People starting construction work purchase lumber ready-made. Different types of rocks are used to produce planed products. There are 4 types of lumber, each of which has its own quality and purpose. Based on the type of wood, its shape and type, a classification has been developed. Wood classification is a set of characteristics, after understanding which, the buyer will be able to choose the right timber for himself.

Selected variety

The most expensive type of wood, may be called class “A”, is 2-3 times more expensive than the first grade.

They are mainly used in shipbuilding and automotive industry. They can be used to make the “sides” of trucks, parts of cabins, in shipbuilding they are used to make deck boards, elements of cabins, sometimes yacht masts, etc.

Basic requirements - knots are allowed, but only large ones, or at a distance of 2 meters from each other. Rotten knots and rotten parts of wood are not allowed. Cracks may be present, but they should not be more than 10%, and they should not be deep, mainly formed as a result of shrinkage. The slope of the fibers is no more than 5% of the length. There should be no parts of the root system in the wood. That is, the lumber must be clean without any flaws.

Distinctive characteristics of wood grade

The abundance of lumber from wood today has flooded the markets with its quantity, quality and price. And everyone shouts with one voice that their products are the best and brought exclusively from the distant corners of Siberia or the Arkhangelsk lands. But with all this, we must be responsible for the quality and quality of the products provided. In this article we will talk about the distinctive characteristics of wood grades, tell you how they are designated and what their differences are between each other.

Market for various lumber

First, let’s find out what grade is?

The most basic indicator that influences the grade of wood is the presence of knots located in different parts of the trunk, the size, quantity and characteristics of which determine the grade. Other parameters that are certainly taken into account when setting the type of wood are the presence of resin pockets, cracks, wane, the slope of the fibers, and various defects in the shape of the material. For each breed, only its own variety is used with a regulated or non-regulated number of knots.

Lining in a certain grade

The natural conditions in which various tree species grow, located at certain geographical latitudes, have a huge impact on the properties of wood. That is why differences in the structure of the tree necessitate its classification into varieties. Basic grading indicators can be applied to various types of lumber and finished products.

1

Arkhangelsk forests

Main types of wood

Woodworking enterprises daily supply their products to markets with basic grade indicators. But in addition, based on the specifics of the product, they can produce types of wood with individual characteristics, combining the indicators of the main varieties and have subcategories. According to its qualitative properties and characteristics, wood is divided into 4 main grades: - Extra - Prima (A) - AB (B) - BC (C)

1

Types of grades for different types of wood

Now let's look at each variety separately.

Extra complete absence of defects with a perfectly smooth surface, as they say, no hitches. No resin pockets or defects, making this grade the most popular among wood finishes.

2

Lining calm larch Extra grade

Prima (A) the difference between this variety and extra is that it has a small knot, which is regulated by no more than 1-2 per linear meter. For the most part, this grade contains all the material that did not fall into the highest grade. The presence of small light knots and resin pockets only gives the tree an even more natural, natural look.

1

Lining calm Angarsk pine grade Prima (A)

AB (B) this grade represents an unregulated number of knots of 2 or more per linear meter with minor wood defects. Resin stripes, pockets and small defects on the edge are also found in this grade. But all these points in no way spoil the beauty of the finishing panel and the appearance of the wood.

Calm pine lining grade AB (B)

BC (C) is the most budget option in terms of grade, which is well worth paying attention to, no worse than its above-mentioned leaders, as they say, the third grade is not a defect. This variety contains everything that is not included in other varieties, and for lovers of natural style, these minor defects that do not affect performance will not look critical, but on the contrary, they will show themselves quite worthy as a material.

Planken straight pine grade BC (C)

Let's sum it up

All this abundance of grades applies to lumber, and has its own name. When choosing one or another grade of wood, you must clearly understand for what purpose this or that finishing product will be used, namely for internal or external work. Each variety is beautiful in its own way and flaunts its natural patterns on the wood, so that everyone can appreciate and choose the material they need with a certain variety.

1

Coniferous trees

What class should I use to build a frame for a house?

You can often hear this question - guys, the frame should be at least second class wood (and preferably either “first” or “select”). Moreover, it needs to have additional treatment against rotting and moisture absorption, only then can it last for a really long time. Also, drying the wood must be done correctly.

A short video on how wood is chosen in Egypt, there are as many as 7 classes.

