Articles

All photos from the article

A jigsaw occupies an important place in the arsenal of any home-conscious person. With this tool you can work not only with wood, but also with plastic, tiles and even glass. Moreover, working with these materials is not limited to simple sawing; a jigsaw also allows creative individuals to show off their skills; you can even use it to do wood carving.

Jigsaw

Classification of hand jigsaws for wood

Today, hand-held jigsaws for woodworking are often used at home, in schools for labor lessons, and in manufacturing companies.

It has several advantages over a hacksaw:

- When cut, the surface remains smoother, which is important in some cases.

- It is possible to quickly change the canvas if necessary.

- The teeth are small, so the safety of using this tool is much higher.

Externally, the tool consists of a handle made of wood or other material, a metal frame that holds the blade, as well as the cutting blade itself. When choosing, you need to pay attention to the size of the frame. It can be rectangular or pointed. It is necessary to understand how the tool will be used in order to choose the right one.

Expert opinion

Levin Dmitry Konstantinovich

Thus, the difference between manual jigsaws lies only in the size of the frame. However, you should not buy cheap Chinese models. They have a small margin of safety, so there is a high risk of damage to the frame during operation. It is better to purchase proven brands like Stayer Master, Fit, and so on.

How to choose

The selection of such a tool is carried out taking into account such parameters as:

- frame shape (limites the length and shape of the cut);

- frame material and elasticity (affects the elasticity of the canvas under load);

- the presence of clamps and their type (how difficult and how long will it take to replace the blade?);

- the type of blade itself (thickness, size of teeth, material);

- weight (the less the better);

- handle (optimal comfort and ergonomics);

- other features that determine the purpose of the instrument.

For an electric jigsaw, the engine power consumption and the number of movements (strokes) of the blade are added.

Classification of files

There are several types of saw blades that are designed for hand jigsaws.

| File name | Short description |

| Standard or Standard tooth | The teeth are the same size and equally directed from each other. Used to perform most tasks. |

| Reverse or Reverse Skip-tooth | Some of the teeth of this blade are directed upwards. This allows you to cut the wood while moving it backwards. Thus, there are almost no chips on the reverse side, making it easier to process the wood. |

| With a missing tooth or Skip tooth Blades | Such files are necessary to reduce the risk of the hand jigsaw jamming and to avoid excessive heating of the blade itself. Also, sawdust is better removed, resulting in a smoother surface. |

| With double teeth or Double tooth Blades | In this case, you can get an almost perfectly smooth cut. The file hardly heats up and removes sawdust well. |

The canvases also vary in length. There is a gradation by numbers from 2.0 to 12. The higher the number, the rougher the processing. That is, large files need to be purchased to work with thick bars. If you need to make complex patterns, then you should buy small files.

Depending on the type of work planned, you need to purchase one or another type of saw blade. They are quite strong, but can break if over-tensioned, so it is always worth having a reserve so that you can complete the job using a spare blade.

Preparing the tool for work

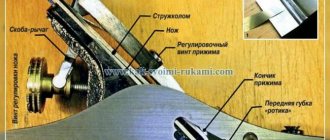

Before starting work, you need to prepare the tool . The quality of the work performed will depend on its preparation. Preparing the jigsaw is carried out in the following sequence:

- The clamps on the top and bottom of the tool are unscrewed.

- The file is inserted into the clamping devices with the teeth down.

- The clamps are tightened to the optimal tension of the file.

When working with a jigsaw, specialists make cuts along a curve, create straight lines, and cut a cutout.

Assembly instructions

Not everyone knows how to properly assemble this tool, as electronic models are increasingly being used. They are highly effective, but cannot be used for some jobs. And the high cost also does not allow them to be purchased for teaching in schools.

Jigsaw assembly steps:

- First you need to purchase the necessary files. It is important that their length matches your model. Some people create their own hand jigsaws. Then you need to ensure that the distance between the ends of the frame is standard.

- Then you need to unscrew the clamps. These can be drums or regular nuts.

- Insert the file into the special groove and tighten the clamps.

Expert opinion

Levin Dmitry Konstantinovich

It is necessary to ensure that the file stands firmly in the tool. Do not pull it too hard, otherwise it can easily break. If a file breaks, you need to unscrew the clamp and remove it, then insert a new one.

