A high-quality cutting part of a sawing tool most often creates conditions for high productivity and efficiency in completing the task. When cutting with a jigsaw, the quality of work is also affected by the correct installation of the file, which requires periodic replacement. Difficulties in replacing it can arise for both beginners and specialists with considerable experience working with this tool. Often the problem also depends on a new, low-quality file. We talked about how to choose the right saw blade in a previous article. And today we suggest that you familiarize yourself with a short guide to installing the cutting part in a jigsaw.

Tips for choosing saws

When replacing a file, it is important to know what you are going to change and for what. Even if you work only with wood, you may need to replace the saw blade due to wear of the old one or a change in the thickness of the timber.

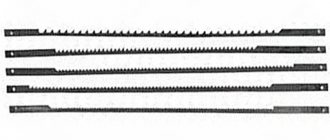

All saws have their own designations. Those used for woodwork are marked with the abbreviation HCS, and those for metal have the HSS marker.

- When choosing a saw for using a jigsaw, it is worth knowing what material will be processed with it. For soft materials, high carbon steel tools are suitable.

- If you need to get a straight cut, you should choose a straight saw with wide teeth.

- For shaped cuts, thin models are used.

- It is recommended to cut laminate with special devices that have a reverse slope.

- But metal tools, as a rule, are not straight; their teeth have different sizes.

- For steel, it is recommended to use a wave-shaped tool.

- For ceramics, files that have no teeth at all (with carbide coating) are suitable, but for plastic, medium teeth are required.

- Don't choose short models. According to the rules, the saw must come out of the cutting material.

- Do not use a tool with teeth that are too large, as this may damage the material.

Saws made from bimetallic material are the highest quality and most durable. They need replacement less often than other models.

Jigsaw file made of bimetallic material

Fastening

The saw blade is fixed, as mentioned above, by three types of locking mechanisms:

Quick-clamping. The main advantage is clear from the name - quick change of cutting tools. But there are some disadvantages:

- The mechanism works only with “native” types of shanks specially developed for it. Other types will not work.

- There are restrictions on the geometric parameters of the files - width and thickness.

- mechanism, a plastic handle-block (lever), is pulled inside the jigsaw, the rod is released;

- the file is inserted all the way, with the shank into the slot;

- The block is released - the saw blade is fixed.

ADVICE. From practical experience: saw blade jams occur due to abnormal cutting conditions (excessive force, curved cut with a wide blade). Pounding, using pliers and other “brutal” techniques is extra work and risks damaging the instrument. It’s easier to carefully disassemble the jigsaw itself and unlock the exposed locking mechanism.

2. Block screw fastening. By the way, it should be noted that all types of shanks are suitable for this system. The procedure for installing the file:

- the fixing screws must be loosened, - the protective casing is moved and the threaded elements are unscrewed with a wrench (two or three turns);

- a file is installed in the groove (slot), with the cutting part from the jigsaw, in the direction of the cut;

- the screws (located frontally, at the bottom of the tool) are tightened with a hex wrench (must be included in the kit);

- the casing returns to its place.

The main disadvantage, which appears immediately or over time, is inaccurate fixation in the cutting direction. The canvas leads to the side. Another disadvantage is the thread breaking due to excessive tightening efforts. The third negative factor is the failure of the support block. It is almost always impossible to find a replacement; you have to grind it yourself.

3. Side screw fastening (with locks). Occupies an intermediate position in terms of ease of changing the file between the shoe-type fixation and the quick-clamping mechanism. Stages of work:

- the side screw unscrews;

- the shank is installed in the opened groove;

- the canvas is exposed visually and to the touch;

- the screw is screwed back in.

Accuracy of installation depends on initial factory assembly. Over time, individual elements wear out, play appears, and the file begins to wander.

Recommendations for selection

In addition to the main tactical and technical characteristics, the attachment point in a jigsaw is a mechanism that affects the accuracy of cutting the workpiece. Hence, when visually inspecting the selected tool, you need to take a closer look at the operation of the fastening elements:

- Check for play - insert the file and move it; there should be no free yaw motion.

- Turn on the tool and try to determine whether there is any beating in the blade. Minimal displacements are difficult to notice, but visible to the eye, indicate poor quality assembly.

- Perform a test cut (if the seller allows it). The cut must coincide with the markings - the file follows exactly the cutting path.