This is the information, I think it was useful to you. Read our construction site.

Industrial softwood

Edged softwood lumber dominates the construction market. Conifers account for 80% of building parts and structures. The material does not require adjustment and can be clearly taken into account when planning the needs for construction work.

The spread is due to natural factors:

Types of products for sawmills

- Relative cheapness;

- Resistance to rotting due to resin content;

- Less susceptible to warping;

- An inexhaustible resource, especially in the Urals and Siberia.

The region of distribution affects the quality of wood. Timber with a denser structure is delivered from the northern logging area. The number of wood defects is insignificant.

Manufacturing technical conditions, size range, grade, quality deviations of boards, beams and beams are subject to 11 GOST, as the main regulatory and technical documents. Lumber from coniferous trees for aircraft construction and the manufacture of musical instruments are subject to special GOSTs.

Edged board - pros and cons

Such lumber has a number of advantages, and among them are the following:

- Load bearing capacity

. With their help, strong but lightweight structures are erected. For example, wooden houses that are built on a minimal foundation. - Quick and easy installation

. With the help of special fasteners, the board can be quickly and easily mounted in complex structures. - Natural origin

. Wood is a highly environmentally friendly material that retains heat well.

However, along with the positive characteristics, edged oak boards have several disadvantages. Among them are:

- Increase in material costs

. The price depends on the quality, the section performed and other factors. - Limitation in load-bearing capacity

. The material has a limit on weight and load-bearing capacity.

MARKING

3.1. Lumber with a length of 1.0 m or more and blanks of all lengths are subject to marking. Labeling of lumber supplied for export is carried out in accordance with the regulatory and technical documentation for the products.

3.2. The end or face of the lumber or workpiece must be marked indicating the type of lumber or workpiece. The variety designation is indicated in Table 5.

Table 5

| Variety | Variety designation | ||

| paint | chalk | ||

| lumber | blanks | ||

| Selected | One horizontal stripe (-) | 0 | |

| 1 | One dot or vertical bar (. or |) | | | 1 |

| 2 | Two dots or two vertical stripes (.. or ||) | || | 2 |

| 3 | Three dots or three vertical stripes (... or || |) | || | | 3 |

| 4 | Not marked | ||

Markings must be legible and applied with permanent paint or wash-resistant chalk. When marking lumber intended for shipbuilding, selected and 1st grades, the letter “C” is additionally applied (for example, 0C or 1C). When marking blanks intended for equipment construction, the letter “O” is additionally applied, for skis - the letter “L”, for resonant ones - the letter “P”. Lumber and blanks with a thickness of less than 25 mm are marked with stripes, those with a thickness of 25 mm or more are marked with dots. The location of markings on the ends and faces must correspond to the diagrams specified in Appendix 1.

3.3. Lumber and blanks of the same grade, shipped in packages, are not marked individually. Package marking is in accordance with GOST 19041. (Changed edition, Amendment No. 1).

GOST lumber

GOST 24454-80 regulates technical requirements for lumber for export and domestic use. Applies to boards, beams, edged and unedged bars.

Assumptions for deviations in dimensions in length, thickness and width on the domestic market are established by GOST 26002, GOST 9302. The list of lumber of softwood includes the following wood species:

Assortment of softwood lumber (edged boards) GOST 24454-80

- Pine;

- Larch;

- Spruce;

- Fir;

- Cedar.

The properties and business qualities of breeds vary. Pine and Siberian cedar are subspecies of the same species, the difference is in texture. Cedar is a godsend for the decorator. Spruce loses in strength. Larch is durable and resistant to decay. Justifies the high price of lumber.

The gradation of the quality of industrial wood, bars and boards includes 5 grades. The highest is a selected variety. Others are numbered from 1 to 4. The bars are divided into 4 grades. Nominal sizes of parallel edge lumber include thicknesses of 16–250 mm with face widths of 75–275 mm.

The size of the wane, narrowing of unedged and non-parallel boards is limited to a percentage of the main size. The maximum tolerance factor for reducing the value is 0.6.

The cross-sectional dimensions of edged lumber for vehicles, carriage building, oil rig beams, and export shipments follow a separate GOST. The nominal dimensions of boards and timber are set on average for wood with a moisture content of 200. The amount of shrinkage to obtain the actual dimensions is regulated by GOST 6782.

