Basic information

One of the most proven methods of connecting two parts is considered to be a tongue-and-groove connection.

This method of fastening wood products is the most widespread. It is used to fasten parts of window frames, doorways, various furniture elements, and the walls of wooden boxes. Each element of such products has a specially made tenon (or several pieces) or a groove (several grooves). The types of main connections of parts made of wood are defined in GOST 9330-76. This document defines the following characteristics of such fastening of wooden parts:

- rules for abbreviation (abbreviation) of various compounds;

- drawings showing the appearance;

- permissible dimensions of each element;

- the procedure and rules for determining the size of each element;

- expressions for calculating the dimensions of the required cutting tool;

- formula for calculating the strength of assembled elements;

- inspection procedure and strength testing.

GOST 9330-76 Basic connections of parts made of wood and wood materials. Types and sizes

According to this standard, all connections are divided into the following categories:

- corner (end and middle);

- box (mainly belongs to the corner category);

- along the edge;

- the so-called “on the mustache” length.

For each of these categories, the standard has its own abbreviation (short designation). This marking consists of two capital letters of the Cyrillic alphabet and one number. For example, UK-2 means that we are talking about a connection with a double open end-to-end tenon, UK-9 is a “mental” connection with a plug-in non-through round tenon. The entire list is set out in more detail in the text of the adopted standard.

Any type is accompanied by a detailed drawing. Each of them shows frontal and profile projections indicating dimensions, formulas for calculating each element, and finished results. To obtain a strong connection, the standard defines tolerances that must be observed in the manufacture of each element. The parameters of the corner tenon (its length, pitch and bluntness) are given in detail. Based on the results presented, the guest developed recommendations for choosing the necessary cutting tools. Separate references are made to other documents (standards) that determine by what means each of the listed products must be secured.

Selecting the type of connection

In general, there are a huge number of types of joints of wooden blanks, so we can only talk about some of them, the most common.

One of the easiest ways to extend a wooden part (timber, log, board) and increase its width is an end connection. There are several options for its implementation. A simple and functional half-thickness (half-tree) method is often used. Depending on the expected load on the part, the cut can be straight or oblique. In some cases, the joint is strengthened using figured cutouts - locks. This type of connection prevents stretching, twisting, and bending. This is how the beams are spliced together for the purpose of lengthening.

Creating three-dimensional frames or wooden frames requires reliable connections at various angles. In this case, it is rational to use a tenon-groove or tenon-eye connection. The nodes at the junction of parts can withstand displacement, bending and compression loads. If the structure requires high tensile strength, the cutouts are made trapezoidal.

Additional connections of frame products, which impart rigidity to the structure, are implemented using T-shaped or cross-shaped connections. The main load at the joints is compression, displacement and rupture. In special cases, the structure is additionally reinforced with metal corners, screws or nails.

To connect boards together into box-shaped structures at right angles, it is convenient to use a special box groove. As the name implies, this method is often used to create three-dimensional structures, including furniture boxes. A high-quality box joint looks monolithic, has an attractive appearance and can withstand impressive loads. When creating wooden furniture, dowel, dowel and domino joints are often used (when the groove is oblong, as opposed to a round dowel).

Half-tree connection

Quite often in carpentry they use various options for half-timber joints (simple or straight lock). This type of assembly of wooden structures is characterized by ease of manufacture and high reliability. The following varieties are distinguished:

- cross connection;

- half-tree - dovetail;

- gusset;

- on the mustache;

- half-tree splicing.

The first two methods are used to connect parts that intersect at right angles. Especially popular is the dovetail, in which the neckline is trapezoidal and the sides are not at right angles. The lock groove widens slightly from the end, providing a more reliable fixation. It should be noted that a tenon joint can also be called a dovetail if the tenons are cut in the form of trapezoids.

The second and third methods form a completed angle. Splicing is used if it is necessary to increase the length of the workpiece.

The principle of connection and its varieties

In terms of design, all tongue-and-groove joints are made according to the same principle: a protrusion is made on one part, and a recess is made on the second. They are exactly the same in configuration and size.

When these two parts are tightly joined, a strong technological unit is obtained.

When building houses, such a connection prevents the shift of one part of the structure relative to another; in the manufacture of furniture, it significantly increases the area on which glue is applied, thereby providing additional strength to the product.

Based on the geometric shape of the protrusion and recess, such joints are divided into two main types:

- rectangular cross-section (sometimes with rounded edges of tenons and grooves);

- in the form of a trapezoid (also called a “dovetail”).

Based on the number of spikes and grooves that need to be made for one joint of parts, these connections are divided into:

- single-spike;

- multi-spike.

Important! Regardless of the number and geometric shape of the protrusions and recesses, they must be made only parallel to the grain of the wood.

