It is useful to know the standard sizes of wood both when doing various homemade projects with your own hands and during thorough construction. The dimensions of lumber are regulated by GOST and the products of each sawmill are focused on standardized dimensions. Lumber can be edged, unedged, boards, beams and beams, etc.

the dimensions of tongue and groove floorboards here >>>

Wood quality

Deciduous wood is divided into three grades, coniferous - into five. The best grade lumber is called selected (marked with a horizontal stripe or the letter “O” ), the remaining grades are designated by numbers 1-4 (marked with the corresponding number of dots, vertical stripes, or just a number).

The quality of lumber is assessed based on the worst side or edge. The grade is determined by the presence/absence of knots, rot, cracks, warping and deformations, wormholes, the degree of precision of machining (non-parallelism of planes and edges is regulated by GOST 24454-80 ).

- 1st grade wood is used for the manufacture of elements of building structures, windows, doors, stairs (for standard sizes of stair elements, see this article ), finishing of floors and walls.

- The 2nd grade is used for flooring, load-bearing building structures ( category II ), formwork, lathing and planed parts ( GOST 8442-75 and GOST 475-78 ).

- Grade 3 is used for the manufacture of load-bearing structures ( category III ).

- The 4th grade is suitable for the manufacture of containers and small workpieces.

The permissible humidity of the 4th grade is not standardized. The humidity of other varieties should not exceed 22% . If this value is exceeded, the lumber is called “raw” - a significant loss of its strength occurs.

Wood requirements and grade

The grade of a board or its grade is a classification that indicates the permissible defects of wood and their number. Boards and bars can be of five grades - selected, 1st, 2nd, 3rd and 4th. The timber is not selected, so it has only four grades, designated by numbers.

Sawn timber of selected, first, second and third grades is produced:

- from dry wood with a moisture content of no more than 22%;

- from raw;

- raw, treated with antiseptics.

What defects and defects may there be on boards, beams and bars, what do they look like (photo)

Knots, their types and quantity depending on the grade of lumber

Knots, their types and quantity depending on the grade of lumber

There may also be cracks, but small and not through

Wood flows depending on the board grade

Wood flows depending on the board grade

There may be some types of fungal infections

What other disadvantages could there be?

Wood for the fourth grade is not regulated. The grade is determined by the worst face or edge. That is, find the worst part, and determine the grade based on the presence and number of defects and flaws. All of them are shown in tables, and the possible defects themselves are shown in pictures.

Please note that the grade data is taken from GOST 2140. It is used for lumber for the domestic market and for export. Recently, another standard was adopted: GOST 26002 for lumber that is sold only on the domestic market. There, varieties are defined differently (and permissible size deviations too). So be careful, check according to which GOST the grade was determined.

How to determine the grade of a board

Do you know how the grade of boards is determined in production? Approximately. No one counts knots, cracks and other defects. And the difference between, say, the first and second grade is very small. And not all manufacturers try to really sort it correctly. So it’s better to control everything yourself. But the tables are so large, and there are so many defects - it’s impossible to remember everything. But there are certain criteria that can help you determine whether the quality corresponds to what is declared.

Selected and first-class edged boards cannot have such damage

- If there is at least one fallen twig, this is definitely not the best and not the first grade. At least second, or even lower.

- First grade boards and timber should be free of rot, fungi and core. These are all the places that are destroyed first. So there shouldn't be any.

- When choosing timber, pay attention to the number of annual rings. The more there are, the higher the quality of the wood.

It’s also worth looking at the storage conditions. In general, high-grade boards should be stored at least under a canopy. It should be placed in ventilated stacks and not lying in bulk. Ventilated stacks are those with spacers that separate one row from another and allow the wood to dry evenly.

Legend

In the designation, the material is written in plain text (board, block, timber), then a number indicating the grade, type of wood (coniferous or individual species - pine, spruce, larch, cedar, fir), cross-sectional size in mm. and designations of the regulatory standard.

Example: Board - 2 - pine - 40 x 150 - GOST 8486-86

Responsible manufacturers also indicate length and cubic capacity in their price lists, i.e.: Board - 2 - pine - 40 x 150 x 6000 - GOST 8486-86 Quantity per cube: 27 pcs

Source material and regulatory documents

The timber is made mainly from coniferous wood - pine, spruce, larch, fir, cedar.

