Working with lumber in small volumes is a task that hand hacksaws and jigsaws can handle quite well. But what if you need to get maximum performance in minimal time? The obvious solution is to use hand-held circular saws, which, firstly, have sufficient power, and secondly, are distinguished by convenience and mobility, which are not characteristic of stationary sawmills.

We invite you to get acquainted with the classification and design features of circular saws for wood, as well as take a look at the rating of the most popular models of this year.

How to choose a circular saw and blades for it?

Before you go to the store or place an order for a “circular”, it is important to understand how it works, where, how often, under what conditions and for what purposes it will be used. In fact, the common name unites a wide class of tools and consumables with different design features, which can significantly complicate the choice for a beginner. Therefore, a little theory.

Purpose of the tool

In a private home, a circular saw is indispensable, especially when high performance is required from the tool.

Circular saws are used for:

- Trimming large branches and felling trees

- Longitudinal or transverse cutting of boards, beams and slats

- Cutting plastics and soft non-ferrous metals

- Dissolution of sheet materials

It is important to remember that circular trajectories are not suitable for curved trajectories; for these purposes it is better to use a jigsaw. By the way, “circular saw” is not quite the correct name for the tool. In technical documentation, the term “circular saw” is usually used, which indicates the working body - a cutting disc for wood. So, it is more correct to call chainsaws “chainsaws”.

Circular saw device

The design of a circular saw is relatively simple.

In addition to the body, which combines all the parts of the instrument into a single whole, it includes:

- An electric motor with a mechanical gearbox is necessary to create and convert torque.

- Saw blade - secured to the gearbox spindle with a locking nut, is a consumable material that is used directly for making cuts.

- Platform with riving knife - provides a reliable stop and a constant angle relative to the supporting surface, and also prevents the cutting disc from becoming jammed in the lumber.

- Protective covers are parts that redirect sawdust thrown down when cutting wood.

Some models have additional components and mechanisms installed. Thus, laser path indicators, sawdust suction systems have recently gained popularity, and in powerful industrial “circular machines” there are additional safety covers that prevent accidental injury to workers.

Expert opinion

Kuznetsov Vasily Stepanovich

Other methods of ensuring emergency safety include a slip clutch, which switches the tool to idle mode when the disk jams, as well as a shaft braking unit, which instantly stops the disk when the button is pressed.

Classification of “circulars” and criteria for their selection

The most obvious criterion for classifying a power tool is power.

It is important to take into account that as the power of a circular saw increases, its weight and cost inevitably increase, so think three times before overpaying for a top-category tool if you plan to saw with it, for example, plywood.

So, according to their power, “circulars” are divided into:

- Low power (up to 800 W)

- Mid-class (800-1500 W)

- High class (more than 1500 W)

In addition to power, pay attention to the rotation speed of the disk. The average value is considered to be 5000 rpm; many tools do not allow you to adjust it. Please note that for cutting hardwood it is better to choose models with higher speeds, but for working with soft, polymer or glued materials, low speeds are preferable, which will reduce heating in the working area.

Finally, the third classification criterion is the type of power supply of the instrument. Depending on it, circular saws are divided into network saws (connected to a regular household outlet with a voltage of 220 V) and battery-powered (have a power source built into the body). The latter are preferable in the case where there is no centralized power supply near the future location of the main work. But you can’t count on long battery life - with such engine power in most circular cars, it is limited to 1-2 hours.

Types and features of saw blades

Saw blades differ, first of all, in diameter - the larger it is, the greater the depth of cut the tool can provide.

Since the disk can only penetrate the material to the level of the support platform, it is usually about 40% of the diameter.

In addition, disks are classified according to purpose, for example:

- For soft woods

- For medium and hard breeds

- For sheet lumber

- For aluminum profile

- For plastics, etc.

Expert opinion

Kuznetsov Vasily Stepanovich

Pay attention to the number of teeth. If there are few of them (12-16), the work will be fast but sloppy. The more teeth, the straighter and smoother the cut will be, but the time required and the heat level will increase proportionally. By the way, to combat heating, radial slots are made in the disks, most often ending with a through hole.

It is not necessary to read the technical documentation to find out the characteristics of the disk.

As a rule, there is a marking of three numbers on it, which respectively indicate:

- Disc diameter, mm.

- Number of teeth, pcs.

- Landing diameter (diameter of the saw shaft).

In addition, the marking may indicate the recommended blade rotation speed, cutting depth and, most importantly, the type of material for which it is designed to work.

The latter is indirectly indicated by the shape of the tooth, for example:

- Soft and medium woods – ATB teeth

- Wood with nails, fiber cement boards – FWF teeth

- Laminated chipboards, thin non-ferrous metal – TCG teeth

- Hardwoods, reinforced plastics, non-ferrous metals – fine-toothed precision discs

To install or replace the disk, lock the landing shaft with a special button, use a wrench to unscrew the spindle nut, install the disk and tighten the nut firmly. If the lock is not provided by the design of the saw, two keys will be required.

