Building materials made from hard deciduous and coniferous trees have a wide range of applications; they are used for the construction and cladding of houses, paving paths, and interior decoration of buildings. The lumber on the market is divided according to the cutting method; it can be tangential, radial, longitudinal, disk or mixed. Depending on the presence of edges, boards are classified into edged, semi-edged and unedged.

Mechanical processing of logs can be carried out using special machines or electrical appliances by cutting or splitting. There are the following methods of cutting wood: planing, turning, drilling, grinding, all of which involve removing chips. There are three types of cutting - longitudinal, transverse and straight. The first involves cutting along the fibers, the second and third – perpendicularly. Sawing is the main stage in the manufacture of all lumber; the operational and aesthetic characteristics of the finished product depend on the quality of the procedure.

Tools and equipment

Trunks and large branches are used for production. All material is divided into groups according to thickness and presence of bark. Often, timber processing enterprises have workshops near the harvesting site, in which machines for the initial processing of wood are installed.

Manual debarking of wood

Wood that has not passed the debarking stage can be used on floors or as ridge beams in the corresponding interior, or as a supporting device during construction.

Industrial debarking of forests

If another option for using the wood is planned, then sawing is carried out, resulting in the following segments:

- unedged and semi-edged (rough material from which the bases of the floor, walls or ceiling are mounted);

- edged (intended for finishing flooring).

The cutting can be carried out by a mobile organization that has all the necessary tools.

Wood cutting map

Rational use of the material is ensured by compliance with the cutting map. This allows you to reduce costs due to waste, the percentage of which the card can significantly reduce. The tools and types of forest processing equipment used depend on the volume, desired quality and size of the finished lumber.

Wood sawing machine

The most commonly used are a circular saw and various machines:

- The circular saw allows you to make precise cuts in various directions. Suitable for both professional and home use, it copes well with above-average round timber diameters;

- chainsaw;

- machines for clean bark removal;

- sawing on a band sawmill makes it possible to process dense logs; it is considered the most popular, since the output is high-quality material and a small amount of waste;

- disk machine: production of double-edged timber and unedged boards;

- a frame sawmill does not require a foundation, the technology using it allows you to install the equipment in close proximity to the felling site;

- the fine gauge is processed by universal machines, the output is high-quality building materials even from low-grade logs;

- sawing of round timber at a large woodworking enterprise should be carried out with the largest amount of lumber, differing from the rest in its special quality and precise dimensions. For this purpose, special lines are installed for sawing.

At the sawmill, timber and edged boards are obtained by cutting logs up to 7 m long and 15-80 cm in diameter along the longitudinal line. A circular saw has one or more disks and processes wood of different diameters according to their number.

Sawmill

If you need to process a small amount of wood at home, you can use a regular chainsaw.

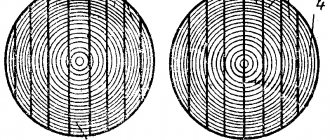

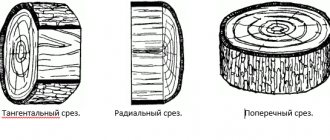

Tangential sawing

This method of processing logs is considered one of the most popular. With a tangential cut, the plane of the cutter passes at a certain distance from the core of the trunk, tangentially to the growth rings. The result is practical and durable boards that are resistant to shrinkage and swelling. Such lumber has an attractive texture - the graceful wave-like pattern of annual rings is clearly visible on them. Boards obtained by tangential cutting can be used for exterior decoration of buildings and creating a cozy interior.

High-quality parquet is also produced in this way. When cut perpendicularly, a natural pattern is visible on the boards - rings, arches, waves, curls. If the parquet is made from Siberian larch, it can be used for laying floors in rooms with high humidity, since products made from this species not only do not collapse when in contact with water and steam, but also become stronger. A wooden floor covering created as a result of tangential sawing will last for many years without needing repair or renewal.

Cutting wood

Before choosing a tool, you need to decide on the type of cut, focusing on the annual rings of the log. There are several types:

- radial (along the radius);

- tangential (the cut is parallel to one radius and touches the annual rings);

- the fibers are located parallel to the cutting being performed.

Among the cutting methods, the one that is most suitable for a particular case is selected:

- Waddle. Sawing wood in this way is carried out for deciduous trees with a small trunk thickness, and is considered the simplest processing. Output: unedged elements and slabs.

- If you have another forest processing machine, then it is possible to cut up to 65% of the material to produce edged boards of equal width. First, the double-edged timber and boards on the sides are cut, and then a certain amount of edged lumber is obtained from the timber.

