Types of lumber

To produce lumber, tree trunks of various species are used, which are first cleared of bark and branches. Boards made from coniferous trees are intended for the construction of load-bearing structures, and from deciduous trees - for creating furniture, finishing and decorative work. Based on this, as well as the shape, type and grade of lumber, a classification of lumber has been developed. During the production process, most waste, including sawdust, is processed into valuable building materials.

Usually birch and poplar are used. Depending on the required characteristics, other breeds may be used.

Oak is best suited as a raw material for furniture; if finishing work with high humidity is required, ash is the best solution. It is better to make decorative objects from spruce that bend strongly during processing.

Classification of lumber by processing

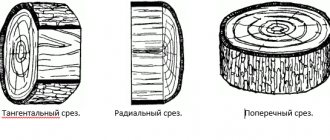

Finished products differ not only depending on the type of raw materials, but also on the processing method. There are several types of log cutting, among which are:

- transverse (logs are cut across the wood fibers) - usually used in the production of decorative parquet;

- semi-radial (wood is sawed at an acute angle to the grain) - used in the manufacture of flooring;

- radial (the cut is made strictly through the middle of the trunk) - boards obtained by this method are distinguished by high strength, resistance to external influences and an attractive appearance;

- tangential (a little further than the middle) - used for aesthetic purposes, to create a beautiful decorative pattern.

After cutting, the lumber must be dried. This process can take place naturally or artificially. Most industrial enterprises use drying chambers, which allow the boards to dry faster and reduce moisture to a level lower than when drying in air. If necessary, such a chamber can be built with your own hands.

Depending on the degree of processing and manufacturing method, the following types of lumber are distinguished:

- unedged - the edges of the finished board are not processed in any way;

- edged - the side parts are sawn off to form a rectangular board shape;

- planed - all or some surfaces are sanded to get rid of roughness;

Each of these types is used in construction and finishing works. Often this is only primary processing; if necessary, lumber can be bent, cut, varnished, or polished. Sometimes holes or grooves are made necessary for installation work.

Classification of lumber by size and shape

When carrying out construction work, various types of lumber are required, which differ depending on the size, shape, and structure.

The traditional classification distinguishes the following types, the so-called lumber assortment:

- Timber – Timber is a traditional building material that is made by cutting off the edges of a log to create a square or rectangular shape. Most often, timber is used to create load-bearing structures, doors, staircase windows. The thickness of the timber usually exceeds 10 cm.

- Bars are similar to radiation bars, but are smaller in size. Typically used in furniture production, construction and finishing works. Can be customized to the required size, shape and degree of processing. Often the gauge is indicated on the bars, based on which it is easy to select the required material.

- The board is the next stage of timber processing. May differ in thickness, degree of edge and surface treatment. It also has a certain calibration based on standard sizes.

- Sleepers are a special type of lumber, which is characterized by high strength and resistance to environmental influences. Because of this, they were widespread in the railway sector, where they were used to lay tracks.

- Croaker is a type of board, its distinctive feature is its shape. When cut, one side is given a flat surface, and the other is swollen, semicircular. Often used for decorative purposes, usually as a façade covering.

- Obapol - made from the outer parts of a log, usually during the production of timber. It has no edges, only one smooth side and one swollen side. If necessary, the cavity is cleaned of traces of bark and sanded.

- Rounded logs are used for the construction of wooden houses (log houses). Only smooth tree trunks of a certain diameter without large branches are suitable for its production. During the production process, the log is stripped of its bark and outer layers, achieving an almost ideal shape. Special grooves called locks are cut out on the finished rounded log, which ensure high structural strength. Finished log houses are very beautiful, warm and do not require additional interior finishing.

- Profiled timber is becoming increasingly popular in the construction industry. The basis for its manufacture is ordinary timber, on the surface of which connecting ditches are cut by milling or planing. Structures made from connected profiled timber are highly durable. Also, in most cases, it does not require additional finishing work. To construct buildings from such timber, it is not necessary to create a powerful foundation.

- Glued laminated timber - made from boards or other individual elements by gluing lamellas together. This design is stronger, more durable and resistant to the external environment. The use of individual lamellas allows you to create timber of the ideal length and shape.

- Block house is a type of slab, which is distinguished by the presence of grooves and protrusions on the edges. They are necessary for fastening individual parts during finishing work. Used to create building facades. Can be additionally polished and varnished. This material has excellent insulating properties, retaining heat inside the building and protecting against street noise.

