Industrial waste present in wood processing plants, sawmills and furniture factories has become widespread in many areas of activity. Crushed sawdust is used in the construction and agricultural industries, while the raw material is ground to the smallest state, with a structure reminiscent of flour. Wood flour is a product of processing natural wood and its derivatives. The popularity of recycled wood is explained by its low cost, while the performance qualities of products made from wood powder are much higher than those of synthetic materials and composites.

What is wood flour?

Wood flour or wood dust is very small particles of wood of arbitrary shape, which are obtained specifically in the process of grinding hard and soft hardwood and softwood varieties.

Since the beginning of the 20th century, the production of wood flour has grown at a fairly rapid pace. There is information that in the first half of the last century, global production of wood flour reached 100 thousand tons.

The main direction of use of wood flour in the initial period of its production was the creation of products from phenolic plastics, such as bakelite, carbolite. Before the invention of PVC and polyolefins, wood phenolic compounds were used to make a large number of products for civilian and military use. They are still popular in a number of industries today.

A large volume of wood flour is used, for example, to make linoleum.

The raw materials for the production of wood flour are, most often, lump waste from timber and wood processing industries, sawdust and technological chips, which are obtained from firewood.

Recently, the raw materials for creating such flour are other types of plant materials, for example, straw and stems, grain husks, nut shells, cardboard waste.

Sales of the finished product

At the beginning of your activity, you should focus on consumer enterprises operating in your region. This way, you will minimize shipping costs and be able to offer better prices than “non-local” suppliers.

As production volumes grow, expand your supply geography. Wood flour is used in large enterprises for the production of a number of polymers, building materials, road surfaces, and glass.

It is also worth paying attention to retail buyers. In everyday life, natural material is used in low-rise construction, for growing mushrooms, and as bedding in chicken coops and pigsties. Place advertisements in the private sector, newspapers, and the Internet; the consumer will not have to wait long.

The main qualities of wood flour

Wood flour is fine wood. Particle sizes do not exceed 1.2 mm. The color range of wood flour depends on the type of wood and ranges from light straw to dark brown.

Wood flour particles have random, irregular shapes. First of all, this is due to the peculiarities of the structure of timber, as well as to the fact that the procedure for crushing particles in working mills is carried out as a result of random multilateral actions - compression, displacement, blows, collisions.

A more specific fractional composition of wood flour in each delivery depends on the type of grinding and classification of particles (centrifugal, sieve). According to the document GOST 16361-87, there are several grades of wood flour:

- light-colored phenolics are created from grades 120 and 160

- grades 140 and 180 are used to create phenolic plastics, industrial explosives, polymer composites and building materials

- grade 200 is used to create alkyd linoleum, building materials, and also in starch production

- Industrial explosives are created from grade 250

- Pigment titanium dioxide is created from grade T

- Filter elements and catalysts are created from grades 560 and 1250.

It is worth noting that flour grades 120 and 160 are created exclusively from coniferous wood. Flour grades 140, 180 and T can contain up to 5% hardwood. Flour moisture content should not exceed 8%. In some cases, a different humidity may be needed. For example, to be used in the production of thermoplastic WPC, flour must have a moisture content of less than 1%.

Wood undergoes almost no chemical transformations during the production of wood flour. For this reason, the chemical composition of wood flour completely coincides with the composition of the original wood, and wood flour can be called a completely natural material.

Wood flour has pronounced sorbing qualities, as well as thixotropic qualities, that is, it smears, but does not flow.

Material characteristics

Wood pulp with a mealy consistency has many positive properties. This version of the material has characteristics determined by the following features:

- In accordance with the approved GOST 16361-87, 9 grades of flour from wood residues are determined: 120, 140, 160, 180, 200, 250, T, 560, 1250. Each option has its own distinctive features, which are determined by chemical and physical properties and composition.

- A completely natural base, without the use of chemical impurities, makes the raw material completely safe for the life and health of animals and humans at the time of contact.

- The ground base may vary in color depending on the type of tree used. It is usually yellow, gray or brown.

