There is no construction project that could be completed without the use of lumber.

Therefore, there is a need to determine their exact number. You can calculate how many boards are in 1 cube using formulas, or you can use ready-made tables. These tables are called cubic tables.

Note that we are considering products made from softwood.

Types of lumber

In this section we will talk about lumber in the order in which they are obtained when cutting a log.

Obapole and croaker

For some reason, there is confusion with the definition of these materials: some claim that they are one and the same thing, and others claim that both sexes are made from slabs.

The proposed table will provide complete clarity.

As can be seen from the table, both sexes are not used in construction, so we will not consider it further.

The requirements for slab are standardized in accordance with OST 13-28-74. This means that croaker is a valuable building material.

The croaker is used:

- for installing a subfloor;

- roof sheathing;

- production of formwork.

Unedged board

It is sawn along two opposite surfaces, called layers. The edges are left uncut, hence the name.

Its standard dimensions are as follows: thickness - 25, 40 and 50 mm; length - 6 m.

The scope of application is wider than that of the slab.

Also used for construction:

- warehouses;

- utility rooms;

- temporary fences;

- awnings

In addition, it can serve as a base for clapboard lining, block house and other finishing materials.

Edged board

It differs from unedged in that it is propylene along the faces and edges.

Used as:

- roof sheathing;

- sheathing of walls of frame houses;

- racks and braces of frame houses;

- stairs;

- material for making country furniture, etc.

timber

This is lumber with a thickness of 100 mm or more with a difference in cross-sectional width and height of no more than twice. Usually the timber is of square section. The most used timber has a section of 100 × 100 mm and 150 × 150 mm.

Used:

- in the construction of frame houses in the form of posts and beams;

- as a material for external and internal walls of wooden houses;

- for the construction of stairs, fences, etc.

Bar

It differs from timber in that its maximum cross-sectional size is 75 mm. Like timber, it is most often made with a square cross-section.

Used for interior work such as device:

- stairs;

- railing;

- window sills;

- bases for finishing cladding;

- roof counter-lattices.

Variety of boards

All inch boards differ from each other in quality, appearance, strength and the material from which they are made. 25 mm wood products can be made from various types of wood. The strength and, accordingly, the price of the board depends on the type of wood. More often, the inch is made from common types of wood: pine or spruce. Such products have low strength and cost. They are not suitable for outdoor use or harsh environments.

For extreme operating conditions, expensive but durable products made from cedar, larch, oak, and beech are more suitable.

The strength of a tree can also be determined by the growth rings visible on the cut of a piece of wood. The older the tree, the stronger it is. As trees age, their growth rings shrink.

Therefore, if the rings on the cut are located close to each other, then the board is made of strong, aged wood. If the rings are distant from each other, then the wood is young and fragile.

Wooden products undergo varying degrees of processing, and therefore may vary in the smoothness of their surface.

By appearance they are distinguished:

- Unedged board. It contains remnants of bark and has an unkempt appearance. Used for work where aesthetic appearance is not important. This wooden product is inexpensive.

- Planed wooden product. The side edges with bark are cut off and the product acquires a neat appearance. This type of wood is used for decorative finishing work.

The quality of the product is affected by its grade: boards of the highest grade have no flaws, boards of the lowest grade have cracks, knots and blue stains. In total, there are 5 types of finished wooden products. The scope of their application depends on the quality of the boards. High-grade inch gauges are very expensive and are used only for the construction of sea and river vessels. The first and second grades are used for finishing the interior of buildings or for the production of furniture. And the lower grades, third and fourth, are suitable for construction work and the erection of temporary structures.

When choosing wood to purchase, you need to pay attention to its appearance: it must be perfectly straight. If the product is twisted, this means that it was not dried correctly. It is better not to buy such products, because they will no longer level out. High-quality timber is also harvested in winter. Therefore, if you need strong, high-quality and beautiful wood, it is better not to purchase another wood.

Conclusion

When purchasing an inch, do not hesitate to ask the seller for the classification and accompanying documentation. The dimensions of the material differ, so the approach to calculating the required quantity is individual for each case. The edged board must comply with GOST; only in this case can the quality of the construction work performed be guaranteed.

It is unacceptable to use third and fourth grade inch for finishing work. Building fences from first and second grade materials is unnecessary waste.

How to calculate the number of boards in a cube

Edged board

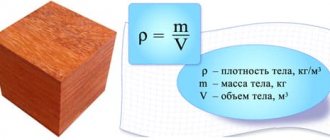

As you know from the high school course, the volume of a rectangular parallelepiped (and that’s exactly what the edged board, beam and block are) is equal to the product of the lengths of its sides.

Calculated using formula 1:

V = L × b × h

where: V – volume; L – length; b – width; h – height (in our case thickness) of the board.

Having calculated the volume in this way, you can easily find the number of boards in a cube.

