Wood waste causes significant harm to the environment. Processing of slabs is not practiced by sawmills; this is not their core business. Many types of wood chips are used to make building materials, but in other factories. Basically, wood scraps obtained from cutting trunks are sold at bargain prices as fuel.

Croaker: waste or recyclables?

WasteRecyclables

This method of getting rid of waste is not welcomed in developed countries of Europe and America. There the wood is used without residue. The cuttings are used to make briquetted logs that look like natural logs. Sawdust and shavings are used as structural polymer fillers in the production of paving and facing tiles. Enterprising owners find practical applications for slabs.

What is a croaker?

The cuttings of the trunk with bark, formed when cutting harvested wood, are called slabs. It comes in a convex shape, with pieces of bark on one or more sides. Croaker accounts for 10 to 13% of the total volume of processed timber.

There are two types of croaker: wood and business. Wood is not used in construction. Business consists of non-standard boards with traces of bark on the side walls. According to current legislation, croaker is not allowed to be burned; it must be recycled.

For a small recycling workshop, special equipment is purchased. You don’t need serious investments to create a business; the main thing is to identify a sales market and start producing a popular product.

Advantages

The advantages of the slab are as follows:

- The cheapest lumber. Its use as load-bearing elements brings significant cost savings when constructing lightweight buildings.

- The low weight of the boards when constructing small objects allows you to create cheap foundations.

- Cladding with slabs does not require additional finishing of building structures. Walls covered with decorative wood carry an aesthetic value.

- Barked surfaces are varnished or painted, which gives the furniture a special appeal.

- The ease of installation of lumber does not cause difficulties when carrying out facing work.

- Wood waste is widely used in the manufacture of various products - from parquet to the design of accent walls.

- Using industrial wood as lining will allow you to avoid unnecessary costs for purchasing a factory profile.

Recycling process

Manufacturers of graded wood are not interested in additional costs. They try to sell waste to small businesses. Local authorities are interested in recycling waste, and this includes wood trimmings.

Entrepreneurship support funds provide assistance to start-up businessmen and provide consulting services. The package of permits is minimal; a small enterprise does not require a license.

The main problems when processing slab:

- curvature of wood during transportation and unloading;

- excessive knotiness;

- uneven pieces of bark.

The business is of interest to individuals who are willing to work from home. This is beneficial since expensive complex equipment is not required. No regulatory documents regulate the size of the scraps; they can be of any thickness and length. Both business and wood slabs are purchased for reuse.

How is its cost determined?

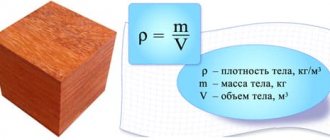

Like any other material, slab has its own unit cost, equal to the unit cost of the logs that were purchased for sawing into boards.

After all, to obtain boards, you first need to buy logs, then cut them at a sawmill, obtaining industrial wood and waste in the form of sawdust and slabs.

However, it is impossible to sell the waste at such a price, so it is usually written off as a loss.

In addition, gradually so much waste accumulates that it begins to interfere with the work of the sawmill, after which its owners are ready not only to sell, but even to give away the interfering trimmings for free.

Therefore, the main criterion influencing the cost of scraps is their demand, which depends on:

- size and shape of the slab;

- wood species and quality;

- the presence of nearby businesses or individuals interested in purchasing this material;

- distances between seller and buyer;

- the condition of the roads along which wood sawing waste will be transported;

- transport costs.

Dimensions and shape

The thicker, wider and longer the slab, the more wood it contains, which can be used not only as fuel or boards for making greenhouses. Even furniture is made from large material, because it contains enough wood.

The thicker, wider and longer the slab, the better suited it is for use as support posts or boards, so the size of the material is the main factor influencing its cost.

Fare

If buyers are located thousands of kilometers from the supplier, then transport costs will make the price too high, even if the croaker is released free of charge.

Therefore, the shorter the distance between the manufacturer and the buyer, and the better the road surface on the route of transport, the lower the transportation costs, as well as their impact on the overall cost.

After all, regardless of who pays the transportation costs, they in any case affect the price. If they are borne by the buyer, the final cost will be higher than the price stated by the supplier. If the costs are borne by the supplier, they will have to be deducted from the sales price, which will reduce the income from this operation.

