Reasons to choose timber for building a house

Timber made of wood eliminates some of the properties of wood that complicate the construction process and make it more labor-intensive. The beams are made of a standardized profile and length. You can quickly build a house out of it. If you carefully calculate the required volume, you can avoid unnecessary waste of material, which will significantly reduce the estimated cost of construction.

Glued laminated timber is not subject to shrinkage and does not crack due to exposure to the surrounding climate. It does not lose its properties during long-term use. When laying timber with flat edges, a smooth wall is formed; it can be easily covered with finishing material or insulation.

How to choose quality material?

To avoid getting into trouble, it is important to visually check the product for quality during the purchasing process. To do this, the timber is placed with all its edges one at a time on a flat surface, checking it for the presence of bending and inversion. The growth rings visible on the end section are also important. There should be an equal distance between them - this is a guarantee that over time the timber will not begin to bend.

The color of the wood should be uniform on both the side and end faces . If it changes noticeably, it means that there are layers with different internal stresses, which indicates future deformation of the material.

Visually determining the moisture content of timber is quite difficult. If you have doubts, you can carry out additional drying of the beams on your own. This will take some time.

Types of timber for building houses and sizes, advantages and disadvantages

Let's figure out what types of timber are used to build a house. There are 4 types of material:

- non-profiled from solid wood;

- non-profiled glued;

- profiled from solid wood;

- profiled glued.

Ordinary construction timber

This option represents a blank made of logs with planed side semicircular edges. They are given a square cross-section, with a side size from 100 to 250 mm. Before use, the material is dried under natural conditions.

Beams of different sizes are selected depending on the purpose of the future structure Source kar-as.ru

Its use in construction cannot be called the best solution. Suitable for the construction of simple building structures. It has certain disadvantages, we list them:

- Naturally dried wood is subject to shrinkage, warping and cracking during use;

- loose connection of the bars to each other leads to the need to insulate and seal the gaps between them after some time;

- the material is not subjected to finishing, so it is necessary to finish the surfaces to get a beautiful and neat wall;

- requires additional strengthening of load-bearing walls and corners of the house;

- impregnation with special compounds is necessary to impart fire and bacterial resistance to the structure.

Of course, this is a fairly cheap and widely available material. If you are willing to incur additional costs to refine it to the required qualities, then this option will be quite acceptable.

Profiled timber

The same whole logs are used for it as for regular planed logs. Processing is carried out on woodworking equipment with precise settings. It allows you to get a perfectly smooth surface and ideal dimensions.

Profiled timber allows the material to adhere tightly to each other and, during the operation of the house, to prevent drafts between the cracks Source walls-club.ru

The process differs in that the sawn logs are first dried to 22% moisture content or less, and then further work is done with them. The connecting planes have a comb or tongue and groove. When the comb touches adjacent bars, a tight joint between the crowns is obtained. The tongue and groove allows insulation to be placed in it, which creates a tight connection of the crowns that does not allow air and moisture to pass through.

Among the disadvantages of such a material, they note the preservation of wood defects that can exist inside the log, and the mandatory time for shrinkage, since it is inherent in all types of wooden structures.

See also: Catalog of double-timber house projects presented at the Low-Rise Country exhibition.

Glued laminated timber

This option has a calibrated cross-section, the connecting surfaces are made in the form of a comb or spike. Sometimes it is given the shape of a rounded log - D-beam. Externally, a wall made of it looks like a natural log wall, which is very popular now.

A house made of laminated veneer lumber is ready for use much faster, but it is important that the gluing of the lamellas is carried out with high-quality glue Source nkkconsult.ru

This material is made of separate wooden plates, they are glued together with a special glue under pressure. It has a number of positive aspects, namely:

- A well-finished surface has a finished appearance and does not require additional finishing. The presence of locks creates a dense wall without gaps.

- The design of the timber eliminates warping, it does not crack and is not subject to deformation during operation.

- The constructed building does not experience shrinkage. This significantly reduces the period of construction work.

Flaws:

- High price of the material compared to conventional timber.

- The glue included in the timber makes it less environmentally friendly.

- The microclimate in the house will differ from the conditions arising in a real wooden building. In houses made of laminated wood it is necessary to provide ventilation

LVL timber

Its production technology is similar to the production of laminated veneer lumber. Only the material used for it differs. For production, veneer is taken from various trees, 3 mm thick. In adjacent layers of veneer the direction of the fibers coincides.

Veneered timber is quite expensive in terms of cost; it is more often used for individual components of a building Source ciflorestas.com.br

It is a durable and flexible material, but very expensive. It is used to complete individual house structures. In most cases, it is unprofitable to build an entire house out of it.