To do this, you need to divide one by the resulting number (formula 2):

N = 1 ÷ V

where: N – number of pieces, 1 – 1 cubic meter. m, V – volume.

We should not forget that the dimensions of edged materials are given in millimeters, so before calculation they must be converted to meters.

Example

There is lumber with the following parameters:

25 × 150 × 6000, where 25 is the thickness; 150 – width; 6000 – length.

Let's calculate the cubic capacity of the board.

To do this, convert millimeters to meters and substitute the resulting values into formula 1:

V = 0.025 × 0.15 × 6 = 0.0225

We substitute the resulting number into formula 2:

N = 1 ÷ 0.0225 = 44.4

The result is always rounded to whole numbers by discarding the decimal part.

Thus, one cube contains 44 whole boards.

Unedged board

Solving the previous problem in this case is more difficult.

The unedged one has a large difference in width on opposite layers, so when calculating the volume, you need to substitute the average width into formula 1: these two widths are added and the resulting amount is divided in half.

The measurement result is rounded to the nearest 10 mm, fractions up to 5 mm are not taken into account, and fractions of 5 mm or more are considered 10 mm.

In addition, uncut edges do not allow the board to be stacked tightly, and various increasing factors are used to calculate the exact volume.

The calculation method is not so much complicated as it is tedious, so it is easier to use the table from the next section.

Tongue and groove boards and lining

They differ from each other only in size, so the calculation method for them is the same.

They are mounted using the tongue and groove system, as shown in the figure.

In this case, the width b is taken to be the so-called “working” or “visible” width - the distance from the base of the tongue to the edge of the board (see figure). It is this size that should be substituted into formula 1.

Classification

Edged board

An inch board can be classified according to two parameters: the type of processing and the class of raw materials used.

According to the type of processing, the inch is divided into:

- Edged - during the manufacturing process, the ends of the board (edges with tree bark) are cut off. In this case, the width is regulated and corresponds to the dimensions given above.

- Unedged - the edges are not cut during the manufacturing process, the width of the board corresponds to the diameter of the original raw material.

Classification by grade of lumber made from coniferous trees is carried out on the basis of GOST 8486-86 “Coniferous lumber. Technical conditions", and hardwood - on the basis of GOST 2695-83 "Lumber of hardwood. Technical conditions".

In accordance with these documents, coniferous wood is classified into 5 grades - selected, first, second, third and fourth, and deciduous wood - into three: first, second and third.

Each grade has standards for limiting lumber defects, such as:

- number of knots and cracks per linear meter;

- structural defects of wood;

- the presence of areas affected by fungus;

- biological damage to wood;

- foreign inclusions, mechanical damage and warping of the board.

Tables of the number of boards in a cube

In order not to calculate the quantity and volume each time, special cube tables were compiled, in which for each size of material its quantity in one cubic meter is given.

4 meter boards

6 meter boards

4 meter timber

6 meter timber

Unedged material

Due to the wide range of sizes in length, thickness and width, it is impossible to calculate the exact amount of slab in one cube, so there is no cubature table for it.

Here is a table for converting the folded volume of a slab into a dense one.

In this case, we solve the inverse problem: we determine the actual volume of a known amount of slab.

To do this you need:

- Disassemble the slab into debarked (from which the thickest end closest to the tree root has been removed) and unbarked.

- Sort by length - up to 2 meters and more than 2 meters.

- If necessary, sort by thickness.

- Place in a bag, alternating thin and thick ends.

- Calculate the folded volume of the package.

- Select the appropriate coefficient from the table and determine the actual (dense) volume.

Cube for unedged boards.

Lumber block 4 meters, table values

Table values for the cubic capacity of 4 m edged timber:

Table values for the cubic capacity of a 4 meter long edged board:

Coverage area calculation

When the main construction is completed, it is time to begin finishing work: sheathing the walls and laying clean floors.

Now you need to calculate how much area can be covered with one cubic meter of material.

To do this, remember formula 1. When calculating the volume of one element, we write down the intermediate result - the product:

L × b = S (3)

where S is the area of this element.

Having calculated the quantity using formula 2, we multiply the result by the area.

Lumber table 6 m long

6 m edged beam block in the table:

The cubic capacity of the edged board is 6 meters in the table:

Those. The cubature table for lumber of demanded lengths of 4 and 6 meters allows you to quickly find out the following data:

- how many products are contained in 1 m³;

- how many linear meters are contained in 1 m³;

- what is the volume of one product;

- what is its area?

When designing building structures at a dacha, such as cubicles, the owner certainly needs such tools. They allow you to not only calculate the required amount of wood for construction with sufficient accuracy, but also not overpay extra money when purchasing.

This is understandable, because the price of a product is affected by the volume of wood, linear dimensions and quality indicators. The following parameters are usually taken into account in any cubicle.

- Wood species.

- Type of lumber - timber or board.

- Linear dimensions.