- More specific methods are sector and segment sawing. The number of elements in the first method varies from 4 to 8, and depends on the thickness of the trunk. After dividing, elements are cut from each sector along a tangential or radial line. The second method begins with the timber coming out of the central part, and boards are cut from the side segments in a tangential direction.

- For individual cutting of wood, the circular method is suitable. It is based on turning the log along the longitudinal line by 90° after each sawn board. This allows you to monitor the quality of the wood and promptly remove affected areas of the trunk.

Setting up a hand saw

A hand saw is an indispensable assistant.

It is important to select and configure (sharpen) it correctly. Before sawing wood, you need to make sure that the saw is in proper condition. Otherwise, you should configure it correctly. Setting up the saw involves the correct setting and sharpening of the saw teeth.

At first glance, this may seem difficult for the average user. In reality, everything is not so complicated. It is only important to understand the entire setup mechanism.

Manual work: using a chainsaw

For home cutting of several trunks, it is not advisable to purchase a tool whose cost is several times higher than the price of finished products. If you have the necessary skill, then it is more efficient and cheaper to do all the necessary work with a conventional chainsaw or chain equipment powered by electricity. Of course, such work requires much more physical effort and time, but the cost of the issue is significantly reduced.

Working on a garden plot requires pruning fruit trees, and it also becomes possible to additionally produce material for outbuildings without resorting to the services of specialists, so any thrifty owner will prefer to buy a chainsaw. Most often, coniferous wood is harvested for the home, and this tool does an excellent job of cutting it. Thanks to straight trunks, it is easier to mark cutting lines, which increases the speed of work. Professionals, by the way, most often use a chainsaw, since it is more powerful than an electric one and can be used anywhere, regardless of whether there are power sources at the cutting or cutting site.

Wood cutting options

To use a chainsaw to cut logs, you will need a device such as a saw attachment, as well as cutting guides and base-trunk fasteners. The frame-shaped attachment is attached to the tool so that it remains possible to adjust the distance between the chain and the frame itself. This is done to make it possible to produce finished lumber of different thicknesses. For the role of a guide, you can take either a profile of the required length, or a flat wooden plank with sufficient rigidity. A special chain is selected for the tool, designed to cut the trunk lengthwise. Its difference from the others lies in the teeth sharpened at a certain angle.

Before you start work, you need to not only prepare all the necessary tools. Regardless of whether a woodworking machine or a manual device is intended for processing the trunk, the first thing you need to do is familiarize yourself with the cutting map. This is done in order to minimize the percentage of waste and increase the yield of useful products.

The first thing you need to worry about when cutting longitudinally is the uniform density of the finished boards. To do this, a competent sawyer directs the tool from the east side of the log to the west, or in the opposite direction. This is explained by the higher density of round timber in its northern part than in the southern part.

Types of sawing

Next, use a chainsaw to remove the slab from both sides so as to obtain a double-edged beam. It, in turn, is sawed in accordance with the cutting pattern chosen at the beginning of the work. The solution is an unedged board. If there is a certain percentage of defects in the trunk, then a circular cut is possible with the trunk turning at a right angle or 180°.

Wood sawing methods

Different methods differ in the log cutting algorithm. The most common scheme is one that involves passing a log through a sawing frame once and dividing it into several boards. This method is called tumble sawing, and the boards are unedged. Depending on what part the board is made of, it can be core, side or central. This method also produces a certain amount of slab. This lumber is rarely used in construction in its unchanged form. Much more often it is used for the production of wood chips.

Another method is sawing followed by planking. It already involves running it through the frame twice. For the first time, a double-edged beam is created from the middle of the log, and unedged boards are created from parts close to the edges. Then the resulting timber is driven a second time. The result is unedged boards from the side elements and edged boards from the remaining ones.

Sometimes customers have specific requirements for the structure of the timber, for example, according to the criterion of the relative position of the layers to the annual rings. Then less common methods are used, such as circular, camber-segment or timber-segment.

Segmental methods are used to work with large logs - those whose diameter is at least 26 centimeters. In this case, the beam method is used for tangential work, and the camber method is used for radial work.

The circular method differs in that after the slab and 1-2 units of lumber are separated from the log, the log is turned at a right angle and then a new portion of material is separated. It is used for individual processing of large logs (those whose diameter exceeds 32 centimeters), especially those that have damage to the core (rot, false core, etc.) - after all, this method allows you to obtain lumber from an area not affected by destruction. More often it is carried out on band sawmills.

