The quality of materials plays a very important role in construction. Like other building materials, wood (any lumber) varies in properties and characteristics. These characteristics depend on the type of wood used as the material used. For certain tasks and purposes, appropriate types of wood are selected that are capable of performing the tasks assigned to them.

Properties related to wood:

- Wood Density

- Hardness

- Wood moisture content

- Shrinkage

- Swelling

- Warping

- Cleavability

- Wear resistance

- Flexibility

- Deformability

- Thermal properties of wood

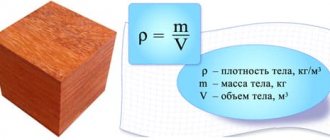

Wood Density

What is wood density

Wood density is the ratio of wood mass to wood volume, that is, density is determined by the mass of wood substance per unit volume. Density is expressed in kg/m³.

The density of wood depends on its moisture content. Like all other indicators of the physical and mechanical properties of wood, it is determined at a moisture content of 12%. There is a close relationship between strength and density. Heavier wood is generally more durable. When determining the density of a wood substance, its mass is determined by weighing, and the volume is calculated by the difference between the volume of a wood sample and the volume of liquid that filled the voids in this sample.

Based on the density of wood at a moisture content of 12%, all species are divided into three groups:

- with low density (540 kg/m³ and less) - balsa, spruce, fir, pine, cedar, juniper, poplar, aspen, willow, linden, alder, chestnut;

- medium density (540...740 kg/m³) - larch, birch, beech, oak, maple, ash, walnut, rowan, apple, pear, elm (elm), hazel;

- high density (750 kg/m³ and more) - acacia, hornbeam, iron birch, oak, ash, boxwood, pistachio.

It should be noted that almost all wood from coniferous trees, with the exception of larch and some types of pine, has low density.

table of wood strength when chipped along the grain

| Breed | Tensile strength, kg/cm2, when chipping | Breed | Tensile strength, kg/cm2, when chipping | ||||||

| radial with humidity | tangential with humidity | radial with humidity | tangential with humidity | ||||||

| 15% | 30% and above | 15% | 30% and above | 15% | 30% and above | 15% | 30% and above | ||

| Larch | 91 | 63 | 86 | 56 | Walnut | 100 | 59 | 106 | 61 |

| Pine | 69 | 43 | 67 | 45 | Oak | 93 | 76 | 111 | 90 |

| Spruce | 63 | 41 | 62 | 44 | Birch | 85 | 50 | 102 | 59 |

| Cedar | 60 | 40 | 64 | 43 | Elm | 83 | 65 | 93 | 73 |

| Siberian fir | 58 | 45 | 59 | 42 | Pear | 81 | 56 | 126 | 81 |

| Hornbeam | 141 | 88 | 177 | 106 | Linden | 78 | 56 | 74 | 50 |

| Ash | 126 | 94 | 122 | 87 | Alder | 74 | 52 | 91 | 63 |

| Maple | 113 | 84 | 129 | 90 | Aspen | 57 | 36 | 78 | 50 |

| Beech | 106 | 70 | 132 | 89 | Poplar | 55 | 34 | 66 | 42 |

Tests for shearing across the grain are carried out in the same way as for shearing along the grain: the sample is strengthened in the same device and loaded at a speed of 200 ± 50 kg/min. Tests for cutting across the fibers are carried out in a special device in which the sample is clamped at the ends and cut in the middle of the length with a flat knife (the test diagram is shown in Fig. 60). Loading is carried out at a rate of 1000 ± 200 kg/min for the entire sample. Characteristics of the relationship: if the tensile strength when shearing along the grain is taken as one, the tensile strength when shearing across the grain will be 2 times lower, and when cutting across the grain it will be 4 times higher.

