Wood, along with natural stone, is one of the oldest building materials. Despite the huge variety of all kinds of artificially created materials currently present on the construction market, wood is still in constant demand. Wood is a universal and affordable material, and not a single construction project can be completed without its use.

Cutting logs into boards and types of lumber.

The main raw material for the production of lumber (timbers of various sections, edged and unedged boards, etc.) is a log - freed from branches and twigs, as well as from the thinnest upper part of the tree trunk. Logs can be used as a completely independent building material as pillars, piles, masts, etc., however, in most cases they must be sawed to obtain beams and boards. How to cut a log into boards, beams and other lumber will be discussed further.

Sawing logs can be done in various ways:

- manually, using a saw tool;

- on sawmills;

- on woodworking machines and specialized lines.

The price of lumber largely depends on its thickness and the amount of production waste.

In order to make the most efficient use of available raw materials and correctly saw a log, the woodworking industry uses special sawing schemes to reduce the percentage of waste and thus reduce the cost of the final product. Therefore, before cutting a log yourself, it would be useful to familiarize yourself with similar diagrams.

Tools and equipment for sawing logs

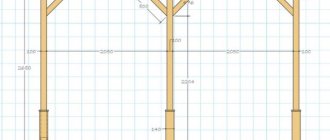

Scheme of cutting on a sawmill.

Depending on the total number of logs, their length, thickness and the expected quality of the future lumber, various tools and specialized equipment are used for sawing. To obtain a small amount of lumber at home, the manual method of processing trunks using chainsaws and ordinary hand-held hacksaws with teeth for longitudinal sawing is quite acceptable.

The sawmill is a fairly common type of sawmill equipment. It is a woodworking machine with frame saws, designed for longitudinal cutting of logs to produce edged boards and timber. Sawmills can process logs with a diameter of 15 to 80 cm and a length of up to 7 m.

Sawing tree trunks on circular saws (circular saws) is carried out using a circular saw. Such machines can be single-saw (single-disc) and multi-saw (multi-disc). Single-disc circular saws usually work with small-sized and low-quality raw materials. Multi-disc machines are designed for cutting large-diameter round timber.

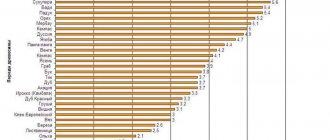

Approximate cutting maps.

The most popular currently are the so-called band sawmills, both vertical and horizontal. They use a belt cloth mounted on pulleys as a cutting tool. Band saws provide high-quality longitudinal and mixed sawing of logs into boards and beams with a minimum amount of waste.

Wood sawing lines are used at large enterprises in the production of lumber on an industrial scale. They provide high surface quality and precise geometry of the final product and have the highest productivity.

In addition to the above, other types of highly specialized sawmill equipment are used in the mass production of lumber: debarkers, edgers, band-dividers and other machines.

Features of sawing logs using a chainsaw

Creating additional equipment for sawing logs is quite simple:

- The frame is used to create a support that can be created from the desk legs. The most suitable are square pipes 20 × 20 mm.

- When designing the frame, you need to create 2 clamps and secure the cross member at one end. This element must have holes for connecting bolts. A protrusion for the tire is created in the middle.

- To cut a log to length, it is necessary to build a support frame, the width of which must be at least 8 cm.

- For convenience, the handle should be welded to the frame.

- Before carrying out any work, ensure that the frame is securely attached to the tire.

Using a homemade tool is quite simple. Before sawing it is necessary to install 2 sawhorses. These will be used as support for the journal. Also, prepare a metal rail or flat board to serve as a guide.

Types and methods of cutting logs

Before sawing a log into boards and beams, it is important to choose the most optimal sawing method, which is determined by the size, geometry and surface quality of the future lumber, the necessary technical requirements, as well as the type of wood. By orientation to the growth rings of the trunk, types of sawing can be distinguished. This:

Cutting diagrams.

- radial, carried out precisely along the radius of the growth rings;

- tangential, when sawing is done tangentially to the growth rings, parallel to one of the radii;

- parallel-forming, when cutting occurs parallel to the direction of the fibers (this way, a minimum inclination of the fibers in the lumber is achieved).

Depending on the direction of sawing, there are several ways to saw logs:

- waddling sawing;

- sawing with beams;

- segment method;

- sector method;

- circular sawing.

Scheme of sawing logs on a sawmill frame.

Tumble sawing is carried out using several parallel cuts along the entire cross-sectional plane of the log and produces an unedged board and two slabs at the output. Tumble sawing is the simplest method of processing logs and is used primarily for cutting hardwood round timber of small diameter, since other methods greatly reduce the width of the finished lumber.

Sawing with beams involves cutting out double-edged timber and side boards at the initial stage. The timber is subsequently sawn into edged boards of the same width. Up to 60% of all raw materials are cut using lumber. The disadvantage of this method is the need to use two sawmills simultaneously.

The above methods for cutting logs are the main ones. Special methods are used much less frequently: sector and segment. When sector sawing, the log is first divided into several fragments - sectors, numbering from 4 to 8, depending on the diameter of the trunk. These sectors are then sawn into boards along radial or tangential directions.

