Coniferous wood

In construction, coniferous wood is most often used because of its greater strength, biostability and lower production costs compared to hardwood.

In addition, coniferous trunks have a more regular shape with fewer defects. The most popular conifers in construction are pine, spruce, larch, fir and cedar.

Juniper and yew are not used for the manufacture of building elements. These species are valued as a good finishing material and are used mainly for the production of carpentry and furniture.

What does density depend on?

The wood fiber structure of the species on the market is varied. For lumber made from the same species of wood, there are differences in density. This depends on the following factors:

- Humidity. All types of wood have the ability to absorb water to varying degrees. Some types of fiber in their raw form practically double the weight of the dry material. Accordingly, the density of such a tree increases;

- Place of growth. The climatic zone, soil characteristics, quantity and quality of natural light matter;

- Within one species, there are separate subspecies that change their characteristics due to natural factors. The differences do not exceed a few percent in density at the same humidity.

The main reason for the increase in density is humidity. For this reason, raw wood is less valuable and less expensive. Natural drying is a long-term procedure, at least a year in a dry, warm room. On an industrial scale, it is unprofitable to spend so much time on this operation, so a forced procedure for removing excess moisture is widely used. In drying chambers of various designs, the time is reduced tens of times. The basic humidity indicator is considered to be 12%. This material is classified as dry wood. Exceeding the specified threshold automatically makes the lumber damp.

Larch

Larch wood

Larch (Larix) (see link) is a coniferous tree from the genus Larix of the pine family (Pinaceae). It is durable, lives up to 900 years or more and reaches a height of 45 m with a trunk diameter of 80–180 cm. It is found in nature in the east and northeast of the European part of Russia, in the Urals, in Western and Eastern Siberia, in the Altai and Sayan Mountains.

This is the most common breed in Russia. It makes up 2/5 of the forested area. The breed is sound with resin passages. Has a beautiful texture. The annual layers are clearly visible in all sections. The sapwood is narrow, white with a slight brownish tint. The kernel is reddish-brown, sharply different from the sapwood. The medullary rays are not visible, the resin ducts are small and few in number.

The wood contains essential oils (pinene), has a fairly strong pleasant odor and includes bioflavonoids and phytoncides - microscopic volatile substances that evaporate during the entire period of use and have a positive effect on health, preventing colds and viral diseases.

Larch wood is an excellent building material because it has high density and strength, it has few knots, and it belongs to the group of biostable (it does not rot or be damaged by fungi). Larch is strong, elastic, hard, durable, and resists rot and insects well. Long-term exposure to water leads to an increase in the hardness of larch, which is why it was used for the construction of bridges and piers. All Venetian buildings stand on larch stilts.

Larch wood easily cracks during the drying process and splits. It is more difficult to process on a machine than other rocks (due to its high density and resin content) . Resinous substances make planing, polishing and varnishing somewhat difficult, but in general the wood can be painted and polished successfully after proper filling.

The best wooden buildings are built from this type of wood. It is used for carpentry, window frames and flooring.

This is interesting

The parquet flooring of the Ostankino Palace of Counts Sheremetyev and the window frames of the Winter Palace prove that larch can serve for many years.

Volumetric weight at standard humidity (12%) – 650–800 kg/m3.

Pine

Pine wood

Pine (Pinus) (see link). Eurasian tree coniferous species, grows in the territory from Scotland to Eastern Siberia. It occupies about 1/6 of the area of all forests in Russia. It lives 400–600 years and in adulthood (120–150 years) reaches a height of about 30 m. The most common species is Scots pine (Pinus sylvestris) .

The rock is the most popular building material because it has the most straight, even trunk. Pine is well saturated with antiseptics.

The rock is sound, with resin passages, soft, moderately light, mechanically strong, non-plastic. It is well processed and finished.

Pine wood has a slightly pinkish core, which over time becomes brownish-red, wide sapwood from yellowish to pink, clearly visible annual layers with a clear boundary between early and late wood, rather large and numerous resin ducts.

The wood is of medium density, medium hardness, fairly high strength and resistance to decay, can be processed well, and glues relatively well. Widely used in construction, mechanical engineering, furniture and packaging production, railway transport, for securing mine workings, etc.

It is used as a raw material for chemical processing to obtain cellulose and feed yeast; Pine timber is exported in large quantities.

Volumetric weight at standard humidity (12%) – from 460 to 620 kg/m3.

Application

Ship pines are still used in the manufacture of floating ships. Growing in harsh northern conditions, they are suitable for the production of especially important parts that require strength. Long boards are obtained from tall trees with almost no side branches. The straightest and strongest ones are used to make masts. Previously, pine resin was also used to impregnate ship parts.

Pine wood is used to make furniture, house siding, pencils, beehives, planks and roof shingles. The raw materials do not deteriorate for a long time, are resistant to rotting, are characterized by beautiful coloring and durability. Paint and tannins are obtained from the bark of the ship's pine; the cork layer is used for the production of thermal insulation boards. Some types of nuts are edible, suitable for fresh consumption and adding to dishes.