- Evidence of reliable fastening - during the test test, the cutting tool remained in place and did not fall out of the fixation mechanism.

Mastering the method of installing a saw blade into a power tool will not be difficult; just carefully study the instructions included with the product. During further operation of the jigsaw, carefully monitor the condition of the file attachment unit.

Types of jigsaws

Before moving on to the immediate specifics describing the process of installing a file, it is worth clarifying the types of tools involved. Since the jigsaw device has quite a few incarnations, we inform you in advance that in this guide we will touch on 3 of its varieties: manual, electric and stationary. A band saw, which is also sometimes called a jigsaw, will not appear in this article. Now a few words about each type of device under consideration.

Hand jigsaw

The cheapest option for a tool for making figured cuts in wood and its derivatives. When using special blades, it can be used for cutting metal of small thickness. The speed of work and the quality of the cut depend entirely on the experience and physical characteristics of the worker. Quite easy to use and does not require hours of study.

Electric jigsaw

A more advanced and expensive type of tool for making straight, transverse, inclined and figured cuts. Depending on the installed saw blades, it can work with wood, plastic, metal and even ceramics. It has a high saw stroke frequency, which usually reduces the quality and accuracy of the cut. Sometimes an electric jigsaw is rightly called a manual jigsaw, since it must be held during use. This tool is considered one of the most popular in everyday life, second in popularity only to the screwdriver and drill.

Stationary jigsaw

A very convenient and functional machine for amateur and professional work. Widely used in industry and at home. It works with thin files like a manual jigsaw, but the cutting speed is not inferior to an electric one. The main advantage of using a stationary jigsaw machine is complete freedom of both hands, which allows you to more accurately control the position of the workpiece during processing. The device copes well with straight cuts, but is primarily intended for figured cuts.

Having finished with a brief description of the devices, you can move on to the main question of the article. Let's look at how to insert a blade into a jigsaw and what nuances should be taken into account. Let's start with electric models.

Life hacks: How to change, replace or insert a file into a jigsaw?

All types of work with wood or other materials are in one way or another connected with the process of cutting them to specified sizes and contours. Carrying out these steps manually is tedious and unproductive work, so various mechanized devices have been created to make this procedure easier.

READ Transverse Hacksaw and Longitudinal Hacksaw: What is the Difference?

Initially, only large stationary machines were created that were capable of cutting large objects - logs, stones. Later, devices were developed to make it easier to work with small fragments of building or finishing material. Finally, hand-held power tools were developed, which significantly changed the approach to work and the productivity of the individual craftsman.

The modern market is replete with similar tools, a bright and unique representative of which is the jigsaw. Let's take a closer look at its features.

What is an electric jigsaw?

Figure 1 – Electric jigsaw.

A jigsaw is a hand-held power tool designed for cutting sheet materials or boards along the intended contour. A special feature of the tool is its focus on curved cuts - it does not require the installation of guides, and control over the direction and accuracy of cutting is carried out exclusively visually.

The use of guides or templates is not excluded, but the main purpose of the tool is precisely cutting curved shapes of complex configurations along both an external and internal closed contour.

The quality and result of the work largely depends on the level of skill and skills of the user.

The design of the jigsaw consists of an electric motor and a crank mechanism installed in a housing with a handle equipped with a start button. Unlike a conventional tool, a jigsaw has a file that is attached at only one end and is held in a given position only due to its own rigidity and elasticity. Outwardly, it resembles an iron, from the working surface of which a file protrudes in a perpendicular direction. The tool is convenient for performing openwork cutting, as it does not require permanent fastening of the second end of the file, which is typical for a regular jigsaw.

Jigsaw Interskol: correction of sawing curvature

It is worth paying attention to the domestically produced Interskol jigsaw.

It is produced in Izhevsk. For household use, this is a completely acceptable option. It has many positive qualities, and the most impressive is its low cost. But there are also disadvantages

For domestic use this is a completely acceptable option. It has many positive qualities, and the most impressive is its low cost. But there are also disadvantages.

Replacing the quick release saw blade mount

This is the curvature of the saw. What is the problem, and is it possible to get rid of it? The culprit was the quick-release fastening of the file. The fact is that it is designed for saw blades of maximum thickness. All cutting tools of smaller thickness simply dangle in the mount.