Species and quality of wood

The type and quality of wood directly affects the mechanical properties and, consequently, the use of the slab.

Therefore, leaf waste is in demand only in cases where:

- the mechanical strength of this species is higher than that of most coniferous species (this applies to slabs made of oak, ash, maple and other hard species);

- The texture of this type of wood is better suited for the purposes for which sawing waste is purchased.

What is made from slab?

Product List:

- boxes for transporting agricultural products (vegetables, fruits);

- trays for storing and transporting bread, the surface of the wood is additionally sanded;

- semi-finished products for the production of containers (bars, slats), for processing slabs into container boards, universal machines are purchased;

- fence picket – having milling equipment, it is easy to give the strips the desired shape;

- glazing beads are small bars with a beveled edge or a shaped surface;

- shingles for plastering, this is a small glazing bead without cuts;

- firewood, for fireplaces they make sets of slats of the same length, they look aesthetically pleasing and are stored in special baskets;

- non-commercial wood - it is necessary for builders for formwork and is used in finishing work;

- chips – the process of processing slabs into chips is minimized, waste is generated during other operations;

- sawdust – sold in bags, the main consumers are gardeners;

- bark - as mulch or fuel.

Kinds

Depending on the linear size and thickness of the slab, it is sorted to produce various types of lumber. Usually there are 2 main subspecies:

- business - used for further work as finishing and building materials;

- wood - has such small dimensions that it can only be suitable for processing into fuel materials.

The first type is subjected to further processing and sawdust. Depending on the dimensions, it can be used to make formwork, boards for a subfloor or fence, lining or a block house. From the second type of slab you can make slats for pallets, decoration of small products, and plating. However, it is mainly used for further disposal as sawdust or small chips for lighting stoves and fireplaces.

Equipment for processing slabs

Manufacturers offer machines for processing slabs into chips or sawdust. When choosing, it is important to focus on the final product, the conditions for its sale, and the estimated cost.

Machines for business slabs are:

- dividing, makes longitudinal and transverse cuts in wood;

- Edge trimmers are used for cutting areas with bark and uneven surfaces.

The waste is used to produce multi-format lining necessary for minor repairs and private construction. They sell products in cubic meters or individually.

No lengthy special training is required to operate the equipment. We just need to ensure the safety of the work.

The cost of each machine is from 100 thousand rubles. It is better to purchase multifunctional devices that perform several operations at once.

Lines cost from 200-300 thousand rubles. They are automated, easy to operate, and the machines are easy to repair. In one pass, several finished boards are obtained.

Another option is a crusher, which turns the trimmings into wood chips. They are purchased for wood waste, trimmings remaining during the processing of business slabs.

Classification

Waste is divided into two main groups, depending on the physiology of the fish and the method of their use:

- The first includes internal organs - liver and heart, skin and scales, caviar and milk. The amount of waste recovered depends on the type of fish caught, location and fishing season.

- Waste generated as a result of the technological processes and production schemes used belongs to the second group. Their volumes are also influenced by the range of finished products, equipment used in the processing process and technological modes.

If for the first group the amount of waste is determined by factors beyond human control, then for the second group there are many ways to reduce their amount.

There are many reasons: from the imperfection of the equipment used to the low qualifications of cutting workers.

Almost all fish processing waste can be used in the future to create secondary products for various purposes, so they should be considered raw materials.

The classification of fish production waste is intended to summarize information for making certain decisions regarding the disposal or processing of secondary resources, and the improvement of processing technologies.

State of aggregation

Waste can be separated according to its state of aggregation:

- Solid waste is generated during the technological operations of cutting, smoking, pickling or salting.

- Liquids are formed during washing and defrosting fish, sanitary processing of processing equipment. This group also includes various broths formed during the cooking of raw materials and the production of flour.

- Pasty sediments are filter cakes and sludges after separation.

The waste can even be in a gaseous state. This is steam from cooking raw materials, various smokes.

Each of them has its own processing technology with a set of special equipment.

Technological stages

When cutting fish, primary waste occurs.

These include:

- heads;

- skeletal and costal bones;

- scales;

- fins, tails;

- entrails and blood;

- gonads (caviar and milk).

Technological waste is also generated at the secondary and final stages of processing. These include, for example, waste from cooking and canning.