Wood hardness

The hardness of wood primarily depends on the species. The growth conditions of the tree also affect this indicator (one type of wood may have different hardness depending on the surrounding natural conditions in which the particular tree grew). The moisture content of the wood also affects the hardness level. In European countries and Russia, it is customary to measure hardness using the Brinell method, in the USA - using the Janka method. The hardness of wood within one species may differ depending on the cut (The end surface has a higher hardness than the tangential and radial surfaces by an average of 30% for hardwoods and 40% for conifers.).

The essence of the Brinell method is the ability of wood to resist the penetration (pressing) of a harder body (indenter) into it. When making Brinell measurements, indenters in the form of hardened steel balls are used. Initially, the indenter is installed on the wood sample being tested, and then the main load is applied. After a certain time after application, the load is removed and the depth of the imprint remaining on the tree is measured. The Brinell hardness of wood is calculated in this way: the applied load is divided by the surface area of the indentation, while the corresponding regulatory documents determine the diameters of the indenter and the exposure time.

The Janka method also uses an indenter in the form of a metal ball, but it is not the depth of indentation that is assessed, but the force that must be applied to press the ball into the wood by half its diameter.

All wood species are divided into three groups based on hardness:

- soft rocks (end hardness equal to or less than 38.5 MPa). Soft woods include: spruce, pine, cedar, fir, poplar, linden, aspen, alder.

- hard (end hardness of wood species from 38.5 to 82.6 MPa). This group includes: birch, Siberian larch, beech, maple, elm, ash, apple tree.

- very hard (end hardness more than 82.6 MPa). This group includes: white acacia, keruing, iron birch, boxwood, dogwood.

Wood moisture content

Humidity is the ratio of the mass of moisture (water) contained in a given volume of wood to the mass of absolutely dry wood, expressed as a percentage (%). In wood, water permeates the cell membranes and fills the cell cavities and intercellular spaces. Moisture that permeates cell membranes is called bound. Moisture that fills cell cavities and intercellular spaces is called free.

There are the following degrees of wood moisture content:

Wet - kept in water for a long time. The moisture content of wet wood is above 100%.

Freshly cut (freshly sawn) - the moisture content of such wood is from 50 to 100%.

Air-dry - this category includes wood that has been stored in air for a long time. Its humidity indicators depend on the humidity of the surrounding air, but on average range from 20 to 35%.

Basic (humidity 15 - 20%), depending on climatic conditions and time of year, such wood shows a moisture content of 15 to 20%.

Room-dry humidity 8 - 12%

Absolutely dry humidity 0%, wood dried at temperature t = 103°C.

The moisture content in the trunk of a growing tree varies along the height and radius of the trunk, and also depending on the time of year. For example, the moisture content of pine sapwood is 3 times higher than the moisture content of the core. In deciduous trees, the change in humidity along the diameter is more uniform. Along the height of the trunk, the moisture content of the sapwood in conifers increases up the trunk, but the moisture content of the core does not change. In deciduous trees, the moisture content of the sapwood does not change, but the moisture content of the core decreases up the trunk.

Humidity in young trees is higher and its fluctuations throughout the year are greater than in old trees. The greatest amount of moisture is contained in the winter (November-February), the minimum - in the summer months (July-August).

WOOD SHRINKAGE RATIO, %

| Breed | Shrinkage | ||

| volumetric | in tangential direction | in the radial direction | |

| Larch | 0,52 | 0,35 | 0,19 |

| Pine | 0,44 | 0,28 | 0,17 |

| Spruce | 0,43 | 0,28 | 0,16 |

| Fir | 0,39 | 0,28 | 0,11 |

| Cedar pine | 0,37 | 0,26 | 0,12 |

| Birch | 0,54 | 0,31 | 0,26 |

| Beech | 0,47 | 0,32 | 0,17 |

| Ash | 0,45 | 0,28 | 0,18 |

| Aspen | 0,41 | 0,28 | 0,14 |

Tree structure. From cells to roots

In this article, we decided to remind you what a tree is and talk about each of its parts: cells and tissues, wood and bark, branches and twigs, leaves and roots.