How to get out of this situation? You need to replace the quick-release mount with a simple device with regular bolts. It's not difficult to make. You need to take a square rod, cut two blanks, drill holes in them and connect them with two M5 bolts and nuts. The procedure for attaching the saw blade will become somewhat more complicated, but the tool will produce an even cut.

Refinement of jigsaw design

In addition, you can modify the design of the tool itself and limit the movement of the file in the transverse plane.

To do this you need:

- take sheet aluminum and cut the plate to the size of the jigsaw sole;

- In the front part of the workpiece, it is necessary to make a cut to the size of the working area of the cutting tool. File all edges, make bevels on the inner longitudinal edges of the cutout;

- You need to cut a plate from plexiglass to the size of the working area of the saw blade. File all sharp edges and make reverse bevels on the outer longitudinal edges;

- The aluminum plate must be marked for its installation on the jigsaw base. Drill holes and make chamfers for installing countersunk screws;

- A piece of plexiglass must be inserted into an aluminum plate, having first made a cut at its location.

Now, during operation, the saw blade will be limited in transverse movement almost in the cutting zone, which will give it even greater straightness.

Instructions for replacing the saw

How to replace a saw blade in a jigsaw? There is no universal method - instructions will vary depending on the type of fastening . Let's look at the instructions for each type.

Jigsaws with quick-release system:

- This tool is equipped with a special lever that releases the file, so it is not necessary to remove the protective cover.

- Pull the lever, this will open the lock, pushing the rod forward.

- Insert the saw blade into the jigsaw and release the lever.

- Use the adjusting screw to fix it in the correct position.

Jigsaws with lock fastening:

- Open the protective shell of the instrument.

- Turn the lever on the rod to install the file.

- Release the lever and move the file towards the clamp.

Jigsaws with screw system:

- Remove the protection (casing).

- Use a special hex wrench to loosen the screw.

- Insert the blade into the special hole with the teeth facing forward.

- Tighten the fastener.

- Install protection.

Understand in detail how to install the file correctly. Do not clamp it too tightly, otherwise the cut will turn out uneven.

Installing a blade into a jigsaw machine

When cutting on a stationary jigsaw tool, thin files with pins at the ends, similar to blades for a manual jigsaw, are suitable. Rarely, there is an adapter function for working with blades without pins. If you find it difficult to install the blade into a stationary jigsaw, we offer our guide below.

The advantage of pin files is their ease of installation, when you do not need to unscrew or tighten the clamps. In any type of jigsaw there are specific recesses in which the ends of the file are fixed. First install the blade in the lower fastening element, then in the upper one. The teeth of the installed saw blade should point downwards and point towards the operator. If the cutting side is installed correctly, you need to tighten it using a special lever located on the opposite side of the device, on top. To check the tension, lightly click on the file with your fingernail, like you would on a guitar string. A specific click will make it clear that the device is ready for use.

The installation of blades without pins in each jigsaw machine is implemented differently, but everywhere, without exception, it goes through adapters. First you need to tighten the tails of the saw into the adapter, then fix the assembled structure in the fasteners of the machine.

Blade clamp repair

Unfortunately, many manufacturers of power tools often skimp on materials, which reduces the service life of manufactured devices. The clamp for the jigsaw file, which is subject to serious pressure during operation, is also subject to periodic breakdowns. Below, we will tell you what can happen to the block fastening and how to fix the damage.

During prolonged use of the jigsaw, due to the loads on the blade fastening unit, the block clamp can be seriously deformed. Damage can be minor, expressed by slight deformation of the pad, or very serious, turning the part into a useless piece of metal.

The easiest option for restoring the functionality of your jigsaw is to purchase and install a new, identical block. A similar element can be found in construction markets and tool stores. Fortunately, such details occur quite often. At the same time, it is not a fact that the quality of the new mount will be better or at least no worse than the old one. The main thing is that the tool can be used. See below for a video on installing a new pad.

A longer and more reliable option is suitable for advanced craftsmen with experience and a set of necessary equipment. The next method is to make a saw blade holder for a jigsaw with your own hands. To make your own pad, you will need:

- Piece of steel: 18x15x15 (length, width, height)

- Hacksaw for metal

- Grinder with a metal disc (preferably diamond)

- Drill with 4 mm metal drill

- Vise

- Ruler or caliper

The manufacturing process is extremely clear for an experienced tinsmith, but for greater clarity it is demonstrated in the following photos.