Which timber is best for building a house should be determined taking into account the requirements for it and the availability of material resources from the developer. Well-dried and properly processed ordinary planed timber will serve no worse than expensive laminated veneer lumber.

What kind of timber is there in terms of humidity level?

Natural moisture timber

This is the cheapest option - the wood is delivered to the construction site immediately after processing. A beam of natural moisture can be smooth or profiled, but after shrinkage, cracks and crevices still appear in it.

All types of timber houses undergo a shrinkage process, but wood with natural moisture deforms more than others. The material behaves unpredictably: it bends, twists, cracks, shrinks unevenly, and changes linear size. The owner will have to seal the gaps, cracks, insulate the walls and begin the final design no earlier than a year after assembly.

Chamber drying timber

The material is brought to the required humidity (usually 8-14%) in special drying chambers, then processed and collected in a dry state. The shrinkage of such wood is close to the parameters of laminated veneer lumber, unless the wood gets wet during construction.

The main problem with chamber drying of timber with a thickness of more than 100 mm is cracks. To preserve the surface, it is necessary to increase the time spent in the chamber. Standard processing of thin wood is 10-12 days. High-quality drying of 150-200 mm timber lasts up to several weeks and even months. Attempts to increase the temperature and speed up the process lead to uneven drying - the wet center breaks the dry outer part.

Additional drying time and a large number of rejects (some parts crack) increase the cost of the material. The wood needs to be protected from moisture until it is covered, but the walls are deformed much less and repairs are not required after shrinkage. If you choose solid timber, then chamber drying is much better than material with natural moisture. It is from chamber-drying boards that high-quality laminated veneer lumber is produced.

| Natural humidity | Chamber drying | |

| Shrinkage time | Intensive - 3-4 months Gradual - up to 12 months | Up to 3 months |

| Shrinkage percentage | 8-12 % | Up to 3-4% |

In practice, manufacturers often use “dried” timber, that is, the material spends the required 10 days in the chamber in normal mode. The result is a workpiece with a dry surface and a wet core, which can be processed well on machines. Such wooden log houses quickly take a permanent shape, but there is no protection against deformation and cracks.

Types of beam connections

When constructing a log house, it is necessary to connect individual elements when crossing at an angle or when the elements are not long enough. Several types of connections are used.

The most popular and convenient connections are with or without residue, in a cup or in a tooth.

Connection with remainder

One way connection. One side of the beam is sawed across the element, the width of the notch is equal to the width of the attached element. This is the simplest and most commonly used method.

The connection of beams with the rest is used more often than others, and the fastening of such beams is more reliable Source pinterest.ru

A double-sided lock requires making cuts at the top and bottom of the block. Their depth is a quarter of the thickness of the element. The use of this technology creates a high-quality connection, but will require the work of experienced carpenters.

The four-way connection is the most complex and the most reliable and accurate. The cuts are made on all sides of the block. The building is assembled like a construction kit - quickly and efficiently. In this case, all dimensions must be strictly observed, the cuts are made strictly at right angles.

Connection without residue

This type has many options. Here are the frequently used ones.

Butt connection. It is carried out using studded metal plates, they are secured with nails or staples. For this purpose, connecting dowels are also used, which secure the joint well, preventing the beams from moving and turning.

In this case, it is necessary to use additional fastenings, otherwise the house may lead to the side Source orpro.ru

It is good to use a tenon connection. The spike can be shaped like a triangle or trapezoid. The root thorn is popular. A groove is cut out on one of the beams, a tenon of the appropriate size is cut out in the other. With this connection, you can use insulation made from vegetable felt or jute fiber.

Material for making timber

Pine

The most affordable type of wood. When using pine, it is important to organize full incoming and production control - the lumber can contain defects in the form of resin pockets, chips, cracks, and parasite damage.

Spruce

Spruce must be checked for knots and cracks. The tree has a special smell and does not release resin as intensely in its natural form. Many customers prefer laminated veneer lumber from spruce.

Exotic and combined materials

Along with pine and spruce, cedar or larch timber can be used, but the cost increases significantly. In addition, larch is a denser material, which means it is heavier, which complicates the assembly process. Also, larch has higher thermal conductivity, which means worse thermal insulation properties.

Correct combination of materials

It is possible to use a backing board or make a lower crown from larch. The breed is less susceptible to rotting than others, tolerates moisture well and protects the rest of the log house from damage.

Incorrect combination of materials

Sometimes manufacturers offer combined laminated veneer lumber: the middle is made of pine or spruce, and the top is made of more expensive material. Such gluing is unreliable: different types of wood differ in temperature deformations and react to changes in humidity.

Choosing the thickness of timber for building a house

The range of standardized timber sizes has the following values: 100, 150, 200, 250 mm. The main requirement when determining the thickness of the walls of a house is that it must impart a certain strength to the structure and have sufficient heat capacity to create a favorable climate in the house.