In wooden structures, hardwood is used mainly only for dowels, pillows, liners and other critical parts. Although for wall beams, excluding window sills, rafters and for the two lower rows, GOST 11047 allows the use of aspen and birch with a moisture content of less than 28%. Requirements for grade, appearance, size, physical and mechanical characteristics are set out in the following basic standards:

- GOST 8486-86 “Softwood lumber”

- GOST 24454-80 “Softwood lumber. Dimensions"

- GOST 11047-90 “Wooden parts and products for low-rise residential and public buildings”

- GOST 20850-84 “Glued wooden structures”

- GOST 2695-83 “Hardwood lumber”

- GOST 18288-87 “Sawmill production. Terms and Definitions"

- GOST 23431-79 “Wood. Structure and physical and mechanical properties. Terms and Definitions"

Production technology

Solid beams are produced on circular saws by longitudinally cutting 2-4 parts from a log, followed by drying under natural conditions. Glued laminated timber goes through more complex stages, but as a result it becomes the strongest of all wooden beams (stronger than solid timber by 50-70%):

- Sawing logs into boards, drying in special chambers to a humidity of 10-15%;

- Treatment of boards with an antiseptic agent (which is also anti-corrosion), calibration by size;

- Splicing workpieces, orienting them in the direction of the fibers so that the beam does not subsequently “twist” or “lead”;

- The resulting lamellas are glued together under pressure using wood glue;

- Profiling is the final stage, during which the timber acquires clearly defined parameters.

How to measure lumber correctly

The length of lumber and blanks is fixed at the shortest distance between the ends, and the width anywhere, but 150 mm from the ends.

Thickness is measured similarly at an arbitrary point with an indentation of 150 mm . The width of unedged lumber is determined in the middle of the length (excluding bark). The volume can be determined in cubic meters based on the dimensions defined by GOST 5306 - 83 .

Selection of cross-section of laminated veneer lumber

This lumber is produced by gluing fibers alternating in direction. It is made from processed, dried raw materials. Therefore, such timber has excellent characteristics: good density, high insulation, no deformation, slight shrinkage. Using laminated lumber during construction, you can count on its original dimensions, which will not change over time.

Prices for laminated timber are the highest, so you need to choose the most suitable size for the construction of outbuildings or a house. Manufacturers offer lumber with a thickness of 40 to 270 mm. The cross-section of laminated veneer lumber is classified according to its purpose:

- For walls, material with a height of 140 to 170 mm, a width of 160 to 270 mm is used, the length is taken depending on the building design.

- For floors and ceilings, the height is usually 100–150 mm, thickness - from 100 to 250 mm.

- For the installation of windows, the average sizes of timber used in construction are 80×85, 80×115.

Sources

- https://stroynedvizhka.ru/stroitelnye-materialy/derevyannyiy-brus/

- https://pilka-nn.ru/drugoe/brus-razmery-tablica.html

- https://WoodShpala.ru/stroitelstvo/brusok-razmery-tablica.html

- https://m-strana.ru/articles/vidy-brusa-dlya-stroitelstva-doma/

- https://DrevoGid.com/materialy/vidy-brusa.html

- https://woodneva.ru/info/standartnye-razmery-obreznoj-doski-brusa-i-bruska/

- https://stroy-podskazka.ru/brus/vse/

- https://stroyka-gid.ru/supplies/stroitelnyiy-brus-i-ego-raznovidnosti.html

[collapse]

Similar posts:

- Which timber is best for building a house - detailed...

- Fastening a wooden beam to a metal profile pipe

- FBS GOST blocks: foundation blocks 13579 78

- Step-by-step instructions for building a frame...

- How to obtain permission to build a house - instructions

- Strip foundation, its manufacturing technology,…

Edged boards. Size tables. Weight.

The dimensions of the cross section ( axb ) and length ( L ) of edged boards are determined by GOST 8486-86

Interstate standard. GOST for softwood lumber here >>>

- Length 1 - 6.5 m with gradation every 0.25 m. Today, increasingly, consumers are offered lumber exactly 6 m long, which has already become a standard.