Classification by wood species

For the manufacture of lumber, various tree species are used, differing in strength characteristics, durability, stability and degree of flexibility. Based on the type of wood used, there are:

- Lumber made from softwood.

- A product based on the wood of deciduous trees.

- Products combining coniferous and deciduous wood.

The main types of conifers used:

- pine – characterized by a soft, bright red structure, saturated with resin, used in the construction of load-bearing structures and the manufacture of furniture, windows and doors.

- cedar - has a red color, the wood is quite hard and strong, lends itself well to processing, which is why it is widely used in construction and for the manufacture of small items, such as pencils.

- spruce – distinguished by its white color, resinous structure, is often used in construction, the furniture industry, the manufacture of windows, doors, and musical instruments.

To determine the grade of softwood lumber, you can use a calibration table, which indicates the parameters of weight, size, structure, color and other characteristics.

Quality classification

Based on the quality of wood and its processing, a range of timber products has been developed, which is based on the assessment of the finished material according to several parameters. These include: worst side, edge, face and section structure.

The generally accepted classification contains the following list of varieties:

- Selected variety. Materials of this group should not have obvious defects, such as mold or rot, overgrown knots and other inclusions. The assessment is carried out after drying, during which cracks may appear, which are also not allowed. It is possible to allow shallow cracks that do not affect the strength, as well as a small number of healthy ingrown knots (maximum 2 knots per 1 m of product).

- First grade. It is not very different from the selected one, it has a greater tolerance for knots (no higher than 1 cm, must be healthy and not wobble) and cracks (cracks up to 1 cm deep are acceptable). The finished material should not have rot, rottenness, mold, various inclusions, damp layers and mechanical damage. Typically used in construction.

- Second grade. Used in the furniture industry, large cracks are allowed, not exceeding a third of the length of the product, small wormholes. Must not contain traces of mechanical damage, rottenness or rot.

- Third grade. This grade allows a small amount of rotten knots, wormholes over the entire surface, as well as through cracks. Most often, third-grade material is used for the production of containers, less often for the construction of sheds and other small buildings, as well as commodity pallets.

- Fourth grade. This is low grade wood. It is used for the production of structures and objects that do not require increased strength and durability characteristics. Scaffolding, pallets, boxes, gazebos and temporary buildings are made from such materials.

Classification

The shape, size and mechanical characteristics determine the division of lumber into several types.

A timber is a log, hewn on all sides, used in the construction of houses, as well as for the manufacture of individual large elements of windows, stairs and others. The thickness of the timber is 100 mm.

Bars are “timber in miniature”, less than 100 mm thick, and can be untreated, planed (at least one side is processed) and calibrated (adjusted to a certain size). Scope of application: furniture production, lathing, flooring, frames, gazebos and other objects.

Boards are made from logs or beams. They come in unedged, edged (having a smooth edge) and edged only on one side. In addition, the boards can be calibrated, that is, they have specified dimensions.

Sleepers are a material with increased strength and minimal sensitivity to temperature fluctuations.

Slabs are boards obtained by sawing logs, having a smooth and semicircular surface.

Obapol is lumber produced from the side of a log, having only one flat side.

Purpose of lumber

Various types of lumber have found application in almost all spheres of human activity. But the majority of all wood produced is used in the construction and furniture industries, as well as for interior and exterior finishing work. Moreover, lumber is often further processed before final use; it is sanded, polished, painted or varnished, and grooves, patterns and holes are cut out. In some areas, additional processing is required; the wood is treated with chemicals against rodents, high moisture, or fire-fighting liquid.

When making furniture, it is often necessary to bend wood to obtain unusual shapes and patterns. Curved products are the most expensive, since their production technology is very resource-intensive, requires a lot of time, certain knowledge and special equipment.

It is noteworthy that an already curved product can be bent again, changing its shape. To do this, you just need to wet and heat the wood; often steam under pressure is used for such purposes.

Advantages and disadvantages

Man has always been surrounded by objects and wood products. This material was used for the construction of houses and churches, baths and all kinds of outbuildings.

The man was surrounded by wooden windows, doors, tables, chairs and other furniture. Wood has not lost its popularity even today. On the contrary, thanks to the positive qualities of wood, construction and finishing materials made from wood are becoming even more in demand.

