Classification

The copier is used in lathes for wood and metal. It significantly simplifies the work on the template and speeds up production.

On wood

There are the following types of woodworking equipment with a copier:

- Classic, where a chisel is used as a cutting tool. Such machines are not suitable for large industrial production.

- Copiers with manual control type.

- Copy milling machine. It is used for processing flat and three-dimensional workpieces.

- Units with Numerical Program Control are used in mass production for the manufacture of expensive products.

Machines with a copier have an increased level of accuracy and performance in terms of technical characteristics.

For metal

For metal, the classification of lathes is similar. There are classic models where the workpiece is fixed in a faceplate or chuck and processed with a cutter. Copying machines are used to produce products in circulation.

Milling types of machines are used for processing flat surfaces and volumetric workpieces. CNC is used on an industrial scale.

Wood cutting machine Proma DSL-1200

The model in question is intended for processing wooden products that can be used as decorative elements. Experts call a distinctive feature of the design the presence of two incisors:

The first is designed for processing cylindrical workpieces; more than 10 mm can be removed in one pass. Using the first cutter, you can get a round workpiece, just like on a conventional lathe.- The second cutter is designed for copier work. It is this that allows you to produce various products using a copier.

This machine model can be used to work with large workpieces. To do this, the structure is equipped with a steady rest, which is mounted on rods that act as guides. The installed faceplate allows processing multi-faceted products.

Main characteristics of the model:

- The installed electric motor operates from a three-phase network with a voltage of 380 V. That is why the machine is not purchased for installation in a private workshop.

- The maximum length of the workpiece is 1200 mm.

- The layout is represented by a combination of two columns, between which the workpiece is placed. Note that the machine has a compact size, due to which it does not take up much space in the workshop.

The disadvantage of this proposal, like many others, is the rather high cost.

Device

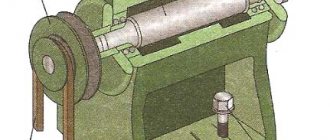

The classic design of a turning unit with a copier includes 5 main components:

- Solid metal frame. This is the main element to which other machine components are attached.

- Front and rear headstock. They contain a drive, an electric motor, and a gearbox. The stop head is necessary for fixing the workpiece.

- An electric drive and motor ensure rotation of the workpiece.

- Directly to ensure high-quality work on the machine there is an emphasis.

- Master and slave centers.

The copier itself is a removable structure.

Copy model CL-1201

To produce wood products, a machine model CL-1201 or CL-1500b can be used. The first version has very attractive performance characteristics:

- The spindle used can change the direction of rotation. Due to this, the scope of application of the model is significantly expanded. Changing the direction of rotation of the spindle is carried out with a special handle.

- The machine allows you to select the spindle rotation speed with high precision. Due to this, it is possible to provide the most favorable conditions for turning wood based on the weight, dimensions and type of wood.

- There is a remote control to set basic parameters. The design can be installed on the headstock or tailstock, depending on the preference of the master. The remote control is represented by a combination of several keys.

- Cast iron is used in the manufacture of the column. In addition, the frame is manufactured using high-quality steel. By combining these materials, the degree of vibration of the structure during operation is reduced.

- The basic delivery includes a copier, which can be used for processing. Due to this, costs are reduced and the machine becomes more functional in use.

- The design of the machine has a milling attachment, which can be used to produce longitudinal grooves.

- The tailstock is used for more precise fixation of the workpiece. Its position may also change. The supply includes centers, which are selected depending on the characteristics of the workpiece.

- The support is characterized by high mobility. The cutting depth of the tool can be adjusted using a lever.

In addition, the manufacturer paid quite a lot of attention to the degree of protection of the machine from environmental influences. For example, the engine has a protection system against overheating or overload, all electronic parts are also protected from moisture and dust.

The only but significant drawback is the high cost of the proposal. A homemade design will cost several times less.

Do-it-yourself homemade lathe and copying machine with drawings

Buying an industrial copy lathe is not so cheap. Therefore, many craftsmen prefer to make it at home with their own hands. If you have certain knowledge and a drawing, this is not difficult to do. The capabilities of such equipment depend on the characteristics of the copier itself.

Required Tools

To make equipment, a turner will need the following tools:

- manual frezer;

- support made of plywood or metal;

- bolts;

- persistent bars;

- a pipe 2.5 cm in diameter to give direction for movement around the site.

The main tool when creating a copy lathe is a milling cutter.

Design elements

The main equipment spare parts that should be in a simple machine:

- bed;

- headstock and headstock;

- electric motor;

- master and slave centers;

- support for equipment.

The simplest model is made from a drill.

Manufacturing stages

The manufacturing algorithm for a turning unit is as follows:

- According to the finished drawing, it is necessary to manufacture the frame by welding. It must be reliable and withstand varying levels of vibration.

- Then install the electric motor. The optimal option is 200-250 W, rated at 1500 rpm.

- Attach the faceplate to the shaft.

This creates the basis of a standard machine. Then you should make the copier itself.