Joinery Joints by Luke Peterson

Some joinery joints from aspiring Australian woodworker Luke Peterson

Tenon and groove with dowel reinforcement

With two through dowels

With one through dowel

Dovetail with different sized spikes and rounding

Handcrafted dovetail with rounded edge. The wood creates a natural color gradient, moving from longitudinal to end grain.

Application area

The tongue-and-groove connection has found application in many areas of our daily life. For example, when arranging the floors of premises according to this principle, common coverings such as laminate, parquet, parquet boards, ordinary floorboards, chipboard, fiberboard or MDF boards are joined together.

Wood, as one of the most environmentally friendly materials, is used to make a wide variety of furniture (from a simple kitchen stool to a designer set for a living room or dining room), roller blinds, blinds and much more. And all these products are mainly made using a tongue-and-groove connection.

When constructing wooden frame buildings, houses made of timber, when arranging the beam-and-truss structure of the ceiling and roof, one also cannot do without arranging protrusions and recesses.

Tenon-to-socket joints in a wooden structure

/ Wood processing / Tenon joints

Tenon joints (tenon joints, tenon-to-socket joints) have a long history of use in wooden frame structures. One piece fits into the other and provides a decent mechanical connection, which was made the most of by carpenters in traditional wood frame buildings. Currently, it is rarely used in construction, where economics dictate the need to simplify manufacturing technology.

The connection has been improved over the centuries by carpenters and furniture makers, and they have invented many types of these connections. The tenon joint has a large gluing area and is widely used in the manufacture of tables and chairs, where the greatest possible joint strength of the parts is required.

Start with the Basics: Basic Rules for Male-Socket Joints

Regardless of how you form your tenons and sockets, these tips will help you achieve perfectly-fitting, strong joints for any project.

- Correct connections always start with careful markings. Use a proven steel ruler and square, and mark the marking lines with a sharp pencil, surface planer or marking knife.

- A simple rule that is easy to remember: when marking a socket on the end or edge, the thickness of the workpiece must be divided into three equal parts. The outer two thirds will become the walls of the nest, and the middle third must be removed. So, in a board 18 mm thick, a 6 mm wide nest is made in the center of the edge of the workpiece. When using material with a thickness of more than 18 mm, the width of the socket can be more than one third of the thickness of the workpiece, provided that the thickness of the walls of the socket is at least 6 mm - this is due to strength considerations.

READ Cap and suvel what are they and how are they different?

- Fitting a crossbar tenon to a socket with rounded edges is easier than making a rectangular socket. To round corners, use a rasp or a knife with replaceable blades.

First make the nests, and then form the spikes that match them. It is much easier to precisely adjust the tenon than to change the dimensions of the finished socket.

- A correctly fitted tenon should be held in its socket without glue and should not fall out when parts are turned over, but at the same time, only a small amount of hand effort should be enough to assemble and disassemble the joint.

The highest bond strength is achieved when the mating surfaces are smooth.

- Drilled or milled sockets will have rounded ends. To fit them to a rectangular tenon, you can trim the corners of the socket with a chisel. To save time and effort, you can simply round the corners of the tenons.

Through tenon connection

Through tenon joints are widely used in frame structures. The end texture of the tenon is visible on the edge of the vertical trim beam. In order for a connection to have a good presentation, it must be manufactured carefully and accurately. Wedges can be used to provide additional strength, and if made from contrasting wood, they will double as decorative elements.

Marking connection elements

Cut the tenon part blank to length; You can leave a small allowance, which will be removed after gluing. If the part must have tenons at both ends, mark the distance between the shoulders as accurately as possible. Draw the lines for marking the shoulders with a marking knife (1).

Mark the position of the socket on the end of the corresponding part, then the width of the socket using the part with the tenon as a stencil (2). Use a pencil to draw all the lines. Choose a chisel keeping in mind that the width of the socket should be approximately one third of the thickness of the material. Set the thicknesser to the width of the chisel blade. Now adjust the position of the thicknesser block so that the socket is in the middle of the edges.

The thicknesser is installed and works from the front edge. Using a thicknesser, draw marking lines between the width marks on both edges (3). Mark the tenon with a thickness planer using the same setting. Working from the front side. draw a marking from the line of the shoulders on one edge through the end along the other edge to the line of the other shoulder (4). If the tenon part is thinner than the socket part, reset the pad position only.

Cutting the connection

Always cut out the socket first as it will be easier to fit the tenon to the socket if necessary. Press the workpiece onto a workbench or table. It’s a good idea to place a piece of wood underneath it to avoid damaging the surface of the workbench.

Stand in line with the workpiece to control the vertical position of the chisel. Start from the middle, with the bevel of the chisel pointing away from you (5). Using a mallet, cut the chisel to a depth of approximately 3 mm. Work towards you in increments of approximately 3mm and stop 2-3mm from the end. This is so that the bit has a fulcrum on the waste material when removing chips (chips). Turn the chisel over and work towards the other end. Remove the chips by using the chisel as a lever on both sides and holding it with the sharpening bevel down (6).

