For many people, the word “stain” is associated with a certain liquid that can be used to give a wooden surface a particular shade. This property is present, but not only.

Wood stains have excellent antiseptic characteristics and can make wood more durable. The material is not a coating material, like paints and varnishes. Stains belong to the category of impregnations, as they are able to penetrate deeply into the structure of the wood. They are used for processing new wood products or coatings, as well as in the process of restoring old wooden objects.

Varieties of stains

So, what is stain? This is a ready-made liquid composition based on water, alcohol or oil, as well as a special powder that must be dissolved in water or alcohol-containing liquids.

Water stain is considered the cheapest. It penetrates the wood quite deeply. Available in a wide range of colors, it can be used to give any color to a wooden product or structure.

A significant disadvantage of water-based wood stain is its ability to lift fluff from the surface, thereby reducing moisture resistance. The negative impact of this impregnation can be reduced by pre-wetting the surface with clean water. After curing, the product is processed with sandpaper and then covered with stain. Oil stain for wood can give a wooden surface any color shade.

It is easy to apply to the surface and distribute evenly over it. Dries quickly and does not raise lint. It is obtained by mixing oil-soluble dyes.

It is diluted to the desired consistency with white spirit. An alcohol-based stain is a solution of aniline dyes in any alcohol. Most often it is used with a spray bottle. It is difficult to distribute this liquid with a brush, since due to the almost instantaneous drying of the solution, the coloring turns out to be uneven and spotty.

If the above varieties of stains impregnate the wooden surface, coloring, strengthening and disinfecting, then new acrylic and wax impregnations in addition to this create a protective film on the wood. The surface treated in this way does not require additional coating with varnishes or paints.

How to make it yourself

You can prepare a simple stain for wood processing at home:

- from plant ingredients;

- from tea and coffee products;

- from chemical components.

Based on plant materials

- Decoction of onion peels to obtain a bright red hue.

- A decoction of walnut peels to obtain a rich brown hue. To do this, the shell is crushed to a powder and boiled for 12 minutes in water. Add 1 tsp to the finished strained broth soda _ To obtain a red tint, potassium bichromate is added instead of soda; for a gray color, vinegar essence is added.

- Decoctions of oak, willow and alder bark give a rich black color.

- A decoction of buckthorn berries will paint the wood an attractive golden color.

From coffee, tea and vinegar essence

- To get a rich brown tint, it is enough to combine natural ground coffee and soda .

- To stain light wood, you can use a strong brew of black tea .

- To obtain a deep black shade, you need to place metal nails in a container and fill them with acetic acid . Leave for 5-7 days in a dark place.

Based on chemical components

- The brown tint is obtained after treating the wood with a solution of slaked lime .

- A deep cherry tint is achieved by applying a solution of potassium permanganate . To do this, you will need 60 g of potassium permanganate, which is diluted with a liter of heated water.

- A rich yellow tint is obtained by treating the surface with a decoction of barberry roots , to which alum is added.

- The herbal color will be obtained by combining 60 g of verdigris and vinegar essence . The mixture is boiled for 10 minutes.

- The dark brown color is obtained by combining wolfberry with copper sulfate . Glauber's salt with these berries gives a red color, and soda gives a blue tint.

With whitening effect

Bleaching stains are used as a base before painting wood, allowing you to achieve unusual color solutions . For example, apple wood can acquire a noble milky hue, and walnut can acquire a red or light pink color.

Whitening stains can be prepared as follows:

- Composition based on oxalic acid. To do this, 6 g of acid is diluted with 120 g of warm water. The finished stain is suitable for processing light or bleached wood. After application, the surface is thoroughly washed with the following solution: 4 g of soda and 16 g of lime are diluted in 110 g of water.

- Hydrogen peroxide based solution. To do this, you will need a 30% peroxide solution, which is available for sale at any pharmacy. It is suitable for bleaching various types of wood. However, it should not be used on oak, rosewood or mahogany.

How to prepare wood for processing

Treating wood with stain is not such a simple process as it may seem to an ignorant person. To achieve the desired result, it is necessary to take into account some of the subtleties and nuances of this procedure, and also perform all stages of staining in order.