Based on the criterion of the relative position of the cuts with the axis of the log, it is possible to distinguish methods of working parallel to this very axis and parallel to the generatrix. The second method allows you to obtain smoother materials and minimize differences in width.

Vertical sawing

The choice of the preferred way of working is determined by a number of factors, such as:

- Shape of the trunk;

- The diameter of the log that is planned to be cut;

- What the planned lumber products will be used for;

- Dimensions of product elements specified by the customer;

- Features of the available equipment;

- Wood defects.

Quantity of finished material, cutting price

The yield of useful material from coniferous and deciduous trees differs in percentage. The following indicators are typical for lumber obtained from coniferous trees:

- provided that the operation is carried out by a professional and a circular sawmill is used, the percentage of finished wood will be the highest (80-85%);

- the edged material produced by the machines averages 55-70%;

- When used with a chainsaw, an unedged board leaves up to 30% waste.

The figures are given without taking into account the finished culled timber, the amount of which can reach 30%. However, such material is used for products that allow certain defects.

Finished wood products after sawing

Deciduous round timber produces 60% of the finished unedged timber and about 40% of the edged timber. This is explained by the initial curvature of the round timber. It is possible to increase the amount of products obtained: this will require forest processing machines of various types. A certain kind of device can increase the amount of lumber by 10-20%. For one cube of lumber you will need about 10 cubes of deciduous round timber. The cost of installing additional equipment will be recouped by the cost of the finished timber. Special lines provide greater volume, but their use is only advisable over a large area. The average price of sawing wood at a regular sawmill will be approximately 150-180 rubles per cubic meter of boards.

Mixed wood cutting

Semi-radial sawing is a common method of producing lumber. It involves cutting logs at an angle of 45°. This technology allows you to save raw materials and reduce the cost of the finished product. The only drawback of this cutting method is that the resulting board may be subject to deformation due to improper drying. Therefore, special attention must be paid to preparing wood for processing.

Semi-radial sawn timber can be made from both hardwood and softwood. Products made from Siberian larch are especially popular today; their demand is due to their strength, resistance to mechanical damage and aesthetics. Coniferous cladding reliably protects the building from the effects of atmospheric phenomena, helps retain heat and create a comfortable microclimate indoors.

Sawing map

The sawing map is a calculation of the optimal amount of finished lumber from one log. You can calculate it yourself for each specific log diameter, or you can use a computer program that greatly facilitates the calculation, and the price of which is quite affordable.

Material yield after cutting wood

Or the source could be a regular sawmill reference book. The result is a table that is used as a basis. The sawmill attachment should always be oriented to its data in order to obtain more lumber of any type of wood.

Radial sawing

It is customary to call a radial cut of a log, carried out perpendicular to the annual layers. Lumber produced by this method has a uniform texture, they are characterized by increased strength and wear resistance, and are practically not subject to deformation. Radial cut boards have minimal shrinkage and swelling coefficients, so they do not collapse due to the negative influence of the environment and are excellent for external cladding of buildings. With this processing method, lumber has virtually no flaws. Defects may be caused by a violation of sawing technology (displaced core, incorrect size).

Radial sawing is used for the production of edged boards, a sought-after lumber used for finishing houses, summer houses and cottages. If the cladding is made of Siberian larch, it is ideal for decorating baths, saunas and bathrooms. Products made from this coniferous species do not require additional processing, have an attractive texture and have a long service life. Edged boards are widely used by interior designers; with its help, you can create a cozy atmosphere in a room. Lumber from Siberian larch contains resin, when released, it spreads a pleasant aroma.

What types of wood cutting are there?

If you resort to laser cutting, sawing trees will be done accurately, saving time and raw materials - this technology allows you to accurately cut wood with a minimum amount of residue and waste. You can use a laser to cut wood of any thickness. To avoid fire, cool the cut areas as laser cutting involves heat treatment of the cut.

Types of wood sawing.

Machines for producing wood materials are used on an industrial scale. These devices are very bulky, but can work for a long time without interruption. Among the machines, there are circular saw and multi-saw models. The former perform longitudinal and transverse sawing using a circular saw, while the latter saw and cut wood with several saws - simultaneously or alternately.

A wood sawing line is a complex of one or more machines. This device is expensive and is purchased only when there is a large volume of wood raw materials. There are several types of this type of machine:

- splitting and splitting - saws and splits logs of any species using a chain or circular saw;

- line processing round timber - equipped with two saw modules and a pneumatic system that removes sawdust;

- log sorting line - helps to optimize sawmill operations;

- optimizing line - automates the supply of trunks for processing, allowing you to replace manual labor.