To prevent the bottom from splitting, select wood only up to the middle. Remove excess wood from the ends by holding the chisel vertically and beveled into the socket (7).

Turn the workpiece over. Shake out any chips and clean the surface before pressing the workpiece, as jammed chips or chips can damage the surface of the part. Select the waste in the same order, so as to go to the already cut out first half of the nest.

Drilling the socket

An alternative to cutting out the nest with a chisel is to drill it out. Use a drill press or electric drill in a stand. This will ensure more accurate work than drilling by hand. Set the drill bit to the size or slightly smaller than the width of the socket. Fix the board with the fence on the drill press table and adjust its position so that the drill is in the middle of the socket.

Set the drill to a depth equal to half the thickness of the material. Drill a hole in each end of the socket (1), then drill a series of slightly overlapping holes in between (2). Turn the workpiece over and, placing the same side against the stop, drill from the other side. After placing the workpiece on some scrap, press it against the workbench. Remove any remaining waste and use a chisel to level the ends of the nest.

Marking and making a tenon

To ensure the reliability of the structure, the manufacture of a tenon must begin with careful markings. At the first stage, it is determined what type this element will be manufactured and where it should be located. According to its location, positions are distinguished: corner end, middle and box. In addition, you need to decide how many of them will be in the connection. One of the factors influencing the quantity is the thickness of the workpiece. If the part has a thickness that does not exceed forty millimeters, choose a connection with one tenon. If the width is in the range from forty to eighty millimeters, two or three are made. For thicker workpieces, a triple or multiple connection is cut. The experience of professionals shows that the tenon should have a thickness equal to one third of the total size of the part, and the length should be equal to the thickness of the elements being fastened.

The main stages of making a spike are:

- marking the future spike (horizontal and vertical);

- tool preparation;

- sawing;

- cleaning the walls;

- fit.

Marking the locations of the required cuts is done using measuring tools in both planes. The choice of cutting tool depends on the capabilities of the manufacturer. At woodworking enterprises, this operation is performed on special machines. If you plan to make a tenon with your own hands, use ordinary saws. The most suitable are: a bow saw or a hacksaw. After making the spike, its surface is cleaned. This is done using files and sandpaper. Next, the insert tenon is adjusted to fit the prepared groove. After completion of this operation, its final fixation is performed.

Spike in eye

Corner and T-shaped (example: T-shaped connection of a window frame) intersections are conveniently performed using the tongue-to-ridge method. In this case, the eye is made at the end of the vertical part, and the cuts for the tenon are made in its horizontal component.

The work begins with marking the eyelet. The thickness of the workpiece is divided by three. With a thin hacksaw, cuts are made to a depth equal to the width of the other workpiece. Excess wood is removed using chisels, and the walls of the eye are smoothed with sandpaper.

Mark the second workpiece. The width of the tenon should be equal to the width of the first workpiece, the thickness should be equal to the thickness of the tenon. The cuts are made with a hand hacksaw, carefully controlling the depth and angle of inclination. Remove excess with a chisel.

The final adjustment of thickness is carried out using sandpaper. The parts should connect with light force and not fall apart under their own weight.

Tools used

In this case, the sampling of material is carried out on the surface of the beams and boards from the side. The main thing is that the proposed connection maintains its dimensions in terms of geometry.

To complete the process using a milling cutter, it is possible to use tools equipped with shanks with a diameter of 8 or 12 millimeters. The so-called groove cutter will become a universal option when performing any type of work. The device is equipped with a cutting part, the basic operating principle of which is described as follows:

- The side surface is involved in the formation of the sides of the tenon, the wall part of the grooves.

- The side with the end part is used when processing the bottom. After this, the required layer of material is removed from the base of the spike.

The result is the simultaneous formation of both tenons and grooves on the surface on the sides. The sizes can be individually adjusted, and the owner has quite a wide range of options in this regard.

Sometimes for grooves and tenons they choose not a rectangular shape, but the so-called “dovetail” type. This option is relevant if increased requirements are placed on connection reliability. Accordingly, the cutter used is also called a “dovetail” in this case. Such work can be easily done with hand tools if the need arises.

T-shaped (T) connection

The lap joint is another variation of the half-timber joint, which is widely used in the creation of frame structures. In this case, the end of one part is adjacent to the middle of the second. A fold is cut out on the first (according to a similar pattern as in a corner joint), and a landing groove is cut on the second. Below is one of the schemes for creating such a groove manually.

Make markings on the front side, focusing on the width of the counter part.

Using a thicknesser and a square, mark the edges.

