Products called sleepers are used as supports for rails for various purposes. The following materials are used for their manufacture: concrete, wood, metal, modern synthetic materials. Wooden sleepers are considered the cheapest to produce. They were the first to be used for laying railway tracks. Wooden sleepers have a number of advantages that allow them to be used quite widely. They are used to fasten rails on main and secondary tracks. Various types of wood are used for production. The production technology and final cost depend on this. Currently, they have been replaced by railway sleepers made of other materials. However, wooden products are still used in various fields.

Reinforced concrete sleepers.

- Reinforced concrete sleeper type Ш -1-1.

- Reinforced concrete sleepers Ш1-Ч.

- Reinforced concrete sleepers Ш1-М.

- Reinforced concrete sleepers Ш3.

- Reinforced concrete sleepers Sh3D.

- Reinforced concrete sleepers Ш3-К.

- Reinforced concrete sleepers Ш3 1067/1520.

- Reinforced concrete sleeper Ш3-D 4x10.

- Reinforced concrete sleepers Sh3 SD.

- Reinforced concrete sleepers ShS-ARS.

- Reinforced concrete sleepers ShS-ARS-K.

- Reinforced concrete sleepers ARS M.

- Reinforced concrete sleepers ARS-Ch.

- Transformer sleeper SHT-12

- Transformer sleeper ШТ-27

- Reinforced concrete sleepers Sh-3-D750 for children's railway.

Beams BRP for crane tracks.

- Reinforced concrete beam BRP 62.8.3-32.

- Reinforced concrete beam BRP 62.8.3-16.

- Reinforced concrete beam BRP 62.8.3-22.

LLC “Company “PromPutSnabzhenie” provides enterprises and construction organizations with everything necessary for the construction of railways and tracks in any quantity.

- We buy illiquid assets, leftovers. Let's look at the railway. branch.

- Urgent information from warehouses.

- Special conditions for the countries of the customs union: Kazakhstan, Belarus and Kyrgyzstan.

Meaning of the word sleeper

Examples of the use of the word sleeper in literature.

Teacher fists grow from the soles of the feet these are unborn fists failed failed fists bam bam right right left right Mondini nice guy that's great the shadow of my coat blown by the wind bandaged hands flailing the air I got them all I'm running with bandaged hands you don't have to fight what the hell all the fight you always fight this is what I like in boxing a fight without end when you run when you eat when you jump over a rope when I tie my shoelaces when I sing before a meeting it would be nice to run with gloves before a meeting how great it is my shadow is impossible great Larry Larry Lower Larry Lower against Stanley Poredy what the fuck bam bam uppercut bam Poreda shitty name bam I'll cut my hair down just a little bit just a little bit longer on my head everything sticks out touch it here Jody she laughs puts her hand on my head I want a nightgown with the word Lower got it Larry Lower on Gorman’s place you understand of course you understand bam Mondini will say what crap this is all Mondini bam bam doesn’t want to understand anything go to hell L

But they were not satisfied with this and carefully examined the entire base area under the sleeper and if any violation of the ballast layer was detected, they carefully excavated it.

“It’s not true,” the tall Red Army soldier in the Budenovka uniform said calmly, pushing aside the sleeper with his foot.

And all around there were several craftsmen perched on old springs, on rusty axle boxes and on sleepers.

Immediately, you hear, immediately send the sleepers back and find the bunglers who sent the sleepers instead of firewood.

I found partisans in the vicinity of Dyatkov, and they, despite the documents presented and the saved patch with a sleeper, put Serebryakov in charge of a machine gun for testing.

Musya, captivated by Karpov’s story, vividly imagined how at night she crawls up to the canvas with such a wooden box, in which an unimaginable destructive force is concentrated, how, muffling her breathing, she listens to the silence, transfers black stones, sticky from fuel oil, onto the raincoat, digs the creaky sand, places the box under the sleeper and...

A flat-backed old man, wearily lifting a heavy cleaver, was chopping a half-rotten sleeper.

The smells of smoldering slag in the depths of dumps, scorched creosote sleepers in places where furnaces were cleaned, the machine smell of large twin locomotives and steam swirling around them always excited and attracted the boy.

