Manufacturing process of LVL timber

A building material called LVL timber was created in America at the beginning of the 20th century, although it became widely used in the 60s. It appeared in Russia in the 2000s and since then has become increasingly popular in industrial and private construction.

To obtain LVL, the bottom, thickest part of a softwood tree is used. The logs, cleared of bark, are soaked in hot water for about a day. This procedure makes further work with wood easier. Then it is cut into logs, peeled - cut into plates no more than 3 mm thick, called veneer. After processing in water, they have high humidity, so they are sent to a drying chamber, having been pre-sorted. Poor quality pieces are removed.

When the veneer is dry (humidity no more than 10%), it is placed in a certain way. Better and more beautiful pieces are placed along the edges, and the rest are distributed evenly. The pieces are placed so that their edges do not coincide in different layers. This allows you to increase the length of the workpiece. Glued using formaldehyde resin. Press, compacting the layers. The finished building material is cut and labeled.

Marked blanks Source bouw.ru

It is impossible to make timber from veneer at home or in an underground workshop. To do this you need to have high-precision equipment. All operations, from peeling to checking the uniformity of veneer and finished products, are controlled by computer programs using laser devices.

The properties of the resulting material depend on how the fibers are arranged in the individual layers of veneer.

- Typically, individual pieces are arranged so that the fibers in each piece are parallel to each other. Such a beam is called structural. Its disadvantage is that the edges of large-width parts may curl.

Using structural timber Source lignumc.ru

- To make the material even stronger and increase resistance in two directions, some of the sheets are positioned so that the fibers are perpendicular to the rest. Usually this is every fifth layer. The resulting material is used to create wide products: panels, floors, doors.

With this structure, the timber resembles plywood, but all the fibers are located perpendicularly. Plywood layers are much thinner and their number is smaller.

What is LVL timber and how is it superior to solid and laminated timber?

LVL timber is not new to the global construction market - it has been actively used abroad for more than half a century, and the demand for this material is constantly growing. But in our country it has not yet become widespread. Well, let's help the LVL-beam "oBRUSET"

LVL ( Laminated Veneer Lumber ) is produced by gluing seven or more layers of 3mm veneer from coniferous wood. In addition to pine, spruce and larch are also used for its production. The second name for this material is laminated veneer lumber.

Like laminated veneer lumber, LVL timber is produced by gluing together wood elements. But the whole point is what these elements are. In the first case, the timber is assembled from planed boards (lamellas), and in the second - from thin veneer plates glued apart, offset, which makes the material homogeneous, almost monolithic, and gives it significantly higher performance properties compared to laminated timber ( its strength is 1.5–3 times lower than that of LVL), and with traditional one.

To make LVL timber, the thick, root part of the trunk is usually selected. After the initial processing, the logs are peeled - thin layers of wood are removed to obtain veneer plates. Next, the veneer is subjected to chamber drying (its humidity should be no more than 10%), sorted according to quality and external indicators, rejecting material with defects; an adhesive composition (formaldehyde resin) is applied and pressed. All processes are automated, and the parameters of the workpieces are monitored using laser devices, which provides the finished products with high technical characteristics and dimensional accuracy.

Material characteristics

Thanks to its layered structure, LVL timber is particularly strong and durable. Veneer of a higher grade is placed closer to the surfaces of the product, and the inner part is glued in such a way that veneer of different densities is distributed evenly throughout the entire volume of the timber and its joints do not coincide in different layers of material. Due to this, the products are provided with stability (kinking is eliminated, as well as longitudinal and transverse warping), wear resistance and excellent physical and mechanical properties (in terms of resistance to bending and stretching along the fibers, it is almost twice as strong as solid timber). The same purpose is served by the use of a heavy-duty adhesive composition and compaction of the layers by pressing.

Unlike solid wood, LVL timber is uniform along its entire length, does not reduce its strength characteristics over time and does not change linear dimensions depending on temperature and humidity conditions. It does not shrink, is not subject to cracking, and is not affected by rot.