In many species of wood, there is a central dark-colored zone - the core and an outer light-colored zone - the sapwood . At an early age, all trees consist only of sapwood, but after some time (it is different for all species, and its width is also different) living elements begin to die off, blockage of water-conducting paths occurs and the deposition of extractive substances in the central part of the trunk - thus the core is formed in breeds called sound . These, for example, include: juniper, yew, pine, larch, cedar, oak, ash, elm, elm, walnut, willow, poplar.

In other breeds, the death of the central part is not accompanied by darkening. They have a uniform color of wood throughout the entire thickness of the trunk - such species are called coreless .

There is another type of species - mature wood , which have ripe wood in the central part of the trunk (drier than the rest). Their sapwood is the same color as mature wood. These include spruce, fir, beech, and aspen.

There are also rocks in which the central part does not differ from the peripheral part either in color or in properties - such rocks are called sapwood . These, for example, include: birch, linden, maple, hornbeam, etc.

In some deciduous trees, on a cross-section of the trunk, light shiny lines are clearly visible, diverging radially from the core - medullary rays. In radial directions they are visible in the form of narrow stripes, but are often invisible to the naked eye. They can be seen in oak, beech, maple and some other species.

Deciduous trees have water-conducting vessels that run along the axis of the trunk in the wood, and in the cross section only their sections of different shapes are visible. In some rocks they are large and clearly visible, forming rings. Such species are called ring-vascular - oak, ash, elm. Species with small, randomly located vessels are called scatter-vascular - birch, aspen, linden, maple, alder, beech.

Shrinkage, swelling and warping of wood

Shrinkage is a reduction in wood volume and linear dimensions when bound moisture is removed from it. Removing free moisture does not cause shrinkage. It begins only after the complete removal of free moisture at the moment the removal of bound moisture begins. The more cell walls there are in a unit volume of wood, the more bound water it contains and the higher the shrinkage. Wood shrinkage is not the same in different directions: in the tangential direction it is 1.5 - 2 times more than in the radial direction.

On average, linear shrinkage of wood of most species in the tangential direction is 8 - 10%, in the radial direction 3 - 7%, and along the grain 0.1 - 0.3%. Total volumetric shrinkage is in the range of 11 - 17%. Wood shrinkage is taken into account when sawing logs into boards (shrinkage allowances), when drying lumber, etc.

When drying wood, regardless of the participation of external loads, internal stresses arise. They are formed as a result of unequal changes in body volume during drying (drying stress), impregnation and during the growth of the tree. It is convenient to imagine total drying stresses as a combination of two components—humidity and residual stresses.

Humidity stresses are caused by non-uniform shrinkage of the material. In the surface layers of wood, where the humidity is lower than in the center, tensile stresses arise due to the restriction of free shrinkage, and compressive stresses arise in the inner layers. Residual stresses are caused by the appearance of heterogeneous residual deformations in wood. Residual stresses, unlike moisture stresses, do not disappear when the humidity in the board is equalized and are observed both during drying and after its complete completion.

If tensile stresses reach the tensile strength of wood across the grain, cracks appear. This is how surface cracks appear at the beginning of drying and internal cracks at the end of drying.

The presence of various stresses within the wood can lead to warping.

Warping is a change in the shape of wood during drying, storage, and sawing. Most often, warping occurs due to varying degrees of shrinkage in different structural directions. Warping can also occur during mechanical processing of dry lumber: during asymmetrical planing, rib division due to imbalance of residual stresses.

Swelling is an increase in the linear dimensions and volumes of wood with an increase in the content of bound moisture. It occurs when wood is moistened and is the opposite of drying out. Swelling occurs when humidity increases to the hygroscopic limit. The greatest swelling occurs along the width of the fibers (tangentially), the least swelling occurs along the fibers.

Swelling, as well as shrinkage, are negative properties of wood. However, in some cases it plays a positive role, for example, ensuring the tightness of joints in boats or wine barrels.