Make cuts in the waste part. They will facilitate subsequent sampling with a chisel.

Use a wide carpenter's chisel to remove the waste. Remove layers, moving from the center to the edges.

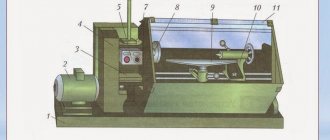

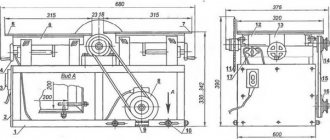

Making a device for picking out a tenon

When parts are processed manually, the milling cutter itself does not have additional spatial fixation. But the overall result of the work and the accuracy of the connection itself in the future depend on this.

To assemble the simplest design that can cope with the task, you will need to use:

- Several guides that remain stationary. They should be side and top or bottom.

- The length of the sample is adjusted through the use of an appropriate movable bar.

For manufacturing, the following sequence of actions is used:

- A plywood sheet is taken, from one edge of which the side elements are mounted in a vertical plane. It is necessary to create appropriate cutouts in the center of the material.

- The sides are equipped with guides. The base of the hand cutter moves along them later.

- The side strips are fixed on the upper guides. Then the movement of the working milling cutter associated with these parts becomes limited.

- The plywood sheet, which became the basis for the installation, also serves as a surface for installing the moving element. Then the amount of edge overhang for the future workpiece is easier to control under any circumstances. Fixation is ensured with ordinary screws and other types of fixing devices.

Thorn in socket

A more complex connection is the tenon-to-socket method. It requires more skill, but is much more reliable and durable. The scope of use is the same as in the previous case, namely T-shaped joints. The difference between this method is that the tenon is made at the end of the vertical part, and a socket is cut out in the body of the horizontal part.

This is one of the most common furniture connections. There are connections with a through tenon and with a blind one. The difference is that in the first case a through socket is cut out, in the second the slot is made to a certain depth.

Types of tenon joints

Very often, when making various wood products, it is necessary to connect different parts by gluing. The use of a tenon joint gives the product the necessary strength.

The tenon joint consists of two parts - the tenon and the eye socket. A tenon is a protrusion that is located at the end of one of the parts being connected. The spike is inserted into the eye or socket of another part being connected. You can find single, double and multiple spikes. Spikes are divided into solid and inserted. A single tenon is a tenon that forms a single whole with the part. The insert tenon is made separately from the part. In addition to the above, there are several more solid tenon joints: dovetail, toothed joint

In addition to increasing the strength of the product, the tenon joint can be used to increase the useful yield. The figure shows a furniture panel with and without knots.

The furniture panel without knots has a better appearance compared to the previous one.

Types of spikes: a - single; b - double; c - round; g - one-sided dovetail; d - multiple; , e, g - “dovetail”; z - toothed.

As you know, there are various types of structural defects in wood that can significantly worsen the appearance of the product. These include knots, cracks, wane, etc. (Fig. 2). These defects are cut out (Fig. 3), the tenon joint is milled (Fig. 4), and the remaining parts of the bars are spliced along the length. A jagged tenon in some way visually worsens the appearance, so such parts are used for painting (Fig. 5).

Gluing short lengths of solid wood lumber together increases yield. End gluing is characterized by low strength (less than 10% of the strength of natural wood) and is therefore not used. Miter gluing (Fig. 6) is a fairly strong connection. However, this requires a long tenon length and, as a consequence, increased material consumption. Tongue gluing is most preferable as it provides 50-60% of the strength of solid wood.

Defects in the structure of wood in lumber

Scheme for removing defects

Tooth tenon connection

Gluing along the length

Types of toothed tenon joints: a - miter gluing; b - gluing onto a toothed tenon.

Flat and trapezoidal spines have lateral edges called cheeks; the cut end parts of the bar, forming tenons, are called shoulders, the end part of the tenon itself is called the butt. The length of the tenon is the distance from the shoulders to its end; tenon thickness - the size between the shoulders or cheeks; The width of the tenon is the transverse size of the cheek. The side walls of the eye are also called cheeks (Fig. 17, a).The thickness of the tenon in corner joints is usually taken on the basis of: for single-tenon joints - from 1/3 to 3/7 of the thickness of the bar, for two-tenon joints - from 1/5 to 2/9, for three-tenon joints - usually 1/7 of the thickness of the bar. The width of the lugs should be such that the spikes fit into the lugs with little effort.

The shoulders should be the same and equal to 2/7-1/3 of a single tenon and 1/6-1/5 of the thickness of the double tenon bar.

The socket for a blind tenon should be 2-3mm longer than the length of the tenon. This is necessary to prepare the joint and to allow excess glue to drain there. The spikes are made on horizontal bars, the eyes on vertical bars. In addition, depending on the thickness and length of the parts, cylindrical or rectangular shaped tenons with a thickness of 8–15 mm and a length of 60–120 mm are also used.