Being non-hygroscopic, LVL timber, even in conditions of high humidity, retains not only its dimensions but also its weight unchanged, which is especially important, for example, when covering long spans. In addition, the stability of the product geometry guarantees the reliability and accuracy of their connection with other structural elements

In terms of resistance to aggressive influences (ammonia, salt vapors, etc.), LVL timber is superior not only to wood, but to metal and reinforced concrete, and therefore it is ideal for the construction of objects such as greenhouses, swimming pools, etc.

A common problem with all types of wood is low fire resistance, but even here the performance of LVL timber is higher (class E fire resistance) than that of its wooden “competitors”. This is explained by the same layering, density and low porosity of the material. In addition, the adhesive used in its production does not support combustion. Being in the fire zone, the timber will char at a rate of 0.7 mm/min at a temperature of 300°C and can “hold out” without losing its integrity for at least half an hour.

According to experts, LVL timber makes it possible to solve complex architectural problems and at the same time comply with the requirements for thermal protection of residential buildings. Thus, a beam made of freezing material protruding beyond the outer wall of the house (for example, used as a cantilever support for a balcony), even with careful sealing of the joints, becomes a cold bridge. This will not happen with LVL timber, which has excellent thermal characteristics.

Load-bearing structures made from laminated veneer can also act as enclosing structures, especially since the sound insulation properties of this material are excellent. In Russia there is a practice of using it for the installation of pediments; construction of a base box, replacing the foundation, for a frame house; construction of prefabricated buildings for residential and commercial purposes, etc.

Types of products and their applications

On the market, laminated veneer is presented in the form of beams (beams) or slabs of different sizes.

The timber can have a thickness from 18 to 102 mm, a width from 100 to 1800 mm, a length of up to 18 m (longer products can also be made to order, and this will not greatly affect the price; by the way, the cost of laminated veneer lumber as its length increases increases significantly).

There are two types of LVL timber. The first, called structural, is glued from veneer so that the fibers of all its layers are oriented in the longitudinal direction. Due to its excellent strength properties, it has a higher load-bearing capacity than laminated and solid timber, with smaller cross-sectional dimensions. The material is used for the construction of frame houses, rafter systems, and installation of interfloor ceilings.

An important point: load-bearing structures made of laminated veneer do not require a massive foundation.

However, the weak point of such timber is the tendency to curl the edges of large-width products.

The second type of material differs in its structure: every fifth layer of veneer in it is laid transverse to the direction of the fibers in the remaining layers. This increases the rigidity, as well as the bending and shear strength of the beam (which is especially important for beams). In addition, it does not have a curling effect, and therefore it is optimal for creating wide structures: wall panels, interior partitions, door panels, etc.

LVL timber will never become covered with cracks, which can hopelessly spoil the appearance of wooden elements, and therefore, for example, beams made from it can be safely used for decorative purposes

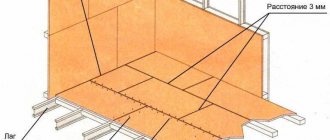

Thermal insulating properties and immunity to moisture make LVL timber an ideal material for use as lag. This will prevent the appearance of cold bridges, as well as pockets of rot in the floor structure. The strength and stability of the timber allows it to be successfully used for the manufacture of roof trusses, window and door frames, stairs, and reusable formwork. Glued veneer slabs are an excellent option for cladding walls of frame buildings.

The material is easy to process (you need ordinary carpentry tools), involves the use of traditional fasteners, and due to its low weight, as a rule, does not require the use of lifting equipment during construction, thereby reducing the time of work and saving money for the developer.

Appearance and characteristics

Externally, the timber looks like wood or laminated veneer lumber, although it is inferior in decorative properties. The view depends on which side you look at the workpiece from. The front side is not much different from solid wood. From the side, thin layers of veneer are clearly visible, of which there can be from 9 to 24, mixed with a hardened adhesive composition.