Specifications

Selected grade lumber

As is easy to understand from the name, this grade includes lumber of the highest quality. Only minor defects that do not affect performance are acceptable. The price of selected and 1st grades can differ by 2-3 times, and it can be difficult to visually distinguish them.

Scope of application: Selected grade is widely used in shipbuilding (which is why such a board is sometimes called a deck board) and motor industry; parts of the structures of agricultural machines, railway cars, truck platforms and trailers are made from it.

Technical requirements:

- Complete absence of rot, fungus, wormholes, areas of the root system and bark residues,

- warping (these are any changes in the geometry of lumber that occur during sawing, after drying or during storage) and other mechanical damage are excluded;

- The permissible inclination of the fibers is no more than 5° if the length of the product exceeds 2 m;

Grain slope is the angle between the direction of the wood grain and the longitudinal axis of the lumber. Measured on one of the layers. The angle of inclination is not always uniform, which may be due to the curvature or spiral growth of the tree.

- The presence of non-through end cracks that do not reach the face or edge is acceptable, provided that their depth does not exceed 10% of the thickness of the end.

- Maximum accuracy of geometric dimensions. The permissible deviation based on the total length of the lumber varies from 0.1 to 1%.

- The presence of healthy (i.e. with a complete absence of rot) fused knots is acceptable. Their number is regulated in the GOST tables, but the location does not matter.

An fused knot is a knot whose annual layers have fused with the surrounding wood. The fusion area is more than 75% of the knot cut.

First grade lumber

Application area. Same areas as the selected variety. In addition, it is widely used in construction during the installation of load-bearing structures, in repair work, and in the manufacture of window frames and doors. It is widely used in the production of furniture and special-purpose containers.

Technical requirements:

- Absence of any external signs of rot or fungal attack.

- Dropping knots and accompanying through holes are unacceptable.

A loose knot is a dry knot that does not have a strong connection with the surrounding wood. As a rule, such a knot is kept in its bed, but is movable when exposed to it. Dropout knots are also called holes from already fallen knots.

- Cracks on the face or edge, the length of which exceeds ¼ of the total length of the lumber and a depth of more than 1 mm, are unacceptable.

- It is possible to have a blunt wane if its length does not exceed one-sixth of the entire length of the lumber. The presence of acute wane is not allowed.

A blunt wane is a wane that takes up part of the width of the edge. Acute wane is a wane that occupies the entire area of the edge.

- Rot is unacceptable - i.e. decomposition of wood by fungus or other microorganisms, leading to its softening.

- Blue staining (coloration caused by fungus or mold) is acceptable in limited quantities - the size should not exceed 10% of the total area of lumber. This defect is considered purely cosmetic, since it does not lead to destruction of the wood structure and does not affect the performance characteristics.

- Healthy knots not exceeding 10mm in diameter are acceptable. The number of knots is regulated in GOST tables in accordance with the dimensions of the lumber.

Second grade wood

The 2nd grade is characterized by a significant relaxation of requirements, however, it is also used in critical areas and is in great demand among consumers. This is explained by the fact that the operational reliability of the material remains quite high, and the cost is noticeably lower. Visually, a 2nd grade board can be easily distinguished by the large slope of the fibers.

Application area. In addition to shipbuilding and automotive construction, construction, furniture production, and furniture manufacturing, it is widely used in the manufacture of lathing, installation of wooden panels, roofing and all kinds of supports.

Technical requirements:

- Traces of rot and decay are unacceptable. Traces of insect activity - wormholes - are acceptable, but not more than 3 per linear meter.

- The presence of small resin pockets is acceptable (this applies to coniferous wood).

Resin pocket is a lens-shaped cavity filled with resin, located inside or between the annual layers of wood.

- It is permissible to have not only a blunt, but also a sharp wane along the entire length of the edge.

- The length of the cracks should not exceed ⅓ of the length of the lumber.

- There may be loose knots whose diameter does not exceed 20 mm.

