Equilibrium humidity

When wood is exposed to the same air environment for a long time, without significant changes in air humidity and temperature, the material reaches equilibrium moisture content. This is a state when the process of drying or saturation with moisture under given conditions has stopped, and the percentage of humidity has become constant. It is worth noting that different types of wood under the same conditions achieve almost equal internal moisture levels.

Depending on different conditions of maintenance, there are 5 degrees of wood moisture content.

:

Wet

– humidity is more than 100%, this condition is achieved by long-term storage of wood in water.

Freshly cut

— moisture level from 50 to 100%.

Air dry

– from 15 to 20%. Such indicators are achieved when stored in air; they vary depending on temperature and precipitation.

Room dry

– from 8-10%. The moisture level is set during indoor storage.

Absolutely dry

– wood with 0% moisture content.

Free and bound moisture

There are 2 types of liquid in wood tissue:

Associated moisture

– located inside the cells of the tree.

Free moisture

- that which fills the pores and channels of tissues, but has not yet been absorbed by cells.

Wood fiber saturation point

Associated with these two concepts is the so-called fiber saturation point: that percentage of wood moisture content when all free moisture has been removed from it, but bound liquid remains in it.

For different types of wood, this degree is determined from 23 to 31%

.

Ash – 23%

Chestnut, Weymouth pine – 25%

Pine, Spruce, Linden – 29%

Beech, larch – 30%

Douglas fir, sequoia – 30.5 -31%

This value is important because the volumes and dimensions of wood change at moisture content from 0% to the saturation point. Once the cells are completely filled with water, the volume of the tree will not increase significantly.

Measuring wood moisture with a moisture meter

Humidity measurement methods

Wood is an anisotropic material. The properties of this group of substances depend on the direction of the fibers - strength and thermal conductivity are different along and across. Wood is also inherently hygroscopic - the ability to absorb and release moisture in large quantities.

It is anisotropy and hygroscopicity that cause the appearance of stresses inside the lumber, which lead to cracking and the appearance of inter-crown gaps during the shrinkage of a wooden log house.

Special film-forming compounds used to treat the ends of a log structure help reduce anisotropy. And special devices help control the humidity indicator - moisture meters, which can be of varying degrees of accuracy, portable and stationary.

There are three methods for determining the moisture content of lumber. These are contact (conductometric), non-contact (dielcometric) and drying method (thermogravimetric).

Thermogravimetric method

The drying technique gives the greatest accuracy; it is its result that is included in GOST 17231-78 and is considered officially recognized. The method is very labor-intensive, taking at least five or even eight hours. The point is this:

- A small sample is sawed off from the product at a distance of more than 50 mm from the edge. This is due to the fact that the surface layers of wood dry out faster than the middle. Therefore, a prototype with volume is needed.

- After this, the sample is weighed on a laboratory scale to 0.1 or 0.01 g and dried in a drying chamber at a temperature of 100 degrees C.

- Periodically, the sample is removed and weighed. All results are recorded. Weighings continue until the same value is obtained two times in a row. This means that the sample has lost all liquid and its moisture content is zero.

After receiving a completely dried sample, calculations are made using the formula:

Wrel = ((m0 - m)/m)*100%,

where m0 is the initial weight, and m is the final weight.

The final weight is subtracted from the initial weight. This number is divided by the final weight and multiplied by 100%. The result is the desired humidity.

Contact measurement

The moisture content of lumber is calculated based on the coefficient of electrical resistance. Needle moisture meters convert the value into a unit of humidity and display the result on their screen.

The photo shows the moisture content of a rounded log from ABC Lesa using a contact moisture meter.

To take measurements, metal probes are inserted into the wood and an electric current is turned on. The longer the probe, the more accurate the instrument readings.

The disadvantages of needle devices include:

- Violation of the integrity of lumber at measurement points.

- When the moisture content of the material is less than eight percent, the error is large.

Non-contact technique

At the beginning of the measurements, a small, as smooth area as possible is prepared on the surface of the wooden product. The essence of the technique is to determine the dielectric constant of the sample under study using microwave radiation.

The device compares the resulting number with the standard value that is in its memory. The difference between the standard and the obtained value is the moisture content of the wood. The main advantage of the method is the absence of dependence on air temperature and static electricity.

Using such measurements, you can check the moisture content of the sample along its entire length, and this takes a few minutes. When using such moisture meters, the material at the point of contact is not damaged.

Disadvantages of the method:

- Error associated with the non-uniform distribution of moisture and density throughout the entire volume of lumber.

- Inexpensive models are characterized by a small scanning depth.