The veneer layers are clearly visible in the cut Source green-ply.ru

See also: Catalog of companies that specialize in the construction of turnkey country houses

The thickness of the timber or layer ranges from 1.8 cm to 10 cm 2 mm. The minimum width of the beam is 10 cm, the maximum width of the plate is 1 m 80 cm. The standard length does not exceed 18 m, but you can order beams up to 30 m long. In this case, the price of the product will increase slightly.

Along with LVL, laminated veneer lumber is used in construction. It differs in its manufacturing method and characteristics. It is created by gluing lamellas of the same length. This does not allow obtaining workpieces of great length, although externally the laminated timber looks more like solid wood. Its strength is 1.5-3 times less than that of LVL.

Glued laminated timber Source infobrus.ru

Cost of LVL timber

The production of the material is energy-intensive and requires the installation of expensive equipment, which affects the price of the product. But using LVL timber ultimately saves money. When installing frame structures made from it, no special equipment is required; they are erected quickly and last a long time. This reduces repair costs.

The price of LVL timber depends on the thickness and length, and differs depending on the manufacturer. The cost of 1 m³ starts from 55 thousand rubles. It may seem to those who do not know the advantages of LVL timber that it is expensive.

Production and its features

At enterprises today, the procedure for manufacturing lvl timber is as follows:

- First, prepared logs of appropriate length are processed on a debarker (the bark is removed)

- Then, in special pools, a hydrothermal process occurs, thanks to which the stages of further peeling are simplified. Logs are kept in water for about a day, sometimes a little more

- Logs are made from logs, veneer is obtained as a result of further processing

- The veneer is cut, sorted depending on the degree of humidity and sent to dry

- After this process, the material is again sorted depending on the density and quality characteristics. Those sheets that have changed their parameters as a result are glued together using special equipment. Get maple lvl timber.

- The material is pressed and cut

- Then the finished products are checked, labeled and packaged

Important: timber manufactured at domestic enterprises meets the strictest quality conditions and is not inferior to imported analogues

Properties of LVL timber blanks

LVL timber has the following features:

- During the production process, the natural structure of the tree is destroyed. It becomes uniform along the entire length. But this benefits the finished material, which is not afraid of temperature changes. Due to the absence of pores, it does not absorb moisture from the air and does not produce condensation. Therefore, the product does not warp, does not change shape or size. It can be used in any climate zone, including regions with high humidity.

- It is not affected by fungus, does not rot, and is not damaged by insects.

- Buildings made from LVL timber protect against noise.

Cozy house made of LVL timber Source best-dom.su

LVL-beam brand Ultralam (Ultralam)

The Ultralam trademark is owned and products are manufactured under it at the Talion Terra enterprise (Torzhok).

Distinctive features of the products of this company are such indicators as:

- The production process is based on continuous pressing technology with microwave heating;

- The press installed at this enterprise is one of the longest, which allows the production of products up to 55 meters in length.

Important! The use of high-tech equipment from the world's leading manufacturers allows us to produce high-quality LVL timber using waste-free technology.

LVL timber can be simply irreplaceable in the manufacture of complex building structures of original shape

Application

When constructing LVL buildings, timber is used for manufacturing:

- long spans;

- lag;

- floors;

- wall frames;

- ridge beams;

- rafter systems;

- fencing.

LVL timber is used in the construction of one to three-story houses, stadiums, and commercial buildings. The fact that the dimensions and weight of the product do not change over time makes it possible to use it to create long spans and reliably connect it with other structural elements when constructing garages and hangars without installing additional columns.

Sports facility built without the use of columns Source best-dom.su

Varieties and areas of application

The material is used in the construction of facilities in various industries ; they are used to make workshops, offices , and build houses from LVL timber . The slab variety is installed as a power permanent formwork .

Glued beams are mainly used for the construction of load-bearing elements of buildings :

- floors with installation of purlins;

- wall frames;

- ridge and balcony beams;

- rafters, elements of interfloor membranes.