- Size a (width) of the edged board: 75, 100, 125, 150, 175, 200, 225, 250, 275 mm.

- b (thickness) 16, 19, 22, 25, 32, 40, 44, 50,60, 75 mm.

How many boards are there in 1 cube (pieces/meters)

| Board dimensions | Volume of 1st board | Boards in one cube (pieces) |

| 25x100x6000 | 0.015 m3 | 66.6 pcs |

| 25x130x6000 | 0.019 m3 | 51.2 pcs |

| 25x150x6000 | 0.022 m3 | 44.4 pcs |

| 25x200x6000 | 0.030 m3 | 33.3 pcs. |

| 30x200x6000 | 0.036 m3 | 27.7 pcs |

| 40x100x6000 | 0.024 m3 | 41.6 pcs |

| 40x200x6000 | 0.048 m3 | 20.8 pcs |

| 40x150x6000 | 0.036 m3 | 27.7 pcs |

| 50x100x6000 | 0.030 m3 | 33.3 pcs |

| 50x150x6000 | 0.045 m3 | 22.2 pcs |

| 50x200x6000 | 0.060 m3 | 16.6 pcs |

Finding out the number of meters of edged boards in 1 cube is very simple. If we multiply the number of boards in a cube (third column of the table) by the length of the board (in table 6m), we will find out how many usual linear meters of board are in 1m3 .

How much does a cube of board weigh?

Weight is calculated using a simple formula: M= V*P

M - weight.

V - volume

P - wood density depends on the type of wood, its humidity, place of growth, and the specific part of the trunk from which the board is cut.

Did you know?

The weight of 1m3 of freshly sawn edged lumber (pine) depends on many factors.

- If a beam 18*18 will be lighter than a board 0.025*0.18 , because the core of the trunk itself is looser and the board, which is usually cut from the edges of the trunk, is denser.

- Sometimes the forest (pine) comes across “cut”, i.e. This is the forest from which resin was once collected (there was an organization called “Khimles”), the lumber is not rotten, not blue, and can be almost twice as light.

- Timber (pine) harvested in winter after January will be lighter by about 10-20%

- Lumber always has an exact length, for example, if a timber is considered to be 6 meters long , then as a rule it has a length from 6.05 to 6.25 and maybe more, depending mainly on the sobriety of the “gooseberry”

- On the number of knots on the lumber.

- From many different standards for measuring the mass of 1m3 of lumber.

Wood Density

| Breed | Density, kg/m3 | |

| Lightweight | ||

| Balsa | 150 | |

| Siberian fir | 390 | |

| Spruce | 450 | |

| Willow | 460 | |

| Willow | 470 | |

| Alder | 460-640 | |

| Aspen | 510 | |

| Pine | 520 | |

| Linden | 530 | |

| Poplar gray | 550 | |

| Average density | ||

| horse chestnut | 560 | |

| Cherry | 580 | |

| Common yew | 600 | |

| Teak | 620-750 | |

| Walnut | 640 | |

| Pear | 650 | |

| White maple (sycamore) | 650 | |

| Virginia maple (bird-eyed) | 650 | |

| Birch | 650 | |

| Cherry | 660 | |

| Larch | 660 | |

| Teak | 670 | |

| Beech | 680 | |

| Oak | 690 | |

| Switenia (mahogany) | 700 | |

| Sycamore (plane tree) | 700 | |

| Dense rocks | ||

| Ash | 750 | |

| Plum | 800 | |

| Hornbeam | 800 | |

| Pecan (cariah) | 830 | |

| Olive tree (olive) | 850-950 | |

| Apple tree | 900 | |

| Boxwood | 960 | |

| Ceylon ebony (ebony) | 1080 | |

Calculation example

For example, we need to find out the weight of one cube of pine board:

m = 1m3*520kg/m3= 520kg at a humidity of 12% (physical and mechanical properties of wood are determined by this indicator )

For absolutely dry wood, the density will be lower (equilibrium humidity of wood for indoor use is 6-8% ), and for natural humidity it will be higher.

Natural humidity is not standardized and can range from 30% to 80% . When using wood in contact with the external environment (any external wooden elements of the house, wooden window frames, exterior cladding, etc.), we exactly fall into 12% humidity for which the table above is given.

