To use various wood compounds in the field of construction, you cannot do without just tools, but also without the appropriate experience. That is why inexperienced craftsmen do not always make such connections accurately. One of the best options is for professionals to use various types of fasteners for the array, which are made of metal.

Many surviving architectural monuments made of wood were built without nails, using only an ax. This fact causes true pleasure to this day. However, centuries later, the fasteners made of metal, used to build solid wood buildings, have changed radically, and it is for this reason that today it makes no sense to repeat the experience of our ancestors.

It is preferable to build quickly and without difficulties. Let's talk in more detail about the fasteners offered by manufacturers, taking as an example details that make it possible to simplify as much as possible the connection of beams with floor joists or solid wall surfaces.

Kinds

Fasteners differ in size, the functions they perform in the joints connecting wooden elements to each other and in fastening wood to other materials: concrete, brick, metal. The use of parts allows you to evenly distribute loads and avoid destructive deformations inside the tree .

Kinds:

- with perforation;

- corners;

- shaped;

- hidden details "Hedgehog";

- tongue and groove;

- supports;

- hidden;

- with complex carvings;

- decorative overlays.

Main elements of the rafter frame

The rafter frame of the roof of a house is a system of interconnected supporting elements made of wood or metal that give the structure its shape, slope, and also evenly distribute its weight between the load-bearing walls. Its main component is the rafter legs, which are beams installed at an angle, which are connected in pairs along the slope, forming a ridge at the top point of their connection. There are two main types of rafters:

- Layered. Layered rafters are called supporting elements that have two points of support in the roof structure - on the ridge girder and the mauerlat. A rafter system of this type is used in structures that have one or more load-bearing walls inside on which rafters can be “leaned.” This fastening of the rafters allows you to relieve them through the use of additional vertical supports.

- Hanging. Hanging elements are those that have only one support point, located where the rafters are attached to the wall or mauerlat. A hanging type rafter system experiences load not only in bending, but also in expansion, so it is reinforced by horizontal compensating elements (crossbars, tie rods, tie rods).

Gable roof rafter system

Perforated fasteners

The main material of the mounting elements is galvanized steel. The geometry of the structures may be different. A common feature is the presence of many holes. Perforation makes it possible to select the desired attachment point in the tree . Self-tapping screws are screwed in through it or screw nails are driven in. Advantages of this type of fastener:

- Saves time on connecting wooden structural elements.

- A small amount of waste when attaching units.

- Possibility of installing several hardware in one plane. This increases the load-bearing capacity of the fastening unit.

- Variety of types of installation products. Allows you to select the optimal solution for uniformly distributing the load on the wooden components of a building or structure.

- Versatility. Suitable for all lumber.

Types:

- plates;

- corners;

- beam holders;

- three-dimensional slats;

- mounting tape.

Plates

Planks with many holes are used to fasten wooden elements in one plane. In terms of plan, parts can be of different shapes (for example, in the form of the letters T, Z). The plates are made of steel with a thickness of 1–3 mm or more.

The parts bend easily, which is convenient when joining wood at an angle of 90° or more. You can cut the plates with metal scissors.

Corners

To connect wooden structures at right angles, equilateral, reinforced, double-reinforced, anchor metal corners are used. There are more complex products: Z-shaped, sliding, and other modifications.

Beam holders

The product allows you to connect beams and beams. The fastening is installed on self-tapping screws or self-tapping screws. The supporting part of the beam is fixed from the sides and bottom. The perpendicular planes of the steel part are fixed to the transverse beam. The photo shows one of the holder options.

Three dimensional slats

They come in different lengths. The design feature is that the connection elements fix the tree in three planes. The slats form a strong and reliable connection in the nodes . Metal longitudinal slats perform two functions: they bind the wood into a single system, they are load-bearing beams that take on a significant part of the vertical load.

Fasteners - T-shaped profile made of durable steel alloy . They are produced by the Italian company Alumidi. The slats are selected based on the cross-section of the elements being connected, the level of dynamic and static loads.

Mounting tape

Perforated galvanized steel tape is used as an auxiliary fixation when making complex joints of wooden structures. It is easy to cut into fragments. It is also used as fastening of non-metallic products to wood.

Special purpose self-tapping screws

Using similar elements, fairly massive wooden products are attached. The cap has milled ribs and is easily recessed into the product, while the tip is created like a drill. In the middle of the screw, the cutter makes a larger hole, helping to tighten the element as tightly as possible.

An adjustable self-tapping screw will be useful for fastening door frames, window openings, and solid wood sheathing to wood and metal. The self-tapping screw is screwed directly into the box, as well as the wall surface located behind it, or the power part.

The self-tapping screw acts as a weather vane for high-quality fastening of solid wood cladding to a base made of steel. It has a tip in the form of a drill and wings placed above it to expand the hole in the tree.

When drilling metal products, the wings break. As a result, having made a thread in a metal part, the self-tapping screw fits tightly to it, while the solid element is attracted by its head to the metal.

Hidden details "Hedgehog"

Steel washers have an internal thread at an angle. Through holes are drilled in the wood through washers. A washer is also installed on the reverse side. A pin is screwed into the channel, which tightens the tree.