- Slight blue discoloration and other color changes are acceptable (fungal effects).

Third grade wood

The most budget option, which, of course, is reflected in the quality of the edged board or timber. Since the requirements for the 3rd grade are much softer, the load-bearing capacity of the workpiece is sharply reduced. Meanwhile, the scope of application of grade 3 edged lumber is quite wide.

Application area. This grade is recommended for the manufacture of structures that do not bear loads and do not require a beautiful appearance. Rough finishing, construction of temporary shelters, canopies, production of budget furniture, pallets and containers.

Specifications:

- Blunt and sharp wane is acceptable along the entire length of both edges.

- Wormholes are acceptable on any section of an edged board or timber.

- Through cracks are allowed, including those extending to the end. However, their length should not exceed 100 mm.

- In addition to healthy fused knots, the presence of falling out, as well as rotten and tobacco knots is acceptable.

A tobacco knot is a rotten knot, the wood of which is softened and looks like a loose mass of rusty-brown color (which is why it gets its name). Less often it has a whitish color.

- It is permissible to have a double core on the surface of the lumber.

- Minor warping of the material

- A significant roll area is acceptable.

A heel is a sharp thickening of the annual layers in a limited area of wood. Characteristic of compression-prone areas at the junction of the trunk and branches. The wood in these places is darker and denser.

- Sprouting is acceptable if it is located only on one of the surfaces of the lumber.

Sprouting is a trace of a wound in a tree trunk (overgrown or overgrown). It looks like a slit-like cavity. It can be either empty or filled with remnants of bark and dead tissue.

This is the most budget and lowest quality lumber. This grade includes all material that has not passed the characteristics of a higher grade. Here you can already see significant damage by wormholes, serious warping, and large cracks with mechanical damage.

Wear resistance and flexibility of wood

Wear resistance is the ability of wood to resist destruction during friction. The wear of the same wood is greater on the side than on the end. The higher the hardness and density of the wood, the less its wear and tear. Wet wood is more susceptible to wear and tear - which is why experts recommend dry cleaning for decorative panels or natural floorboards.

Flexibility is the ability of wood to deform under the influence of external forces. Technologically, the bending operation is based on the ability of wood to deform relatively easily when exposed to bending devices, especially in a heated and wet state. During cooling and drying under load, a significant part of the elastic deformations turns into residual deformations, and a new shape of the part is fixed. Wet wood has a higher bending ability than dry wood.

Deciduous ring-vascular tree species (oak, ash) and diffusely vascular trees (beech, birch) have the greatest ability to bend (bend). In coniferous species this ability is very low.

The ability to bend is widely used in the manufacture of furniture and interior items.

Impact strength is the ability of wood to absorb work during impact (impact bending) without destruction and is determined by bending tests. The impact strength of hardwood wood is on average 2 times greater than that of coniferous wood.

conditional tensile strength when crushing across the fibers

| Breed | Conditional tensile strength, kg/cm2, in compression | Breed | Conditional tensile strength, kg/cm2. when crushed | ||

| radial | tangential | radial | tangential | ||

| Pine | 34 | 51 | Elm | 52 | 50 |

| Larch | 44 | 63 | Hornbeam | 147 | 111 |

| Oak | 76 | 56 | Beech | 78 | 52 |

| Ash | 90 | 99 | Maple | 112 | 73 |

| Elm | 51 | 39 | Birch | 65 | 41 |

| Elm | 52 | 55 | Aspen | 36 | 29 |

Wood of species with wide or very numerous rays (oak, beech, maple, partly birch) is characterized by a higher nominal tensile strength under radial crushing (about 1.5 times); for other hardwoods (with narrow beams) the indicators of the conditional crushing strength in both directions are practically the same or differ little.