The smells of smoldering slag in the depths of dumps, scorched creosote sleepers in places where furnaces were cleaned, the machine smell of large twin locomotives and steam swirling around them always excited and attracted the boy.

He gave them to the peasants for the work of hauling long logs from the logging site, which they put instead of sleepers.

For the craftsman himself only gets the opportunity not to carry logs to the saws and not to roll balans - sleeper blanks, a small part of the tea falls to him, and he works from morning to night.

The gray concrete ties of the single-track stretched out for miles, as if they were trying to reach the edge of this desolate area.

Not all numbers will be included in your program,” says Paisley, chewing on a piece of railroad sleeper.

But he is ready to give up everything until the last pfening and run at night along the sleepers to the Soviet border.

Source: Maxim Moshkov library

A little bit of history.

The word sleeper came to us from the Dutch during the time of Peter I, when more than a hundred years remained before the appearance of the first railway. And the original meaning of the word “sleeper” meant “support” (from the Dutch spalk).

Over time, the concept of “railroad sleeper”, and from a certain point onwards, this term has been used to designate specialized supports for rails, made in the form of beams. These beams are laid on the ballast layer of the upper track. It is the railway sleepers that take on the pressure that the rails create, while the intermediate fastenings transfer the pressure to the under-sleeper base.

Initially, wood was chosen as the main material for the production of railway sleepers, since it is a material available on an industrial scale and is easily processed.

Sleepers in the subway

In the Moscow Metro, on closed sections of the track, block sleepers made of pine wood of types I and II, impregnated with creosote, are used. Reinforced concrete sleepers are used in open sections of lines. The length of the sleepers is 270 cm, the cross section is 16x25 centimeters. At metro turnouts, bars with a length of 270 to 675 cm are used. At stations, so-called “sleeper shorts” 90-100 cm long are used to create a safety trench.

In the first stage of the metro, 1,600 sleepers were laid on the straight section of the track, 1,760 on the curve, from the second to the fifth stage the number of sleepers was increased, amounting to 1,680 and 1,840, respectively. During the construction of the ground part of the Filyovskaya line, the number of sleepers was further increased and amounted to 1,840 and 2,000, respectively.

Wooden sleepers

Made of wood, sleepers have good adhesion to crushed stone ballast and low sensitivity to temperature changes. Wooden sleepers

have such advantages as: ease of processing, elasticity, good dielectric properties, low sensitivity to temperature fluctuations, excellent adhesion to crushed stone ballast.

The most important property of wooden sleepers

is the possibility of increasing the rail gauge in curves, the radius of which is less than 350 m. One of the main disadvantages

of wooden sleepers

is that they are susceptible to rotting (especially in those places where they are attached to the rail).

The relevance of the problem becomes more noticeable if we consider that for the production of railway sleepers from wood, pine is mainly used, which is not highly resistant to rotting.

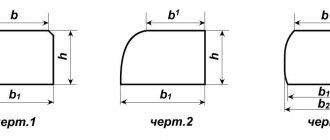

Overall dimensions and weight of wooden railway sleepers

The accepted standard establishes the geometric dimensions of a wooden sleeper. For all types, the sleeper length is set to 2750 mm. The permitted tolerance is 20 mm. The weight of the wooden sleeper will depend on the other dimensions. The height varies from 150 mm for the first type to 105 mm for the third. The width is determined by the shape and design. These parameters determine the purpose of the railway sleeper and its operating conditions. How much the railway option weighs depends on all the listed parameters. After impregnation, the weight increases slightly. The weight of one sleeper depends on its design. The mass of a wooden sleeper of the first type is 85 kg. It must withstand the heaviest loads. The weight of the second type does not exceed 80 kg. The dimensions of wooden sleepers in the standard are specified taking into account the condition of the wood. Humidity should not exceed twenty-two percent. Therefore, sleeper sizes may differ in one batch, but within tolerance. Before production begins, the dimensions of future products are set. Particular attention is paid to this parameter thickness. It must be constant along the entire length.

