birch wood is not very hard and dense, but it is viscous and homogeneous, and does not have a very pronounced texture.

Among the disadvantages of this material, it is necessary to highlight the tendency to cracking and warping, poor resistance to rotting, and pest damage. In addition, birch wood dries out greatly. Despite all its shortcomings, this material can be easily processed with hand tools; birch makes good plywood, the material is well polished and painted. Since birch wood is viscous and homogeneous, fine relief carvings can be applied to its surface.

Aspen is a soft material with an almost complete absence of knots, which makes it easy to process, but due to its porous structure, small parts cannot be made from aspen.

Linden is widely used for making carved parts in furniture production. It does not warp or crack at all during the drying process.

Linden wood has a strong structure and resists rotting well.

Maple is a durable and dense material that is practically not subject to warping.

However, it rots quite quickly and is severely damaged by pests. Maple is well processed, glued and painted. Maple wood is used for a variety of purposes, both in construction and furniture production.

Mahogany, which grows in tropical forests, is a very beautiful material with a rich red color.

It is used mainly for the production of luxury, expensive furniture. What’s interesting is that “mahogany” is not a separate species; the name is used for many types of trees that have similar properties. Mahogany wood can be easily processed, polished and absorbs varnish. Due to the very high cost, full-fledged products are rarely made from mahogany; most often the material is used to make individual parts.

Smoking products

In addition to the main part of the tree, in everyday life we actively use woodworking “waste”, such as firewood, sawdust and wood chips. This material is used with great success in cooking and for smoking various products.

The quality of the wood used for smoking determines the finished appearance and taste of the final product, so its choice should be approached quite seriously. It is believed that hardwood is better suited for this.

It is good to use wood from deciduous trees for this purpose, which is well suited for both meat and fish. This can be aspen, which gives the finished dish a very subtle, refined aroma, as well as beech, oak and aspen, which form persistent smoke and a rich aroma.

Types of materials for building a wooden house

Barked log

To obtain it, you just need to remove the bark from a tree trunk. You can do this in the classic way - with an ax. Or use a special machine, which is much faster. In this case, the fresh top layer of wood, which has not yet had time to harden and is impregnated with resin, remains on the log. It resists moisture well.

The length of this building material can be different, even more than six meters. The thickness of the logs also varies; there are specimens with a diameter of up to forty-five centimeters. The structure, erected from debarked logs and commonly called a wild log house, looks impressive and picturesque, reminiscent of a hut from a fairy tale. Currently, debarked logs are used extremely rarely.

Barked log.

Wood waste products

As a result of processing wood raw materials into lumber, the average yield of finished products is about 65%. The remaining 35% comes from waste in the form of slabs (14%), sawdust (12%), trimmings and small items.

In the case of processing lumber for the production of building materials, furniture and household products, about 40% of waste is obtained (sawdust, cuttings, shavings). Therefore, for a more rational use of this material, this “rejection” is also used in industry.

In particular, sawdust is used for the manufacture of thermal insulation and wall materials, which contain astringent solutions. In addition, they are one of the components of partition and finishing gypsum boards. The shavings are also used for the production of particle boards.

From small lumpy waste and scraps, shavings are obtained by crushing for the manufacture of chipboard, wood concrete, etc. Large waste is used to create glued structures for various purposes (sleepers, beams, window blocks, etc.).

Eco-products from valuable wood waste:

Wood-based materials

Other wood-based panel materials are not far behind plywood in popularity. The most famous of them are chipboards and fibreboards (chipboard and fibreboard, respectively). The first ones are made from pressed shavings impregnated with different types of resins; different pressing technologies can be used, but the result is an excellent building material, the best examples of which are not inferior in quality to plywood. Fiberboard is a material similar to chipboard, but instead of shavings, the filler is sawdust and other crushed wood waste.

In addition to chipboard and fiberboard, there are other types of wood-based panels, such as blockboard, Canadian plywood (OSB), cement-bonded particle board, thermoplastic wood-based panels and many others. But they have not yet become as widespread as those listed above, although technologies are changing, and it may happen that completely new wood-based construction and finishing materials will appear, which can safely be called nano-wood construction materials!

This entire range of lumber is widely represented on the Baltic construction market on the Novorizhskoe highway, 10 km away. from MKAD

Source: baltiya-tk.ru

Advantages and disadvantages of the material

Thus, the main advantages of wood include:

- Low volumetric weight of about 500 kg/m3.

- High relative and specific strength.

- High elasticity (due to this indicator, wood can be used in earthquake-prone areas).

- Good chemical resistance.

- Excellent thermal insulation properties.

- Excellent acoustic characteristics, allowing the use of wood for the arrangement of the best concert halls in the world.

- Safety for humans and environmental friendliness.

- Easy to obtain.

- Convenience and speed of operation (from this point of view, it can be assigned a solid “A” on a five-point rating scale).

- No seasonal restrictions when working.

Disadvantages of wood:

- Differences in mechanical properties depending on the breed.

- Susceptibility to change in shape and size as a result of swelling, shrinkage, warping and other natural processes.

- Possibility of cracking.

- The occurrence of putrefactive processes as a result of exposure to bacteria and microorganisms.

- Poor fire resistance.

Returning to our rating scale, we can reasonably conclude that wood, as a universal natural material, deserves “excellent” for its affordable price, ease of use, appearance and environmental friendliness. And for durability and practicality it can be given a solid “B”.

Glued laminated timber

Wood beam is a tree trunk that undergoes a special treatment, where four sides are cut (Glued laminated timber), creating a rectangular shape, or using special equipment, you can create a different shape of the product. As a rule, timber is most suitable for the construction of houses, extensions and many other building elements. After final processing of the timber, it receives a very decent appearance of wood, retaining its shape for a long time and, as a rule, does not lose its thermal insulation characteristics. As described above, the timber can have not only a rectangular shape, but also a profiled one, which is set in the equipment during its processing. When constructing a certain object, as a rule, builders pay special attention to ensuring that the structure has the maximum characteristics of resistance to moisture in order to prevent it from getting wet in further use. The most important advantages of profiled timber are that it does not require repeated insulation, since during operation it was noticed that the structure does not lose these properties for quite a long time. It is also a very attractive price for homeowners who decide to build a certain structure, since for a reasonable price it is offered to build a high-quality and durable building.