Directions for use

When organizing processing plants, the direction of use of processed fish waste is taken into account. They may be:

- use for human food;

- production of animal feed;

- manufacturing of technical products;

- production of dietary supplements and cosmetics.

The list of destinations is constantly updated due to the emergence of new technologies and inventions.

Now fish cutting waste can be completely used. So far, broths, saline solutions, and waste oils are only partially used.

Unused waste includes filter cakes and various sludges.

Processing slabs at home

Business croaker is a source of non-grade boards. According to experts, up to 10% of non-format sized boards are chosen from slab. They are cut to length and width. With proper sorting, small batches are formed. They are allowed into retail trade and used for their own needs.

Mass production of semi-finished products from wood trimmings is easy to organize in a garage or shed. A private factory will be profitable if it purchases two or three machines that process slabs into sawdust. Wood fuel is formed from resinous rocks; leaf chips are used as a soil loosening agent and mulch, necessary for all gardeners. It is better to pack sawdust into thick garbage bags made of recycled plastic.

All ways to get rid of waste

Here are the main ways to get rid of sawdust:

- burying in the ground;

- burning;

- disposal to landfill;

- use for own needs;

- sales to various buyers;

- transfer to those who are ready to receive them.

Burying in the ground is a good way to dispose of wood waste if its volume does not exceed several cubic meters. Having rotted, this waste will turn into an excellent fertilizer that can be used to grow various plants.

If an enterprise produces at least a cubic meter of such waste every week, then after 3–5 years there will be nowhere to bury it. In addition, this disposal method may raise questions from Rosprirodnadzor and other regulatory organizations, as a result of which various commissions will come to the enterprise and it is unknown what conclusion they will come to.

Incineration is suitable for recycling a small amount of sawdust, but you can try to burn several tens of cubic meters.

In addition, burning a large volume of this material will attract the attention of neighbors and organizations such as the Ministry of Emergency Situations or State Fire Supervision. As a result, inspections will begin that will find out whether you had the right to burn wood waste and whether you caused damage to nature or to an enterprise/person.

The removal of waste from sawing wood to a landfill does not require any special permits; it is sufficient to conclude an agreement with an enterprise that provides services for the disposal of household waste.

However, in this case, you will have to pay for the landfill to accept each cubic meter of waste, and given their low density, the amount will add up to a considerable amount.

Therefore, this method is also not the best option for getting rid of large volumes of sawdust.

Sawdust is a valuable material that can be used in many different ways.

For example, they make good insulation, so in winter the workshop or sawmill will be warmer, and heating costs will also be reduced.

However, you will first have to adapt the boiler or stove to operate on this type of fuel and store the sawdust in a spacious, ventilated room equipped with a fire extinguishing system.

Selling to various buyers is the most profitable way to dispose of wood waste, but it can only be implemented where there are many people and enterprises interested in receiving sawdust and there is no supplier.

The greater the number of suppliers, the less potential buyers are willing to pay for them, to the point that sometimes they have to give away for nothing, only by concluding an agreement on the free transfer of tangible assets.

The only problems that arise with this method of disposal are:

- searching for those who are ready to accept;

- costs of delivering material to them;

- documentary evidence of the transfer of waste to write it off from the balance sheet of the enterprise.

Construction of buildings

While a wood slab is only suitable for fuel chips, a business one can be used for many purposes:

- in the construction of premises for domestic needs such as a change house, a woodshed;

- for the construction of baths (panel or frame);

- in the construction of fences;

- in solving the dacha issue with fencing flower beds and beds, for the construction of greenhouses;

- as formwork;

- in the manufacture of all kinds of furniture and pallets;

- in the design of structures intended for keeping animals (goat shed, aviary).

If you give the slab a decent appearance, you can build it into a veranda or gazebo for the garden.

Building

The slab serves as an excellent replacement for timber or boards in the construction of houses. For example, if you use it during the construction of load-bearing structures or at the stage of building cladding.

Sheds/outbuildings

If you plan to store things in the utility room that are not susceptible to the influence of drafts, low temperatures or high humidity, the building needs to be sheathed only from the outside. However, if the materials in the utility block require special protection, then it is designed in the same way as panel buildings.

Garages

When building a garage, the requirements are much stricter than when building a greenhouse or utility room. For this reason, only the load-bearing frame, roofing, panel sheathing and ceiling lining are made from slab.