Tenon knitting should be done so that the tenons and eyes are connected with the appropriate density without additional cleaning with a chisel. The thickness of the tenon should be such that it fits into the eye with little effort. But an overly thick tenon will only split the part. When the tenon is thinner than the eye or socket, the connection is weak. Sometimes such a spike is wrapped with thin strong paper or a bandage with glue, which increases the strength of the connection.

Tenon connections are made in the following sequence.

Square or rectangular bars are cut exactly to size. All sides of the bars are checked with a square. Then the tenons are marked: using a comb, marks are made on two opposite sides of the block (Fig. 17, d). You can also use a surface planer to mark the studs. It's more versatile. But the comb is more productive and convenient - with it the marks are carried out at a time, and the thicknesser bars have to be rearranged for each mark separately.

The arrangement of tenons and grooves must be uniform across the entire width of the parts. The outer tenons may be slightly wider or narrower, but all other tenons and grooves should be the same.

Since the length of the tenon is taken equal to the thickness of the bar, then, in addition to the longitudinal ones, it is also necessary to make horizontal (transverse) marks along the square, limiting this length.

Marks are also placed on bars with eyes, limiting their height, which should be equal to the width of the tenon. The areas to be removed are marked with hatching in order to guide the saw within the unnecessary piece of wood and not confuse anything when working with a chisel.

After marking the face, you should transfer the contours of the tenons and grooves to the end side of the board. Depending on the type of wood, it may be useful or even necessary to whiten the end side of the board with chalk: the markings will be more visible on a white background.

To mark tenons, especially dovetails, it is very convenient to use special templates, cut, for example, from tin (Fig. 18).

The marked workpieces are secured in the workbench so that the parallel cutting lines are vertical, and they begin to file the tenons and lugs. The cleanliness of the cut depends on the saw. It should be sharp, with small, equally spaced teeth. In this case, the saw blade should be on the side of the mark, the line of which remains untouched. When sawing the tenons, the saw should go from their outer side, and at the eye - from the inner side (Fig. 17, d). After sawing, a dark cut strip remains (Fig. 17, f).

First, they make a cut, that is, they deepen the saw blade 2-3mm into the thickness of the wood. To do this, place the saw blade on the side of the mark and press the nail of the left thumb against it. The saw is first pulled towards itself, making a cut in which the saw teeth slightly cut into the tree (Fig. 17, g). Then the saw is moved forward with short movements, gradually deepening it into the wood by 2-3mm. As the tool deepens, sawing is performed at full swing. You should cut without pressing on the saw, otherwise it will deviate from its direction (especially the bow saw). Correct cutting without distortion should be on both sides of the tenon or eye.

Having completed all the cuts, the cheeks of the tenon parts are cut off (Fig. 17, h), and the cut line should be perpendicular to the face or beveled inward, and not vice versa. For double tenons, the wood is hollowed out in the middle between two tenons; for triple tenons, the wood is hollowed out twice between three tenons. For eye parts, only chiselling is performed. The wood should be chiselled along the marks at the nests and along the cut lines at the tenons and eyes. For through sockets, markings are applied on both sides of the part, for blind sockets - on one side.

Start processing the grooves with a chisel without touching the end of the part: this way you will avoid its splitting. In addition, when processed with a chisel, soft wood can split in the place where the growth rings pass. To avoid this, you need to make several additional cuts. In this case, if the tree splits, it will be between two adjacent cuts, and not across the entire width of the groove.

The part should be well secured, and a wooden lining should be placed under it so as not to damage the workbench. The chisel or chisel should be chosen so wide that it is several millimeters narrower than the groove or socket.

Chiseling is performed in two steps. First, the tool is placed so that the blade is 2-3mm away from the marking line and does not cut it off. The chamfer is turned inside the socket, and the tool is held vertically so that the wood does not wrinkle. Another board fixed on top of the part so that its edge runs along the marking line can help guide the chisel more accurately. With light blows of the mallet, the chisel is deepened into the wood. Slightly rock the tool, throw out some of the chips and continue working. To make the cut wood easier to remove and not break the tool, the shavings are removed with a thickness of no more than 5 mm.

When chiseling through nests, select a piece of wood up to half the thickness of the workpiece, then turn it over, secure it again and begin chiselling from the reverse side. This method allows you to avoid cracking of the board, as well as inaccuracies in the processing of grooves.

After the through passage, they begin trimming the remaining wood. The chisel must be very sharp. They place it at risk and cut off the excess wood, while simultaneously cleaning out all the roughness.

The above technique can be slightly modified. First, two holes with a diameter slightly less than the thickness of the tenon are drilled along the edges of the future eye, or a solid piece of wood is drilled over the entire area of the nest. Then use a chisel to select and clean the entire eyelet.