Creating a copier

Basic principles for making a copier that will help increase productivity when creating identical parts:

- you will need a hand router, and to install it, a plywood surface;

- holes should be made in the plywood platform to secure the bars;

- secure the bars with self-tapping screws;

- when making a copier, it is necessary to use a level, since even a small inaccuracy can lead to significant errors in the manufacture of the product;

- the platform must move without obstacles along the machine bed.

Installation of structural elements

After creating the copier, you need to install all the structural elements:

- Place the block horizontally and attach the template to it with self-tapping screws;

- The structure itself must be made in such a way that, if necessary, the copier can be tilted or moved aside and the machine can be used as standard turning equipment.

Horizontal block

This is an important element. The size of the block is ideally 3x7 cm. It is attached to vertical stands on a plywood platform using self-tapping screws.

Sample

The template is made from plywood. Attach it to the front of the beam. The upper platform must be checked for alignment with the axis directly on the template.

The edges must be treated with a sanding machine so that there are no nicks on them.

Personal assembly of equipment at home

Lathe

In order to assemble a small copying machine for wood with your own hands, you will need to make some effort and patience, as well as invest financially (about 7-7.5 thousand rubles). But this is several times less than the costs that await you if you purchase a ready-made option.

These are the masterpieces of interaction between hands and head found in private workshops

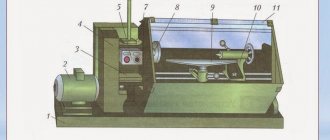

The model of small-sized equipment of the so-called beam type proposed for assembly can be divided into the following components:

- Frame.

- Slave and leading center.

- Electric motor.

- Front and rear headstock.

- Stop for cutter.

Now we’ll tell you in more detail about how a wood copying lathe looks and is assembled:

- It is clear that the frame is the foundation of the entire structure, on which all other parts will be based. Therefore, appropriate requirements are placed on it. It must be strong, stable and reliable. Therefore, it is better to make it from a steel profile, but a wooden beam with a large cross-section is also quite suitable. The electric motor and the driving center are connected to each other and fixed to the front of the base. Due to the electric drive, the blank is rotated.

Another option where the sampling depth depends on physical strength (pressing the handle, in the photo)

Attention! The selection of an electric motor for a copying device for a wood lathe is carried out taking into account the size and complexity of the parts planned for production. For the simplest tasks, a 200-watt unit will be sufficient.

- The headstock serves as a stop for the workpiece, so it is permanently attached to the frame.

- By moving the tailstock along the frame, the workpiece will be transformed into a part of a given sample.

- A stop for the cutter is installed between the tailstock and the front headstock, which will serve as a holder.

- The tailstock and front headstock and the stop for the cutter are mounted clearly along one line.

- All components of the machine must be securely fastened with bolts.

Read also: LED strip led rgb

Fasteners should be chosen only new, galvanized, tightening all individual elements with force so that the connection does not come loose. And wood turning and copying machines should be installed only level to avoid the slightest vibration.

Milling machine

If you wish, you can also assemble a homemade copy milling machine for wood with your own hands.

Such a device is capable of:

- Planar milling for creating profiles.

- Volumetric milling for the design of reliefs.

A copying cutter for wood made of carbide metal reproduces the surface or contour of the master copier on the product.

The following is used as a copier:

- Spatial model.

- Flat template.

- Reference model.

- Outline drawing.

The simplest milling copier consists of a supporting frame - a base, a work table and directly a milling head equipped with an electric drive.

A hole is made in the center of the board and a router is attached in place of the hole, only on the reverse side

- The dimensions of the workbench depend on the specific tasks for which the copy milling machine is assembled, as well as on the dimensions of the workroom.

- Based on the nature of the work and the dimensions of future products, methods for fastening the workpieces and template are determined.

- The power of the electric motor that rotates the cutter is also selected taking into account the planned loads.

Advice! For milling wood products and engraving at home, a motor with a power of 150-200 watts is sufficient.

Thus, having a copy-milling machine for wood in your workshop, you can create copies of the parts necessary for repairing furniture and other wooden structures with your own hands. You can also make souvenir or decorative items according to your own drawings.

Since work on such equipment is quite dusty, it is best to place the machine outside or under a hood

Important! In pursuit of savings, people often forget about the safety of themselves and their loved ones. Please note: working with such a machine is quite dangerous. Especially in cases where a person has not encountered such a product before.

Features of operation and safety precautions

The operating principle of copying and turning equipment is simple:

- the blank of the future product is clamped in a horizontal position;

- the machine is started, which rotates the workpiece around an axis;

- the cutter removes excess wood from the workpiece, giving it the required shape.

To avoid injury during work, you must follow basic safety rules:

- Do not expose or remove the workpiece from operating equipment.

- Do not lean or press against the machine while working.

- Remove chips only with a special brush.

- The machine must not be left unattended during operation.

- The technician must wear safety glasses to prevent chips from getting into his eyes.

A turning unit with a copier is successfully used both in large mass production and in home workshops for the manufacture of identical products. You can make such a machine yourself, having an unnecessary hand router, a sheet of plywood and horizontal bars of a certain size.