If you do not have enough skills in working with metal, we recommend that you take the following drawing to the nearest turning workshop, where the part will be made to order.

Possible problems

A jigsaw is a fairly reliable electrical device; all its components, during normal operation, can work for quite a long time without any interruptions or interference. But the file holder, even with the most careful handling, is doomed to breakage and ultimately be replaced, not to mention the files, the replacement of which is a natural and necessary event.

- One of the problems remains determining the degree of tightening of the fastenings of the canvases. It cannot be over-tightened - this can cause the blade to break, but you also cannot under-tighten it, in which case the blade dangles and it is impossible to make an accurate cut with its help; it may fly out of the saw holder during operation.

- Over time, with intensive work, the bolts securing the file have to be replaced, the edges are erased and it becomes difficult to screw them in; it is less common to break the thread of the bolt or in the block itself; in the latter case, the device will have to be replaced.

- Failure to pay attention to the condition of the saw can cause the engine to overheat or the jigsaw rod to fail. It is better to throw away blades with blunt teeth immediately and not put them aside “for a rainy day”; high-quality work of the tool with them is impossible.

- If the file turns out to be bent, you shouldn’t hope for high-quality work either; the cut will lead to the side.

It is useless to try to straighten the file; it is better to replace it with a new one.

- Working with a dull or bent saw can cause charring of the wood, which is also one of the signs of overloading the device.

- A guide roller is installed in jigsaws; if it is not lubricated in time, this can lead to jamming of the unit and, as a result, overloading the jigsaw motor. In particularly advanced cases, the roller has to be replaced.

- monitor the position of the electrical cord;

- monitor the cleanliness of the air intake openings supplying air for cooling the electric motor;

- periodically cool the unit, for example, by running it idle for some time;

- Do not cut with excessive force; this may cause the blade to become jammed or the rod or clamping device to fail.

Read also: How much does a square meter of metal weigh?

To learn how to insert a file into a jigsaw, see the following video.

A jigsaw is not a guest, but a necessary tool in the house. Working with wooden blanks and parts, metal, plastic is not the entire list of operations performed by the tool. The jigsaw itself is long-lived, which cannot be said about the cutting equipment. The saw blade wears down over time and requires replacement. Another option is to update the cutting tools when processing different materials.

Need some advice on why the file is sticking?

You have gotten a good feel for the jigsaw, have achieved smooth movement and are maintaining a neat cutting line, but then the movement of the tool becomes difficult and the file jams in the workpiece. This is a typical situation that arises when carving plywood with a hand jigsaw. It happens for the following reasons:

- Overheating of the file - during prolonged use, the blade expands due to heating. To avoid such situations, take short breaks or periodically wipe the canvas with a damp cloth.

- Features of wooden blanks. The movement of the jigsaw may be difficult due to the fact that the file has run into a denser area: a knot, a lump of glue in plywood, etc.

- On long cuts, the saw blade can become pinched between two nearly separated pieces of plywood. You can continue sawing comfortably by pinning the separated ends together with a clothespin.

Let's get down to business. How to cut out plywood and wood with a jigsaw?

To get an accurate and neat cutting line, you should follow a number of basic rules:

- The hand with the jigsaw should only perform vertical movements.

- Up and down movements are made without sudden jerks and with maximum amplitude in order to use the entire working length of the blade.

- The second hand smoothly turns and moves the workpiece during the sawing process.

- There is no need to press the file onto the workpiece or apply lateral pressure to the blade.

- Sawing occurs only at the moment when the file moves from top to bottom, so the reverse movement should be performed freely without pressure.

When working with a hand jigsaw, it is not guided along the line of the pattern, but along the inside of the contour, since even the thinnest blade leaves a cut, the width of which should be taken into account. This is especially important when cutting items with precise fitting elements, such as puzzles or intarsia.

When you're done, don't forget to loosen one of the clamps so that the jigsaw frame doesn't lose its elasticity.