When drilling wood, it is advisable to prick the center of the hole with an awl; The axis of rotation of the drill must coincide with the axis of the hole. To avoid the formation of chips or flakes, it is necessary to place a piece of board under the part, and at the end of drilling, release the pressure on the drill. When manufacturing several identical parts that have through holes, it is advisable to drill the parts folded into a stack.

The finished parts are first connected without glue, inconsistencies are noted and cleaned until they fit tightly together. The more accurately the parts are joined, the better the glue will grip them. First of all, you need to pay attention to the squareness of the connection. If you insert the tenon at an angle, you can crush the outer edge of the groove. To make the tenon fit better into the groove, the corners at the end can be slightly beveled. But for a through tenon, you should not make a chamfer that is too large, otherwise the connection from the outside will look sloppy.

After correcting all the defects, the connection can be finally assembled or glued.

A router with a groove or special cutter and a comb-shaped metal template will help you save a lot of time when making straight and wedge-shaped tenons and grooves for them (Fig. 19). The groove is obtained in one pass of the cutter and is also much more accurate than a groove made with a conventional saw and chisel. However, it is recommended to test the selected parameters on a scrap board before moving on to the parts.

Both types of tenons are cut with a milling cutter on the parts to be joined in one step. In a comb template, they are fixed so that the edges are mutually offset in both directions by the width of the tenon. When forming straight tenons, both boards are fixed parallel and vertically, and wedge-shaped tenons - one board vertically, the second - at a right angle to it. The direction of work on the comb pattern is from left to right.

The guide roller prevents the milling machine from getting out of track. In this case, the cutter independently maintains its distance without touching the edges of the template. The distribution of tenons and grooves in such a connection depends on the size of the cutter used.

Further

Return to contents

Creating tenons on bars and boards

Processing is performed using the following sequence of actions:

- The part to be processed is mounted on a plane from the bottom side.

- The edge of the part where the tenon is formed accommodates the cutouts at the guides at the top. The structure moves inward until it hits the end.

- A movable type element must be fixed while maintaining a certain position.

- We use a wedge tool to connect the guides and the plane located at the top to each other.

- Connection of a hand router with the upper guides.

- Using a router tool on a home router table, wood is removed from one side.

- When the first side of the workpiece is processed, begin the second.

The operation will be successful only with high performance and accuracy parameters. Setup refers to the required steps before the instruments are turned on. To resolve the issue, actions are performed in the following sequence:

- The milling tool is lowered until it reaches the surface of the base.

- Measuring the thickness of a part.

- The thickness result is divided by 4. The result is the distance parameter that is maintained when lifting the cutter above the base.

Tongue-Groove connections

As a rule, we are all accustomed to standard connections, for example, permanent tongue-and-groove connections. But even these ordinary connections can be made in a special way that is beautiful and functional!

Flat tenon. A straight tenon can be made in three different ways: 1. With hand tools: using a handsaw and a chisel

2. Using a power saw Typically, connections of this type are made in a carpentry workshop on a milling machine. However, if you do not have a milling machine or cannot currently use one, you can use a mounting circular saw for this type of work.

3. Using a router and a special tenoning device

or using a router and a milling template:

There are a great many options for using this type of tongue-and-groove connection:

Hidden spikes, as in the photo below, look so that it is unclear how this structure is made and how it is held in place:

door assembly in the final stage, made using classic tongue-and-groove joints. Nice moment of completing work! Gluing is done using Titebond glue, popular among professionals.

The photo below shows a designer table from Matthew X. Curry (USA): a tabletop made of figured walnut with the addition of wenge inserts and a crossed “X” in a natural knot.

Planing the end part of the tenon with a hand plane (a miter plane or even number 4 or 5 for wide tenons as in the photo) helps to finally form the decorative, attractive appearance of the joint:

The main “feature” of this connection in the photo above is the production of a three-dimensional product from flat elements - plywood. A regular tenon is used, made in different planes.

In the photo above, the decorative element in the form of an X is the simplest tenon joint, which is made elegantly and beautifully, but not hidden, but on the contrary, “open” - the joint is placed on the front surface of the tabletop. Technologically, a locking connection with a cross-mounted wedge into a tenon is used here. The connection only seems simple: its execution requires high manufacturing precision. Coffee tables with beautiful tongue and groove connection options:

Everything about this photo above is mesmerizing! And the beauty of the wood, and the craftsmanship, and the genius and simplicity of the connection itself (tenon and groove).

Imagination and skill are limitless when you have experience working with wood and stone!

Another original example of a combined tongue-and-groove and dowel joint on contrasting wood. The trick is that the table leg is not attached in the classic way from below to the tabletop, but crashes into the solid surface of the tabletop. The base with drawers is completely missing.