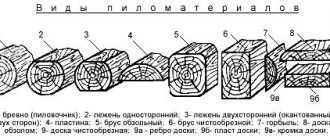

Classification and sizes of different types of lumber

There are several approaches to the classification of lumber, the main one of which is based on two parameters of any lumber - the width of the face and the thickness of the edge. The type of lumber depends on the ratio of these two indicators.

Lumber is divided into 2 types depending on the nature of edge processing:

- edged;

- unedged;

Edged ones have four pairs of perpendicular planes (the lower and upper planes are perpendicular to the side edges).

The board and the dimensions of the board or bar are measured with a tape measure or other instruments, perpendicular to the length. In this case, they retreat from the end (edge) of the lumber by at least 150 millimeters. All standard sizes of edged boards are specified in GOST.

If the board is planed, as well as tongue and groove boards are measured based on the nature of its processing. tongue and groove board, for example

Unedged lumber has only two planes parallel to each other - faces. Their edges are not processed, there may be unevenness or bark. The thickness of unedged boards is measured with a caliper, and the width is measured in the middle of the length without taking into account the thickness of the bark.

GOST 24454-80

The table presented in GOST 24454-80 is a set of acceptable width values for certain standard thickness sizes. Each dimension is indicated in millimeters. GOST standardizes the sizes of edged and unedged lumber.

The thickness, according to the standard, can be from 16 to 250 millimeters, and the width - from 75 to 275 millimeters. In this case, for some thickness values, a certain width value corresponds. And if lumber with a certain thickness indicator cannot have the corresponding width, then in the table there is a dash in the place where the second indicator should be indicated. It is taken into account that the width is always greater than the thickness.

Thus, edged boards with a thickness of 16 or 19 millimeters and a width of over 200 millimeters do not correspond to this standard, and therefore are not listed in it, as are beams 125 by 275 millimeters.

The standard length for most types of wooden materials is 6 meters, but thinner ones are usually made shorter.

In addition, the standard provides that, depending on the customer’s requirements, the production of a cutting board or bar can be carried out with a deviation from the standard dimensions. There are also special requirements for materials intended for use in oil rigs, trucks, bridges and other structures.

Types of lumber

The main principle of classification of lumber is their division into the following types:

- boards;

- beams;

- lining and thin floorboards.

- special.

Boards , including floorboards, are determined by length (2100-6000 mm), width (64-140 mm) and thickness (21-40 mm).

Bars (bars, slats) differ from boards in the ratio of thickness and width. The width of the bar, as a rule, if it exceeds the thickness, is no more than 2 times.

Lining is a type thinner than that specified in the standards, which can have a fairly large width and length. As a rule, they are used for external work or coating. Parquet , laminated flooring and others are often made with a deviation from the standard in order to provide a sufficient margin of safety, but at the same time not significantly raise the floor level. Laminate most often has a combined composition. For the floor, tongue and groove boards , which also have non-standard dimensions.

Designation

Lumber is also designated according to standards. For example, the designation “Beam - 1 - pine - 100 x 150 - GOST 8486-86” corresponds to a pine beam 15 cm wide and 10 cm thick. The number 1 indicates the grade.

Four types of wood are determined, which are used for different purposes (I - for elements of building structures, windows, doors and others, IV - for wooden containers and small workpieces).

Effect of humidity and shrinkage

Humidity for grades I-III of wood is 22%, and permissible deviations are indicated in GOST.

Moisture is an important factor in influencing the size and volume of the board. Its excess can lead not only to an increase in the weight of the lumber or to its rotting, but can also affect its expansion and increase in thickness.

If there is a lack of moisture and under conditions of increased waterproofing, boards, beams and wooden floors may also dry out. This leads to lumber becoming lighter, sagging, and so on. Lack of moisture can lead to cracking of lumber during storage or after installation.

Since normal moisture provides additional strength, during storage, as well as during construction, normal operating conditions should be ensured in order to avoid deviations from standard dimensions, divergence of parts and damage to wooden structures.

Construction timber

A beam is a board whose dimensions correspond to the inequality: a/b < 2

The length of the beam is similar to the length of the edged board. Other sizes can always be made to order for you.