Visual methods

These folk methods are not accurate. But sometimes this option can provide the necessary information.

- If liquid appears on the cut, this indicates excessive moisture in the lumber. And, conversely, if the board crumbles when cutting, it is overdried.

- They draw on the planed surface of the lumber with a chemical pencil. If the image turns purple, there is a lot of moisture in the lumber.

- Dry wood shavings are easily painted, while damp wood shavings are elastic.

- When the butt of an ax hits wood, a dull sound indicates high humidity, and a soft sound indicates good drying.

- When storing boards in the fresh air, drops of resin appear on the ends. If the resin crumbles under pressure, then it is a dry tree.

Absolute humidity of wood

Let's look at the concepts of absolute and relative humidity.

Let's take a wooden block. Absolute humidity is the ratio of the mass of the internal liquid to the mass of the completely dried bar. The value is calculated by the formula: W = (m – m0) / m0 x 100, where (m) and (m0) are the mass of the wet and dried bar. GOST 17231-78 interprets this value simply as “humidity”. But this concept is inconvenient to use in calculations, since the amount of water refers specifically to the dry mass, and not to the total weight. As a result, discrepancies arise: for example, 1000 g of wood contains 200 g of moisture, but the absolute humidity is calculated as 25%.

Determining the degree of humidity

To correctly determine the amount of liquid, craftsmen use several methods. At home, you can use an electric moisture meter. The principle of operation of the device is based on changing the conductivity of the material.

An experienced master will always acquire such a necessary device. If you are interested and would like to purchase a portable pocket electric moisture meter, then I recommend looking at an interesting and inexpensive model.

Convenient pocket moisture meter…

Some craftsmen are able to determine dry or wet wood just by looking at it. This requires correct knowledge about the species and density of lumber.

Relative humidity of wood

This is a more convenient concept for calculations, since it reflects the ratio of the mass of the internal liquid to the total mass of the block. The calculation formula is the simplest:

Wrel. = mwater / msample x 100.

This formula is used in heating engineering calculations to determine the volume of water evaporated from firewood. According to it, at a humidity of 20%, a 1000-gram bar contains 200 grams of moisture and 800 grams of dry fibers—a completely logical result.

What is natural moisture wood?

Anyone who has ever worked with wood has come across the concept of “natural moisture” and tried to understand what it really is. It should be noted right away that it is very important, since it determines what the final result of the work will be, so a good construction specialist must understand what natural moisture wood is.

Wood is a natural material that is extremely sensitive to any changes in temperature or moisture level. In accordance with atmospheric conditions, the percentage of liquid in it changes. This phenomenon is called hygroscopicity.

Factors affecting wood moisture content

There are three main factors that influence the moisture content of wood:

- breed;

- season;

- climate.

The level of moisture in wood can change both under the influence of climatic conditions and depending on its species. Experts believe that the most susceptible species are beech, pear and campass, and the most stable are merbau, bamboo, oak and other hard materials.

The time of year also affects the moisture content of wood, as it becomes drier in winter. But if you cut it down in the spring or summer, the tree will need to be dried.

Types of humidity

Humidity is a basic and important characteristic when selecting/preparing wood. It is classified according to certain criteria, it happens:

- absolute (it is different for each tree; there is a special GOST to determine it);

- relative.

In addition, the following three types are distinguished:

- natural;

- transport;

- furniture.

This classification defines the use of wood material in various fields of construction. For example, the natural moisture content of wood is important in the construction of formwork or sheathing, furniture moisture in the production of furniture, transport moisture in the production of sheet piling, lumber, for construction purposes, etc. For construction, boards with transport humidity (20%) should be used, as they are not susceptible to fungal infections and do not become deformed. If you use a board with natural moisture, then it is worth remembering that intensive drying can cause it to deteriorate.

Experts also distinguish such types as initial (natural) and final (equilibrium).

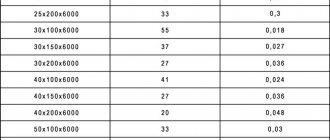

Table of wood densities of different humidity levels

| № | Wood species | Humidity percentage, % | ||||||||||

| 15 | 20 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 100 | Fresh* | ||

| 1 | Larch | 670 | 690 | 700 | 710 | 770 | 820 | 880 | 930 | 990 | 1100 | 940 |

| 2 | Poplar | 460 | 470 | 480 | 500 | 540 | 570 | 610 | 650 | 690 | 760 | 700 |

| 3 | Beech | 680 | 690 | 710 | 720 | 780 | 830 | 890 | 950 | 1000 | 1110 | 960 |

