Features of warm corners made of timber

The quality of a wooden house depends on how well its assembly is carried out. The more airtight a timber house is assembled, the longer it will retain heat. When assembling log houses, warm corner technology is used to avoid the formation of gaps and cracks.

Most often, the places where heat escapes in wooden houses are corners. To create a hermetically sealed connection between the beams, a special assembly technology is used to ensure tight joining of the crowns. Those who are going to build a house from timber themselves should study different types of assembling a warm corner in order to build a durable and warm wooden house.

Joining the timber with the remainder

The easiest way to join timber in the corners of a log house is “into the floor of the tree”. A rectangular groove is cut, the dimensions of which depend on the thickness of the timber and are: The depth of the notch is half the thickness of the timber. That’s why it’s called “half a tree”.

The “tail tail” method is distinguished by the presence of an additional tenon, which provides a stronger and more reliable connection, but requires more carpentry skill. More difficult is connecting the timber into an okhryap. Here you cannot make a mistake when calculating the width of the jumper, but it is much easier to implement than on a log: the geometry here is standard and you can use a template, which significantly speeds up the work, and then an error can only occur when cutting.

We invite you to familiarize yourself with: Sauna and steam bath for and during colds 2019

Description

A warm corner made of timber is a special technology for connecting logs using tenons and grooves in a certain way. Only by following this technology can you avoid the appearance of “cold bridges” through which heat will escape from the house and dampness will form on the wood.

To assemble a warm corner, a special technique to saw off the ends of the beams, which then fit tightly together when laying the crowns. To create a good sealing of a wooden house, you must follow a number of important rules:

After assembling the crowns, you can carry out additional insulation of the corner with natural hygroscopic materials:

Correct assembly of a warm corner provides a number of advantages to a wooden house:

Assembly is carried out in different ways, which have their own characteristics and methods for cutting timber joints. Correct use of this technology allows you to build a durable and airtight house in which there will be no drafts and dampness.

Well-dried timber with properly created warm coal is less susceptible to deformation and more economical to operate.

Types of connections

Each connection method has its own mechanism and can be performed in several variants: with and without residue. Let's look at their types:

The simplest is the one-sided locking system for connecting timber. With this joining method, a cross-cut is made on the profiled wood from above. The groove is made in the shape of a square or rectangle. Sometimes it can be used to secure dowels.

A two-way connection is considered more complex. It is sawed through at the top and bottom to ¼ of the thickness of the timber. This connection makes the frame more durable and completely avoids displacement. This warm corner connection is used only on timber without defects and knots.

The most airtight and most durable is considered a four-way connection, which is not used so often due to the fact that more complex preparation of the timber is required before assembling it.

The most economical and simplest is a connection without residue, in which excess timber will not protrude from the wall. The disadvantage of such a connection is its lower strength compared to the connection with the remainder. Several types of such connections are used.

Direct and longitudinal joints are considered more labor-intensive. In this case, complex types of fastening are used, requiring special training of builders. Oblique locks are used very rarely when creating a joint, since this technology is very expensive.

Warm corner technology

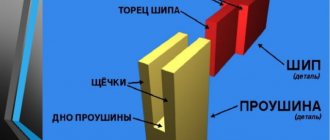

Warm corner is a method of joining lumber. To achieve a truly tight fit, a groove is cut inside the mating barrel, and a tenon is formed on the mating one. When installing such material, an almost hermetic joint is obtained.

In practice, there are only a few basic methods of cutting corners.

- “In the paw” - the beam does not protrude beyond the plane of the wall, thus obtaining an angle without a trace. The structure is assembled using a tongue-and-groove mechanism. However, practice shows that this is not enough for a corner connection. To reduce blowing, the grooves are made slightly differently. There are 3 options that involve the use of a template: butt joint - connections are achieved through the use of metal plates. The method is not the best, since any metal itself is a conductor of cold;

- root tenon - classic method. A groove is made on one of the 150*150 elements, and a tenon on the other. The patterns for them must match;

- It is also possible to assemble the timber into a warm corner using dowels - inserts made from hard wood, which do not allow the lumber to come apart. The most reliable are oblique keys.

A variation of the “in-paw” laying is the “dovetail”. The spike in this case has a trapezoidal shape. The groove must match the template exactly. Cutting it is more difficult, but the connection is much stronger. The photo shows masonry using the dovetail method.

- “In the cloud” or “in the bowl” - a warm corner made of profiled timber. Docking is done using grooves - one-, two- and four-sided. In the first case, a notch is made in the upper part of each beam in width corresponding to the cross section of the upper element. When cutting a double-sided groove, the cuts are made both at the top and bottom and the width is equal to a quarter of the height of the lumber.