- Size a (width) of timber: 50, 60, 75, 100, 130, 150, 180, 200, 20, 250 mm.

- b (thickness) 130, 150, 180, 200, 220, 250 mm.

When ordering lumber, the issue of transporting the required quantity is usually acute. The table shows the volume of 10 m softwood timber. ( m3 )

| Width mm. | Thickness mm. | |||||||||

| 50 | 60 | 75 | 100 | 130 | 150 | 180 | 200 | 220 | 250 | |

| 130 | 0,065 | 0,078 | 0,0975 | 0,13 | — | — | — | — | — | — |

| 150 | 0,075 | 0,09 | 0,0113 | 0,15 | 0,195 | 0,225 | — | — | — | — |

| 180 | 0,09 | 0,108 | 0,0135 | 0,18 | 0,234 | 0,27 | 0,324 | — | — | — |

| 200 | 0,1 | 0,12 | 0,015 | 0,2 | 0,26 | 0,3 | — | 0,4 | — | — |

| 220 | 0,11 | 0,132 | 0,0165 | 0,22 | — | — | 0,395 | — | 0,434 | — |

| 250 | 0,125 | 0,15 | 0,188 | 0,25 | — | — | — | 0,5 | — | 0,625 |

Wooden profile beam (profiled)

Like the classic (solid) one, it is made from whole logs, according to the same dimensions and sections of wooden beams indicated in the table above. With one but significant difference. The two sides, the lateral ones, of such a beam are even. And 2 (top, bottom) respectively have a groove and a protrusion (ridge) for tight alignment with each other. The number and shape of the grooves (ridges) depend on the width of the timber and the design features of the overall construction made from it. Thus, at a higher cost compared to solid timber, profiled timber is an order of magnitude more economical. When working with it, there is no need to additionally seal (caulk) the walls. The adhesion of the beams to each other increases. And what is not unimportant is the construction process itself is significantly reduced in time.

Bruschi

From softwood: Width (a) and thickness (b) : 16, 19, 22, 25, 32, 40, 44, 50, 60, 75 mm.

Hardwood: Width (a) thickness (b): 19, 22, 25, 32, 40, 45, 50, 60, 70, 80, 90, 100 mm.

The length of the bars is similar to the length of the edged board.

Dimensions for building a house

The roof design includes two main components - the rafter system and the mauerlat. If it is necessary to install rafters, then it is advisable to use timber made from deciduous wood, the cross-section of which is 10x150 mm.

When installing the Mauerlat, it is necessary to use wooden beams, the sections of which are 10x10 or 15x15 cm. In this case, the thickness of this element should not be less than 10 cm, and from the edge of the outer edge of the wall should be 6 cm or more.

When constructing a wall from timber, its thickness is determined taking into account temperature indicators in the cold season. If the temperature is -40 degrees, then you need to use timber with a section of 18x18 cm, up to -30 degrees - 15x15 cm. When constructing internal walls, it is advisable to use material with dimensions of 10x18 cm and 10x15 cm.

On the video - the size of the timber for the Mauerlat:

But what type of insulation is used for wooden walls outside can be seen here.

Wood thermal conductivity table

| Wood | λ, in 10 -3 W/(m K) = in mW/(m K) |

| Birch | 150 |

| Oak (across the grain) | 200 |

| Oak (along the grain) | 400 |

| Spruce | 110 |

| Cedar | 95 |

| Maple | 190 |

| Larch | 130 |

| Linden | 150 |

| Fir | 150 |

| Cork tree | 45 |

| Pine (across the grain) | 150 |

| Pine (along the grain) | 400 |

| Poplar | 170 |

Application in construction

Timber is considered a universal structural material, since having only sawn or planed six-meter products at his disposal, a professional will be able to build three types of houses:

- imitation of a log house - timber is laid around the perimeter of the building, forming warm, durable self-supporting walls

- hut - timber is installed obliquely like an attic, the walls at the same time serve as the roof of a garden house

- half-timbered construction is a type of frame building, but the elements of the load-bearing frame - racks, crossbars, beams, rafter legs and ridge span - are cut into each other in complex units, forming a rigid and durable structure, the space between them can be filled with double-glazed windows or any facing materials that do not strength required

In the classic frame house and its variety - the panel cottage - timber is used to build a power frame. However, in this case, you can simplify assembly by using metal corners and other shaped fasteners. In this case, the building will receive final spatial rigidity only after covering the frame with boards, chipboard, OSB and other materials.