| 4 | Elm | 660 | 680 | 690 | 710 | 770 | 820 | 880 | 930 | 990 | 1100 | 940 |

| 5 | Oak | 700 | 720 | 740 | 760 | 820 | 870 | 930 | 990 | 1050 | 1160 | 990 |

| 6 | Hornbeam | 810 | 830 | 840 | 860 | 930 | 990 | 1060 | 1130 | 1190 | 1330 | 1060 |

| 7 | Norway spruce | 450 | 460 | 470 | 490 | 520 | 560 | 600 | 640 | 670 | 750 | 740 |

| 8 | Walnut | 600 | 610 | 630 | 650 | 700 | 750 | 800 | 850 | 900 | 1000 | 910 |

| 9 | Linden | 500 | 530 | 540 | 540 | 580 | 620 | 660 | 710 | 750 | 830 | 760 |

| 10 | White acacia | 810 | 830 | 840 | 860 | 930 | 990 | 1060 | 1190 | 1300 | 1330 | 1030 |

| 11 | Alder | 530 | 540 | 560 | 570 | 620 | 660 | 700 | 750 | 790 | 880 | 810 |

| 12 | Maple | 700 | 720 | 740 | 760 | 820 | 870 | 930 | 990 | 1050 | 1160 | 870 |

| 13 | Common ash | 690 | 710 | 730 | 740 | 800 | 860 | 920 | 930 | 1030 | 1150 | 960 |

| 14 | Siberian fir | 380 | 390 | 400 | 410 | 440 | 470 | 510 | 540 | 570 | 630 | 680 |

| 15 | Scots pine | 510 | 520 | 540 | 550 | 590 | 640 | 680 | 720 | 760 | 850 | 820 |

| 16 | Caucasian fir | 440 | 450 | 460 | 480 | 510 | 550 | 580 | 620 | 660 | 730 | 720 |

| 17 | Cedar pine | 440 | 450 | 460 | 480 | 510 | 550 | 580 | 620 | 660 | 730 | 760 |

| 18 | Birch | 640 | 650 | 670 | 680 | 730 | 790 | 840 | 890 | 940 | 1050 | 870 |

| 19 | Aspen | 500 | 510 | 530 | 540 | 580 | 620 | 660 | 710 | 750 | 830 | 760 |

How to determine moisture level

Builders use various methods to determine the amount of moisture in wood. The most common and accurate is to measure liquid using an electromoisture meter. Almost every good master has it. If you have information about the type of wood and its density, you can determine the approximate moisture level by eye. But this can only be done by an experienced specialist.

Natural and equilibrium humidity

When doing construction, it is important to understand what natural moisture wood is. Every tree has a certain percentage of liquid that does not change after it is cut down. When drying occurs, its trunk decreases in thickness and width. If you do not dry the wood, then during the construction process the boards and beams may decrease in volume, which means that cracks will appear and the cohesion of the structure will be disrupted. Often, natural humidity is also called initial humidity, since, starting from it, the master comes to the final value, that is, the level of moisture that he wants to obtain at the end of drying. Natural humidity varies from 25 to 80%.

It is also customary to distinguish equilibrium moisture content, which represents the same value of liquid distribution both in the tree and in the environment. For example, a parquet board or other material used indoors should have a moisture level of 6-8%.

Drying process

It should be noted that when drying, water from a wooden board evaporates unevenly. First, moisture disappears from the upper layers, then from all subsequent layers; more liquid always remains inside the trunk than outside. That is, it is almost impossible to completely dry the tree in all its layers. The drying process is one of the most important processes when processing wood; it is carried out immediately after it is cut down. It is necessary in order to protect the boards from damage and deformation during transportation, storage or manufacturing of products, and it also improves the quality of gluing.

Drying of wood with natural humidity

Moisture content of wood species

One of the factors affecting humidity is the type of wood. Due to the different structure of the fibers, some rocks instantly react to changes in the external environment, absorb and release water. Others are more stable and very slowly saturated with moisture.

The most actively absorbing moisture species include beech, pear, and kempas.

Oak and merbau are considered stable and resistant to change.

Drier rocks tend to crack when dried. Moderately humid ones, such as oak, are more resistant to such phenomena and change their properties less when conditions change.

When cutting under normal conditions, the moisture content of different types of wood has the following average values:

| Name | Average humidity value, % | |

| Conifers | Fir | 100 |

| Cedar pine | 92 | |

| Spruce | 91 | |

| Larch | 82 | |

| Scots pine | 88 | |

| Deciduous soft | Poplar | 92 |

| Willow | 85 | |

| Alder | 84 | |

| Aspen | 82 | |

| Linden | 60 | |

| Deciduous hard | Elm | 80 |

| Manchurian ash | 79 | |

| Birch | 78…68 | |

| Beech | 64 | |

| Hornbeam | 60 | |

| Oak | 50 | |

| Common ash | 36 |

Natural humidity

The natural indicator is assessed during growth or immediately after cutting the wood. Ranges from 30 to 80%. The amount of moisture depends on the type of wood, its structure and the environment.