First you need to choose a color, a suitable composition of the solution and tools for applying it.

For quick-drying compounds, you need to prepare a spray gun or other sprayer. You can work with oil, water or acrylic stains with a brush, sponges, or swabs. It all depends on the size of the surface to be finished and the expected effect. Preparing a wooden product for painting involves drying the new surface or cleaning the old one from the previous finish to the body of the wood.

The dry product must be carefully treated with sandpaper or a grinding machine. To avoid the appearance of new defects, movements should be carried out along the fibers. Scratches, dents, and chips on an untreated surface may be inconspicuous, but after coating with wood stain they appear quite noticeably. By grinding, the treated surface is brought to a completely smooth state.

Then the dust and removed fibers are removed. To do this, you can use a vacuum cleaner or a soft cloth. The next stage is degreasing, most often done with white spirit. Before applying the main composition, especially water stain, the product must be moistened with clean water. And sand again.

Some nuances occur when preparing coniferous wood products for working with stains, especially those with high resin content.

The fact is that after applying the stain, resinous areas can appear through the coating in ugly spots. It is best to first rid such wood of such manifestations. To do this, use one of the compositions:

- an aqueous solution of acetone, for this purpose mix 750 g of water and 250 g of acetone; a soda mixture consisting of one liter of warm water, 60 g of soda ash and 50 g of potash (potassium carbonate).

To get rid of the resin completely, the treatment must be performed several times. Then rinse the product thoroughly with soap and then with clean water. Dry and then carry out traditional preparation for staining.

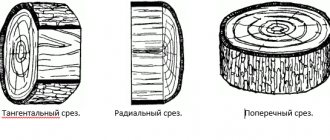

Tree type

Before you start working directly, you must understand what kind of wood needs to be stained. Experts divide wood into soft and hard. So, soft types include trees such as fir, spruce or pine, and hard types include walnut, oak, ash, and so on. If you don't know what kind of wood you have in front of you, use the following advice. Inspect the product. The grainy structure, uneven surface, and spotted patterns indicate that this is soft wood. But the uniformity of the pattern and structure, the absence of pronounced spots indicate that this is a hard type of wood. It should be noted that very hard woods, for example, oak, need to be stained in several layers. But the result will justify the time and money spent on the work.

Dyeing technology

How to stain wood correctly? You should work at an air temperature above +15°C, this will allow the stain to penetrate deep into the pores of the wood. Manufacturers recommend that before applying the base substance, cover the surface with conditioner of the same brand.

The stain should be mixed thoroughly so that the dye does not remain on the bottom or walls of the vessel. When using any tool (brush, roller or sponge), a sufficient amount of stain should be applied to the surface. Let it be better to have an excess (it can be removed after staining) than a deficiency.

When processing a vertical surface, you need to work with movements from bottom to top. If you are staining a horizontal part, you must first move the brush along the grain of the wood, then across it, then again along it. This way you can achieve uniform application and avoid unnecessary smudges.

Staining one part or surface must be done in one go, without interruptions. Otherwise, spots and uneven coloring may appear.

To obtain an even tone and a high-quality result, the staining process is repeated several times. Each subsequent layer is applied only after the previous one has completely dried.

How long does it take for stain to dry? The drying time depends on many factors: the composition of the stain, the ambient temperature, the degree of humidity of the base. On average, alcohol-based compositions dry in 1-2 hours, aqueous solutions - at least a day.

After the impregnation has completely dried, the surface is subjected to the final stage of wood processing, which is called washing. This action removes excess stain that the tree did not accept.

The procedure helps the wood to reveal itself in all its beauty and brilliance. Cleaning is done using acetone and a large paint brush. The product is installed at an angle on a soft substrate.

The brush must be moistened with acetone and brush off excess stain using top-down movements. As soon as the treated surface acquires a uniform appearance, the procedure is completed. Now the product needs to be dried and can be varnished.

How to cover wood with stain - basic rules

In addition to the recommendations described above, there are also universal rules for working with stain:

- For better adhesion, it is recommended to preheat the stain to 35-38°C.

- If you are not sure whether the stain will work or not, it is better to first try it on a similar unnecessary piece of wood. And it is advisable to do this in several layers.