For coniferous wood, on the contrary, the conditional tensile strength for tangential compression is 1.5 times higher than for radial compression due to the sharp heterogeneity in the structure of the annual layers; with radial compression, it is mainly the weaker, early wood that is deformed, and with tangential compression, the load is also taken up by the late wood from the very beginning. Compared to the compressive strength along the grain, the conventional compressive strength across the grain averages about 1/8 (from 1/6 for hardwood to 1/10 for softwood and softwood).

Thermal properties

Thermal properties include heat capacity, thermal conductivity, thermal diffusivity, and thermal expansion.

Thermal capacity is the ability of wood to accumulate heat. It increases with increasing humidity.

Thermal conductivity is a property that characterizes the intensity of heat transfer in a material. Thermal conductivity increases with increasing humidity and density. The thermal conductivity along the fibers is on average 2 times greater than across them.

Temperature conductivity is the ability of wood to equalize temperature throughout its volume.

Thermal expansion is the ability of wood to increase linear dimensions and volume when heated. The coefficient of thermal expansion of wood is 3-10 times less than that of metal, concrete, and glass.

Deformability

Under short-term loads, predominantly elastic deformations occur in wood, which disappear after the load. Up to a certain limit, the relationship between stress and strain is close to linear (Hooke's law). The main indicator of deformability is the coefficient of proportionality - the elastic modulus.

The elastic modulus along the fibers is E = 12-16 GPa, which is 20 times greater than across the fibers. The higher the elastic modulus, the stiffer the wood.

With an increase in the content of bound water and the temperature of the wood, its hardness decreases. In loaded wood, when drying or cooling, part of the elastic deformations is converted into “frozen” residual deformations. They disappear when heated or moistened.

Since wood consists mainly of polymers with long, flexible chain molecules, its deformability depends on the duration of exposure to loads. The mechanical properties of wood, like other polymers, are studied on the basis of the general science of rheology. This science examines the general laws of deformation of materials under the influence of load, taking into account the time factor.

strength of wood under static bending

For static bending tests, bar-shaped samples with dimensions of 20X20X300 mm are used. Fixed supports and knives must have a rounding with a radius of 15 mm; the distance between the centers of the supports is l = 24 cm. After measuring the cross-section length (width b and height h) in the middle, the sample is placed on supports and loaded at two points at a distance of 8 cm from each support, uniformly at a speed of 700 ± 150 kg/min for the entire sample , which is brought to a complete fracture. The maximum Load Pmax is measured on the machine scale with an accuracy of 1 kg.

The tensile strength during static bending depends significantly on humidity. When bending wood, normal stresses arise (tensile and compressive along the fibers) and shear stresses (shearing along the fibers). The former reach their maximum in the outermost fibers, which are farthest from the neutral plane, and the latter - in the neutral zone, which theoretically should pass in the middle of the height of the bar.

In wood, due to differences in tensile and compressive strength along the fibers, the neutral plane shifts towards the tensile zone, which causes inequality in normal stresses (tensile and compressive along the fibers). Bending deformation is externally expressed by the deflection of the sample and is measured by the deflection arrow. Since the compressive strength of wood along the fibers is significantly less than the tensile strength, fracture during bending begins in the compression zone in the form of folds, although it is rarely noticeable to the eye. The final destruction occurs in the tensile zone and consists of rupture or splitting of the outermost fibers and complete fracture of the sample. The fracture of high quality wood is fibrous or pinched, while of low quality it is conchoidal, almost smooth.

The pinched nature of the fracture is more pronounced in the stretched zone of the sample; the fiber bundles there are larger and longer; in the compressed zone, on the contrary, these bundles are small and short. In table The indicators of ultimate strength in static bending for the wood of our main forest species are given.

The strength of wood during static bending is intermediate in value between tensile and compressive strength along the fibers and can be taken on average to be about 900 kg/cm2 for different species. If the compressive strength along the fibers is taken as unity, the static bending strength will be approximately 2 times higher, and the tensile strength along the fibers will be 2.7 times higher. The proportionality limit for static bending is on average 0.7 of the tensile strength.