Types of softwood

According to Russian standards, lumber is made from 5 types of coniferous trees, so these types will be discussed in this article.

Pine

Up to 120 species of pine are known. In Russia, 20% of the territory is occupied by Scots, Siberian and Crimean pine.

Pine is a coniferous tree with a long and straight trunk. The trees grow up to 40 meters tall and have a trunk up to a meter in diameter. The bark of the tree is red-brown in color with deep grooves. The life span of an ordinary pine can be up to 500 years.

Pine and sawn

In cross-section, the pine core does not blend in color with the yellow-white sapwood. The annual rings are clearly visible and have sharp transitions from early and late periods of growth.

In the wood texture, in addition to heart-shaped vessels and growth rings, there are “live” knots every 60-100 cm.

Pine texture and board

Spruce

Spruce belongs to the Pine family. There are 50 species of trees of this species. The common spruce is very common. Spruce plantations occupy large areas in Russia. If Caucasian spruce grows in the northern Caucasus, then white spruce is found in the steppe zone of Russia.

The trees are up to 300 years old. A special feature of spruce is its high demands on soil and air moisture. In the forest, trees grow with a straight trunk and no branches in its lower part. The tree grows 60 meters in height, and the trunk can have a diameter of up to 2 meters.

Spruce and slept

Coreless rock with few resin passages. The cut has a uniform white color, sometimes there is a yellowish or pink tint. Every 30 cm there are “dead” small knots. Wood fibers with a fine texture and low resin content.

The texture is inexpressive. Occasionally there are “pockets” with resin on the fibers. At high temperatures, the resin leaks. Often the spruce is eaten away by the bark beetle, leaving holes.

Spruce texture and board

3. Larch

In Russia, larch occupies most of the forests. It belongs to monoecious plants of the Pine family. About 14 species of this tree are known. Larch is the only coniferous deciduous tree. In forest areas, larch grows more than 40 meters high. The tree grows quickly and lives up to 600 years.

Larch and sawn

The core rock, which has a dark core with a reddish-brown tint, occupies 70% of the trunk. Sapwood has a white or yellowish tint. On a cross-section, annual rings and few resin ducts are clearly visible.

The texture of the wood resembles that of pine, but has a brighter and more decorative appearance. The wood is heavy, chips easily, and has the smell of turpentine.

Larch texture and lining

Cedar

A tree from the Pine family is called Siberian pine in Russia. Cedar includes 4 species and is valued for its wood, needles and seeds. There are three types of cedars in Russia: Siberian, cedar and Korean.

Cedar pine grows up to 40 meters in height, and the trunk reaches a diameter of two meters. The tree bears fruit for up to 300 years, and grows for up to 500 years.

Cedar and sawn

The cedar core has a yellowish-pink or light color. The yellowish-white sapwood does not have a sharp border with the core. Tree rings stand out on the cut, but the transitions between early wood and late wood are blurred and shaded.

The texture of cedar resembles the texture of pine, but it has fewer resin passages and their size is larger. The tree is rich in essential oils, so when heated, it releases a balsamic aroma that kills many pathogenic microbes.

Cedar texture and board

Fir

In the Pine family there is an evergreen coniferous plant called fir, which means “resin” in Karelian. There are 50 types of fir. Russia has the largest number of Siberian fir plantings.

The average height of the tree is 50 meters, but there are specimens up to 80 meters high. The trunk grows to a diameter of 0.6 meters. The life span of fir reaches 500 years, and the tree blooms at the age of 60 years.

The bark of the tree is smooth and even, but cracks with age. At an early age, trees do not get sick because they contain volatile resins. There are thickenings on the bark called nodules. They contain thick resin. This is an analogue of resin passages on the trunks of coniferous trees.

Fir and sawn

The coreless species has a saw cut similar to spruce. There is no visual difference between heartwood and sapwood. Sometimes a false nucleus is formed from old fibers. The wood is white. In some cases, a yellow or brown tint appears, and a brownish-brown tint appears near the middle of the cut.

Tree rings stand out on the cut. There are color differences between ages of wood. Small knots are located between large knots collected in whorls.

The texture of the tree is long-fiber, so fir is widely used in the paper industry.

Fir texture and board

What exactly does GOST regulate for lumber?

The most widely used products in household and industrial use are the products of processing pine needles - pine, spruce, fir, larch and cedar trees. Softwoods are not as durable as heavier hardwood varieties, but retain heat better and are cheap and easy to use.

The regulatory document defining the quality parameters of coniferous wood is GOST 8486-86. Its functions include classification of lumber by grade and identification of ranges of important physical and technical indicators.

Classification of coniferous wood according to GOST

There are several areas of classification, including a set of operational parameters, the degree of preparation and mechanical processing:

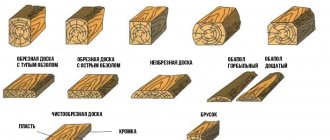

- According to the form of manufacture - boards, beams and whetstones.

- By type of processing – edged and unedged lumber. In unedged wood, the side edges repeat the ovals of the trunk. In edged boards and beams, the edges are cut off, and the cross section has the shape of a square or rectangle.

- By grade - boards and bars are produced in five grades - one selected and four ordinary (from first to fourth, in descending order of quality). A selected grade of beams is not produced, since the specifics of the material limits its external use (cladding). The quality of fourth grade boards is quite low and includes products with a large proportion of defects or damage that occurred during use.

- Based on moisture content , a distinction is made between dry and damp boards, beams and beams. The standard classifies dry wood as products with a moisture content of no more than 22%. Wet materials can be produced in antiseptic or untreated form.

The parameters of the boards are assessed based on the worst of the two layers, and the characteristics of the beams and beams are established based on the least quality face. In the warm season, enterprises can produce raw lumber only by agreement with the consumer, moving to mass production in the autumn-winter period.