Example of test application of stain in 1, 2 and 3 layers - There is no need to heavily wet the brush, roller, swab, etc. stain, otherwise smudges may remain on the material, and the solution itself will be distributed unevenly.

- The stain is usually applied along the grain of the wood. If you are using a tampon, you can do this in a circular motion.

Applying stain with a rag - Vertical surfaces (windows, doors, walls, fences, etc.) are covered with stain from bottom to top to prevent unnecessary smudges.

- You need to work carefully, trying to paint everything evenly, but as quickly as possible - no downtime or interruptions are allowed, otherwise the texture will turn out uneven and with spots.

- If excess or smudges have formed, they must be quickly wiped off along the grain.

- The first (and subsequent) coats should be allowed to dry thoroughly before applying the second. Drying times are usually written on the product label. Depending on the type of stain, this is from half an hour to half a day.

- The stain application process can be repeated several times, layer by layer, until the desired color is achieved.

Useful videos and master classes on the topic:

Multi-colored dyeing

Wood stain, what is it for?

It would seem that the technology and material have long been known. But the question remains open for many. Staining wooden surfaces is done in order to give them a certain shade that emphasizes the texture of the wood.

In addition, stain makes the wood stronger and more resistant to damage from dampness, mold, fungi and wood-boring insects. But the possibilities of staining do not end there. Using stains of different colors you can create various effects on a wooden surface:

- bleaching; aging; color stains.

To create a bleached surface, two compositions of different qualities are used.

First, a continuous coating is made with white water stain, which is thoroughly dried. And then all the recesses and pores are filled with an oil-based stain with the addition of hard wax. In this case, a very thin waxy film is formed, which highlights only the pores in black or gray, while the rest of the surface remains whitish.

If it is necessary to obtain a multi-colored effect, then first a test is made to select shades on a separate piece of sanded board. When it is possible to achieve the desired color combination, we begin processing the product.

First, the main background is applied. Then chaotic or ordered strokes are made over it with other color shades of stain. The finale will be a final coating with clear or tinted varnish.

Wood requires special protection; in most cases, to solve this issue it is enough to use paints and varnishes. For example, you can learn how to stain wood. It will be able to penetrate the wood structure and protect wooden products from deformation, moisture and dirt.

Wood processing materials

First you should study the existing range of paints and varnishes. We pay attention exclusively to options intended for lumber.

Dealing with defects

When treating the surface of wooden and wood-shaving products, you need to act quickly, since the substance tends to dry out instantly. If it is not possible to immediately cover the entire area of the structure, the resulting defect in the form of spots can be removed or made less pronounced. If streaks occur, it is also possible to eliminate the unpleasant consequences. In both cases, it is advisable not to put off work until later.

A numbness has formed

Possible removal methods:

- applying a varnish that can dissolve the bottom layer, after which the treated area is cleaned with a rag;

- old leakage must be removed with a solvent, in this case it should be done locally;

- An alternative option is to use a plane or sandpaper.

The disadvantage of the latter method is the high risk of damage to the tree. Because of this, the treated area may be conspicuous in the future.

Stains

The reason for the formation of such defects, if all the rules are followed, is the uneven release of resin in the wood structure. You cannot influence this process. However, it is possible to close the pores of the wood, so that the stain will be evenly distributed over the surface. For this purpose, special gel-based conditioners are used. They do not contain water, which avoids surface deformation due to swelling of the fibers.

Alcohol varnishes

Shellac

A group of transparent and translucent coatings that can be used to add shine to a surface and also protect it from external factors. They include complex components:

- shellac; sandarac; copal; synthetic resins.

Carefully study the label with the varnish; the strength of the alcohol used must be at least 90º. Ethyl alcohol can be used as a solvent.

The right product will highlight the structure and tone of the wood.

Potential problems

If handled incorrectly, drips may occur. This happens when too much stain is applied to the surface. In such a situation, you need to remove as much excess stain as possible. To do this, you need to apply another layer of stain, and then use a rag to remove the excess layer of the compound. A solvent is used to remove dried impregnation. You can also use sandpaper or a plane.