In practice, frames are more often built from boards 50 x 150 mm or 50 x 200 mm, timber 50 x 50 mm or 75 x 75 mm to save the construction budget. Our organization sells turnkey frame houses in your region at competitive prices.

Frame technology

Very conditionally, methods of frame house construction can be classified according to several parameters:

- nationality – Canadian (aka North American) and Finnish (Scandinavian)

- assembly technology – Platform and Balun

Half-timbering, again conditionally, is considered a separate technology, since the junction points of the load-bearing frame elements are very complex, and there are few qualified specialists in this category in the Russian Federation. SIP panel houses do not belong to frame frames, since the bars or boards necessary to connect the panels to each other cannot be considered a full-fledged load-bearing frame.

Half-timbered

Experts say that half-timbering is the most economical construction technology. For example, for an attic cottage 9 x 9 m, a beam of 7 cut mature trees is sufficient. First, a power frame is made:

- the racks are firmly fixed to the foundation, tied at the bottom with ties and at the top with beams

- the upper corners are reinforced by inclined jibs supporting beams resting on the racks

- the space between the frame elements is filled with facing materials; the lower floor most often has panoramic glazing

- To increase the artistic value of the exteriors of the facades, beams, posts and jibs are left outside, opening them with varnish or painting them with paint

For half-timbering, planed (calibrated) and laminated timber, timber of a smaller cross-section, is used. An alternative to these buildings in terms of the quality of the architectural style are houses made of rounded logs with natural moisture.

Imitation of a log house

All types of timber are used as the crown of the building. However, the construction technology is different:

- sawn - all crowns are in one plane, facades and internal walls are additionally decorated and insulated for buildings with all-season use

- planed - the construction budget can be reduced, since the walls already have high artistic value and do not need to be covered

- glued – you can choose a smaller section of lumber, since the strength characteristics are much higher, and you will need to insulate the walls

- profiled - a complete analogue of a log house, cuts are used in the corners, two opposite crowns are shifted by half in height relative to the remaining two

- double - similar to the previous option, only the internal walls are built separately from the external ones from boards on edge, the internal cavity is filled with insulation

Since solid wood houses are susceptible to destruction by rodents and insects, the best option is considered to be the double timber technology with filling the internal space with Ecowool. Cellulose is impregnated with a special compound that is not tolerated by insects and rodents.

Find out how to save money when buying lumber

- Edged board of working section. This trick has long been known to professionals and they use it to the advantage of their wallets. Why are we worse? The so-called “edged board of working section” is produced in an assortment similar to lumber according to GOST 8486-86 , but has a smaller cross-sectional size ( by 5 mm ).

a grade I edged board , however, with the same number of boards, 1m3 10-15% cheaper than an edged board according to GOST . - As an owner, you can apply for a logging quota to the village council. After agreement with the foresters, we deliver the timber to the sawmill and receive the lumber in the required quantity at reasonable prices.

- In winter, during the off-season, it is sometimes possible to “catch” excellent discounts both for processing at the sawmill and from sellers who are unable to store lumber unsold during the warm season. Use it!

Regulatory Defect Limits

The table of norms for restrictions on defects in wood material according to GOST 2140-81 provides for the presence of knots. Their size is calculated as a fraction of the width of the boards and the quantity per 1 linear meter. There are no standards set for bars.

To characterize the quality of boards there are:

- rib knots;

- rotted and edged;

- 40 mm thick or more.

Acceptable standards for the presence of defects are calculated based on the parameters provided for in the standards. The diameter of the knots is measured along a contour drawn parallel to the longitudinal axis of the material.

The acceptable presence of cracks in a semi-finished product depends on the integrity and preservation conditions of the material. There are through cracks, deep and shallow, extending to the end.

Standard sizes of defects are established for semi-finished products with permissible humidity up to 22%. As the indicator increases, the size of the flaws decreases several times.