Types of lumber products

Physical properties of conifers

Each coniferous wood has special physical properties that are associated with its use.

Density

The density indicator is determined by the relationship between the mass and volume of the material. Density is of great importance for wood. Wood is harder and heavier if its density is high. High density rocks are difficult to process due to their high strength. In addition, dense wood species are poorly saturated with antiseptics, and floors and stairs made of such material wear out little.

The densest wood is larch, while fir, pine and spruce have low densities.

Density of different types of softwood

Humidity

A quantitative indicator of water in wood is humidity. It depends on the porosity of the wood and the state of the environment.

They use the concept of “natural humidity”, which refers to a growing tree or at the first moment after cutting it down.

The term "wood damp" refers to dried wood that is used for interior decoration. It is 8‒12%. During construction, material with a humidity of 14% is used.

Moisture content of different types of softwood

Drying shrinkage

All lumber is dried, as this increases its strength, hardness, and wear resistance. When drying, the wood shrinks and shrinks, which means its size changes. The distribution of moisture inside the material depends on the intensity of drying. Humidity is reduced to 6–8% using different drying methods.

The shrinkage of wood during drying is assessed by its volumetric coefficient. A high shrinkage rate is considered a disadvantage of the wood species.

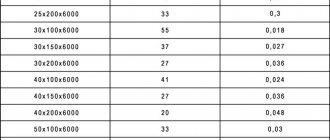

Shrinkage of coniferous wood

4. Permeability

Capillaries in wood create good conditions for the permeability of gases and liquids. Tests are carried out by passing water and air through the tree under pressure.

The level of impregnation of coniferous wood with protective compounds depends on permeability.

Permeability of different types of softwood

Due to the same porosity, pine and spruce have the same permeability coefficient for water vapor: in the longitudinal direction 0.32 mg/(m•h•Pa), in the transverse direction 0.06 mg/(m•h•Pa).

The level of water permeability and resistance to rotting is influenced by resin passages. All coniferous species have them, except fir. Cedar has the largest passages measuring up to 0.14 mm, and larch has the smallest ones, 0.08 mm.

Gas permeability indicators for coniferous species are also different.

Gas permeability of various types of softwood

5. Biostability

The main enemy of wood is moisture. Under its influence, a putrefactive fungus is formed, which destroys the material. Biological resistance depends on the ability of the material to resist the destructive effects of moisture. It is divided into two types:

- Natural durability - depends on the type of wood. All conifers, with the exception of fir, have channels filled with resin. The resin increases resistance to rotting.

- Acquired resistance is resistance to decay, which is increased by introducing an antiseptic into the wood. It does not worsen the properties of the material, but improves its durability. The choice of antiseptic depends on the purpose of the wood. All coniferous trees have different resistance to rot.

Resistance to rotting of various types of coniferous wood

6. Thermal conductivity

An important property of coniferous trees is to retain heat. It is determined by the thermal conductivity coefficient: the lower the coefficient, the better the wood retains heat. Cedar retains heat best.

The thermal conductivity indicator depends not only on the level of density, but also on the moisture content of the wood. Materials with high humidity and density have a high thermal conductivity coefficient.

Thermal conductivity of various types of softwood

Regulations for softwood lumber according to GOST 8486-86

The standard characteristics are the following indicators:

Dimensions and number of knots

The standard defines standards for the presence of various types of knots in coniferous wood. Natural inclusions in the structure of the material are divided into several types of knots:

- · fused – formations that have grown together with the main wood by 75% or more of the circumference of the knot cut;

- · unfused - inclusions are connected to the base by 25%, which causes the risk of them falling out of the layer;

- · falling out are the remains of dead branches. The presence of external falling knots is allowed only for 4th grade timber. External defects are called through knots that extend onto both layers;

- · rotten inclusions reveal themselves by their dark color and rotten, loose structure. In higher varieties their presence is unacceptable.

On the edges of selected and 1st grade lumber 100 cm long, up to 2 pieces are allowed. external knots on each face. In third-grade timber, up to 2–4 knots are allowed on each side of the product. Their number for profiles of the 4th grade is not limited. For timber, the presence of knots is also not limited by anything due to the high thickness of the cross section.

The size of knots in selected and 1st grades should not exceed 30% - 20% of the entire area of the edge width, for the third and fourth grades on half the area of the edges.

Defects of lumber

Cracks

The presence of through cracks is allowed, the size of which is limited to 10 - 20 cm. Through the longitudinal axis of lumber, through cavities from 15% to 50% are allowed for all types of wood profiles.

Damage to wood structure

Small mold accumulations and fungal colonies are allowed for all types of timber. In selected coniferous wood profiles there should be no rot at all. In material of the fourth grade, small putrefactive inclusions are allowed.

Warped

Curvatures are permissible along the length of the material in the following quantities:

- · selected, 1st, 2nd – 0.2%;

- · 3rd – 0.4%;

- · 4th – not limited.

Note: be sure to watch the video “Automatic sorting of timber”

Spruce

Spruce, growing in the northern regions of the country, produces the best wood in terms of physical and mechanical properties.

The species is coreless, mature wood, has resin passages, but little resin. Spruce has light, soft, ripe, uniformly white wood with a slightly golden tint, which retains its natural color for a long time. Late wood has the appearance of a narrow light brown stripe, which gradually turns into early wood. It is resistant to cracking.

Spruce is less moisture resistant than pine and is more susceptible to rotting, but its wood is less susceptible to warping, which is a positive quality of this material. Spruce finishes poorly, but glues better than pine. It is more difficult to process due to the abundance of knots and their increased hardness.

Density: 445 kg/m3.