Stains on wood may appear due to uneven density of the material. On some species (for example, walnut), spots do not spoil the appearance, but on coniferous wood or cherry, spotting looks unattractive. Stains can only be removed with a plane. You can prevent the appearance of stains by using gel stains. Such compositions do not spread over the surface and are absorbed for a long time, so the formation of stains is unlikely.

Oil varnishes

Oil varnish

Among the main components are resins and pigments that are dissolved in oil. The consistency can be liquid or semi-liquid, which allows it to be applied to the surface of wood with a brush or roller.

Affordable price is an attractive and positive factor for the majority of the population. After treatment, a thin transparent film appears on the surface, which acts as a protective barrier to moisture and ultraviolet healing. A characteristic yellow tint may appear.

A high degree of protection allows you to coat wooden products that are in the open air with oil varnishes.

Nitrocellulose varnishes

Nitrocellulose

The base includes nitrocellulose, which is diluted in organic solvents. The applied layer will take a long time to dry, so you should take the item away from open windows and doors. The resulting hard coating will be resistant to both sunlight and mechanical loads.

When working with this varnish, you need to take care of your protection: wear a respirator, safety glasses and rubber gloves.

stain

The staining process is used to impart a specific color to wood, in particular the color of a different type of wood.

The applied composition will penetrate into the structure without creating a film. This allows you to highlight the structure and pattern of the wood and, in addition, protect the wood. Main types of stains:

- water-based; solvent-based; wax-based; alcohol-based.

In a specialized store you can find the following assortment of stains: liquid concentrate, solution and powder.

Popular fighters

Zar Wood Stain Oil Based Wood Stain

Tinting impregnation is suitable for wood, plastic, steel. One layer is enough to get rich color. When working with the coating, streaks and smudges do not form. There is no pungent odor.

| Purpose | for interior work |

| The basis | oil |

| Surface type | tree |

| Properties | dries quickly and is moisture resistant |

| Color | Walnut |

| Consumption when using the rubbing method | 0.946 ml per 65-70 m2 |

| Consumption when using a brush | 1 quart per 30-35 m2 |

| Drying time | 3-4 hours |

| price, rub. | 710 |

Solvent stain for pine CL 58-5719 “Sandalwood” 1l

The impregnation is ready for use and does not require preliminary dilution. Feature – high light fastness. The composition penetrates well even into the dense structure of wood. When applied, it is evenly distributed over the plane. The highlight of the stain is high German quality.

| Purpose | for interior work |

| The basis | organic solvents |

| Surface type | tree |

| Color | sandalwood |

| Spray consumption | 1 l per 5-8 m2 |

| Application method | pneumatic spray |

| Drying time | 2 hours |

| Further processing | water-based varnishes, polyurethane and nitrocellulose varnishes |

| price, rub. | 484 |

Wood stain oil Varathane Wood Stain Dark Walnut jar 0.946l

An environmentally friendly product, for the production of which plant raw materials are used. Beitz has the ability to penetrate deeply into the wood structure, emphasizing the natural pattern. A rich color is obtained even after one surface coating. The product applies smoothly without forming spots or streaks. When used on soft woods, pre-treatment with conditioner is recommended.

| Purpose | for interior work |

| The basis | soybean oil |

| Surface type | tree |

| Color | dark walnut |

| Consumption per layer | 0.946 l per 25m2 |

| Drying time | 1 hour |

| price, rub. | 2124 |

Non-aqueous stain NBCH, ebony color 0.5 l

The composition gives the surface noble shades, the intensity of which depends on the number of layers and the original color of the wood. The main purpose is interior work. But subject to subsequent varnishing, it can be used externally.

| Purpose | for interior work |

| The basis | aqueous polymers |

| Surface type | tree |

| Color | ebony |

| Consumption per layer (brush, roller) | 100 ml/m2 |

| Complete drying time | 4 hours |

| Interlayer drying time | 2 hours |

| price, rub. | 72 |

Removing an old layer

The wooden surface should be prepared

It is necessary to apply both varnish and stain exclusively to the prepared surface, if we are talking about an old piece of furniture. Today, you can use three ways to clean wood from old coating:

- washing; thermal impact; mechanical impact.

Use varnish remover

It is necessary to determine which method is suitable on an individual basis, based on the type of product and paint and varnish materials that were used before. Let's consider each method separately.

