Every tourist knows that charcoal can be an irreplaceable thing on a picnic or on a hike. It is used not only in the barbecue for cooking on vacation, but also in fireplaces for heating the home, and in many other areas of life.

What is charcoal?

The oldest fuel on the planet that was made from plant materials is charcoal. This fact is confirmed by many archaeological finds. Charcoal is produced through a chemical reaction called pyrolysis, a process of decomposition at high temperatures without access to oxygen. Today, wood fuel is an excellent alternative to traditional coal, and its distinctive feature is environmental friendliness and safety in use.

What does charcoal look like?

Many of us will be interested in knowing what charcoal is. It is a microporous wood combustion product with a high carbon content. Charcoal is a black shiny material with a bluish tint. The entire surface of the coal is covered with cracks, and the preserved structure of the wood is clearly visible on the cut. If you hit a piece, the sound will be loud. Such fuel is easy to ignite, and during combustion it releases a lot of heat.

Properties of charcoal

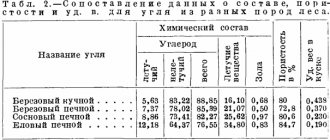

The main component of such biofuels is carbon. In addition, it contains oxygen, phosphorus, hydrogen and some volatile substances. The properties of this solid fuel largely depend on the type of wood from which it is made:

- Absorption capacity

. Possessing high porosity, charcoal at ordinary temperatures can absorb various substances, including inert gases, and when heated, it releases them and again acquires the ability to adsorb. This property is used to clean many organic products. - Density of charcoal

. This indicator depends on the type: if the wood is dense, then it produces hard coal, and vice versa. If the temperature increases during production, the density of the resulting product increases. - High heat capacity

. The temperature of charcoal during combustion can reach +1100ºС or more, and a large amount of heat is released (approximately 30,000 kJ/kg). - Environmental Safety

. If the burning of wood produces a lot of steam, unburned carbon particles and various organic substances, then when burning charcoal all these components are absent, and very little smoke is released, which makes the use of the product safe for human health. - No tendency to spontaneous combustion

. - Light weight

. Thanks to this, transporting the product is easy.

Technology and equipment

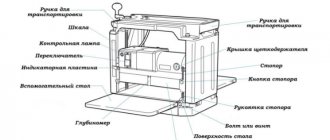

The profitability of producing such products is determined by the demand and wide range of applications of these raw materials. Equipment for the manufacture of these products usually includes:

- Furnace for the production of charcoal;

- Scales for packaging finished products;

- Electric power generator;

- Chainsaws. Their number depends on the scale of production;

- A device for splitting firewood with a hydraulic drive.

You should also rent a territory with a flat area for the production and storage of products. The charcoal stove should be installed on a level and open area. It must meet environmental and safety requirements. For industrial production, it is better to use the services of specialists for equipment installation.

As additional material, you will need bags for packaging products and high-quality raw materials . The material can be used as waste from the logging industry: stumps and tree branches.

The production of charcoal must be carried out using a certain technology. The product is obtained by burning wood without oxygen. For this purpose, special charcoal kilns are used, which have chambers for firing and drying the material. This principle of firing consists in the release of vapors when burning raw materials, which enter the furnace in a gaseous state, providing the manufacturing process with additional heat.

The entire production process can be described as follows:

- The material is placed in a loading chamber and fired at a temperature of 500 degrees.

- After firing and drying, the raw material is removed for cooling.

- The resulting material is crushed and packaged.

The size of crushing depends on the area of application of the raw material. Fine crushing is used for domestic needs. Coarse crushing is used for industry.

Where is charcoal used?