Resin and its processed products are widely used. When pine resin is heated with steam, the result is liquid turpentine and solid rosin. The first is needed for etching woven fabric, producing plastics, camphor, paints and varnishes. Turpentine is used in folk medicine and disinfects the air. Paper impregnated with rosin becomes durable and holds ink and printing ink. The substance is added to soap as a foaming agent. Used for the manufacture of varnishes, insulators, lubricating oils, sealing wax.

Growing in harsh northern conditions, they are suitable for the production of especially important parts that require strength.

Ship pines are not separate types of coniferous species, but trees characterized by certain qualities. Depending on the growing conditions, the structure of the wood changes. Based on color, the kernels are divided into ore and mand. In addition to shipbuilding, culture is used in other areas of industry, folk medicine, cosmetology, and cooking.

Norway spruce

Spruce wood

Norway spruce (Picea abies) (see link) is an evergreen coniferous tree of the pine family (Pinaceae), 20–50 m high, with a cone-shaped crown and flaky brownish-gray bark. Lives up to 300 years. The trunk is round and straight.

It grows in damp places, on rich loamy soils, rising into the mountains to a height of up to 1800 m above sea level (forms pure spruce forests). Widely distributed in Central, Northern and Northeastern Europe above 69°N latitude, north of the Pyrenees to Russia and Scandinavia.

Other species: Ayan spruce (Picea ajanensis), Korean spruce (Picea koraiensis), Siberian spruce (Picea obovata).

Spruce is a coreless mature wood species. The wood is white with a yellowish tint, low resinous. Resistant to cracking. The annual layers are clearly visible. In terms of strength, density and resistance to rotting, spruce is in no way inferior to pine. However, it is more difficult to process compared to pine due to the large number of knots in it and their increased hardness.

Spruce is very susceptible to insect damage.

Spruce wood is characterized by the highest value of the acoustic constant, which characterizes the emission of sound. Tannins are obtained from spruce bark. The wood is soft, easy to process, polish, and varnish. It is used in the same areas as pine, but especially in the pulp and paper industry and in the production of musical instruments.

Volumetric weight at standard humidity (12%) is about 450 kg/m3.

Indicators of elastic deformations

To determine the modulus of elasticity in compression, tension or bending of samples, deformations are measured under loads not exceeding the proportionality limit; then, based on the data obtained (stress and strain), the elastic modulus is calculated using the appropriate formulas. Below, as an example, the simplest method for determining the modulus of elasticity during static bending is briefly described. The sample, the shape of the knife and supports, the span, and the method of applying the load are the same as when determining strength. Deformations (deflections of the neutral line) are measured with an accuracy of 0.005 mm using a deflection meter with an indicator mounted on the sample itself. Each sample is subjected to sequential six-fold loading of up to 20 and 60 kg for the entire sample, with a reading taken from the indicator each time. From the last three readings, the arithmetic average values are calculated separately for the upper and lower loading limits, the difference between which gives the value of the increment in deformation for the accepted load interval (40 kg). The elastic modulus value is calculated with an accuracy of 1000 kg cm 2 using the formula:

where P is the load equal to the difference between the upper and lower load limits (40 kg); l - distance between supports (24 cm); b and h—width and height of samples, cm; f is the deflection arrow, cm, corresponding to the load P. The elastic moduli determined in this way due to the influence of the transverse force are underestimated by an average of 19%. If you measure the deformation in the pure bending zone (between the knives), using the appropriate formula you can determine the elastic modulus, which is not distorted by the influence of shear force.

Cedar

Cedar wood

Cedar (Cedrus) is a genus of coniferous evergreen trees of the pine family. Reaches a height of 36 m or slightly more and a diameter of 1.5 m. It grows in the mountains at an altitude of 1300–3600 m, forming cedar forests. Distributed in the Atlas Mountains, in northwestern Africa (Atlas cedar), in Lebanon, Syria and the Cilician Taurus in Asia Minor (Lebanese cedar), on the island of Cyprus (short-coniferous cedar) and in the western Himalayas (Himalayan cedar). In Europe, cedar is often grown in gardens and parks.

All types of cedar have similar wood colors. The light brown or yellow-brown heartwood, which weathers to a uniform brown color, differs from the narrow whitish sapwood.

Cedar wood is resinous (oily), with a pungent cedar odor. The annual layers are clearly distinguished by the contrast between the early and late wood zones. Medium texture. The grain is usually straight, although straight grain is more common in Himalayan cedar. Longitudinal sections of this cedar show uneven brown lines formed by frequent tangential rows of traumatic resin ducts. Resistant to damage by fungi and insects.

Cedar wood is soft and easy to process in all directions. Cedar dries quickly and without major problems. Before finishing work, the resin must be removed.

In the Urals and Siberia, cedar was used as a finishing material for homes. In Tobolsk, Tyumen and Turinsk, buildings decorated with carved platbands made from its wood have been preserved. Cedar was also used for carpentry.

Today it is used only for exclusive interior work, for finishing yachts and interior decoration and for making wooden houses from logs (most often hand-cut).

Volumetric weight at standard humidity (12%) is about 580 kg/m3.