In the first case, the old varnish is removed using special liquid solutions. It is applied to the surface with a regular paint brush, after which it is wrapped in plastic film to create a thermos effect. After a day, the coating is removed using a spatula and washed with water.

Applying a new layer is possible after 24 hours. The second method is faster, but for this you will need a hair dryer. Armed with a simple spatula, you can begin the process: a small area is heated and the old coating is carefully removed. The third option is suitable for treating a large area, such as a cabinet or floor. You will need a grinding machine from special tools; the residues are cleaned with sandpaper.

After treatment with the remover, cover with film.

In most cases, solvents contain toxic substances, so you should wear a respirator when working with them.

Surface preparation

Defects and cracks are eliminated with putty

It is not enough to simply remove the old layer; the surface needs additional processing, that is, grinding. Regardless of whether the material is new or old, it must be carefully examined for defects. If seams, cracks and knots are found, they should be eliminated.

The gaps at the joints are sealed with a special putty for wood. After drying, the irregularities are smoothed out with fine-grain sandpaper. There is no need to process raw wood, since all actions will be meaningless: when drying, the wood is deformed, and accordingly, the applied layer is also deformed.

How to solve the problem of spotting?

An uneven tone of the finish, when the stain is stronger in some places and weaker in others, is a common problem that is associated with the characteristics of certain types of wood. Spotting can occur when processing resinous wood, as well as wood with uneven density or plywood. In the first case, it is recommended to deresin the surface, in the second - to pre-treat the wood with special conditioners that will close the pores and ensure uniform absorption of the stain.

Applying stain

Due to the property of deep penetration of stain into the pores of wood, the solution enters into a chemical reaction with tannins, due to which the product will be completely protected from fungi, mold and insects.

To know how to properly apply stain to a wooden surface, you need to familiarize yourself with technologies and techniques. Rubbing. The stain is applied to a wooden surface, and then rubbed over the entire area. The result is a pronounced texture and natural pattern. Stains are especially good for porous types of wood; compositions with a long drying time are suitable for them. Spraying. The shade of the stain is selected several tones lighter than the desired one.

The liquid is applied using a spray gun, resulting in a perfectly flat surface. Roller or swab. As in the case of painting the surface with a roller, you will need a special tray. Liquid stain is poured into it and then applied to the wood. No streaks or drips.

This technique is especially popular when treating floors. To make a tampon you will need cotton wool and a clean cloth. A brush. Simple and accessible technology for everyone. It should be noted that coating in one layer will give a color that is relatively deeper than with other similar application methods. Use a brush All of the above tools for staining wood are equivalent, so when choosing, you can be guided solely by your own preferences. The processing technology is no different from conventional painting.

But there is one important point: most stains dry out very quickly, so you should work quickly and carefully. Do not let the applied layer dry before completing the work, otherwise this area will differ from the rest of the surface. The stain must be applied parallel to the grain of the wood, avoiding the layers touching. As you can see, the process is quite simple. The number of layers applied depends on the desired shade.

To consolidate the result, the wooden product or surface must be varnished.

Peculiarities

You should remember the characteristics of wood types before staining. Soft wood will not stain evenly if you simply apply stain. The secret is to apply the primer before you stain. It is this trick that will make the wood stain even. If you want to emphasize the natural grain of the wood, you don’t have to use a primer. By the way, the primer should be mixed with a special composition, which is necessary for a good result on wood. Solid wood is less capricious, and therefore can be stained without prior preparation. Staining will make the product more elegant and attractive.

Removing old coating

Always apply varnish to a clean surface.

If this is a new product, then no problems arise. But there are often cases when it is necessary to varnish already painted wood, such as window frames, doors or wooden floors, the surface of which has been damaged due to long-term use. And if the integrity of the coating is compromised, then its protection is also compromised. Therefore, before starting a new treatment, you need to completely clean the surface of the old varnish layer.

There are three main ways to clean wooden surfaces from old coatings: washing with special solvents, thermal or mechanical action. It is necessary to determine which method is best to use in each case individually, based on the type of product and the materials used to cover it.

The surface of the product is wetted with a solvent, then removed with a spatula.