To determine which timber is better for a house, 150 or 200 mm, you should know what kind of house you will be building. For a one-story building, a thickness of 150 mm is sufficient. If exterior finishing or wall insulation is also done, then this is certain.

Two-story buildings require a stronger and more rigid structure. In this case, a section of 200x200 mm will be justified.

To build a house for seasonal residence in a country house or a bathhouse, if they are not insulated, use timber with a cross-section of 150x150 mm.

For such a house, for temporary residence, a simple beam of medium thickness is enough Source domasibiri.com

If you build a residential building for permanent residence of people, it will have to be heated. The walls of such a cobblestone house must be insulated, otherwise it will not meet modern energy saving requirements.

It is known that the thermal conductivity of wooden walls depends little on their thickness. The difference between walls of 150 and 100 mm of timber will be 12% of heat. From this we conclude that insulated walls can be made thinner.

So which timber is better? conclusions

By all indications it is clear that a high-quality timber should be:

- Profiled. Moreover, it is advisable to make the profile in the form of a comb - this way you can do without insulation and ensure reliable engagement of the crowns;

- Glued. Characteristics and properties of laminated veneer lumber: minimal shrinkage, reduced construction time and absence of deformation, which gives advantages over conventional timber. Compared to thermal timber, laminated laminated material benefits due to the reliability of the walls;

- Sufficient thickness. A difference of 1-2 cm significantly affects strength, heat and sound insulation. For year-round living in central Russia, the best option is a wooden wall with a thickness of 200 mm or more.

The main disadvantage of laminated timber is the price at the initial stage. But after 2-3 years of use, costs level out due to minimal maintenance, savings on finishing and insulation.

House made of laminated timber GOOD WOOD according to project SP-4

What to consider when choosing timber: basic rules

Using the right material is the key to successful construction. This also applies to wooden structures. What we first pay attention to when purchasing it:

- Decide in advance what type of timber to build the house from. A one-story house needs enough material with a cross-section of 150x150 mm. When erecting two-story structures, use 200x200 mm timber.

- In the country version, use simple planed timber, pre-dried naturally. A residential building requires glued laminated structures. A timber with a profiled joint, dried in a chamber, is suitable.

- Attention should be paid to the quality of the product; it must have the correct symmetrical cross-sectional shape, there should be no irregularities or curvature. Choose variety A or AB.

- Use D profile beams instead of rounded logs.

Types of profiled timber for a country house Source kebyx.moketa.ru.net

Common advantages of all types

- The house can be built quite quickly. If you detail the technology and understand all the intricacies, then it is possible to complete the work even without the involvement of a construction company.

- Wooden beams are able to “breathe” and allow you to create a special microclimate and a unique atmosphere in the premises.

- Many types of planed timber can significantly save on both external and internal finishing work.

- Wooden buildings have high quality and performance characteristics that are maintained throughout the entire period of operation.

- Thanks to the wide variety of shapes, sizes, types, calibrated timber allows you to create a unique design and unique appearance of both the premises and the entire structure.

Varieties

Before purchasing edged timber, you need to consider its size and type. Let's look at the characteristics by which lumber is classified.

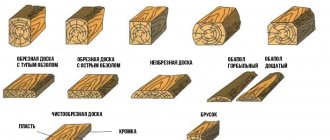

By type of processing

There are 3 types:

- Double edged . In the construction industry it is better known as a carriage. A characteristic feature is that 2 planes opposite each other are cut.

- Three-edged . With 3 treated surfaces.

- Four-edged . 4 processed planes.

The last type is considered the most popular for the construction of buildings.

According to sectional shape

There are square and rectangular . The first type is used more often, but the rectangular section is visually more attractive.

By lenght

If lumber is made from deciduous trees, its standard length is from 1 to 5 meters. The coniferous variety reaches 6 meters in length. Typically, 3-meter products are used in construction. At the same time, there are also atypical dimensions that are made to order.

By variety

To determine the grade, the condition of the material and what defects it has are assessed. The price of the timber and the scope of its use depend on this:

Selected variety .

This is lumber that has no flaws. The product is classified as elite, since all its sides are clean - without damage. It is used as a decorative element used to decorate facades and interiors.- First . Small cracks, knots and chips are allowed in such beams. The main thing is that they are within regulatory limits.

- Second . This variety may have damage beyond normal limits. A second-rate product is, accordingly, cheaper, but still finds use in construction.

- Third fourth. There are many defects in such lumber. Practically not used, except as an auxiliary product.

State quality standards regulate the classification of material by grade.