The question often arises, where is charcoal used? In the distant past, this was the only source of fuel. In our time, it has not lost its position, and its scope of application has expanded significantly:

- Metallurgy

. The high carbon content makes it possible to use charcoal as a reducing agent, and the absence of sulfur and phosphorus guarantees the preservation of the necessary properties of the reduced materials. - Instrumentation

. Coal, which is obtained from soft wood, is used to make an anti-corrosion lubricant, which is needed for polishing and grinding various shapes and parts. - Construction

. Since this material absorbs odors well and is hygroscopic, coal is used as an insulator. - Animal husbandry

. This is an excellent feed additive that is introduced into the diet of calves, pigs, and birds. - Production of activated carbon

. It is used in many ventilation systems in order to trap volatile harmful impurities in the air. - Medicine

. Wood raw materials are used to make tablets and powders that help in the treatment of gastrointestinal disorders and poisoning.

Profitability

By purchasing a furnace with a productivity of about 20 tons of finished product per month, you can calculate the approximate income from production. Costs for taxes, utility bills, transportation, rent - this is about 270 thousand rubles. per month. To produce 1 ton of product, it is necessary to purchase 7-8 m3 of birch, up to 12 m2 of soft-leaved wood. The cost of 1 m3 of split birch is from 1000 rubles/m3, which means that to produce 20 tons of coal it is necessary to purchase raw materials for 140 thousand rubles. Sales revenue at a price of 35 rubles. for 1 kg will be 700 thousand rubles. per month. Profit - 430 thousand rubles. The average payback period for investments is six months.

Charcoal production is a profitable, relevant business, the success of which depends on the professionalism of hired workers, the desire to use new technologies, and careful monitoring of the process of converting wood into charcoal.

What is charcoal made from?

Having planned a picnic in the forest, many people do not cut down trees in the forest to cook food, but bring with them bags of purchased charcoal. This solid fuel is made from:

- apple trees;

- cherries;

- ash;

- hornbeam;

- oak;

- birch trees

There are two technologies for producing this fuel:

- Lumpy

. Wood raw materials must first be prepared: cut, crushed and dried. Then it is placed in an oven, where at a temperature of +450°C without air access, the wood decomposes. The finished coal is kept for 30 hours for final cooling or stabilization. Only then is it packaged. - Briquette

_ To do this, fine charcoal is used, to which starch and paste are added, and then coal briquettes are formed from this mixture using a special press. This charcoal is denser than the previous type, it burns longer (4-5 hours) and gives a more even heat.

Types of charcoal

Such solid fuel is divided into several types. It depends on what type of wood is chosen for the manufacture of products and how much non-volatile carbon it contains. Coal differs by type of packaging: it can be lump charcoal in bags or coal briquettes. For retail buyers, a product weighing 3-10 kg is packaged in paper, and for enterprises, coal weighing 25-50 kg is packaged in polypropylene bags.

Black charcoal

Soft wood is used to produce this type of coal: aspen, bird cherry, linden, buckthorn, poplar. Black coal is considered the highest grade. The content of non-volatile carbon in it can reach 90%, and ash - about 25%. Such fuel ignites easily and burns without strong flame, smoke or odor. When burning, a large amount of heat is released.

Red charcoal

In the production of red coal, coniferous wood is used: larch, spruce, pine. Red coal is produced by charcoalization at low (compared to other types of fuel) temperatures. This fuel is more popular in European countries, where it is burned in fireplaces for heating homes and cooking grilled dishes.

White charcoal

To produce this type of charcoal, hard wood is used. Coal from oak, ash, and birch wood is called white fuel. It is obtained by firing raw materials first at a low temperature, and at the end of the process it is raised to +1000°C. The hot coal is removed from the furnace and extinguished by covering it with a mixture of earth, sand and ash. Due to this, its surface becomes slightly whitish, which explains the name. White fuel is especially popular in Japan.

Cost of the set

To start coal production, you will need not only to rent a suitable plot of land, hire workers, but also purchase equipment. The most important element of production is the oven. Its cost may vary depending on the size and volume of raw materials processed. On average, such a device can cost about 300,000 rubles.

Another 60,000 rubles will be spent on landscaping the area and installing equipment. You should also plan for shipping costs. Transportation of equipment to the production site can cost 50,000 rubles.

How to choose charcoal?