Table “Moisture content of freshly cut wood”

| Breed | Humidity, % | ||

| kernels | sapwood | average | |

| Birch | — | 70-90 | 78 |

| Oak | 50-80 | 70-80 | 70 |

| Spruce | 30-40 | 100-120 | 91 |

| Larch | 30-40 | 100-120 | 82 |

| Aspen | — | 80-100 | 90 |

| Pine | 30-40 | 100-120 | 88 |

| Ash | 35-40 | 35-40 | 38 |

| Fir | — | — | 101 |

| Cedar | — | — | 92 |

The task of material manufacturers is to dry the wood as much as possible, due to which it will become stronger, denser and smaller. It is easier to remove moisture from hardwood trees, because they initially have a lower humidity level.

It is important to dry the wood so that the moisture evaporates evenly. This will allow you to achieve the correct shape, because the part with a lot of water is much larger and heavier than the dry part.

Dry wood is widely used in the manufacture of furniture and various interior items. It is durable and has high ergonomics.

Wood moisture content for pellet granulation

Pellets and fuel briquettes are valued due to the low level of moisture in the fuel. Its moisture content is 8-12%. With such characteristics, a minimal amount of smoke is produced when burned.

The optimal level of wood moisture for pellet production is 12-14%. Hammer crushers also work with wood chips up to 65% humidity, but at such humidity it is impossible to crush the material to the required fraction, so grinding occurs in several stages. To bring crushed sawdust to the desired condition, complexes with drying drums are used.

Natural humidity

So we come to the main issue of today’s article - natural humidity. What is this definition? Water is necessary for the life of a tree; naturally, immediately after cutting it will remain almost unchanged. During the drying process, the trunk decreases in volume, but not along the fibers, but only in width and thickness.

Sometimes the volume of boards or beams decreases so much that they lose adhesion to each other, as a result a large gap can form. It is for this reason that wood with natural moisture must be dried, only then can it be processed or used for its own purposes.

In fact, there are no stipulated standards for determining natural humidity. It can vary from 27 to 81%, and this figure will depend on interrelated factors, such as time of year, place of growth and breed.

Very often natural humidity is called initial humidity. Based on it, the concept of final moisture content (the final result after drying) that the master wants to obtain is identified.

Drying complex for wood from ALB Group

The ALB Group company produces AVM drying complexes

for wood waste granulation and briquetting lines. The main element of the complex is the AVM drying drum, which in one run can reduce the moisture content of fine wood from a level of 50% to the required 8-12%. Drying occurs as a result of turning the raw materials in the drum and circulating hot air in it. The operation of the AVM drum is ensured by connecting a heat generator or combustion unit; a smoke extractor and aspiration system are connected to the complex.

Models AVM 0.65 and 1.5

with a capacity of up to 1200 and 2500 kg per hour, they are the most popular equipment for drying chopped wood.

Find out more about our drying complexes by calling+7

or leaving your contact information in the form!

Technologies for professional wood drying

A variety of wood drying technologies are used in construction. They differ not only in the equipment used, but also in the method of transferring heat to the material that is dried.

Atmospheric drying

This is the removal of moisture from wood through the natural process of evaporation. The wood is stacked and placed in a dry, well-ventilated room so that it is washed by atmospheric air. There must be ventilated gaps between stacks.

If wood is dried in the open sun, its outer surface will heat up more than the inner surface. This can lead to various defects.

This drying method is considered inexpensive, the most gentle, and the resulting wood is more resistant to deformation. The disadvantages of this method include: long drying time (4-6 months); high final moisture content of the material (15-20%).

Chamber drying

This is a highly efficient wood drying technology that allows you to obtain high-quality material with the required moisture content. Lumber is loaded in stacks into forest drying chambers, where liquid evaporation occurs under the influence of a gaseous medium (flue gases, air, superheated steam). The gaseous medium transfers heat to the wood by convection.

For uniform distribution and circulation of warm air in drying chambers, axial or centrifugal fans are used. Timely removal of excess moisture allows you to avoid cracking and warping of lumber, as well as obtain high-quality material in the shortest possible time (from several hours to several days).

The undeniable advantage of this technology is: high rate of evaporation of excess moisture, low stress in the finished material, large chamber loading volume (up to 1000 m3).