- The bulk density can be approximately 100-220 kg/m³. At the same time, wood flour 180 has an indicator of 100-140 kg/m³. this parameter depends on the humidity of the base raw material and the size of the particles.

- The standard dust moisture content should be 8%, but in some cases a moisture content of 1% may be required.

- Has good hygroscopic properties. By absorbing excess moisture, it helps improve microclimatic conditions in the room.

- Does not lose all properties during the period of use. Can perform a given function under the influence of any extraneous factors.

- Wood dust absorbs and has thixotropic properties.

- Raw materials ignite at temperatures exceeding 200 °C. It has a fairly high stability at the moment of ignition. Therefore, it is difficult to put out the fire.

The raw material is a completely natural material, since it does not undergo chemical influences at the time of transformation.

GOST 16361-87 Wood flour. Specifications

1 file 180.15 KB

Packaging and transportation of wood flour

Wood flour absorbs moisture very easily. To prevent this from happening, it is packaged in thick paper or plastic bags, sacks, as well as “big bags”, plastic containers, for example, buckets, barrels, containers. Foreign products, especially those supplied for retail sale, often have artistic, colorful packaging.

Transportation of small packages is carried out by combining them into a transport place on wooden pallets and transporting them by covered transport. A typical 40-foot container can hold approximately 16 tons of wood flour. Therefore, transporting wood flour is not a difficult matter.

To carry out regular transportation of bulk flour, you can use special vehicles and wagons - flour trucks. If such a need arises, wood flour can be compacted by briquetting or granulating.

Product brands

According to the standard, wood flour is divided into 9 grades, each of which has a selective numerical designation from 120 to 1250, with the exception of one grade, designated by the letter T.

Numbers are an integral indicator of several characteristic parameters expressed quantitatively. The products of each brand have a strictly defined color indication on the packaging, approved by the national standard. Different types of wood flour have a specific scope of application, in which the characteristics characteristic of a particular brand are in demand.

Note! All products have a moisture concentration not exceeding 8%, the mass fraction of mineral impurities is from 0.6% to 1%.

The range of permissible content of coloring pigments is wider: from a minimum value of 0.1% to a maximum value of 4%.

Wood flour may contain metallic components with magnetic properties in quantities measured in thousandths of a percent.

The bulk density in flour with a marking of up to 180 can reach 140 kg/m3. For products of other brands, this indicator is not regulated by the standard.

Wood flour contains organic acids in an amount of no more than 0.8%, resin and oily substances in a concentration reaching 5%.

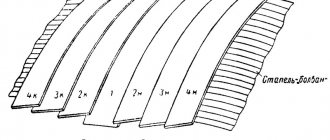

The standard provides for control of the fractional composition by step-by-step sifting through sieves with three different cell sizes. For each brand, the permissible amount of residue on the screens at the next stage of sieve analysis is indicated. Wood flour is so finely divided that it can be spread onto the surface. This is due to its thixotropic properties.

Important! Due to the high concentration of organic matter in the product, it ignites when surrounded by air at a temperature of 200 ℃, and if the influence of several factors coincides, it can spontaneously ignite at the same time.

Wood flour can absorb moisture from the environment, so it is packaged in thick bags, containers made of plastic or multi-layer paper.

Applications of wood flour

Today, wood flour is widely used in various industries both in our country and abroad.

Wood flour is used as:

- component for creating titanium dioxide pigment

- additives in the process of coating welding electrodes (electrode cellulose)

- additives in the firing process of ceramics and bricks

- additives for porous abrasive products

- additives for plastering and finishing building mixtures (dry mixtures, mortars, pastes), concrete, putties

- additives for concrete and plasterboards, concrete and composite road surfaces

- additives for adhesive compositions based on natural and artificial adhesives

- filler in the production of natural and synthetic linoleum and linkcrust

- bases in the production of press powders and press compounds, as well as compounds from thermosetting resins

- components and raw materials for creating various explosives

- filler for the production of adhesive mastics and sealants for parquet and roofing materials

- basics for filters and filter materials

- raw materials for creating activated carbons

- cleaning agent in the process of creating leather and fur

- substrate basics in industrial mushroom cultivation

- raw materials in the process of smoking fish and meat.