When manufacturing boards and timber, defects in raw materials are taken into account, including the slope of the fibers, pockets, the shape and size of the core, and traces of wood disease.

The damage to the workpiece by fungi is analyzed separately. As a result of their influence, poisonous stains and rot are formed on the wood, which affect the quality of the material. Mechanical damage may occur as a result of wood processing.

Foreign inclusions in the form of wire and fragments are not allowed in semi-finished products. Biological damage from a wormhole is calculated in pieces per 1 m of workpiece and should not exceed 2-6 shallow defects.

Timber frame: main features

The configuration of the frame is determined by the size and shape of the structure, as well as the aesthetic preferences of its creator. The variety of joints used is largely due to local traditions and the skill of the carpenter. The picture below shows a typical two-story house frame, and the connections of the frame parts are shown on the following pages.

Due to the fact that part of the wood in each part is removed when making nests, tenons and notches, the beams of a large frame (for example, a barn or house) must be powerful (section 200 × 250 or 200 × 300 mm) to maintain strength, and to work they require significant muscle effort or lifting mechanisms.

ORDINARY RAFTERS - placed in spans between frame frames.

TOP BRACKETS - horizontal beams that tie the rafters together in the middle to prevent them from sagging.

Purlins - beams connecting roof trusses.

LONGITUDINAL BEAM - horizontal beams connecting the racks of two frame frames.

LAYERS - horizontal beams lying on the foundation.

TRANSLATIONS - horizontal beams in the spans between the beams.

BEAMS - parallel beams located between other floor beams and serving as the base of the floor.

FRAME - the main element of a timber frame (above), consisting of two racks connected by a tie, crossbars and struts. May include rafters and beds. Frames are often assembled on the ground and then lifted vertically using cables and pulleys or a crane. The timber frame of an ordinary two-story house consists of four frames connected to each other, forming three volumetric modules.

VOLUMETRIC MODULE - a rectangular space formed by two frame frames connected by longitudinal beams (right). Any timber frame consists of at least one volumetric module, although it often has more, as in example 8 shown on the left. In a traditional residential home layout, the main rooms are located in outer modules, with hallways, staircases, bathrooms and utility rooms grouped in a narrow middle module.

Types and types of corner joints for timber and logs.

Before you begin construction work using timber, you need to know how to properly connect the beams together, for which you need to subject the material to special preparation. Laying a log house in the construction of log houses is one of the most important main stages of construction. A log connection will be needed in two cases: when cutting a corner of a building and in the case of lengthening a beam, when the element was not cut to length.

The joining methods for beams are different from logs. Types of cutting corners from timber are practiced today in two ways:

- With the rest. Or as people call it “into the bowl”;

- Without a trace. The popular name for the method is “in the tooth”;

The connection of beams with the remainder is of three types:

1. One-sided. On one side, a notch is made in each element of the beam - a perpendicular groove. The width of such a notch should correspond to the perpendicular section of the beam. This technology is used by most developers when working with profiled timber, since this type of fastening requires a minimum of effort.

2. Double-sided. When there are cuts on both sides of the beam (top and bottom), a double-sided groove lock is required. The depth of the perpendicular cuts of the beam should be equal to a quarter of the height of the element. This technology can achieve high-quality connections, but carpenters will need a lot of experience, since cracks and chips in the cut are unacceptable.

3. Quadrilateral. Grooves are cut out on all sides of the timber; the use of this joining technology makes it possible to achieve high strength of the log house. The construction process is greatly simplified by cuts that are provided on all sides and all the crowns are laid like a construction set. Connecting the corners of the timber in this way especially increases the reliability and strength of the building.

Connecting beams without residue provides the following options, the most popular of which are now:

What does the thickness of the timber affect?

In order to determine what thickness of timber to choose, it would not hurt to know what exactly this indicator affects? Agree, without this information all subsequent calculations lose any meaning.

Thermal insulation

The thicker the wall, the higher its resistance to heat transfer, and the less money you will have to save on heating your house in the future. Of course, if we mean a barn or some other technical room, this indicator can be neglected, but for a permanent home, the thickness of the timber is very important in terms of thermal insulation.