In the first method, the old varnish is removed using special liquid solutions, with which the entire surface of the product is generously moistened with a paint brush.

Immediately after processing, the product must be covered or wrapped with plastic film to create the effect of a thermos. After 24 hours, the film is removed and the old coating is carefully removed with a spatula. If the coating is difficult to remove, the entire procedure is repeated again, and so on until the wooden surface is completely cleaned.

When working with solvents, it is important to remember that they contain toxic substances. Therefore, they must be applied with glasses, rubber gloves and a respirator.

After cleaning is completed, the wood is wiped with warm water and allowed to dry for at least a day. After this, the surface is sanded and primed again. And only after this can a new varnish be applied.

In the second method, the wood is heated to remove the old coating. At the same time, the varnish softens and can be easily removed with a spatula.

Heat with a hairdryer, you can also use a blowtorch. But it is more difficult to work with, because you need to constantly ensure that the wood does not overheat and catch fire. To protect it, it is better to first moisten it with water and only then process it.

The latter method is more often used if you need to remove the old layer of varnish from a large area, such as a floor or a wooden terrace. Remove it using a grinding machine, and the remaining varnish is removed with sandpaper.

Painting wooden products with stain and varnish

To enhance the wear resistance and attractiveness of the surface of wooden products painted with stain, they are additionally opened with varnish. At this stage, many are faced with a problem when, when applying varnish, the stain begins to smear, which ultimately irreparably spoils all the work done.

At the finishing stage it is important to remember:

- water-based stains must be combined with NON-aqueous varnishes;

- alcohol stains – with non-alcohol paints and varnishes.

Wood is often used in country or home projects. However, in its natural form it does not always look decent, matching the surrounding objects and furniture. When exposed to ultraviolet light, it turns gray. Without being coated with any protective composition, wood is very hygroscopic and begins to “play” not only from moisture that gets on it, but even from the difference in summer and winter humidity. Therefore, wood finishing is an almost necessary procedure if you want a wooden item to retain its consumer qualities for as long as possible. In addition, a properly finished item has a much more decorative appearance than its natural appearance. This article talks about a simple way to finish wood.

You can trim any type of wood, from birch to oak. However, different breeds look different after finishing. For example, birch (not Karelian or birch burl, but our ordinary birch or birch plywood) is quite homogeneous. She does not have contrasting transitions or streaks around the knots. Spruce and pine look quite beautiful, especially their “round-knot” parts. And oak, beech, and chestnut look absolutely gorgeous.

Before finishing, the dry wooden part is carefully sanded with sandpaper. In this case, all movements of the skin should occur strictly along the fibers and without strong pressure. Any deep transverse scratch after staining and patching will immediately become noticeable.

After sanding, the wood must be thoroughly vacuumed to remove all microscopic dust from its fibers. After this, the part is coated with wood stain. Stain can be aqueous or non-aqueous. Water, naturally, on the water. It is used quite rarely and for small parts. Non-aqueous (solvent based) - for anyone. Personally, I prefer non-water. It has a wider range of colors and is easier to work with; it absorbs quickly and dries quickly.

So, the prepared wood is generously impregnated with stain. In general, small parts are stained by immersion in stain. But you can’t immerse a large board or panel, so they use a regular brush. The stain is applied to the wood in excess, trying to apply it so that the wood absorbs as much stain as possible, and the stain penetrates as deeply as possible into the wood. After this, the parts are allowed to dry a little and proceed to the second important stage of finishing - washing.

During washing, all excess stain that remains on the surface of the wood and is not absorbed is washed off. At the same time, the pattern of wood fibers is sharply revealed and its contrast is significantly enhanced. The tree becomes much more beautiful.

Non-aqueous stain is washed using a large amount of acetone. Use a thick, large brush. In order to actually remove excess stain, and not spread it across the wood, proceed as follows. The brush is dipped into a bowl with acetone and, holding the wooden part at a slight angle (20-30 degrees), with light pressure, move the brush from top to bottom, as if driving off excess stain. The other end of the part rests on the work table and some very hygroscopic material is placed under it. I use paper napkins. They are not expensive, and they absorb moisture perfectly - that’s what they are designed for.