Production and supply of selected 1-3 grades of boards with a moisture content of up to 22% is considered dry wood. Excess moisture – damp. During seasonal deliveries in the period May-October, the production of raw material requires agreement with the customer.

Current GOST 6782

Assumptions for deviations in lumber dimensional parameters

Size range along the length of commercial wood:

- For the construction industry - 1–6.5 m;

- Container board - from 0.5 m;

- Special purpose beams and boards – 3.25 m;

- For export – 0.9–6.3 m.

GOST for lumber sizes

Deviations of dimensional values in both directions, permissible according to GOST:

- Thickness 16–100 mm – 2,5%;

- Width – 2%;

- Length - +50, -25 mm.

Restrictions for lumber less than 1.5 m are lifted.

Oak red and white

More than 200 types of oak are used in the production of parquet in different countries of the world. In the USA, the most famous parquet is made of red oak (also known as “American oak”, “Canadian oak”, “holly oak”). Its wood is slightly softer than white oak (1290 Janka or 3.7 Brinell), which is also common in America. Red oak parquet has an interesting color from light golden to reddish pink with a clear grain pattern and coarse texture.

White oak is native to eastern North America and is also used in parquet flooring. It has a warm golden color with a finer grain texture.

The recently popular product “bleached oak” should be distinguished from white oak as a species. The latter is specially bleached oak parquet of various types in various ways, which is used in creating Scandinavian-style interiors.

Below are examples of “bleached oak” parquet boards in our store.

Certain types and types of wood

Despite the fact that there are a lot of options for building materials, Russians prefer wood. Particularly popular are materials that have undergone special processing. After processing, the density increases, the performance improves, and the physical and chemical properties change for the better.

Untreated plain wood is a thing of the past. Although its cost is much lower than processed materials, it loses in many respects. Therefore, buyers try to buy the following types of wood:

Stabilized

Stabilized wood is made from burls of valuable wood. It is not afraid of temperature changes, moisture-resistant, resistant to various acids and solvents, ultraviolet radiation, and salt water. To achieve these properties, wood is impregnated with monomers and acrylic resins, filling all holes and pores with them.

After undergoing this treatment, the wood acquires the following properties:

- does not deform or crack;

- withstands heating up to 100? C;

- has high hardness and strength;

- perfectly polished;

- becomes bright and saturated.

Stabilized wood is mainly used to make knife handles and various exclusive crafts. It is produced in the form of bars. The cost of a bar measuring 40x30x125 mm is about 900 rubles.

In the photo - stabilized wood

Example 1

Example 2

Modified

Modified wood is produced by impregnating wood with an aqueous solution of urea, phenol-formaldehyde or polyester resins. After this treatment, the wood is not afraid of aggressive and abrasive environments and shock loads. Stops accumulating static electricity. Hygroscopicity is reduced, swelling is reduced, strength is increased,

Houses are built from modified wood. They look very elegant and do not need finishing. After the structure is assembled, no shrinkage occurs. This is a very promising material for frame house construction. Its selling price is 18 – 22 thousand rubles per sq.m.

Glued

Glued laminated wood is available in three types:

- layered;

- massive;

- combined.

Layered products are made from veneer, obtaining plywood as gluing. Solid wood includes laminated boards, bars, and slabs. Combined is produced in the form of wood slabs, they are obtained by combining veneer and solid wood.

They build houses and make furniture from glued products. The price per cube ranges from 22 thousand to 25 thousand rubles.

Photo of laminated wood

Impregnated

Impregnated wood is produced by impregnating wood with a special composition. It may contain oil-containing liquids, creosote, as well as arsenic and chromium compounds.

Impregnation is carried out in hermetically sealed chambers into which boards are placed. After loading the boards, the composition is fed into the chambers.

Impregnated products last five times longer than conventional ones and do not require constant touch-up with paints and varnishes.

It is ideal for structures in contact with water or soil. It is used to construct piers and make posts for fences, beds and flower beds.

The approximate cost of impregnated wood is from 14 to 16 thousand rubles per cubic meter. meter, imported - from Finland costs from 35 thousand rubles. for 1 cubic meter

Water-repellent properties of impregnated wood

Heat-treated (thermomodified)

Heat treatment improves the properties of wood and is the only alternative to chemical treatment. The technology consists of saturating wood with water vapor at a temperature of 220 - 240? C. Changes in the structure of the material occur at the molecular level. The processing cycle takes 12 hours.