Tongue and groove connection method

First you need to determine for what purpose this connection method is needed. If this is a table, then the jumpers in it are usually connected to the vertical legs.

Consequently, the wood fibers run vertically and horizontally. If this is a wall table or a bedside table with drawers, then the jumpers here will be located a little differently. They will be horizontal relative to the legs.

Detachable connections: with screws, screws, ties, wedges.

As a rule, we are all accustomed to standard connections, for example, detachable ones with screws. But even these ordinary connections can be made in a special way that is beautiful and functional! Connections with nails, pins and staples : This type of connection is used mainly for fastening or finishing, decorative elements or in frame house construction. We will not talk here about the “seven secret ways” of working with a hammer and show the “beauty” of joints made with nails. But let’s “stop” with special hammers, literally in a nutshell. Hairpin hammers:

Special hammers for frames and windows. They can be with a rotating striker.

Japanese hammers have become extremely popular. They are convenient for both hammering nails and working with tools, for example, chisels.

Jewelry hammers:

Pneumatic pins and nailers

Now they are used in a wide variety of areas: for installing platbands, fastening lining, boards and simply fixing two workpieces before gluing.

Fastening platbands to a micropin (0.6 - 0.64 mm) using pneumatic guns (pins):

Options for trim and door panels:

A micropin or finishing nail (up to 1 mm thick) is also used in the manufacture of caskets and all kinds of boxes:

Pneumatic guns working with staples or finishing nails are convenient for fastening lining, glazing beads and other wooden decorative elements.

In carpentry work, air guns with more serious nails are used

Screw connections :

Direct connection. This type of connection is widespread. And that’s why we focus a little on the types of screws.

Types of screw heads:

Types of thread - single-start and double-start:

To speed up construction and finishing work, primarily the installation of drywall, use screws in a tape and a screwdriver to work with them:

Oblique connection with screws

Due to the ease of use of the device, which provides sufficient accuracy, this type of connection has recently become widely used by both home craftsmen and professionals. The screws can be closed with dowel plugs.

Popular photo

The connection with an oblique screw allows a Craftsman with any level of training to make a variety of products, including furniture, quickly, beautifully and accurately. The screw, hidden in the oblique hole made with the help of the Conductor, does not spoil the front surface with its appearance. And decorative plugs installed in the holes make the product original. The workpieces are fixed to each other and tightened using special clamps - hand vices directly through the holes.

To make such “oblique” connections on a screw, the Kreg Jig system is used. Its essence is that the screw is wrapped at an angle of 15 degrees into both workpieces being connected, which allows you to hide the screw. The hole for the screw is drilled with a step drill using a jig that ensures drilling at a given angle. A step drill drills a hole for the working body of the screw and for the head.

Screw and bolt connections:

The photo shows examples of the use of screw and bolt connections:

The two parts are connected with 2 confirmation screws at an angle of 90 degrees; this is a simple and quick type of fastener. But unlike other types of fasteners, it remains visible, so plugs or overlays are used to hide the confirmation head.

Tie connections:

New connection from Festool using Domino connectors - essentially the same couplers, but with improved characteristics:

Tenon-groove connection: tenoning device and cutters for a hand router

Knowing how to make a tenon and groove with a hand router, you can even at home make not only beautiful but also reliable furniture, but also various wood structures characterized by excellent load-bearing capacity. The tongue-and-groove system connects not only elements of various furniture (tables, chairs and shelves), but also frames of low-rise buildings that experience significant loads during operation.

A tongue-and-groove joint made by hand

In order to make a tenon on a wooden beam using a hand router, several conditions must be met:

- securely fix the workpiece and correctly orient it in relation to the guide sole of the router;

- set the height of the working part of the cutter so that the tool removes a layer of material of the required thickness from the surface of the workpiece.

Even using the simplest tenoning device for a router when performing such processing, you can not only increase its productivity and quality of the result, but also make the technological process safer.

It is especially important to use such a device, which can be made with your own hands, in cases where furniture is produced not in single copies, but in series (in this case, the craftsman has to perform a large number of similar operations both with the same type and with wooden pieces of different shapes and sizes details).

The use of devices will speed up the process of making joinery joints using a router

Tips for working on connections

Anyone can make a tenon joint, but before serious assembly you need to practice properly if you do not have any carpentry skills. As a result, you can get a fairly high-quality fixation. And if you additionally fasten it with metal corners, then the strength of your furniture will be at a high level.

Manufacturing of dovetail tenon and mortise.

There are many ways in which a tenon joint can be made. But before considering the main most common ones, it is advisable to take into account some rules and subtleties that will definitely need to be followed while performing the work:

- If you have the opportunity, make the tenon using special precision equipment. This will ensure that the sizes of the tenons and grooves match each other as closely as possible. Such equipment is available in every carpentry shop or industrial labor training room.