Having planned a trip to barbecue, we buy meat and try to marinate it successfully. However, all your efforts can be ruined if you choose the wrong fuel to prepare this beloved dish. The charcoal should give a good heat and impart a pleasant aroma to the cooked meat. When purchasing this fuel, pay attention to the packaging of the product: the bag should be light, and coal dust should not fall through it. Charcoal packaging must be labeled with the following product information:

- Name;

- manufacturer and its address;

- storage conditions;

- certificate of conformity.

Experienced tourists recommend buying charcoal in specialized stores, where there is less chance of purchasing low-quality goods or outright fakes. When choosing, remember that 1 kg of good fuel is designed to cook 4 kg of meat. For barbecue for a small company, one package of the lump version is enough. You can buy briquetted charcoal if you have a long vacation and there will be a lot of people who want to taste delicious meat.

Charcoal marking

The manufacturer producing such solid fuel from wood labels the packages as follows:

- Mark

A. The product is made from hardwood: birch, oak, beech. - Mark

B. To obtain coal of this grade, soft poplar, linden, and willow wood is added to the previous types of hard wood. - Mark

V. This is how a product is labeled, made from the same trees as the previous brand, but with the addition of coniferous wood: spruce, fir, pine.

Wood briquettes for grilling

Today, the main “competitor” to traditional wood coals is wood briquettes. They are made from several ingredients. May contain:

- charcoal;

- peat;

- sawdust;

- straw;

- and other wood waste and flammable substances.

They are turned into briquettes in a special way, under pressure. This is usually done using potato starch, resin or glue.

This production technology makes briquettes more compact than coal. This material does not deform on its own, making it more flammable. Briquettes also ignite better, burn longer and are capable of producing higher temperatures. Unlike coals, briquettes can burn for several hours.

However, this type of fuel for barbecues, grills and barbecues will cost an order of magnitude more. In addition, briquettes from some manufacturers may contain harmful substances that can settle on your meat and other prepared dishes. That's why, when choosing fuel briquettes for grilling, you should pay attention to:

Chemical composition

As already mentioned, cheap and low-quality briquettes contain a large number of chemical components that can affect the taste and composition of kebab and other prepared dishes. Therefore, when purchasing briquette packaging, pay attention to whether it was made 100% from natural ingredients. Also check whether the briquette binder used contains natural substances of plant origin.

Weight

Like coal, briquette packages are also packaged in 2.5, 5 and 10 kg.

Briquette for grilling. Price

As for prices, briquette fuel will cost more - from 180 rubles per 2.5 kg package. Most likely, it will be a briquette that was produced using synthetic glue, so it is better to spend a little more money to be sure of its quality.

How to make charcoal?

If you want to make charcoal with your own hands at home, then use the simple method that was used in ancient times:

- We dig a hole 50 cm deep and 80 cm in diameter. Its shape should be round and the walls should be vertical.

- Use a roller or just feet to compact the bottom well.

- Having collected dry branches, we put them in a hole and set them on fire using birch bark (without using chemicals).

- As it burns, we add branches; eventually, the entire bottom should be evenly covered with them.

- Into a well-lit fire we add firewood, pre-cut into small logs and cleared of bark.

- So you need to fill the pit to the top with burning wood. This process is lengthy and depends on the density of the wood.

- To allow the burnt coals to cool, cover the pit with green grass, sprinkle earth on top and tamp it down. The cooling process will take approximately 2 days.

- We sift the resulting coal and pack it into bags.

How to organize your own coal production business

As already mentioned, organizing a charcoal production business is simple, and anyone can do it.

Production technology

The charcoal production technology consists of 4 main stages:

- Drying raw materials. It consists of drying the starting material for better smoldering in the oven. The process occurs when raw materials are placed in a furnace and treated with smoke at a temperature of 130 to 160 ° C. With this treatment, wood loses up to 95% of its moisture content.

- Pyrolysis is the burning of wood in a closed retort-type furnace (that is, heated from the outside, without access to oxygen, or with a limited supply of oxygen). The temperature after drying the raw material increases to 300° C, the raw material completely loses moisture and becomes charred.