When the brush reaches the end of the part, it slides onto these napkins and the acetone-mordant mixture is immediately absorbed by the napkins. Then the brush is again dipped in acetone and the stain is washed off. And so on until the part becomes uniform and stops being washed. After this, the parts are again allowed to dry a little, this time with acetone.

The third and final stage is varnishing the part. It is carried out in two stages. The first stage is the so-called raising the pile. As you know, wood is very hygroscopic and readily absorbs any liquid that comes into contact with it. At the same time, it changes its geometric dimensions - i.e. swells. Therefore, after staining and washing, it is no longer as polished as it was before the finishing procedure began. And you can feel it by touch by running your palm over its surface. Therefore, the pile is raised for the purpose of its further removal by sanding.

The pile is raised using quick-drying furniture varnish type NTs-222. This is a nitro varnish, dissolved with acetone or solvent 646. Having diluted a little varnish with a wide soft brush, quickly sweeping movements along the fibers cover the entire part and allow it to dry. After the varnish has dried, you will feel, when you pick it up, how rough it has become. This is lint - small fibers of wood that have become detached from neighboring cells, have begun to bristle and have hardened under the influence of varnish. Therefore, the part is sanded again using fine sandpaper. In this case, sanding machines are not used, but are sanded only by hand.

Having sanded the part, it is carefully vacuumed again and subjected to final finishing. Its type is chosen depending on the purpose of the part, the place of use (house - street), what the owners like (matte or glossy surface), etc. If the part is intended for home use, it is enough to cover it with another 1-2 layers of the same NTs-222 varnish and it will acquire a semi-matte surface.

In general, this method of finishing wood is quite cheap, allows you to get a fairly decorative appearance and has only one drawback. Quite strong-smelling materials (varnish, acetone) are used here. Therefore, all work should be carried out either outdoors or in a well-ventilated area equipped with an exhaust hood. In addition, we must take into account that these are very flammable materials. Therefore, there should be no open fire nearby.

Konstantin Timoshenko

A comment.

Sometimes, while sanding wood, unpleasant scuffing occurs, and sometimes the loose piece is lost. In the vast majority of cases, these exfoliated or completely fallen off acute-angled fragments of the structural pattern are almost the most beautiful places in the entire pattern. (They are clearly visible in the photographs attached to the article) Peeling can also occur during the drying stage of the stain. Regular sanding after varnishing is not enough. The chips, as a rule, bend out of plane by 1.5-2 millimeters, and after patching - even higher. When faced with such a nuisance, you shouldn’t get too upset. Just glue the capricious petal before further processing with any product suitable for gluing wood and do not forget to press down, carefully removing the squeezed out excess. By the way, in order not to bother with glue, you can use varnish prepared for subsequent coating. The gluing procedure is the same. Once dry, sand lightly if e! There is a need, the place has been restored and you can safely proceed to further processing.

If the workpiece has defects (chips, cracks, traces of the vital activity of various insects or the losses described above), and replacement, for various reasons, is impossible or undesirable (unique design, complex shape, for example), then it is necessary to carry out a simple restoration. To do this, it is advisable to collect and store the resulting wood dust at the sanding stage. A little later, it will serve as a filler in the preparation of “putty”. The wood is perfectly putty. But you will have to prepare the mixture for restoration work yourself. The base is preferably colorless furniture varnish; the filler is already known and if there is not enough of it collected, take a homogeneous piece of material and sand it with a sander as much as necessary; the color is still the same stain, non-aqueous, of course. Or in most color schemes - ordinary iodine. Alcohol and a solvent are, of course, an unimportant combination, but I did not observe any rejection reactions. Take a sniff of wood powder, add a drop of varnish, stir it with something! add color little by little, continuing to adjust until the desired shade is reached. You can apply the solution (putty) with any tool that you think is convenient, even if it is not intended for the purpose. For example, I fell in love with poster feathers of different widths. A thin feather is convenient for applying the putty mass, and a wider feather is for “rubbing and smoothing.” And don’t rush to straighten the surface immediately after sanding!! This procedure must be performed only after tinting the product with stain and washing, since the hardened mixture practically does not take on the color. But if he does (you can force a mountain to move), then the result obtained will be far from the desired one. You know, it is very difficult to give a leveled tiny area the required shade by repeatedly poking it with a brush or swab, without coloring the adjacent surface. And she already absorbs the color with great pleasure. So you will have: it’s dark there, it’s light here, and then vice versa. And on the wood drawing! your daub won’t work at all.