Today, interest in the production of wood flour is spurred by the growing popularity of a new direction for its use - the creation of thermoplastic wood-polymer composite materials (WPC), in which it occupies at least 80%.

Business profitability

Provided that sales and supplies of raw materials are well-established, investments in the production of wood flour can pay off in 1.5-2 years. To purchase equipment, the first batch of consumables and set up a workshop, you will need from 1 million rubles. A small business based on used low-power equipment can be set up with at least 500,000 rubles on hand.

When developing a business plan, you should focus on the size of the actual starting capital and the purchasing power of the market in a particular region. In other words, it makes no sense to invest in large-scale production if interested wholesale buyers are not found at an early stage.

The profitability of the business will depend on the productivity of the workshop and sales volume. On average in the Russian Federation, the wholesale price of wood flour is from 10 rubles per kilogram. An average-capacity enterprise can produce up to 20 tons of products within a month.

Technology for creating wood flour

Wood flour is obtained by grinding wood, in devices for continuous or periodic operation, from dry and clean industrial chips and sawdust.

Since timber is not the hardest and most durable product, its grinding is carried out in a variety of types of mills. Note that the classification of flour particles can be carried out both inside the unit and on external classification devices (sieve, air). Grinding is carried out in one or several stages. Special devices have also been developed for drying wood flour.

Naturally, the final result of grinding (energy consumption, productivity, uniformity of the fractional composition) differs not only depending on the type of mill, but also on the perfection of the device, i.e. the experience of its developer in processing wood flour.

Today, grinding devices for creating wood flour are compact in design and do not require large areas. Equipment for the production of wood flour can have a unit capacity from several kilograms to several tons per hour.

The creation of wood flour is not accompanied by the release of toxic substances, however, one should not forget about certain safety measures, namely, respiratory protection. Just like wheat flour or starch, wood flour is fire and explosive. Therefore, it is worth following appropriate measures for its safe production, storage and use.

In production, flour is stored in special dry rooms in bags, containers or in bulk, as well as in silos, bunkers and elevators.

Production

At the first stage, raw materials are selected; they must meet standards, have low humidity, and be free of bark and chemicals. Next, the raw materials are prepared for the start of production, wood waste is selected and sorted. Afterwards, the selected residues enter the mill, which grinds them into flour. Next, the crushed waste is sorted and excess fractions are eliminated. The mass is then transferred to the dryer, where the humidity is reduced to the required level. Afterwards, the already dried product is packaged and packaged in special bags or big bags.

Wood flour market

The domestic wood flour market has been actively developing over the past five years. Over the past five years, production volumes of finished products in Russia have increased by almost 57%. Domestic production decreased only in the crisis year of 2009.

After this, the volume of wood flour production shows continuous growth every year. The largest region for the production of wood flour for several years in a row has been the Republic of Mari El. The production of wood flour in Mari El fills almost 93% of the market for this material in our country.

In addition, wood flour is produced in the Kostroma and Ulyanovsk regions. But the volume of the finished product is quite low.

Search for premises and personnel selection

To accommodate low-power equipment, significant areas will not be required. However, along with the workshop itself, the organization of warehouse space, office space and sanitary facilities will be required. Thus, the minimum area for locating the production of wood flour will be 100 m². In addition, given the hygroscopicity of the material, you should take care of a high-quality ventilation system - dampness can cause damage to the finished product.

You can reduce the monthly costs of renting buildings by finding suitable areas outside the city limits. It should be taken into account that the fire inspection authorities will pay increased attention to the enterprise producing flammable materials. Therefore, already at the initial stage it is necessary to bring activities into compliance with current standards.

To launch a full-fledged workshop, you will need at least 4 workers, a technologist, two security officers (one per shift), a cleaner, and a truck driver. At the first stage, accounting and advertising promotion can be undertaken or outsourced to specialized organizations. However, with the growth of production volumes, it is better to employ relevant specialists.