Advantages of lumber:

- have a high load-bearing capacity with a relatively low weight; despite sufficient strength, the material is characterized by simplicity and ease of processing (it is flexible to drilling, easy to saw, allows you to produce figures of various shapes and complexity); ease and speed of installation; due to its natural origin and environmental friendliness, the material is considered completely safe for human health and the environment, does not cause allergies; processing does not require expensive and time-consuming work; visual appeal; the pleasant smell of wood creates a favorable microclimate in the room; variety of shapes and sizes of products; affordable price.

Minuses:

- ability to quickly ignite, maintain combustion; are destroyed under the influence of fungus, mold, various insects; prolonged exposure to water and a humid environment often causes the process of wood rotting.

To protect lumber, make it more wear-resistant and durable, they are treated with special protective substances that can significantly reduce the above-mentioned disadvantages.

Regulatory Requirements

Based on the characteristics of lumber and the requirements put forward for their properties, a regulatory framework has been developed on which wood producers rely. All detailed information about the grade of lumber is indicated in GOSTs.

Download GOST 8486-86

GOST contains the following characteristics of lumber:

- Varieties. Boards and bars are divided into 5 grades, and timber into 4.

- Roughness. Indicates the maximum permissible amount of unevenness on the surface of the wood, described separately for each class.

- Humidity. The moisture content of wood from grades 1 to 3 should not exceed 22%; for materials of lower classes the permissible moisture content is not regulated.

Additional characteristics specified in GOST are the number of knots, their type and condition, the slope of the fibers, the presence of rot, fungus, areas of high moisture and various shades.

Based on GOST indicators, it is possible to determine the grade of lumber with high accuracy.

Production technology

The technology for the production of lumber is practically the same depending on the type of wood, the type of lumber and the size of the enterprise.

The whole process begins with the purchase or harvesting of round timber. This is a very important stage, since the quality of the finished product directly depends on the quality of the forest. A large number of flaws in the wood will result in low-grade lumber.

This is followed by primary processing. The round timber is cleared of bark, branches, large knots and other inclusions. Often the wood is sold already cleared. Cleaned logs can be sawn. The type of cut depends on the size of the log, the quality of the wood and the desired end product. After cutting, the resulting material is sorted by quality and purpose. The longitudinal and wide sides are sanded and the edges are processed (the edge is the side of the lumber). Then the process of drying the lumber elements begins and the product is ready for sale.

Equipment for the production of lumber plays an equally important role. The efficiency of production and the variety of the resulting assortment depend on its diversity and productivity. It is very important to fully train personnel to operate machines, since due to inexperience they can often fail and wear out quickly. Machines need to be serviced on time and worn parts must be replaced in a timely manner. It is also important to follow safety precautions, since making lumber is a very dangerous activity.

How to classify them

Sometimes you can hear that “a board is a board in Africa too.” To a person far from construction, the types of lumber look almost the same, differing only in size. This means that he will almost certainly acquire, perhaps good, but not the most suitable material.

Meanwhile, each type of board has its own set of characteristics; They are suitable for different types of premises and require different processing technologies. By choosing the right material, you will maintain quality and extend the life of the floor. A thoughtful choice will eliminate squeaking and deformation. If you need a floor board, which one to choose will depend on the tasks at hand. To make the task easier, it is useful to rely on the following classification by category:

- Purpose (method of use in construction).

- Material of manufacture, grade, dimensions.

- Processing quality, profile.

Source remstroiblog.ru

Processing methods

Wood can be processed in various ways. The most common are:

- Splitting - this method involves separating wood along the grain with a wedge-shaped tool. It is used in the production of parquet staves, firewood, tiles or ax handles. In most of these cases, sawing the tree cannot be done, but splitting is more effective.

- Sawing is the process of cutting wood using a saw. Usually performed perpendicular to the direction of the grain.

- Planing refers to processing processes. Performed with planes of various types.

- Looping - this method is similar to the scraping process. Usually done using a chisel. The process produces a smooth surface and an almost perfectly round beam. This method is used in the production of rounded logs.

- Zining is a method that involves leveling surfaces to create roughness. This is necessary when gluing individual elements.

- Chiseling – used to produce recesses or holes of various types. Chisels are usually used for these purposes.

- Drilling – necessary to create holes, usually done using machines or hand tools.

- Grinding is the process of cleaning a surface and smoothing out roughness. It is performed using hand tools with a set of abrasive sandpaper of various calibers.

Depending on the type of product being produced, a technological map is developed with a clear indication of the processing methods used and the order in which they are carried out.