Also, you should not prepare the mixture for the entire volume of work at once, unless, of course, you have a single defect of a uniform color. Adjusting shades is not a quick task, and the mixture dries before you know it. Therefore, mix the “putty” exactly in the amount that is necessary to straighten one specific color fragment. Upon completion of the repair and after the mixture has completely hardened, very carefully rub the restored areas with “zero” and, having appreciated the result, proceed to varnishing and polishing.

Dmitry Petrov.

It should be added that, as a rule, unfortunately, soft fibers that have a lighter color are best impregnated with stains, and dark fibers that have a higher density are impregnated worse. After staining we get a certain tone, of course, but in professional language this color is called negative.

To prevent this from happening, the surface must be primed with a solution of liquid glass and water before staining. After drying, the surface takes on a slightly older appearance and the pile rises. Now all this just needs to be sanded a little and can be treated with stain. The liquid glass has closed some of the pores of the light fibers and will now stain more beautifully and with contrast.

Finishing any wooden structures is a responsible process and requires careful work. Any wooden product requires staining. Staining is coloring. So, let's talk about how to stain wood yourself to get excellent results.

Surface preparation

All cracks on the wooden surface must be carefully puttied and sanded.

The varnish can only be applied to a sanded smooth surface. Regardless of whether the new material needs to be varnished or the old one, it must be carefully examined. All discovered seams, cracks and knots must be processed and eliminated.

Any gaps found between seams and joints must be sealed with special putty. After application, the putty is allowed to dry, and then, to remove possible unevenness, the putty areas are sanded again with fine sandpaper.

It is also necessary to take into account the fact that it is pointless to putty on raw or even under-dried wood, much less treat it with drying oil, stain or varnish.

When drying, the wood becomes deformed, and the applied layer will inevitably be damaged.

The stain should be applied parallel to the grain of the wood, avoiding contact between the layers.

To better protect wooden products, they must be treated with stain (impregnation).

The stain, penetrating deeply into the pores of the wood, enters into a chemical reaction with the tannins found in the growth rings and gives the wood a durable water- and light-protective color. It also protects the tree from mold fungi, grinding beetles and other pests and infections. Modern liquid stains are divided into three groups: alcohol, oil and water.

Water stains come in two types: in the form of ready-to-use solutions and in the form of powder, from which such a solution must be prepared. This is the only type of stain that does not require white alcohol, drying oil and other solvents.

Stains of this group have one significant drawback: penetrating into the wood, they lift its fibers, which makes the wood unprotected from excess moisture. Although, on the other hand, such processing of wood allows you to emphasize and highlight its structure. Therefore, today this is the most common type of stain.

Alcohol stain is produced in the same two varieties: ready-made and in powder. This stain cannot be applied manually with a brush, but only with a spray gun, as it dries in almost seconds.

Oil stain is the most convenient to use.

It is easy to apply evenly, does not lift wood fibers and dries quickly. In addition, by mixing dyes in oil, you can use it to give the wood almost any shade. Oil stains are diluted with white alcohol or drying oil.

To treat wooden surfaces with stain, the following are used:

- paint brush; foam roller; manual or automatic sprayer.

All of these tools for staining wood are of equal value, and when choosing, you need to be guided solely by common sense. For example, it takes a very long time to stain several dozen squares of wooden floors with a paint brush, and you can’t treat the window frames with anything else other than a brush.

The staining technique is no different from conventional painting.

The only condition: since most stains dry quickly, you need to work quickly but carefully. It is important not to let the stain layer dry before finishing the work, otherwise there will be a seam in this place that is noticeably different from the rest of the surface. Therefore, you should not put a lot of solution on the brush.

The stain is always applied parallel to the direction of the wood grain. And you cannot move on to processing another figure or section without finishing the first one. In places where two sections are connected, care must be taken to ensure that the applied layers of stain do not overlap each other.