Chamber drying of wood is not a cheap pleasure, so lumber dried in this way is much more expensive than naturally moist lumber. However, if you choose wood with natural humidity to build a house, you can win in money, but lose in quality, over time by filling holes between dry boards or replacing rotten structures.

Since technically dried wood is a high-quality raw material for the construction of all types of wooden structures with high protective and stable physical and mechanical properties, it is ideal for building a house.

Types of humidity

Wood is of natural origin, so it is very sensitive to fluctuations in air temperature and atmospheric pressure. Subject to the state of the environment, it changes the percentage of humidity. Experts say that wood breathes, absorbs or emits air vapor and this phenomenon is called hygroscopicity. It is generally accepted that the most important characteristic is humidity, which determines the ratio of moisture to dry mass. It is divided into:

- Absolute - has different meanings for each type of wood. Wood moisture content is determined according to GOST 8486-86.

- Relative - measurements are taken in a wet state and are divided into free and bound.

You may be interested in: John Mill: biography, personal life, achievements

In addition, humidity can be:

- Natural – 27–81%. Used for various auxiliary works: making formwork, rafters and sheathing.

- Furniture – 8–12%. It is used in furniture production and for the production of laminated veneer lumber.

- Transport – 18–22%. Used for all other types of work, except those listed in the first two paragraphs: for the production of lumber, construction, sheet piling.

You may be interested in: Schematic diagram of reverse engine starting

The most suitable wood for construction work is transport wood. The material with a humidity of about 20% is easy to process, it does not warp and is not subject to fungal infections.

Drying Features

A true master must understand how to find out the moisture content of wood using improvised methods. Moisture continuously circulates through the trunk of a living tree - this allows it to maintain development. Every cell of the wood gets juice containing useful substances. In freshly cut wood, the equilibrium moisture content changes due to the cessation of circulation. The free space is filled with water. There are several ways to reduce the percentage of liquid, but the most effective is evaporation.

During the drying process of wet wood, moisture loss is uneven. First, it leaves the upper layers. Following the capillary water, the hygroscopic water evaporates. What percentage of moisture do you think remains inside dry material? Significantly more than outside. Drying all layers completely is an almost impossible task.

Wood fiber saturation point

This is an indicator of equilibrium humidity, at which free moisture from the wood has already evaporated, but capillary moisture remains. The percentage of humidity at the saturation point ranges from 23 to 30. Depends on the type of wood and external conditions. If the indicator of the presence of moisture is lowered below this point, the drying process will slow down, the material will begin to dry out, shift, and settle. During the natural drying process, the upper layers of the material quickly release free moisture and begin to release bound moisture. As a result, the properties of the workpiece change. This process introduces difficulties into the drying process.

| Breed | Coefficient of shrinkage (Ku) and swelling (Kp) in directions | |||||

| Volumetric | Radial | Tangential | ||||

| Ku | Kr | Ku | Kr | Ku | Kr | |

| Larch | 0,52 | 0,61 | 0,19 | 0,20 | 0,35 | 0,39 |

| Pine | 0,44 | 0,51 | 0,17 | 0,18 | 0,28 | 0,31 |

| Cedar | 0,37 | 0,42 | 0,12 | 0,12 | 0,26 | 0,28 |

| Birch | 0,54 | 0,64 | 0,26 | 0,28 | 0,31 | 0,34 |

| Beech | 0,47 | 0,55 | 0,17 | 0,18 | 0,32 | 0,35 |

| Ash | 0,45 | 0,52 | 0,18 | 0,19 | 0,28 | 0,35 |

| Oak | 0,43 | 0,50 | 0,18 | 0,19 | 0,27 | 0,29 |

| Aspen | 0,41 | 0,47 | 0,14 | 0,15 | 0,28 | 0,30 |

After reaching the saturation point of the fibers, further wetting and drying of the workpiece is no longer as important as before.

Features of moisture content in wood

Everyone has known for a long time that air humidity has a significant impact on products made from wood. This is especially noticeable with sudden changes in moisture content in the air. The phenomenon is explained by the peculiarities of water content in tree species.

There are two forms in which it is found in the material:

- Bound - stored in the cell membrane, held by physical and chemical bonds and greatly affects many properties of wood.

- Free – located in intercellular spaces and cell cavities, preserved due to mechanical connections, easily removed and has little effect on the quality of the material.

When wood dries, free moisture evaporates first, and bound moisture evaporates only after that. The process will continue until the water is evenly distributed throughout the material and equals the relative humidity of the air. The same thing happens when moisture is absorbed.