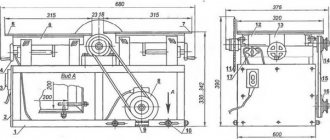

Operating principle and structure of the saw

All circular hand saws differ little from each other in their operating principle. The cutting disc rotates the motor, which is located inside the body of the device. This torque is transmitted to the machine by the drive belt.

Before you start cutting, you should place and securely fasten the cutting blade. When the handle is lowered, the protective cover should open without effort and return to its original position. After checking the correct installation of the riving device, before starting work, you must keep the tool in the on mode for at least 10 seconds without load.

Using a caliper, you need to adjust the position of the disk and the guide pin. The riving knife should be in line with the blade. To protect the machine and table from vibration, the mounting bolts should be securely tightened.

The design of the tool includes the following basic elements:

- gear housing;

- protective casing;

- engine;

- platform;

- guides.

Units are divided into several types. Electric saws are :

- Household. These are easy-to-use machines that cope well with cutting on the farm. They are small in size and power with the necessary minimum set of settings.

- Semi-professional. The equipment differs from household equipment in a more powerful engine.

- Professional. The machines are used for long-term work and can withstand heavy loads. They can be equipped with additional functions.

Despite this classification, high demands are placed on all models. The machines must comply with modern safety standards, be quite powerful to cope with the planned volume of cutting and have high precision settings.

Rating of popular models

The power tool market is constantly changing, but, as elsewhere, there is a group of leading companies whose products are considered the standard of reliability and performance. These usually include brands Bosch, Einhell, Makita, Dewalt, DWT. However, competitors also have interesting products. Do not forget that domestic and Chinese companies in most cases offer circular saws at a price significantly lower than their European and Japanese counterparts.

Having analyzed the technical characteristics, reliability criteria, ergonomics and prices of modern circular saws for wood, we have compiled a summary rating of the best models of this year.

Compact disk

Metabo KS 55 FS (8500 RUR)

Specifications:

- Power : 1200 W

- XX frequency : 5600 rpm

- Disc diameter : 160 mm

- Bore diameter : 20 mm

- Weight : 4 kg

Advantages:

- High power

- Stable and reliable operation

- Comfortable grip

- Excellent safety and cutting product removal systems

- Precision and multi-level adjustment

Flaws:

- High price

- Large dimensions and weight

DWT HKS12-54 (4000 RUR)

Specifications:

- Power : 1200 W

- XX frequency : 5000 rpm

- Disc diameter : 165 mm

- Bore diameter : 20 mm

- Weight : 3.6 kg

Advantages:

- Relatively low cost

- High power

- Reliability and unpretentiousness in work

- Two-level adjustment

Flaws:

- Not the best quality of case materials

- No bottom guard

Design features of circular saws

The design of any circular saw is based on one similar design. The differences may include qualities such as:

Layout of a circular saw.

- performance;

- additional functions;

- drive power;

- cut thickness.

With the help of additional functions, the area in which the circular saw is used can be significantly expanded. Such a tool is characterized by increased safety, and working with it, as a rule, is much easier and more convenient.

As for the circular saw device, it is presented in the form of a flat frame equipped with a drive on which a cutting disk is mounted in a vertical position. The saw also has a handle with a start button and several auxiliary devices, which include:

Related article: DIY wardrobe bed

The circular saw must be held very firmly when working.

- a nozzle that performs the function of removing sawdust;

- guide rulers;

- hinged devices that allow sawing of material at a certain angle.

Cutting is done by pressing the bed against the panel (or some other material). The disk, which rotates up to 5000 rpm, begins to cut the material.

Mid-range saws

Makita HS7601 (8500 RUR)

Specifications:

- Power : 1200 W

- XX frequency : 5200 rpm

- Disc diameter : 190 mm

- Bore diameter : 30 mm

- Weight : 4 kg

Advantages:

- High power

- Durable and comfortable body

- Multi-level adjustment

- Reliability and unpretentiousness in work

Flaws:

- Lack of a soft start system - “jerky” start

Bosch GKS 190 (RUB 10,000)

Specifications:

- Power : 1400 W

- XX frequency : 5500 rpm

- Disc diameter : 190 mm

- Bore diameter : 30 mm

- Weight : 4.2 kg

Advantages:

- High power

- Good ergonomics

- Precise cuts both straight and at an angle

- Convenient sawdust removal system

Flaws:

- No bottom guard

- High price

Under a large disk

Hyundai C 1800-210 (7500 RUR)

Specifications:

- Power : 1800 W

- XX frequency : 5300 rpm

- Disc diameter : 210 mm

- Bore diameter : 30 mm

- Weight : 6 kg

Advantages:

- High power

- Comprehensive employee protection

- Rugged and durable housing

- Precise stepless adjustment of the main cutting parameters

Flaws:

- Large dimensions and weight

- Increased noise level

Makita 5008MG (RUB 15,000)

Specifications:

- Power : 1800 W

- XX frequency : 5200 rpm

- Disc diameter : 210 mm

- Bore diameter : 30 mm

- Weight : 5.1 kg

Advantages:

- High power

- Comprehensive employee protection

- High reliability

- Multi-level adjustment on longitudinal and transverse scales

- Availability of backlight; large diagonal cutting angles

Flaws:

- Relatively large dimensions and weight

- Not quite well thought out ergonomics

- High price

Rechargeable

Bosch GKS 18 V-57 (RUB 16,000)

Specifications:

- XX frequency : 3400 rpm

- Disc diameter : 165 mm

- Bore diameter : 20 mm

- Weight : 4.2 kg

- Voltage : 18 V

- Battery capacity : 5.0 Ah

Advantages:

- Adaptive power and blade speed control

- Thoughtful ergonomics

- Reliability and durability

- Precise cutting with multi-level adjustment

- Relatively low noise level

- Availability of backlight

- Worker protection system with quick disk stop

Flaws:

- Relatively low disk rotation speed

Metabo KSA 18 LTX (RUB 38,000)

Specifications:

- XX frequency : 4600 rpm

- Disc diameter : 165 mm

- Bore diameter : 20 mm

- Weight : 3.4 kg

- Voltage : 18 V

- Battery capacity : 5.2 Ah

Advantages:

- Adaptive power and blade speed control

- Thoughtful ergonomics

- Reliability and durability

- Precise cutting with multi-level adjustment on millimeter scales

- Large diagonal cutting angles

- Two new generation batteries included

Flaws:

- High price

- Relatively high noise level

- Large dimensions

Basic requirements for a circular saw

When choosing a circular saw, you should pay attention to the presence of such frequently encountered additional (useful) functions as:

When working with a circular saw, you need to protect your eyes with goggles and your hands with gloves.

- Ability to adjust disk rotation speed. Keep in mind that the method for implementing this function can be of 3 types: mechanical and electronic. You can achieve perfectly smooth and neat cuts (without burrs) only by adjusting the rotation speed of the discs, since each material requires an ideal approach. This type of tool is universal in its application.

- Function of immersion into the material when sawing. This quality is a big advantage of the tool. It is especially convenient in the process of sawing solid slabs. Due to the ability to shift the disk of such a circular saw in the vertical plane, it is possible to cut the material immediately from its middle.

- The ability to stop disk rotation as quickly as possible. This quality of the tool ensures a safer work process.

- The presence of built-in lighting and a laser marker will make your work much more comfortable and safer. In addition, thanks to these functions, the cut will be as accurate as possible.

- The soft start function of the rotating disk can also significantly increase the level of safety, since the possibility of a dynamic jerk when turning on the tool is eliminated. In particular, the presence of this function is desirable for devices equipped with powerful electric motors. In addition, the mechanics of the tool and the electrical network are subject to significantly less stress.

Related article: Toilets with vertical outlet to the floor

The device of saws equipped with powerful electric motors has special elements designed for mounting on a surface convenient for performing work. This ensures the instrument remains stationary. As for sawing, in order to carry it out, the material is fed directly onto a rotating disk. The presence of such a function greatly facilitates the user’s work, especially if he is faced with the task of sawing a very large volume of material.

Service

Of course, this is only a small part of the high-quality models presented on the modern market. The search for the ideal power tool is an eternal search for a compromise between power, workmanship, reliability, the availability of additional options and the price of the device.

It is important to remember that hand-held circular saws for wood are high-precision electrical devices that require appropriate care and maintenance. The device must be protected from moisture, especially network models.

Cordless saws can be used in damp areas, but not outdoors during precipitation. Over time, it may be necessary to clean the housing from accumulated sawdust, which impairs engine cooling, as well as lubricate the mechanical components of the gearbox. Consistent substances like “Solidol” are well suited for this.

Do you use a circular saw?

Constantly! I want to try

Before each new use, remove sawdust, resins and other contaminants from the working surface of the disk with liquid reagents, then wipe dry with a clean rag.

Discs should be replaced immediately after detecting the first signs of damage to the teeth - if you continue to work with a faulty disc, you can not only ruin the cut, but also cause serious injury.

It is acceptable to sharpen dull teeth, but if you do not have experience with a sharpening tool, it is better to entrust this to a professional.

Expert opinion

Kuznetsov Vasily Stepanovich

We hope our tips were useful and helped you understand all the subtleties and nuances of choosing a circular saw and working with it. Use caution and caution when using any power tool. Good luck!

Features of work

A hand-held circular saw cannot be classified as a carpentry tool that is heavily equipped with electronics.

For example, only some models have electronic speed control, since this function is not particularly important for woodworking. More modern professional tools have a system installed that maintains a constant blade speed during operation. Its task is to maintain speed regardless of the load on the engine.

Models with an overload protection system monitor the temperature of the motor windings and, if necessary, turn off the machine. Expensive professional equipment is equipped with this function.

Almost any saw can be equipped with a guide bar , with which you can achieve high precision in your work. They are supplied by tool manufacturers as additional equipment.

Some hand saw models can be converted into a permanent installation. To do this, it is enough to screw the protective disk casing to a workbench table or a long board with special clamps.

Features include the presence of a removable network cable, which is convenient not only during transportation, but also in case of damage. It will be more convenient to purchase a new cable rather than contact a service center.