- It happens that you are going to make furniture that does not require much precision. Then you can make the connections yourself. To do this, the tenons must be cut exclusively along the grain of the wood. In this case, the width should be approximately 17-20 times the thickness of the main part. This way you will be able to avoid chipping and cracking.

- Things are a little simpler when cutting tenons on plywood. In this case, the thickness of the spinal sinus can be absolutely any. The width of the main parts does not affect this. But the principle of matching in the direction of the fiber remains the same.

- After the tenons have been cut out and their size has been checked, the wood must be slightly dried. This refers to the usual keeping of the material indoors throughout the day. This way the wood will be able to take a permanent shape, which will help avoid bending of the joint in the future.

Connection techniques: 6. Connections of wooden structures (4). Tenon connection

Frame house. In the footsteps of old books. .

This connection is considered the most elegant, but it requires high qualifications.

The adjustment of sockets and tenons should be such that the tenons fit tightly into the sockets without destroying the wood fibers. If the fit is very tight, the spaces between the tenons or sockets may peel off, and if the fit is loose, the connection will be weak. To make a tenon, use a surface gauge to mark its height and the depth of the sockets at the ends of the workpiece.

After this, using a chalkboard or a special template, mark the location of the tenons and sockets on the side and end sides of both workpieces and begin sawing the contours along the wood fibers, using a fine-toothed hacksaw. In this case, the cuts should not go beyond the height line of the tenons.

Excess wood from the nests is removed with a chisel or chisel along a line drawn by a surface planer.

Rice. 1 Tenon joints:

A - “thorn nest”;

B - blind open tenon connection; B - jagged spike; G - double spike; D - multiple spike; E - single spike; F - round spike; Z - single through tenon with a blade; And - double-sided dovetail; K - one-sided dovetail; 1 - flat spike; 2 — socket (eye); 3 - blade Fig.

2 Elements of tenon joints: 1 - tongue and groove; 2 - ridge; 3 - round spike; 4 - flat tenon; 5 - eye; 6 — flat spike socket; 7 - round tenon socket

Sockets are selected without preliminary cutting, only using a chisel or chisel. This work is more labor-intensive, but it makes it possible to hide the tenon joint on the front side of the frame. Chiseling sockets and eyes with a chisel requires great attention and accuracy. In the case of a through socket, the workpiece is marked on both sides, and in the case of a non-through socket, on one side. When chiselling, you should adhere to the following rules: - the width of the chisel must correspond to the width of the socket; - use only a well-sharpened tool, since a dull one does not cut, but crushes the fibers; - You only need to chop across the grain.

Cutting along the grain can lead to splitting of the workpiece; - the chisel or chisel is placed with a chamfer inward, that is, in the direction that will be selected during the chiselling process. This will avoid crushing the wood fibers on the remaining part of the workpiece; — you cannot install the chisel blade on the marking line; it is necessary to retreat from it 1 mm in the direction that is selected (when hitting the handle with a mallet or hammer, the chisel will move towards the chamfer);

DIY tools and accessories

If you need to make some kind of piece of wood, then it is not economically profitable to purchase an expensive electric router. Most likely, everyone on the farm has the necessary set of tools, and if they have to buy more, it will be very few. In addition, additionally purchased devices may be useful in the future for minor repair work (for example, repairing wooden furniture). In order to make a tenon-groove joint with your own hands using only ordinary hand tools, you will need:

- wood hacksaw (fine teeth);

- carpenter's thicknesser (a special device for applying markings) or a regular construction square;

- Ruler and pencil;

- wood chisel.

Sources:

- https://lesoteka.com/obrabotka/shipovoe-soedinenie

- https://DrevoGid.com/materialy/soedinenie-derevyannyh-detalej.html

- https://SevenTools.ru/oborudovanie/soedinenie-fanery-v-ship.html

- https://stroyboks.ru/cvoimi-rukami/sovetyi-masteram/shipovoe-soedinenie-4-sposoba-izgotovleniya.html

- https://WoodShpala.ru/oborudovanie/posledovatelnost-shipovogo-soedineniya.html

- https://instanko.ru/drugoe/ship-paz.html

- https://pilka-nn.ru/izdeliya/ship-paz-svoimi-rukami.html

- https://extxe.com/6729/tehnologija-skleivanija-massivnoj-drevesiny/

- https://pilka-nn.ru/oborudovanie/stolyarnye-shipovye-soedineniya.html

- https://ooocentrsvarki.ru/raboty/chem-sdelat-paz-v-bruse.html

- https://MetizTorg72.ru/raboty-s-metallom/kak-sdelat-shipovoe-soedinenie-vruchnuyu.html

- https://dekormyhome.ru/remont-i-oformlenie/kak-mojno-samostoiatelno-sdelat-shipovoe-soedinenie.html