White fir and Caucasian fir

Fir wood

White fir (Abies alba) (see link). Coniferous evergreen plant of the pine family, 30–50 m high, with a narrow pyramidal crown. The trunk is up to 150 cm in diameter, with white-gray smooth bark. Places of growth - mountains of southern, central and western Europe, prefers very fertile soils.

Fir is very similar to spruce, but unlike it, fir does not have resin accumulations. The color of the wood varies from yellowish-white to reddish-white with a gray tint. Fir trunks often suffer from atmospheric pollution, insects, and animals that eat young shoots.

Fir wood is easy to process and covers well with most varnishes and paints. The tree is soft, moderately resistant to weather influences and not resistant to fungi and pests.

Volumetric weight in air-dry condition is about 450 kg/m3.

Caucasian fir (Abies nordmanniana) in its physical and mechanical properties is in no way inferior to spruce, unlike Siberian fir, which has less density and strength. It is used for the manufacture of wooden structures, musical instruments, and is often used together with spruce in the production of furniture.

Very common in house construction (especially Caucasian fir). Previously, shingles were made from fir (along with spruce) to cover the roof. Now these are mainly door and window blocks, floors, baseboards, friezes and many other products.

Volumetric weight at standard humidity (12%) is about 450 kg/m3.

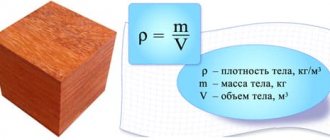

What is material density

The value is determined by the classical formula P = m/V, where m is mass and V is volume. The density of wood is usually indicated in kg/m3, or in g/cm3. For round timber, a special coefficient is applied, taking into account the unevenness of the surface and the correct diameter. In practice, more often you have to deal with already processed lumber that has the correct profile geometry. So the density of the timber is easy to calculate, let’s remember school geometry lessons. The length is multiplied by the sum of the sides of the section. By weighing the workpiece, its weight is determined. A more accurate value will be obtained by measuring timber in stacks or packaged packs.

Juniper

Juniper wood

Juniper (Juniperus) (see link). Most junipers are shrubs, but in southern Karelia there are also tree-like forms up to 12 m high and 16 cm in diameter. The only representative of the cypress family (Cupressaceae) in the northern forests. It is found both in dry pine forests on sandy soil and in spruce forests that are excessively moist and even swampy.

It grows slowly, is frost-resistant, and light-loving. Does not tolerate smoke and soot well. Distributed in the northern and middle parts of the European territory of Russia, in Western Siberia, and enters Eastern Siberia.

Juniper is a sound species. Near the bark there is a narrow light yellow strip of sapwood, forming a wavy ring of irregular shape. Inside the ring is red-brown core wood. Over time, the sapwood turns dark yellow with a greenish tint, and the heartwood acquires beautiful olive-blue hues. On the end section of a juniper, the annual layers are clearly distinguished. The texture is beautiful, with a reddish tint, sometimes striped or wavy. Particularly impressive in cross section.

Juniper, unlike other conifers, does not have resin passages, so it easily accepts various dyes and is easily polished. Strong, heavy and dense juniper wood can be easily processed with a variety of cutting tools. The cuts are clean and glossy.

Juniper wood has slight shrinkage and practically does not swell when wet. It can be successfully used for very thin flat-relief and volumetric carvings; small decorative items, canes, sculptures, small crafts and toys are made from it. End cuts are used in inlay.

Volumetric weight at standard humidity (12%) is about 920 kg/m3.

Tiss

Yew wood

Yew (Taxus) (see link) is a very ancient breed. An evergreen coniferous tree from the yew family (Taxaceae), about 20 m high (the highest known height is 27 m), trunk thickness is 1 m. The crown is wide-spreading, very dense. The needles are soft, flat, dark green, located on the branches in two rows.

Yew berry and yew pointed

Yew berry (Taxus baccata) grows in the mountains of the Caucasus and Crimea. It is often called European because it is found in almost all of Western Europe. The habitat of yew berry also covers areas of Western Belarus (Belovezhskaya Pushcha), Western Ukraine (Bukovina), Southern Crimea, the Caucasus, as well as the Azores Islands, the mountains of Algeria, Asia Minor and Syria.

The second species is the pointed yew, or Far Eastern yew (Taxus cuspidata) , common in the Primorsky Territory and Sakhalin. The wood is hard and heavy, almost impossible to rot. Sometimes on the yew there are nodules, densely covered with very short shoots with pale needles.

The lifespan of yew berry is up to 1500 years, and sometimes up to 3-4 thousand years. The sapwood and heartwood of yew wood are very different from each other. The color of the core ranges from red-brown to orange-brown.

A characteristic feature of yew wood is tiny black dots, ideally grouped on the surface. The annual layers are sinuous and look like wide, dark rings.

Yew is easy to dry and process. Its wood is toxic and must therefore be processed with extreme care. It has a beautiful texture and is used for making furniture and as a finishing material, it is very durable and is used for various carpentry projects.

Volumetric weight at standard humidity (12%) is about 620 kg/m3.

______________________________________________________

Wood protection

Wood is a very popular building material: it is light, environmentally friendly, has low thermal conductivity and is quite durable. The last advantage of this material can be enhanced many times over if it is properly protected.