- Calcination, turning charred wood into coal, and separating resins and gases from it. Occurs at temperatures from 300 to 400° C. The most optimal temperature is considered to be 350-380° C.

- Coal cooling.

After cooling, the finished coal, if necessary, is crushed into smaller fractions and packaged in bags or bags.

The degree of wood combustion and flame temperature are regulated by special sensors installed in the equipment. At home, the best results are achieved experimentally.

The production of charcoal in retort ovens by pyrolysis is shown in the video below.

Making charcoal at home

Making charcoal at home is not much different from the industrial process. The differences lie in the equipment used and the feedstock requirements. To produce coal using the artisanal method, it is necessary to use only solid wood - firewood, logs, large branches, etc.

As equipment, you can use a regular metal barrel with a capacity of 200 liters or more. It is necessary to drill holes in the upper part of the barrel to allow the accumulated gases to escape. The barrel is tightly closed with a lid, placed over the fire and heated to a temperature of 350-380 ° C. When the specified temperature is reached, the barrel should remain above the flame for another 2-2.5 hours, after which it is removed from the heat. The lid opens only after it has completely cooled down.

Instead of a barrel, you can also use an ordinary hole dug in the ground. The lid can be a simple metal sheet. The process of obtaining coal can be seen in the video:

Application of charcoal

In earlier times, the Chinese called charcoal “black diamond” for its ability to cleanse the body and even treat many diseases. Nowadays, such coal is actively used in the production of many cosmetics that care for problem skin: masks, scrubs, soaps, shampoos. Pressed charcoal is used in catering establishments as a valuable fuel for cooking fish or meat.

Charcoal for barbecue

To cook meat and fish dishes on the grill, charcoal from hardwood is used. It is believed that the most delicious barbecue is made with birch fuel. Charcoal for barbecue does not produce a strong open fire, but only the necessary heat, so the food does not burn, but is evenly fried to form an appetizing golden brown crust.

Charcoal for plants

In indoor floriculture, this element, useful for plants, is used in many cases:

- Drainage

. Pieces of aspen or birch charcoal are crushed to 1 cm in diameter and placed on the bottom of pots with plants. - Soil mixture

. Coal from wood is added to the soil (3-8%) to improve its structure, looseness and water permeability. Absorbing excess moisture, charcoal for flowers releases it when there is a deficiency. - Antiseptic

. When transplanting flowers, use fine charcoal powder, which is sprinkled on sections of bulbs and rhizomes. This helps prevent them from rotting. - Adsorbent

. Placed in a flower pot, charcoal absorbs harmful substances from the soil. Plants that are capable of absorbing toxic volatile substances do so more effectively if coal pieces are added to the container.

Charcoal for hookah

Beginners often wonder whether charcoal can be used for hookah. This fuel, made from natural raw materials, gives the mixture a particularly pleasant aroma. The most suitable coals for hookah are those obtained from the following exotic wood:

- Olive

- from crushed olive pits. - Nut

- from crushed nut shells. - Lemon

– made from the wood of the lemon tree. - Grape

- from the grape vine.

Cleaning moonshine with charcoal

For additional purification of a homemade alcoholic drink, in addition to activated charcoal, charcoal is often used. Such cleaning of moonshine with charcoal for barbecue is possible only when exclusively natural birch raw materials are used, which do not contain any chemical additives. Before use, the pieces are crushed to a size of 2-3 mm (no more). This will enhance adsorption.

After this, the crushed charcoal is poured with water and boiled for an hour, and then sent to a hot oven for another hour and a half. Cooled coal can be used to clean moonshine in one of two ways:

- Infusion

. The coal is placed in a container with moonshine and left for 20 minutes. After this, the liquid must be filtered. - Filtration

. We take a funnel, cover the hole in it with cotton wool, on which we pour a layer of charcoal. Strain the alcohol 2-3 times without changing the coal.