With the segment method, a beam is cut from the central part of the log, leaving two so-called segments on the sides. The resulting segments are then cut into tangential boards.

The circular sawing method is used for individual cutting of logs and allows you to separate healthy wood from damaged wood. When circular sawing, after sawing off another board or several parallel boards, the trunk rotates around the longitudinal axis by 90° each time.

Preparing for cutting

Before sawing a log into boards, you need to remove the skin from it. This can be done with a sharpened shovel, scraper, or electric plane.

When using a shovel, the movements are done on your own.

It is believed that the best results are obtained when the bark is removed with a scraper - it does not affect the tree.

Longitudinal cut

This type of dissolving of logs into boards, slats, beams is used. Sawmills, furniture factories, and procurement plants use many different devices. We will look at how to cut logs into boards at home.

For cutting at home, you can use a saw, an angle grinder with special attachments, or a circular saw.

Cross cut

It is carried out to obtain parts in the form of cylinders and disks.

Sources:

https://stroy-podskazka.ru/brevno/kak-raspilit-na-doski-v-domashnih-usloviyah/ https://wood-prom.ru/clauses/derevoobrabotka/kak-raspilit-brevno-na-doski https ://atmwood.com.ua/2018/01/30/kak-raspilit-brevno-na-doski/

Sawing logs at home

Situations often arise when it is necessary to produce a relatively small number of boards or beams for personal needs. In this case, the purchase of sawmills and other equipment is impractical. If you have certain knowledge and skills, it is much more profitable to cut logs manually, using an electric or gasoline chain saw. This is a rather labor-intensive process, but in some cases it is completely justified.

Most experts agree that using a chainsaw is preferable. Such saws, unlike electric ones, have more power and are able to work without interruption for a long time. In addition, when using a chainsaw, no electricity is required, which allows you to carry out work remotely from power sources (for example, directly on plots).

When cutting logs into boards using a chainsaw, you will need special devices: a device for securing the log, a frame attachment for the chainsaw and a guide along which the cut will be made. The attachment frame is attached to the chainsaw bar so that the distance between it and the chain can be adjusted. This will allow you to get boards of varying thicknesses. It is better to choose a special chain for longitudinal cutting, which differs in the angle of sharpening of the teeth. A metal profile of the required length or a flat, rigid board is quite suitable as a guide.

How to cut a board straight

How smart and intelligent our people are!

Sergey Burkov:

How to dissolve a 3-meter board so that both halves are, for example, 10 mm thick

BANDIT #:

You explain it to students with an open mind and so on.

Alex Lobo:

Eco-wild.

COMPUTER:

What if the board is 2 meters long? How did you put that on your ass?

Nikolay Sitkov:

Ha, I wasn’t smart enough to use a chainsaw, although I’ve encountered this problem more than once.&# 128077;.

READ How to Correctly Install a Blade on a Huter Trimmer

HOW?:

Christmas trees, take care of your fingers, brother. I wouldn't do that)))

Bal-Kone Workshop:

Simple, cheap and fun :))). Like

Mike Wiese:

Hello, you have already been on camera several times. Is it AEG or another company? Maybe you’ll take a review, I’ll choose the saw myself, I’d like to hear advice from an experienced person on what to look for.

Andrey Ivanov:

I like it. Like.

Work order

Before starting sawing, it is necessary to free the prepared logs from bark and remaining branches and carefully inspect them for any possible defects. This will allow you to choose the optimal cutting pattern and thereby reduce the amount of possible waste.

When sawing logs longitudinally, care must be taken to ensure that the resulting boards have the same density across the entire width. Since the density of the trunk wood on the north side is much greater than on the south side, the cut is made in a plane directed from east to west (or vice versa).

The first operation when longitudinally sawing a log with a chainsaw is to remove the slab from two opposite sides of the trunk. As a result, a double-edged beam is formed, which is then sawn into boards of equal thickness or other lumber, in accordance with the selected sawing pattern. The output is an unedged board, from which the edges are subsequently removed.

If there is a false core or other defects in the log, it can be rotated 90° or 180°, as with the circular sawing method.

Safety precautions

Neglect of compliance with safety measures when working with powerful cutting tools leads to severe injuries associated with the loss of parts of the limbs. Large blood loss is often the cause of death.

When working with a chainsaw, follow these rules:

- learn the rules for using a chainsaw and the actions necessary to stop the cutting tool in an emergency;

- check the presence and contents of the first aid kit , paying special attention to hemostatic agents;

- control the correct installation of the chainsaw attachment;

- clear the work area of foreign objects; accidental falls lead to loss of control over the tool and serious injuries;

- remove from the workspace unauthorized persons, children and animals that can interfere with the operator;

- wear protective clothing that should fit snugly to the body, use protective glasses and headphones that are protected from sawdust, and, if necessary, a respirator; shoes should have hard soles and large treads;

- the chainsaw is launched on the ground in a stable position;

- During the sawing process, be sure to use wedges to prevent the tire from jamming;

- Persons under 18 years of age are not allowed to work;

- the workplace should be illuminated by the sun or electric lamps.

It is strictly forbidden to work with cutting tools while intoxicated or under the influence of medications that slow down the reactions of the nervous system.