Breakage of saw blades occurs for various reasons. This is usually too much tension. This can also happen due to overheating of the material or accidental external influence on it. The cost of the paintings is low, so everyone can afford to have several spare products.

Additional functions

To choose an electric jigsaw that has all the functions you need, but is not overloaded at your expense with unnecessary bells and whistles, you need to understand these functions.

Pendulum stroke

Currently, the pendulum stroke has become an attribute of even the most budget models. When this option is enabled, the blade begins to move not only up and down, but also back and forth. This speeds up cutting, but at the same time reduces the quality of the surface. The length of the pendulum stroke is adjusted by a switch located on the side wall of the device. It makes sense to enable the option for large volumes of sawing and disable it when performing a curved cut or one that requires special precision and quality of the cut surface.

Sole angle

If your budget allows, then it is better to choose a model that has this function. By turning the sole at a certain angle around the longitudinal axis, you can make a cut at an angle of 30, 45, 60 degrees. In professional models, these positions are not fixed, and the angle can be changed smoothly, focusing on the protractor.

Jigsaw with pendulum stroke and variable angle of inclination of the sole

On inexpensive models, the sole is fastened with a hex key, on more expensive ones - in a quick way, using a special clamping lever.

Smooth start

For a novice master who does not yet have much experience, it is better to choose a model that has the ability to start softly. It allows you to start cutting at minimum speed, gradually increasing it. This will allow you to accurately start the cut along the intended line, eliminating the blade falling off or moving to the side.

Maintaining speed under load

It is worth choosing an electric jigsaw with this function if you plan to do a large amount of work with hard wood or metal. The function protects the engine from overload by stabilizing the speed using an electronic circuit.

Chip blowing

This option should definitely be chosen by those who intend to do sawing. The chip blower system, using the air flow from the engine cooler fan, blows sawdust away from the work area, providing good visibility.

Backlight

Illumination of the work area will be very useful in low light conditions and in cramped conditions.

Laser pointer

It is reasonable to choose a device with a laser pointer when a large number of straight cuts are required.

This option allows you to save time on marking by marking only the start and end points of the cut on the workpiece, and guide the electric jigsaw along a laser-illuminated straight line.

Expert advice on choosing

What wood jigsaw do you use?

ManualElectro

When choosing a tool, you need to be guided by some rules, namely:

- Product weight . Since you have to hold it for quite a long time with one hand, you need to buy lightweight jigsaws. Otherwise, it will be difficult to work effectively.

- The anatomical handle is more expensive, but will allow you to work longer. It reduces the risk of hand spasms, making it more pleasant to work with.

- Frame strength is the main indicator. Models made of aluminum or iron are short-lived and fragile. They are easy to bend or break. It is much better to buy jigsaws where the frame is made of steel or titanium.

- Drum clamps are much more convenient, so it’s worth buying such models. This will speed up the process of changing blades.

Jigsaw and methods of its use

There are several methods for using an electric jigsaw. In everyday life, straight and curved cuts are most often used. In the case of a direct cut, the device is brought to the beginning of the line and the beginning of the platform is supported on a securely fastened board or sheet. The pointer on the edge of the platform or laser marker is aligned with the marking line. The jigsaw is turned on at the lowest speed to mark the beginning of the cut, then the cut is slowly carried out until the platform is completely resting on the part. Now you can turn up the speed.

Curvilinear cut: a hole is drilled inside the marked contour. A special file for curved cutting is attached to the chuck of an electric jigsaw, the pendulum mechanism is turned off, it is inserted into the hole until the platform is in full contact with the part, and they begin to saw at low speed. Bring the cutting line to the intended contour tangentially at a slight angle and make a working cut.

The best manufacturers

Today, the main manufacturers of manual jigsaws include several companies.

Bison

This is a well-known Russian company that specializes in the production of various tools and consumables for them. Hand and power tools are popular among professionals due to their high reliability and excellent ergonomics. Many products are sold outside of Russia, which is a reason to trust this manufacturer. The cost is low, and there are no problems finding components. The Zubr company has many partners who sell jigsaws themselves and elements for them.