Several studs are installed at the connection points at once . In solid wood, the rods occupy a crossed position. This creates a strong hidden fastening of wooden structures. Fastening is also carried out with long self-tapping screws, which are located at an angle in solid wood (usually 45°). This method is used when constructing a wooden roof.

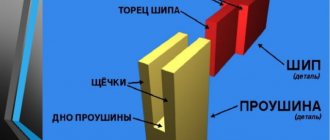

Tenon and groove

The fastening is created by the material of the parts being connected. In one element, the wood around the protrusion (tenon) is removed, in another array a groove is cut out.

The tenon must fit into the groove with some force to firmly clamp the protrusion in the hole . Lateral stresses create frictional forces between the tenon and groove, forming an almost permanent connection.

Depending on the dimensions of the parts, the dimensions of the tenons and grooves are determined .

In cross-section they can be rectangular, square, oval. To increase the load-bearing capacity of the components, the parts are lubricated with carpentry or synthetic glue. In some cases, fastenings are strengthened by installing additional metal fasteners.

Construction of the rafter system

The rafter system consists of many elements, each of which performs its own task.

- Mauerlats are responsible for distributing loads on the walls. These beams take the weight of the entire roof and lie on the walls.

- Rafter legs are inclined beams that create the required angle of inclination of the roof.

- Purlins are horizontal beams that hold the legs together. There is a ridge run, located at the top, and side ones, located on the slopes.

- The puffs are located horizontally and do not allow the rafter legs to move apart, forming rigid triangles with them.

- Racks and struts (rafter legs) are additional elements on which the rafter legs rest. They rest against the beds.

- The beam is a horizontal beam located under the ridge; the posts and struts rest on it. The purpose of the bench is to redistribute the point load from the racks.

- The ridge is the junction of the roof slopes.

- Lathing - bars or boards that are placed perpendicular to the rafters. Roofing material is laid on it. The purpose of the sheathing is to distribute its weight.

- An overhang is an elongated edge of a slope that protects walls from precipitation. If the length of the rafter legs is not enough to create an overhang, additional elements are used - fillies.

The structure of the rafter system is shown in the figure.

Also included in the roof structure are roof trusses. This is a continuous assembly consisting of rafter legs, braces, racks and struts (braces, jibs). The truss can be not only triangular, but also trapezoidal, segmental or polygonal. Which type of truss to choose depends on the size of the house. If the distance between the walls is 9-18 m, then a triangular truss is suitable. For houses with a width of 12 to 24 m, trapezoidal or segment trusses are used. If the building width is larger (up to 36 m), then polygonal trusses are used.

The main fastening points for the roof truss system are beam, ridge and mauerlat.

Supports

These are two supporting steel plates, pulled together by a pin. Installed between the bottom of a wooden house and the foundation. The upper platform is fixed with screws and bolts to the lower wooden structures of the building. The bottom plate rests freely on the base of the house or is secured with hardware or welding. The structure plays the role of a jack . By turning the studs, the horizontal level of the floor is adjusted. This type of fastening makes it possible to prevent upward penetration of moisture and creates a reliable support system for the house.

How much do wood screws cost - review of prices per 1 kg

The price for wood screws is indicated by suppliers both per piece and per kilogram. But if you need to purchase, for example, 2000 pieces of such fasteners, no one will count them. Either they will sell it in original, unopened packaging, or they will calculate it by weight. In any case, let's consider the cost according to several parameters.

| Type of self-tapping screw | Price per piece (as of June 2021), rub. | Price per kg (as of June 2021), rub. |

| Phosphated | from 1.8 | from 180 |

| Black oxidized | from 1.9 | from 195 |

| Galvanized | from 2 | from 200 |

| Yellow-passivated | from 2.1 | from 210 |

| With press washer | from 1 | from 8 |

| Galvanized capercaillie | from 4 | from 500 |

| Roofing | from 1.23 | from 220 |

| Confirmations | from 1.38 | from 150 |

As you can see, the price of such fasteners is not so high compared to the benefits and convenience that they bring when used. Moreover, even a beginner can work with them. All you have to do is choose the right one and you can get down to business!

Watch this video on YouTube

Previous Building materialsStrong flooring for every home: laminate or linoleum - which is better Next Building materialsWhat the walls of new buildings hide: modern technologies for constructing buildings made of porous brick

Hidden fasteners

The advantage is the invisible connection of massive structures . The tie elements are hidden in the grooves of the wood, which are connected by a drilled channel. A pin is inserted inside. On one side the rod goes out and has a nut. By rotating the nut with the stud, tighten the plate hidden in the groove.

Hidden fastenings are used in the interiors of frame houses made of laminated veneer lumber. This type of fastener is expensive. The installation process is labor intensive.

3D slats

Specialized departments provide a detailed catalog of the best wooden fasteners. One of these connections is three-dimensional slats. They are connected perpendicular to each other. As a result, a T-shaped connection is formed, which is considered the strongest.

They are made from durable metal alloys that can withstand all kinds of loads. They have a length from 60 to 750 mm. There are cuts and protrusions along the entire plane of the iron model.

During the installation process, one edge of the part is fixed in one of the parts of the wooden beam. Next, small cuts are made on the logs, equal in length to the protruding part of the three-dimensional lath.