We suggest you familiarize yourself with Additives for concrete in frost. Pouring concrete in sub-zero temperatures: options and their features, recommendations from experts

In the third case, the cuts are cut down from 4 sides. The implementation is more difficult, but the installation of such a “constructor” saves a lot of time and leaves no chance for the wind. The photo shows the working moment of installation.

For additional tightness, the corner is duplicated with inter-crown insulation - flax tow, moss or jute insulation.

Cutting timber into a warm corner provides a number of advantages that are highly valued by builders:

- if the template and dimensions of the grooves and tenons match exactly, the joining is very tight and reliable;

- a warm corner provides the maximum thermal insulation possible when using wood as a material;

- installation is carried out without additional fasteners. And this means a reduction in costs and the absence of cold bridges into which metal fasteners turn;

- since profiled timber 150*150 is prepared in advance, the assembly of the house itself is carried out in an extremely short time;

- the house looks extremely neat and tidy.

The only disadvantage is the slightly higher cost of such material. The video demonstrates the laying of 150*150 profiled timber according to a template.

How to do it yourself?

When assembling from finished profiled timber 150x150 or 100x150 mm, it’s easy to make a warm corner with your own hands. If the timber does not have locking grooves, you will have to make the correct cut of the required size according to the template. If the cutting is done with your own hands for the first time, it is done according to a stencil or template so that the dimensions of the grooves are the same.

Those who do not know how to work with an ax will have to file the grooves, guided by the drawings. Before starting work, you should master the technology of connecting timber “groove to groove” in crowns. Before installation, you need to do a little preparation by checking the fasteners and joints. The blanks from which dowels and dowels will be made are treated with an antiseptic and dried.

For the first three crowns, the most even timber without knots or other defects is used, with a geometry ideal for a strip foundation.

For novice carpenters, it is best to use the simplest method to create a warm corner, which does not require cutting out mortises and tenons.

In this case, the beam rests with its end against the side surface of another log. In corner joints, metal brackets or pins help, which must be coated with drying oil before use.

A lock connection will be more reliable when a tenon is inserted into the groove. The installation in this case is more durable and airtight. Before this, using templates, grooves and tenons are created at the ends of the beams, which are then used to tie the crowns in the corners. To make the seam more airtight, you need to knit it using insulation, placing it between the logs. In this case, the groove must completely correspond to the tenon so that the masonry, for example, 18x180 mm, is airtight.

Alternating cuts along the crowns

To increase the strength and density of the connecting segments, round wooden dowels should be used. Lay joints with a lock, alternating even logs with a tenon, and odd logs with a groove.

The first corner connection is made using a dressing with a half-tree root tenon. The following crowns are attached using the ligation technology with the lowest beam - then it will fit tightly into the lock. Afterwards, the connection should be strengthened using a dowel with the lower and upper rows.

A tenon is made in the first beam 1/3 of the width of the beam. In other crowns, the width of the tenon should correspond to the width of the groove.

Marking diagram for creating joints of a log frame made of 6x9 meters of timber: letters A and C indicate longitudinal walls, D and B – transverse walls, E – internal partition; number 1 – timber joints.

When erecting crowns, you should avoid splicing and longitudinal connections of timber, which will not be strong. Professionals suggest that novice carpenters choose a straight tenon to connect timber.

To use it, you need to create a template where you need to provide 5 mm gaps for the insulation. The cut on the tenon must be done from the side that will look inside the log house. Other walls should have spikes with left and right cuts. To do this, you just need to turn the template upside down.

You can strengthen the connection using a wooden dowel, placing it diagonally from the edge of the outer corner.

When making a warm corner during the construction of a country house or bathhouse, site owners who do not have carpentry experience should purchase ready-made timber with grooves or tenons, which will cost more than usual. You can also invite qualified craftsmen who will process the ends using the tongue-and-groove system and assemble the frame without technical errors.

In the next video you will learn about innovations in the corner connection of profiled timber.

Source

Materials used

Forming the corner of a house is an indispensable part of the wall laying work, and it is also the most difficult, since the shape of traditional lumber does not require special devices for this. This problem, of course, was also encountered during the construction of log structures and was solved through different assembly methods. So all the methods used today have stood the test of time.

We suggest you familiarize yourself with How to insulate a pipe in a bathhouse: how to wrap and secure a metal chimney pipe, insulation from the ceiling, how to do it in a sauna, what to wrap or cover with, photos and videos

Modern builders rarely deal with logs, but lumber for houses is used very widely.