Thermally modified products have three main properties:

- resistance to biological damage;

- moisture repellency;

- dimensional stability.

Thermal wood is used to make furniture, parquet, and is used for cladding houses. Used for finishing work in rooms with high humidity. It is very popular in the production of window frames. Price per square meter from one to five thousand rubles. depending on the thickness of the board, grade and species.

Morenaia

Bog wood comes from flooded forests. It is used in construction and furniture production. This wood is highly prized and the longer it sits in water, the stronger it becomes. After such natural processing, it acquires a number of unique properties and becomes very durable. One cube of stained birch costs 1,600 rubles. Larch costs from 15,000 rubles per cubic meter.

In the video - plates made of black bog oak:

Pressed

Pressed wood is obtained from softwood trees. It is obtained by hot pressing. Sometimes they are impregnated with artificial resins or other substances. Pressed products become strong and hard, acquire impact strength and anti-friction properties.

They dampen vibration well and actively absorb abrasive particles. Therefore, sometimes pressed wood is used instead of metal to make bearings. Roofing structures are made from it. Houses are sheathed with pressed slabs, making them soundproof. The cost depends on the type of slab.

GOST lumber for technological deviations

The presence of wane on the edges and faces is not considered a serious deviation in the quality of the product. The presence of local areas with acute wane is acceptable for the lowest category of timber.

Types of wane

The length of wane inclusions along the edge of the board is allowed up to 17% of the diameter without any length restrictions. Partial inclusions of wane can occupy up to 30% of the diameter, with an extension of no more than 17% of the length.

Exceeding the ash content standard requires a revision of the grade or conversion to unedged lumber. Otherwise, the performance characteristics of the building material may be reduced.

Warping

Warping of lumber during drying

For unedged construction blanks, warping along the longitudinal edge and spiral curvature (winging) are not regulated. After edging, the deflection of wood on load-bearing and enclosing structures is limited to 2% relative to the length.

Deflection of warping in the transverse plane is allowed by the standard within 10% relative to the width. Limitations on plane curvature are valid at humidity up to 22%. Exceeding the moisture content tightens the standards by 2 times.

Violation of storage conditions and deviations in drying technology provoke increased warping and cracking.

Video on the topic: GOST 26002-83

Publications on the topic

Technical characteristics of periodic profile reinforcement according to GOST 52544-2006

Preparation and installation of wooden floors in an aerated concrete house

The difference between A1 and A3 fittings and their classes

TESTS FOR IDENTIFICATION OF FALLED TIMBER

Can it grow in this area? The tree identification guide will help you to immediately weed out many species. Small notes like “located to northwest Oregon coast” will greatly help narrow your search if you are in upstate New York.

Use common sense and follow the smell. The size of the tree already eliminates many candidates: it is unlikely that a persimmon tree can grow to the size of an oak tree. Cut off a small piece of wood core or shavings and rub it with saliva - this will activate the smell. Many types of wood retain a bright smell even when they are completely dry and become like bone. Smell the wood you work with in your workshop often: you will remember many of the smells well.

Black walnut and sapele

Pay attention to the color. The bright yellow wood of orange maclura immediately gives the desired binding. And who can mistake the deep, dark color of black walnut wood? Can you find out the color of the cherry? Learn to remember color on dry, untreated wood. On a fallen tree, the top dirty, weathered layer must be cut off to reveal the true color.

What about the bark? Sometimes bark is a good clue, as in the case of white birch. But often the bark can look completely different on different specimens of the same tree species. The bark of the walnut is sometimes similar to the bark of a cherry tree. The same tree at different ages also has slightly different bark. The location where a tree grows and its growth rate directly affect the color and structure of its bark.

Use the knife. Use a knife or ax to remove a piece of bark from a fallen tree about the size of your footprint. When you get to hardwood, cut a flat piece. It may be lighter in color than the heartwood because it is sapwood, but the grain pattern will be the same as the open-cut lumber you are working with.

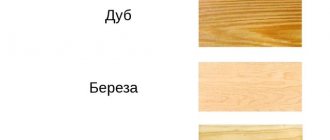

Types of wood