The elements cover large spans up to 36 meters in length; the beams are impervious to harmful air components, dampness, and ultraviolet radiation.

There are different types of LVL material:

- structural;

- with cross fibers.

The timber is used in the construction of swimming pools, agricultural buildings, warehouses with chemically aggressive products, and production workshops with chemical emissions into the atmosphere. The material is well used in seismically hazardous areas.

Structural

Structural timber

In this type of timber, subsequent layers of veneer are placed so that their fibers are turned in one direction (lengthwise). This increases the load-bearing capacity of the product. Due to their high strength, structural beams are used as elements of the skeleton of a frame building, along with metal or wooden racks and crossbars.

The structural type of timber not only withstands the weight of the floor, roof, and wall filling between frame elements, but also protects the interior of the house from the cold. For example, a balcony cantilever beam made of moisture-sensitive material protrudes outside the wall and becomes a conductor of cold in frosty weather. The use of LVL timber solves this problem, since the material is dry and does not freeze.

With cross layers

With cross layers

The second type of product differs in its internal structure. Changing the laying of layers increases the bending and tensile strength. This material does not have twisting along the longitudinal line, which sometimes occurs in structural products.

Gluing method:

- the first four layers are laid with fibers in the direction of the longitudinal line of the product;

- the fifth layer is placed with fibers across the section;

- the remaining layers are placed as the first.

This is how slab LVL is most often produced. The panels are used for wall cladding, construction of internal partitions, and door panels are made from them . The surface of the slabs looks attractive , so often the wall layer is not additionally decorated.

Beam dimensions

The strength of LVL material is higher compared to simple laminated veneer lumber. This is expressed in the fact that the cross-sectional dimensions are smaller and the load-bearing capacity is greater.

Transverse dimensions of timber:

- the thinnest has a thickness of 18 mm, and the most massive is 102 mm;

- width ranges from 100 – 1800 mm;

- According to the standards, the length cannot be more than 18 m.

For comparison, the cross-section of a simple composite beam 80x240 and 160x320 corresponds in strength to laminated laminated timber LVL with a cross-section of 45x280 and 69x400, respectively.

Disadvantages of LVL timber

Like any building material, LVL timber also has disadvantages:

- Products emit formaldehyde fumes. If the manufacturing technology is violated, their quantity exceeds the permissible norms. Therefore, there may be a negative impact on the health of residents. Although there is little chance that this will happen when using high-quality LVL timber.

- Walls made from LVL slabs “do not breathe” and do not allow air to pass through.

- You should not use timber for the construction of a log house. Its thermal insulation, even at maximum thickness, is not enough to make it possible to do without additional insulation.

- High price of building material.

Areas of use of LVL timber: studying the issue

Due to its physical properties and good characteristics, LVL timber is used in the construction of houses and other structures, if it is necessary to create durable building structures, such as:

- rafters and other structural elements of the roof;

- frame house construction;

- load-bearing structures of buildings and structures of complex geometric shape.

In addition, this material is used in the manufacture of individual elements of building structures, which during operation are subject to significant mechanical loads, these are:

- staircases and openings;

- arches and other light open structures used in the construction of summer verandas and cafes.

High strength and resistance to external influences allow the use of LVL timber in the manufacture of complex structures operated in harsh conditions

Expert's point of view

Dmitry Kholodok

Technical director of repair and construction

Ask a Question

“Due to its high cost, this building material is not advisable to use in individual housing construction as the main one used for the manufacture of enclosing structures.”

Briefly about the main thing

LVL timber is a building material that looks like wood. But in its properties it largely exceeds it. It is created by gluing veneer obtained from coniferous wood.

The material has a homogeneous structure. Lightweight, does not deform, does not change size. Not afraid of water and aggressive environments. Does not allow heat to pass through. Burns very slowly. Easy to process. Can be installed without lifting equipment.

It is mainly used to create load-bearing structures. It is not used inside a residential building due to the high content of adhesives.

Disadvantages: high price and low environmental friendliness.

Ratings 0