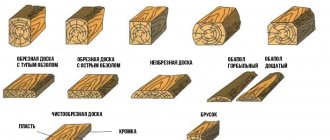

- Planed - has 2 opposite or 4 planes, thanks to which the material can be laid quite tightly.

- Profiled - in addition to the fact that the 150*150 beam has a clear geometric shape and size, grooves and protrusions are formed in it, allowing for a much more dense and reliable joining of the material. This option itself provides better thermal insulation.

- Glued - made by gluing wooden lamellas under pressure. In terms of strength and density of masonry, it does not differ from profiled masonry. However, it has another valuable quality: it practically does not shrink. This means that over time the density of the masonry does not change and there is no need for additional thermal insulation.

Advantage of lumber: it is much easier to make additional grooves here.

Attaching timber to dovetail

It is believed that the dovetail lock has maritime roots; the dovetail was used to secure ships with a wooden hull. This connection turned out to be the most resistant to wet wood and multidirectional loads caused by rough seas. The main advantage of the technology is the reliable joining of wooden parts without the use of additional fasteners; the reliability of fastening is ensured by the lock of the original trapezoidal shape. The tools of ship carpenters included a special saw called a “dovetail.”

Traditionally in Rus', the crowns of a log house were placed “in a bowl”; such coupling was cut out with an ax. With the advent of high-quality carpentry tools, the log house began to be laid “in a paw”; the joint had a rectangular tenon. A further improvement to this lock was the use of a dovetail tenon with a trapezoidal profile.

The dovetail technology for fastening beams has become the main one in industrial housing construction; standard sizes and connection features are determined by GOST 30974-2002. The introduction of the standard has created favorable conditions for the development of low-rise housing construction; domestic industrially produced wooden houses are not inferior in quality to Finnish models.

The standard establishes the types of dovetail joinery:

A distinctive feature of these types of fastenings is the tongue-and-groove design, which has a trapezoidal shape with a straight base.

Length extension

The length of industrially produced timber is determined by GOST 24454-80; of the many sizes of timber, 3- and 6-meter blanks are most in demand. When splicing, the ends of the joined beams are secured in various ways:

- Half-tree connection;

- On the root thorn;

- Straight patch lock;

- Oblique patch lock;

- Oblique cut.

The choice of fastening for the connected beams depends on the tasks at hand. For decking, a straight lock is used; for vertical supports, a half-tree or tenon lock is used; for the construction of 3D structures, oblique locks are used. Locks are reinforced with building brackets, dowels and dowels; bolted fastenings are used for load-bearing supports.

https://www.youtube.com/watch?v=YXx07XTHf2U

The longitudinal installation of timber roof rafters has its own characteristics - it is necessary to take into account the impact of multidirectional loads. For the connection, an oblique cut is used, reinforced with bolted fastening with a diameter of 10-12 mm.

Connection "in the paw"

Fastening the timber “into the paw” is the easiest way to build a log house; reliable grip is ensured by a trapezoidal tenon, which is cut out at the end of each row of the crown. A correctly made and assembled lock reliably fixes the crowns of the log house in all planes. The fastening is universal, it is used for the construction of a log house from timber and rounded logs; the “claw” connection is most often used in shrinkage construction.

The design is distinguished by the absence of ends protruding beyond the corners of the building; such a lock is called a “clean corner”. The spike in this design is a load-bearing element and carries the main load. To build a log house in a “clean corner”, it is recommended to use timber of the maximum standard sizes, with a side of at least 250 mm.

Blind frying pan

This method in construction practice makes it possible to fully use the advantages of trapezoidal fastening; a special feature is the hidden T-shaped groove-tenon connection. The size of the tenon does not exceed half a beam and is completely recessed into the body of the beam. The corner of the house assembled using this technology is called the “warm corner”. The lock provides reliable adhesion to the crown without through gaps; when treated with construction sealant, it creates a completely sealed space. The beam is built up in the same way if its length is less than the length of the wall.

Sawing of the profile is carried out according to the drawing using a circular and axing saw. A rectangular blank for the tenon and groove is cut out with a circular saw, and the given shape is given with a special hand saw. To cut the groove, you can use a hand cutter; it is easy to equip the workplace yourself.

Advantages of the blind “frying pan” fastening technology:

The main feature is the increased requirement for wood moisture content - lumber should have a moisture content of no more than 20%. The technology is widely used by manufacturers of turnkey houses.