Geometric characteristics (sizes of sleepers) and classification are given based on the requirements established by the state standard. For example, GOST 78-2004 wooden sleepers for broad gauge railways combines all the characteristics of finished products. For special routes, their own standards have been developed. GOST 22830-77 wooden sleepers for the subway specifies the individual parameters necessary for their operation in these specific conditions. Each standard is consistent with other guidance documents consistent with the operating rules of the various tracks. GOST imposes certain restrictions on wooden sleepers regarding their area of application. Particular attention is paid to the choice of coating that is applied to the surface to improve their technical characteristics.

READ What is lumber?

Impregnated wooden sleepers

To extend the service life of railway wooden sleepers, they are specially treated using impregnation with coal oils (such as creosote) or special antiseptics.

Impregnated wooden sleepers

are little susceptible to rotting, but at the same time retain one of the best properties of wood - excellent adhesion to crushed stone ballast and low sensitivity to temperature changes. The service life of sleepers (depending on what type of wood is used, the intensity of use, and external conditions) ranges from seven to forty years.

In the 60s of the last century, a worthy alternative was found to impregnated wooden sleepers - reinforced concrete sleepers.

Steel sleepers

Steel sleepers are made from bent steel profiles and are relatively light in weight. Such sleepers are sometimes used for temporary access roads and branches of industrial enterprises. Their advantage is that they are not susceptible to rotting and insect attacks, and they maintain track width well, but the big disadvantage is that they are susceptible to corrosion.

Steel sleepers are used on the railways of Morocco and Algeria. As you know, these countries have a very dry climate (even on the coasts). In Saudi Arabia, where steel sleepers are also widely used, the main reason for their use was the constant theft of wooden sleepers by Bedouins for fires.

Metal sleepers are also used in blast furnace and steelmaking in those areas where, due to high temperatures, wooden sleepers burn, and concrete delamination occurs in reinforced concrete sleepers. In addition, metal sleepers make it possible to construct the upper track structure with increased axle loads on rolling stock - up to 60 tons (axle loads on Russian Railways rolling stock up to 25 tons).

In Russia, steel sleepers on the public railway network are used only in some sections of the Kaliningrad railway.

Laying railway sleepers

The total length of the sleepers depends on the width of the rail track. In Russian production, reinforced concrete sleepers are used whose length is 270 centimeters and wooden sleepers with a length of 280, 275, and 300 centimeters. Under the turnouts themselves, types of sleepers are laid - turnout wooden beams, the length of which takes up to the total length of 2 sleepers.

The number of sleepers per 1 km of railway track is called the sleeper laying diagram. This value in different countries ranges from 1,000 to 2,200 sleepers. The general standard values for Russia are 1840, 2000, 1600 or 1440 sleepers/km. Typically, a diagram of 1840 pieces/kilometer is used (46 sleepers per 25 meters).

When choosing sleepers, you should pay special attention to the expected operating conditions and, in accordance with this, select the quality, type and material of the sleeper.

Our catalog contains products from the factory, some old ones and some used ones.

We provide certificates. Delivery is carried out by containers, wagons and vehicles to any point in Russia and the CIS. Pickup from the company's warehouse is also possible. All calculations and delivery times are regulated on an individual basis.

Part I. Sleepers: facts.

The constant replacement of railway sleepers and the modernization of tracks with the replacement of types of fastenings with more modern ones is carried out everywhere in Russia. The market for railway sleepers in the country is huge. According to JSC Russian Railways for 2015, the length of railway tracks is 85,200 kilometers. This means that with a diagram of 1840 sleepers per kilometer, about 157 million pieces of railway sleepers were laid along the way. But to this we must add non-public access roads, owned by third-party organizations, and amounting to about 40,000 kilometers, which additionally gives an average of 64 million sleepers.

It would seem that these bars lying under the rails are an unremarkable element of the upper structure of the track. But they are the real backbone of the railway.

Every year, tens of thousands of sleepers are manufactured and distributed throughout the country to meet the industry's needs for new, modernization and repair of existing tracks.

In the very early days of railway development, wood was the dominant material used in the manufacture of sleepers. During the 20th century, new materials began to be used in response to the need to accommodate increased axial loads and high speeds. Today there are the following types of railway sleepers:

- Wooden sleepers

- Reinforced concrete sleepers

- Metal sleepers

- Sleepers made of synthetic materials

- Composite sleepers

Next we will look at the advantages and disadvantages of the materials proposed for use.