Stayer Master

This company offers a large number of hand tools. Its distinctive features are yellow and black colors. The cost is slightly higher than that of the Bison, but the quality is about the same level.

Fit

A fairly large manufacturer of tools, which today has more than 140 service centers and 160 territorial divisions in Russia. Thus, finding the necessary components for a jigsaw will not be a problem. The cost of the tools is average, the quality is moderate.

Matrix

It is considered a well-known large manufacturer that is present in several countries. The cost of the products is slightly higher than average, which allows the use of the highest quality materials in production. The jigsaws fully meet all requirements, and a large number of partner stores does not cause problems with finding components.

The price of an instrument is influenced by several factors: store, season, volume of goods purchased, manufacturer, model, and so on. All this must be taken into account when purchasing. Usually consultants are ready to help with the choice if there are doubts.

Advantages over saw

Both tools seem to do the same job, but the results are different.

- The jigsaw provides a smooth cut, which is especially convenient when further grinding and polishing of surfaces is required. The saw, as a rule, produces a rough cut, which then has to be processed in several approaches.

- The replaceable jigsaw blade allows you to quickly replace it; the tension of the blade practically does not have to be changed during operation.

- A jigsaw is much safer than a saw and more often causes only scratches, but a saw can seriously damage both clothing and skin.

If you make a jigsaw yourself, you need a small amount of raw materials; in addition, it is cheaper than a regular saw.

Of course, these two tools are designed for different jobs. For example, a large log with a jigsaw with its thin blade, of course, cannot be sawed. Even a small tree should not be tried to be cut down with its help. Under heavy loads, an electric tool can overheat and burn out, and the blade can burst. But for a large saw, a log does not pose a threat.

Tool selection

Many manufacturers today offer their models, and each may have a lot of nuances in its design, which can make choosing difficult.

Consider a regular electric jigsaw with a standard set of functions:

- A cut regulator, available in almost every modern model. It provides speed control and allows you to choose your own for different materials.

- Fastening the canvas. Different models include screws or wings, but the simplest option today is fixation with a clamp lever.

- A multi-stage pendulum allows you to increase the service life of the blade, since after cutting it changes its position, so sawing occurs in one direction.

- A rotating mechanism that allows you to cut material at any angle to the vertical, without having to turn your hand or twist the mechanisms. Almost any contour or image can be made in almost the same position.

- The cooler is used to cool the motor of an electric jigsaw, which allows you to use the tool without interruption and maintain its functionality under prolonged load.

- Angle lock - at an angle with rigid fastening it helps to make a cut, which is useful for furniture makers and others to get a fairly accurate cut.

Professional models, like simple ones, will help you cut wood no more than 7 cm thick or metal up to 4 mm thick, and their cost will be much higher. But they have a much longer service life and wear out more slowly.

The cost also determines the number of vibrations available. An indicator of 3000 is enough; more may not be useful, but it will affect the cost.

Selection of canvas

The jigsaw is universal primarily because it is possible to replace the working blade. A new blade made of a certain metal will allow processing not only wood, but also other materials.

There are several main directions in which canvases are made:

- for wood;

- for metal;

- mixed type.

As a rule, metal is processed with a blade with a large number of teeth per unit length (TPI - teeth per inch). Mixed teeth have a rather complex shape.

Set and ground teeth provide high cutting speed and large vibrations. Unset teeth are used to ensure a smooth cut. When there is no wiring, the processing speed decreases. Wavy milled teeth are used in cases where cutting requirements are not strict.

The most common breakdowns, how to avoid them and safety precautions

High-quality jigsaws such as Bosch, Vortex, Zubr have a long service life. But even these tools can break down from time to time.

Common problems:

- If metal dust gets into the case, the start button may stop working. In this case, it should be cleaned with a special vacuum cleaner and, if necessary, replaced.

- The tool rod often fails because it is subjected to increased mechanical stress. As a result, a breakdown occurs and the fixing device connected to it deteriorates. This occurs when dust and particles of various materials get inside the housing. Good quality jigsaws do not have such problems.

- Engine stops often occur as a result of burnout of the stator, rotor, or wear of a notch on the shaft. In this case, the parts must be replaced.

Important! When performing various types of work, the power of the jigsaw should be taken into account.