Choosing a professional or household appliance

The main difference between professional jigsaws and household jigsaws is their high wear resistance and more intensive work. They can be used for 10 hours, changing attachments and processing different materials. At the same time, the quality of the result does not decrease. Unless the master gets tired and starts making mistakes. When using household tools, you must take a break of at least 10 minutes every third of an hour. And work no more than 3-4 hours a day. As a rule, this is enough for household use with a jigsaw.

When choosing a more powerful tool, keep in mind that as this characteristic increases, the weight also increases. The most suitable option for everyday use is jigsaws with a power of 500 to 650 W. They allow you to achieve cutting thickness in wood up to 70 mm and in metal up to 5 mm. If you need 160 mm for wood and 35 mm for metal, then take a more powerful jigsaw.

What kind of saw holder can it be?

The file is connected to the movable rod of the jigsaw using a saw holder - one of the most vulnerable parts of the unit. It is the blade holder that experiences the greatest loads during operation of the device; this device especially suffers when using a blade with dull teeth, which is sometimes done by inexperienced craftsmen.

The material for this part is supposed to be of the highest quality, but not all manufacturers think the same. Often the saw holder is the first to require repair or replacement. Modern manufacturers of power tools are constantly working to improve this unit.

This has led to a wide variety of saw blade holders used for jigsaws.

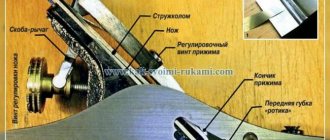

The earliest design is a bolted clamp-block. Although many companies have long moved away from this option, models that use this archaic fastening are still found. There are two bolts on this block. One clamps the blade, and the second allows you to adjust its position.

When installing or dismantling the saw blade, both bolts must be unscrewed or tightened. Their heads are made for a flat screwdriver or a hex key. For such blocks, the shape and thickness of the file shank often does not matter. There are models with one bolt. There is no need to adjust such a clamp; the file is simply clamped by tightening the bolt.

A quick-release fastener is installed on most modern models of jigsaws. Pressing a special key releases the clamp, and the canvas easily comes out of the mount. The same manipulation will allow you to easily insert the file into the slot. This device does not need to be adjusted; it has no bolts. This type of mount is divided into two subtypes, depending on the position of the moving key mechanism: side and front.

Radial clamp is a type of quick-release fastener. It is even easier to insert a file into units equipped with such a unit. The device must be turned 90 degrees, insert the file into the slot and release; under the action of the spring, the clamp will return to its original position and automatically lock the blade shank. All quick-release fasteners have strict limitations on the thickness of the blade and the shape of its shank.

Some craftsmen prefer to make this unit with their own hands, thus trying to increase its operating time. Indeed, it is not always possible to buy a part of the same quality. You can make a saw-block holder from a steel block with a side length of no more than 2 cm. To work, you need the following tools: drill, hacksaw, grinder, vice, precision tape measure, caliper.

Using an old part, you need to try to copy it by making a homemade one from a block. If you have no skill in such work, it is better not to waste time and show the old saw holder and workpiece to an experienced craftsman. If you still decide to do it yourself, be patient and prepare a couple more preparations just in case.

When replacing a saw blade in a jigsaw, you should pay attention to the condition of the fastening unit - the most vulnerable part of the entire tool. Over time, backlashes, beating of the blade, and displacement of the cut from the marking may appear.

All of these signs indicate an impending problem with the fastening and it is better to find out the cause at an early stage.

Base plate

For smooth movement along the surface of the material, the jigsaw design includes a support leg (plate).

With its help, the jigsaw can be set for cutting at the required angle (up to 45 degrees).

The plate is secured with two hexagon screws located at the base of the mount. The numbers printed on the slab support will help you set the desired angle of inclination.

To perform the required installation of the plate, you need to unscrew the screws, move the platform back, tilt it to the required angle, move it forward until it stops and tighten the screws.

Tool prevention

Figure 8 – Prevention Careful and careful operation, avoiding overload and excessive force, and avoiding overheating of the tool will help extend the life of the jigsaw.

The nominal operating mode is indicated in the user manual, which should be carefully studied before starting work.

In addition, it is necessary to regularly perform preventive maintenance of the tool:

- cleaning from dust and dirt;

- replacing lubricant;

- periodic inspection and timely replacement of brushes;

- using only suitable tools;

- compliance with operating rules.

Fulfilling these simple requirements will help increase the life of the jigsaw and free the user from the need to repair or buy a new tool.