Disadvantages of wooden buildings

Construction timber, like every material, besides its advantages, also has its disadvantages. It is important to remember them when choosing material.

- Shrinkage period. Only laminated timber and chamber drying allow you to start using the house and begin finishing the internal and external sides of the walls immediately after completion of construction work. Other types require a technological break to complete shrinkage. At the same time, the use of heating and heating devices is not recommended, as it can lead to uneven drying and an increase in the number of cracks.

- When cutting a tree trunk, the structure of the growth rings is disrupted. To prevent the onset of the rotting process, it is necessary to treat with antiseptic agents.

- It is impossible to remodel or add to the building.

- Any solid timber is subject to cracking and deformation during the drying process.

- To increase service life and protect against negative environmental influences, treatment with special fire-retardant agents is necessary.

- To reduce thermal conductivity in inter-crown seams, you need to use mineral insulation.

Before starting construction work, it is recommended to carefully study the types of timber for building a house and decide on those points that will be necessary and important in a particular situation. And quite possibly I will help you avoid cooperation with unscrupulous suppliers and manufacturers.

Popular timber section sizes

Regarding the size of the timber, of the popular cross-sectional sizes of building timber in the Urals, two can be distinguished: 150x150 mm and 200x200 mm. The most popular size is 150x150 due to its low cost and practicality. At the same time, a house made of timber with a cross-section of 200x200 also needs to be additionally insulated for economical operation all year round, just like a house made of timber 150x150 mm.

Summing up which timber is better for construction, it cannot be said that some of its types are definitely worse, and some are better. Even expensive Finnish laminated veneer lumber, known for its excellent performance properties, can be ruined if you approach the project without understanding the specifics of wooden construction. If you want to get a reliable result, a house in which you can live comfortably and without worries, you should first of all look not at what to build from, but at the developer. The construction result will be good if you work with wood correctly. In fact, many builders offer precisely those types of timber with which it will be easier for them, from which they have more revenue, and not those that are better suited to the customer according to his current financial capabilities.

Specifications

Dimensions:

- The length of the timber (standard) is 6000 mm, but material from 2000 to 9000 mm can be cut to order.

- Thickness – 100 – 250 mm (step – 25 mm).

- Width – 100 – 275 mm.

The most in demand in construction are lumber having a cross-section of 150 mm. If necessary, the dimensions and length of the edged beam can be increased, but this will complicate transportation.

Thermal conductivity coefficient depending on the rock (W/(m*C)):

- cedar – 0.095. The warmest material;

- spruce – 0.110;

- birch, pine, fir – 0.150;

- poplar – 0.170;

- maple – 0.190;

- oak – 0.200.

Strength indicators:

- The average value of the ultimate strength in longitudinal compression is 500 kgf/cm2.

- Tensile strength along the fibers is from 1100 to 1400 kgf/cm2.

- When bending = 1000 kgf/cm2.

Wood species and their density (kg/m3):

- larch – from 650 to 800;

- pine, fir, cedar, spruce - from 500 to 600;

- hardwoods - from 500 to 800.

For solid natural wood, the number of freezing cycles is not regulated. Although the structure of the material is porous, it is endowed with frost resistance by nature.

Source material and regulatory documents

The timber is made mainly from coniferous wood - pine, spruce, larch, fir, cedar. In wooden structures, hardwood is used mainly only for dowels, pillows, liners and other critical parts. Although for wall beams, excluding window sills, rafters and for the two lower rows, GOST 11047 allows the use of aspen and birch with a moisture content of less than 28%.

Requirements for grade, appearance, size, physical and mechanical characteristics are set out in the following basic standards:

- GOST 8486-86 “Softwood lumber”

- GOST 24454-80 “Softwood lumber. Dimensions"

- GOST 11047-90 “Wooden parts and products for low-rise residential and public buildings”

- GOST 20850-84 “Glued wood structures”

- GOST 2695-83 “Hardwood lumber”

- GOST 18288-87 “Sawmill production. Terms and Definitions"

- GOST 23431-79 “Wood. Structure and physical and mechanical properties. Terms and Definitions"

Production technology

Solid beams are produced on circular saws by longitudinally cutting 2-4 parts from a log, followed by drying under natural conditions. Glued laminated timber goes through more complex stages, but as a result it becomes the strongest of all wooden beams (stronger than solid timber by 50-70%):

- Sawing logs into boards, drying in special chambers to a humidity of 10-15%;

- Treatment of boards with an antiseptic agent (which is also anti-corrosion), calibration by size;

- Splicing workpieces, orienting them in the direction of the fibers so that the beam does not subsequently “twist” or “lead”;

- The resulting lamellas are glued together under pressure using wood glue;

- Profiling is the final stage, during which the timber acquires clearly defined parameters.