Open frying pan

This method is used in the construction of internal partitions from timber, laying joists for floors and ceilings. The groove is cut across the entire width of the beam. The lock resembles a “claw” connection in the T-shaped version and ensures fixation of the structure in the horizontal plane. This mount is simple and can be cut with a circular saw and processed with a chisel.

A simplified version of a frying pan lock is a profile in the shape of a rectangular trapezoid; the fastener is called a semi-frying pan. This fastening is designed for damper wood and is popular with individual developers.

Methods for fixing materials together

The construction of structures from wood material has been successful for thousands of years. During this time, several optimal and ingenious options for fastening raw materials in the corners and longitudinally (that is, lengthwise) were developed and implemented, which are relevant for both profiled timber and regular timber.

As was said, when constructing an object, the beams can be fixed to each other along the length and at the corners. What's the difference? The fact is that corner fastening is used in the construction of solid walls and attractive internal partitions in the room. A lengthwise fixer is used when the material needs to be built up. Like this? Well, look: there is a log 4 m long, and the size of the wall indicated in the project is 6 m, in this case, you need to lengthen the raw materials.

disassemble and assemble structures, make temporary flooring.

Reinforced floors are used in warehouses, sports and entertainment complexes. To hold lumber together indoors, synthetic glue is used; when finishing the interior, the timber is fastened with a longitudinal dovetail key.

Fastening with trapezoidal key

The dovetail connection scheme was further developed in a keyed connection. A butterfly dowel formed by two trapezoidal shapes is made from hardwood. The groove is cut on modern milling machines. With a dovetail keyway, the fastening dimensions are minimized, but this design ensures reliable fastening of wooden structures of any complexity and allows the production of wood products to be streamlined.

Features of keyway technology:

Dowel fastening is used by manufacturers of finished wooden houses made from expensive laminated veneer lumber and allows the implementation of the most complex house designs.

Features of the “half-tree” node

The “half-tree” design bears this name because the cuttings that are made in the timber are half the size of the section. Half-tree installation is carried out mainly in the corners. It is possible to connect the timber in length in this way, but you need to use dowels for fastening.

For a corner connection, a notch is made at the top of one link and at the bottom of the other. To make the connection more durable, wooden bushings are used, which are mounted at the end of the cutting. Another option is oblique cutting, this option is shown in detail in the diagram below.

This corner fastening is used for residential construction, for example, for the construction of a house from profiled timber, only after carefully insulating the joint. In order to reduce the ventilation of the structure, the cuttings are made not at right angles, but with a slight slope.

Any of the listed types can be used for a T-shaped connection. But the most appropriate and cost-effective are those that do not require allowances, for example, “root spike”, “dovetail”.

How to make profiled timber with your own hands

Every year the range of lumber is only increasing, and the types of products for building a wooden house or cottage are becoming closer to ideal. But what to do with simple non-profiled timber, which is gradually being replaced by its brothers - laminated veneer lumber and profiled timber. After all, using an inexpensive version of edged timber is much cheaper. Craftsmen solve this problem in their own way.

How to make profiled timber with your own hands, saving money?

There are several options for making profiled timber from ordinary timber, which allows you to save money and obtain higher quality material for construction. All you need is a little patience and free time, as well as the ability to handle some tools.

Many people ask questions: “Is there any point in making profiled timber with your own hands?”, “Maybe it’s easier to buy a ready-made one?” Of course, buying ready-made material is much easier. However, there are many reasons why the production of profiled timber is especially important:

Which profile is better?

When choosing a profile, it is better to calculate your skills and strengths. Making a profile on a block on your own seems like a simple matter. It takes a lot of perseverance and time to carry out such a task more efficiently. When choosing a profile, you should focus on the simplest designs. To implement them, you don’t have to use many types of tools and you don’t have to do a lot of calculations.

Adviсe

A log house is the most common option for constructing such a building. The assembly process itself takes a little time, especially if all the preparatory work was carried out efficiently.

Although it is possible to build such a house yourself, it is better to consult with an experienced craftsman before starting work. It is necessary to take into account every little detail, because the strength and safety of the new building may depend on it.

Of course, reviews about this cutting method are contradictory. But it is supported not only by its obvious, well-known advantages, but also by the fact that this method is still the most common, despite certain difficulties and disadvantages inherent in it.

A reasonable approach to business, strict adherence to all the necessary rules will help you successfully complete this work and get a warm, cozy, durable and safe log house.

See below for information on how to cut into a paw.

Tags: beam, paw, template

« Previous entry