Load bearing capacity

The thickness of the timber and its load-bearing capacity are most directly affected. This means not only the strength characteristics of walls, in the manufacture of which planed and profiled timber is most often used, but also rafter joists, where this lumber is also successfully used.

Weight

A thick beam is a heavy beam, and there is no escape from it. Therefore, the weight of the structure made from wood, and therefore the load-bearing capacity of the foundation made for the building, will depend on the section you choose. Well, what did you think? All elements of the house are interconnected.

Price

And, of course, the thickness of the timber will affect its cost. The one that is thinner will be cheaper, the one that is thicker will be more expensive. And this is logical. Such materials are rarely sold individually. Most often they are ordered by cubic meters. And from the same volume with equal length, much more timber of a smaller cross-section can be cut.

Connection at corners

To avoid building up the length of the beams, you can choose a material of sufficient length. But building a house without corners is impossible. Therefore, the beams are most often connected at an angle. There are many options, among the most common are the following:

- butt connection;

- use of dowels;

- use of root thorns;

- half a tree;

- dovetail connection.

All these methods of joining timber are quite common, reliable and proven. Many people have heard about some, for example, dovetail, while others are known only to professionals. Let's talk about how to connect timber using these methods.

The butt joint of timber is used for the construction of outbuildings

The first method used in the construction of a wooden house is a butt joint. This is the easiest way to make joints in the corners. It is enough to tightly fit the ends of the beams to each other and secure them with studded steel plates.

Do not think that such a connection of beams in the corners will be unreliable. It all depends on the skill of the carpenter. If you have enough experience, the joint can remain motionless for many decades, the main thing is to fit the ends perfectly.

Although the butt method is considered the fastest, it is rarely chosen during construction. The fact is that a lot of heat escapes through such an angle. During winter you will lose a lot on heating. That is why the beams in the corners are connected end-to-end only in outbuildings.

A more durable type of butt jointing of beams is the method using dowels. This method allows you to significantly strengthen the joint. A key is inserted into special grooves of tightly fitted beams. It can be made in different versions - transverse, longitudinal or oblique. The last type of key is considered the most reliable, but also the most difficult to perform.

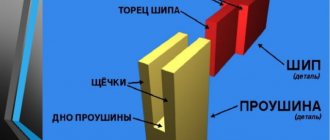

Connecting timber into a warm corner, or scientifically speaking into a root tenon, is considered the most common when building a house. This type of connection does not allow heat to pass through, is reliable and durable.

The principle of this junction is as follows:

- A groove is cut out at the end of one beam. Try not to get the drink on the knots. In this case, the groove will be easier to make;

- a spike or paw is made on another beam. The dimensions of such a “protrusion” must coincide with the dimensions of the groove on the previous beam. The paw, as well as the groove, is made on an area without branches;

- During construction, the paw and groove are combined and thereby make a strong corner connection.

Quite often, for this type of connection, not only a groove and a paw (tenon) are used. For joint strength and stability of the entire structure, a wooden dowel (dowel) is driven between the rows of beams. This additional fastening prevents the horizontal rows from moving among themselves.

You can also connect the beams in the corners with each other using a hitch, which is called “half a tree”.

connecting timber to half a tree

This method was invented a long time ago and is still quite widely used. The connection of a beam into half a tree is made as follows:

- at one end of the beam a cut is made to half its thickness;

- on the other beam the same cut is made, but on the other side of the end;

- When constructing a corner, these cuts are connected, and a strong joint is obtained.

To increase the reliability of the connection here, as in the previous version, wooden dowels or dowels are often used. It is better to make them so that one element is enough to connect more than two rows of beams.

You can choose the options yourself, but many experts will recommend using a connection called a “dovetail.” This option of creating a corner from logs will help retain heat in the house, because it is considered the warmest. Dovetail can be used when connecting profiled or regular timber.

A dovetail joint is similar in principle to a root tenon joint. Here, just as in the previous version, a groove is sawn in one beam, and a tenon (protrusion) in the other. The only difference is in the geometric shape of such cutouts. Both the tongue and groove are trapezoidal in shape. This feature allows you to create a more reliable connection that practically does not allow air masses to pass through (and therefore heat from the house).